Intelligent programmable axial plunger pump controller and control method

A technology for axial piston pumps and controllers, applied in pump control, sustainable manufacturing/processing, pumps, etc., can solve problems such as low precision, long response time, complex structure, etc., and achieve stable work and intelligence Improvement, the effect of high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

[0022] The present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

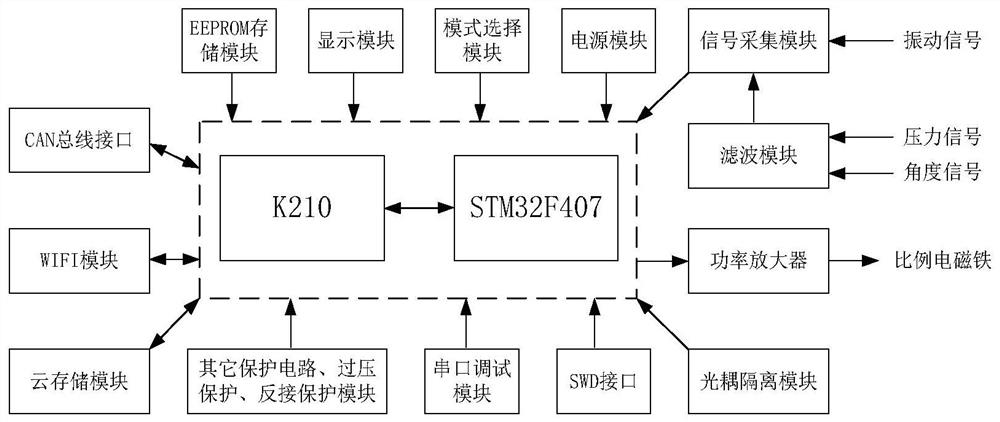

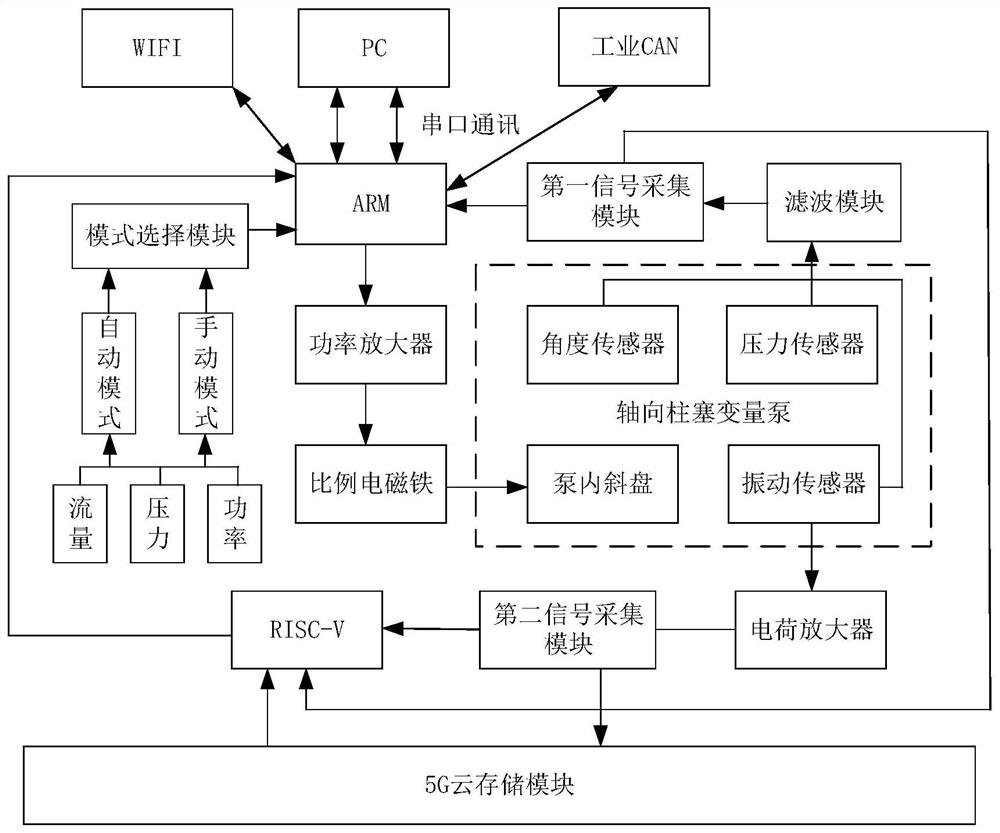

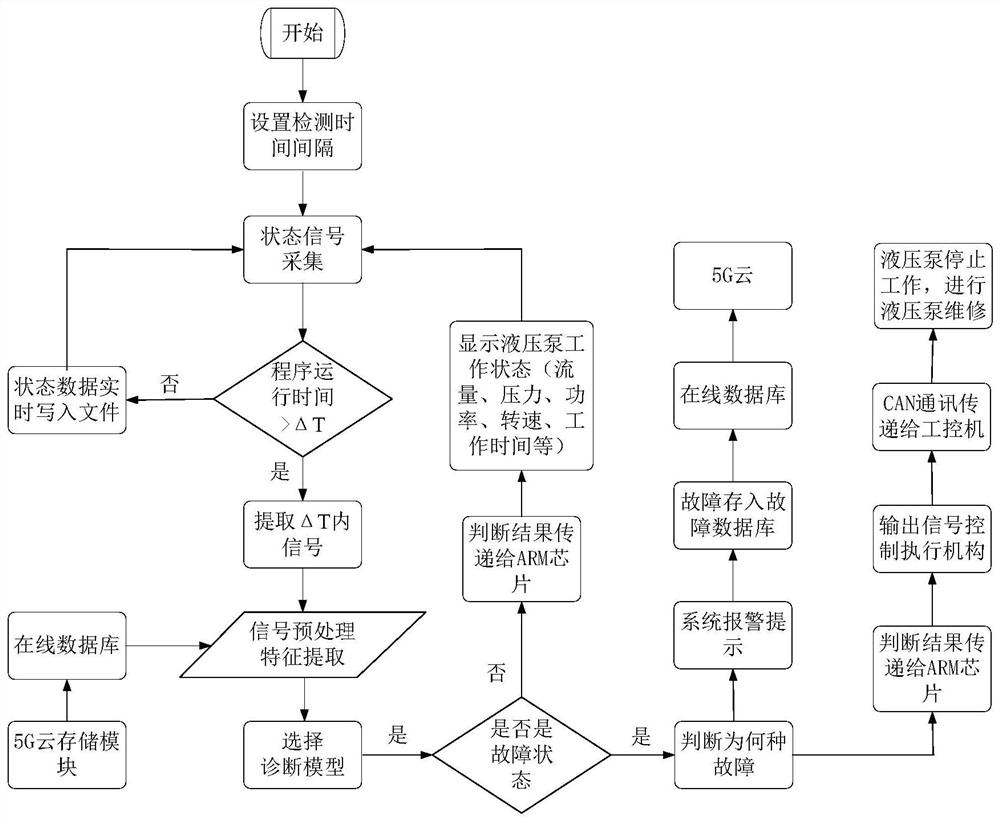

[0023] Such as figure 1 As shown, the present invention installs a non-contact angle sensor on the swash plate of the hydraulic pump, installs a pressure sensor at the outlet of the hydraulic pump, and installs a vibration sensor on the triaxial (X, Y, Z) of the hydraulic pump, so that the hydraulic pump variable can be controlled by the ARM chip The size of the flow rate in the piston chamber and the swing angle of the swash plate can achieve the automatic compound control of the pressure, flow and power of the axial piston pump. and other signals, based on the RISC-V chip to monitor and identify the state of the hydraulic pump, judge the common faults of the hydraulic pump, and transmit the judgment result to the ARM chip, realizing the predictive maintenance of the hydraulic pump, and uploading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com