Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Easy to potting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

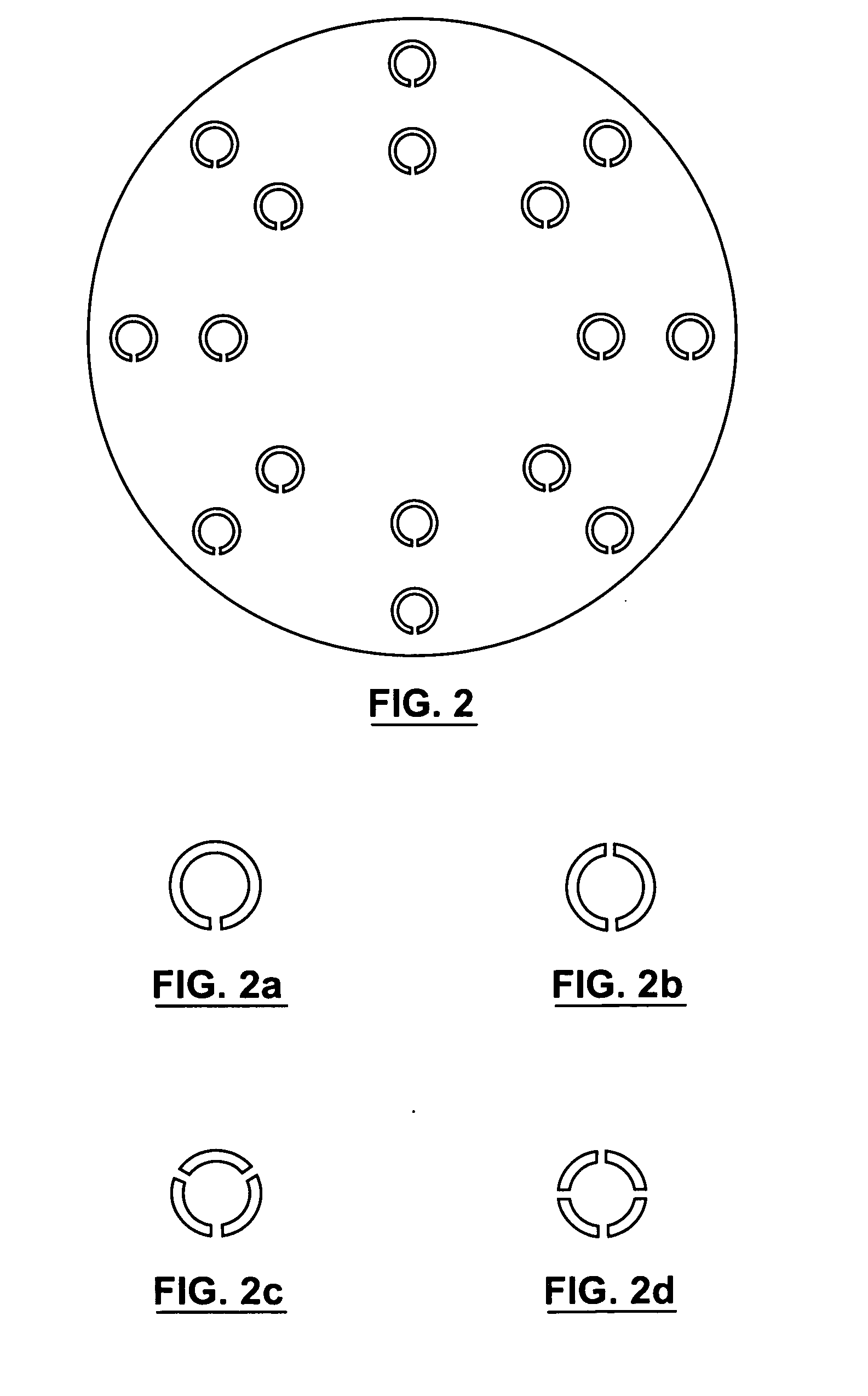

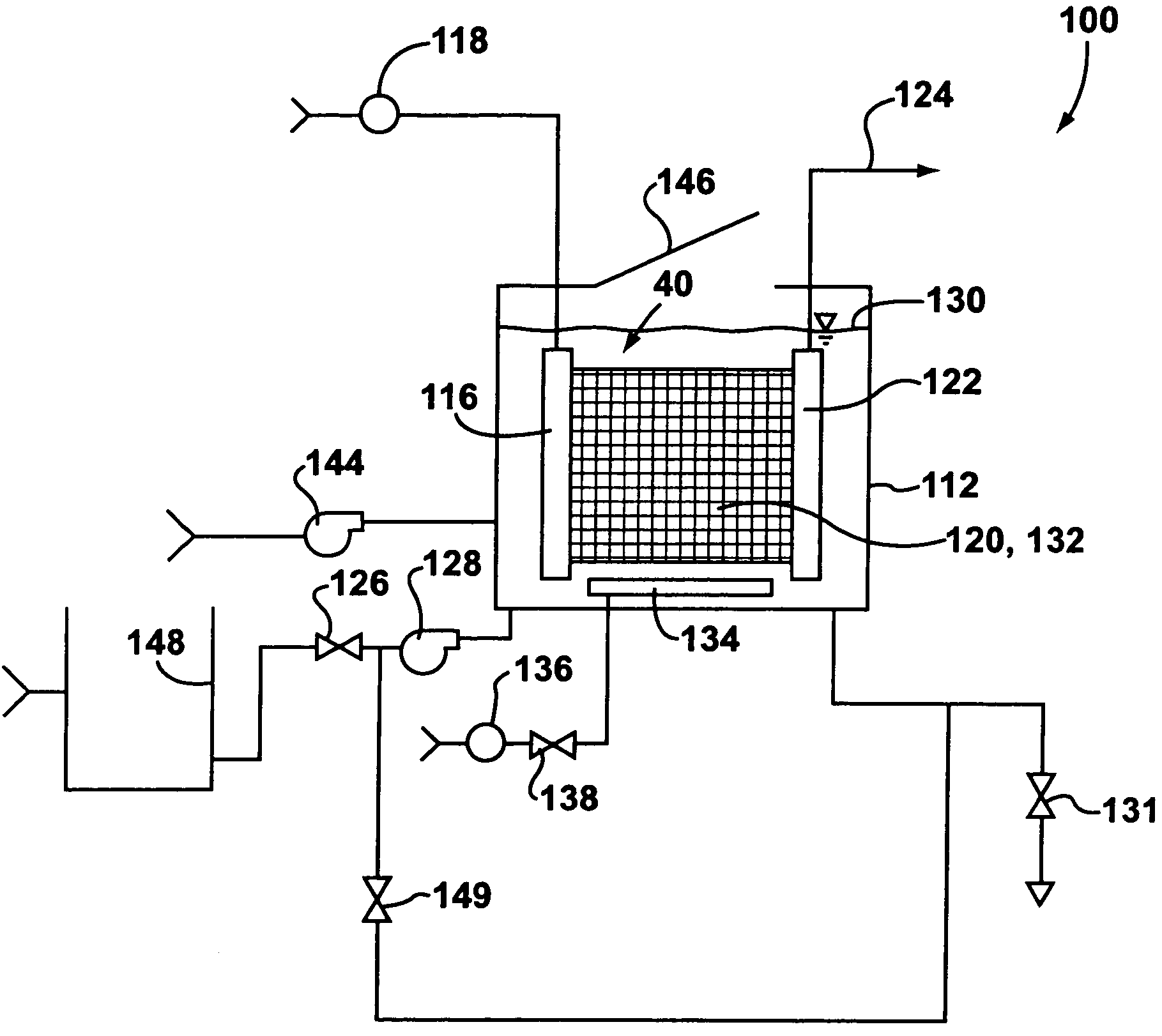

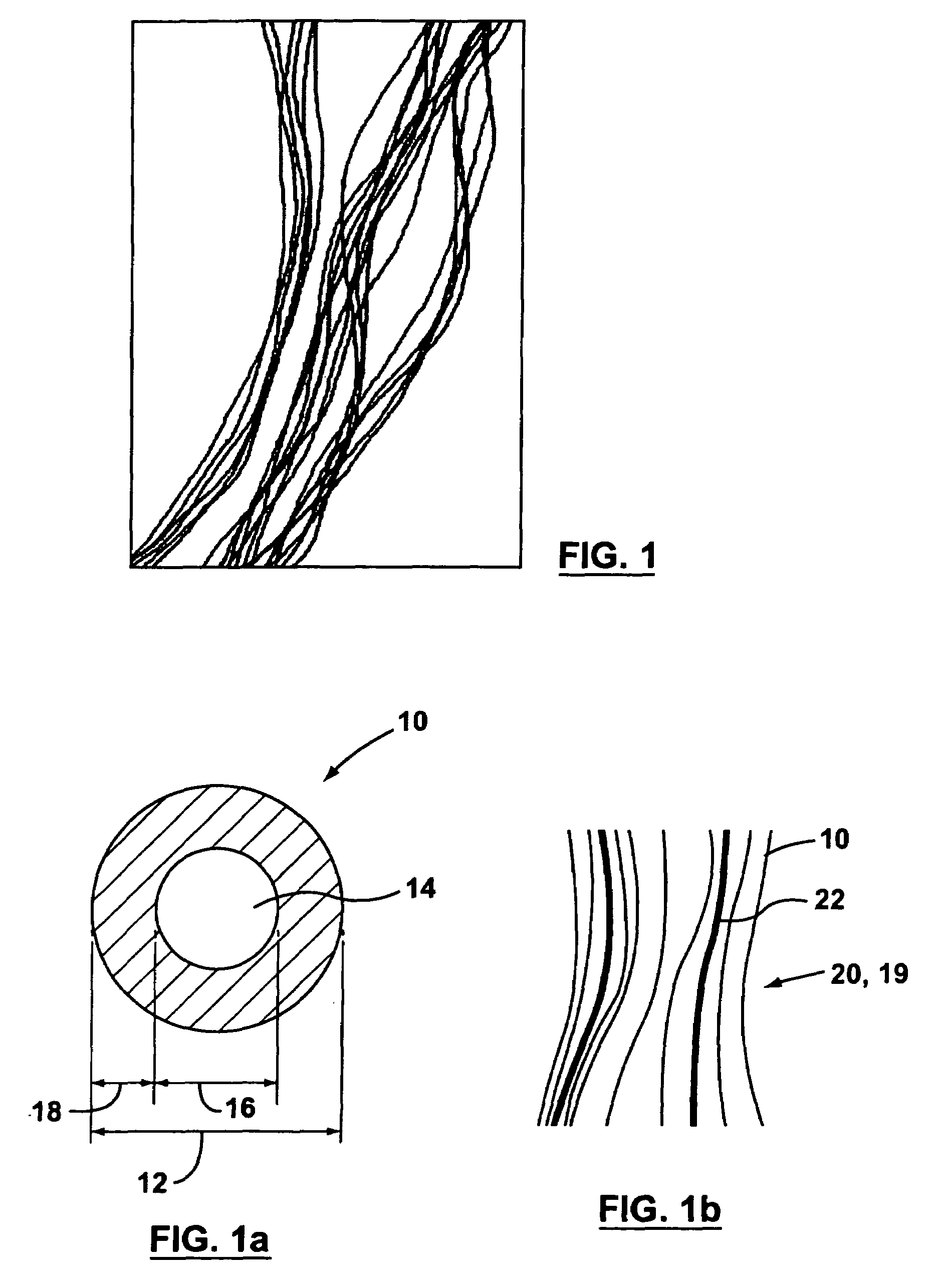

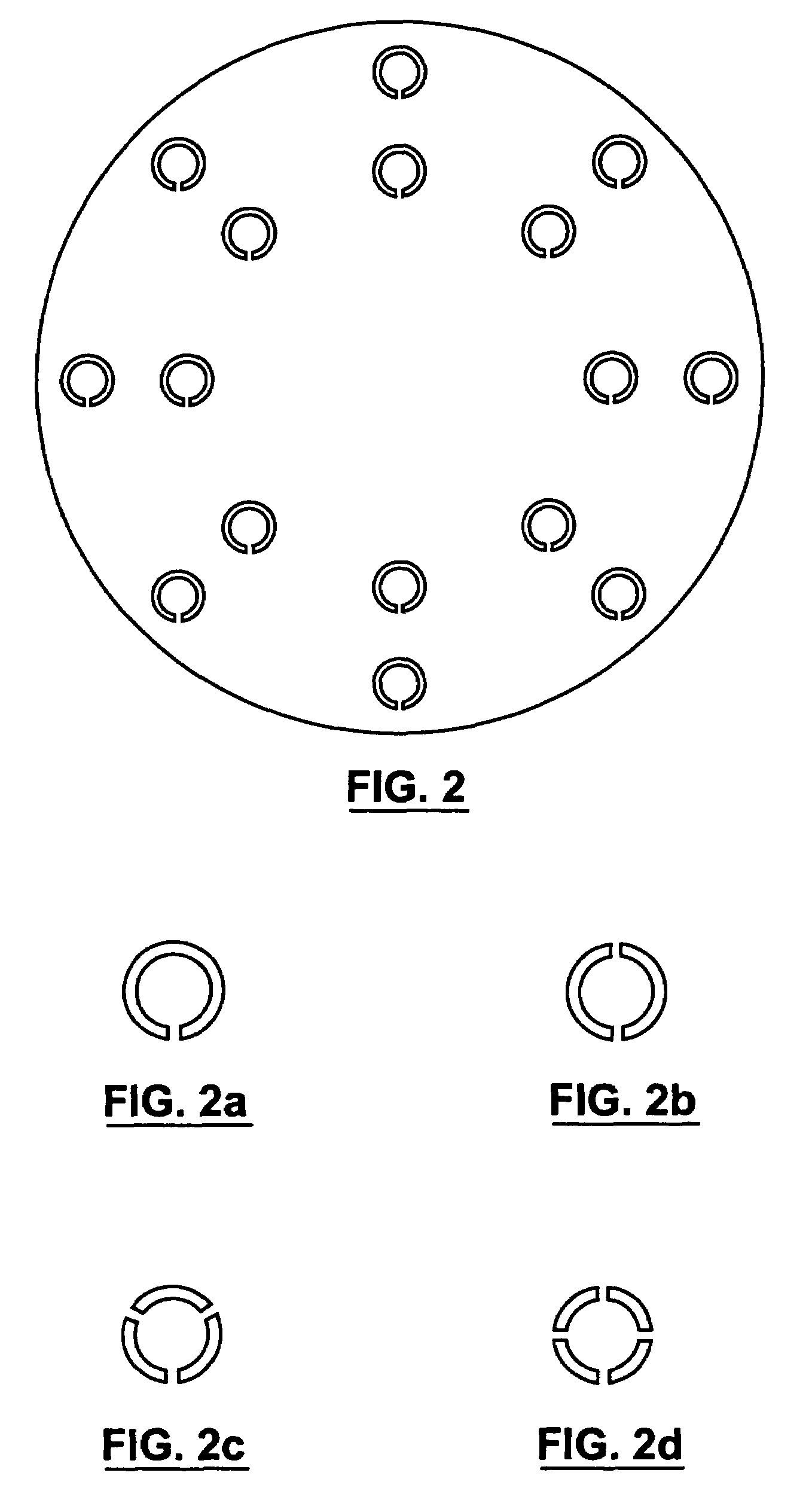

Supported biofilm apparatus and process

ActiveUS20060037896A1High gas transfer rateIncrease the areaSemi-permeable membranesTransportation and packagingBiofilmFiber

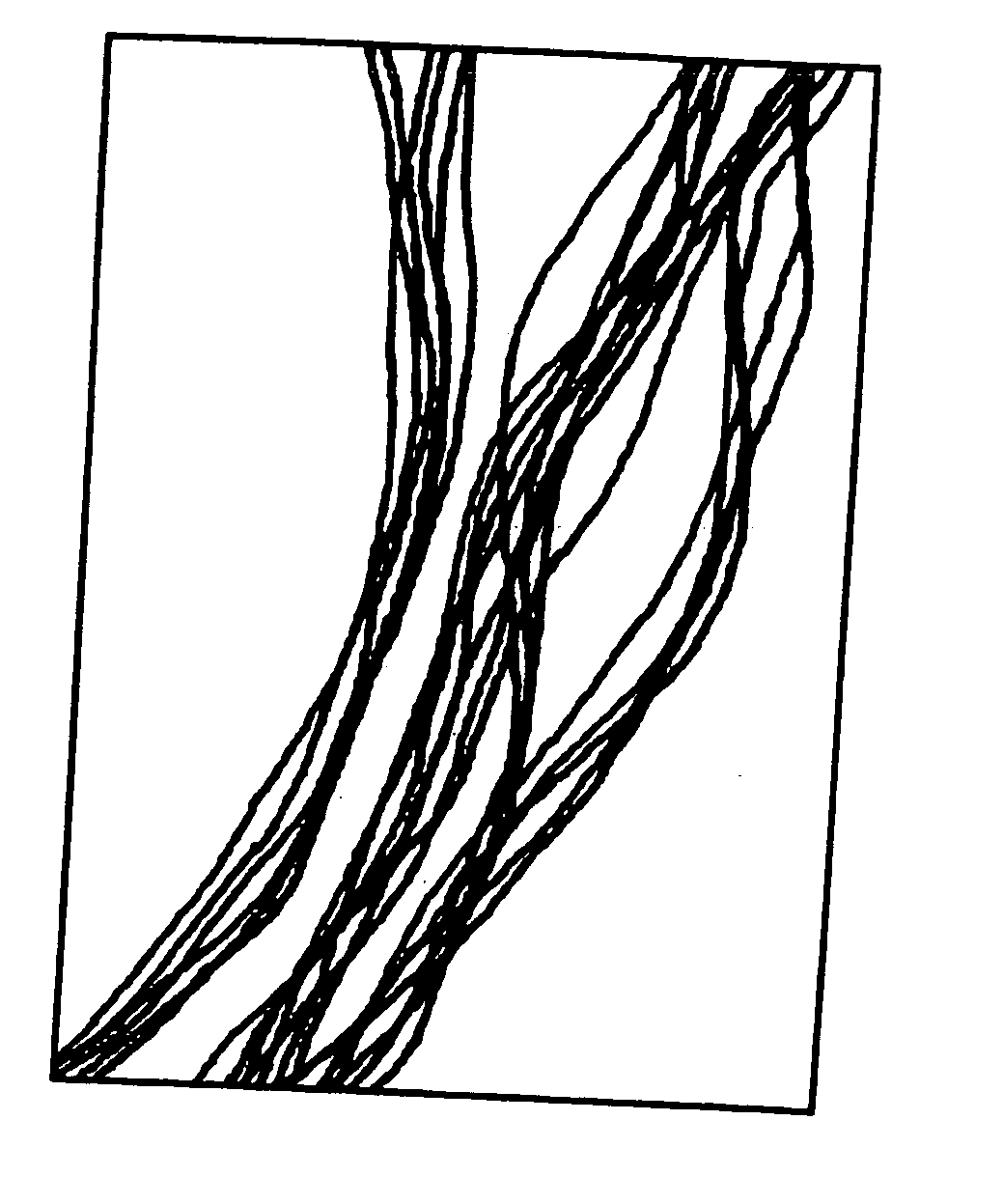

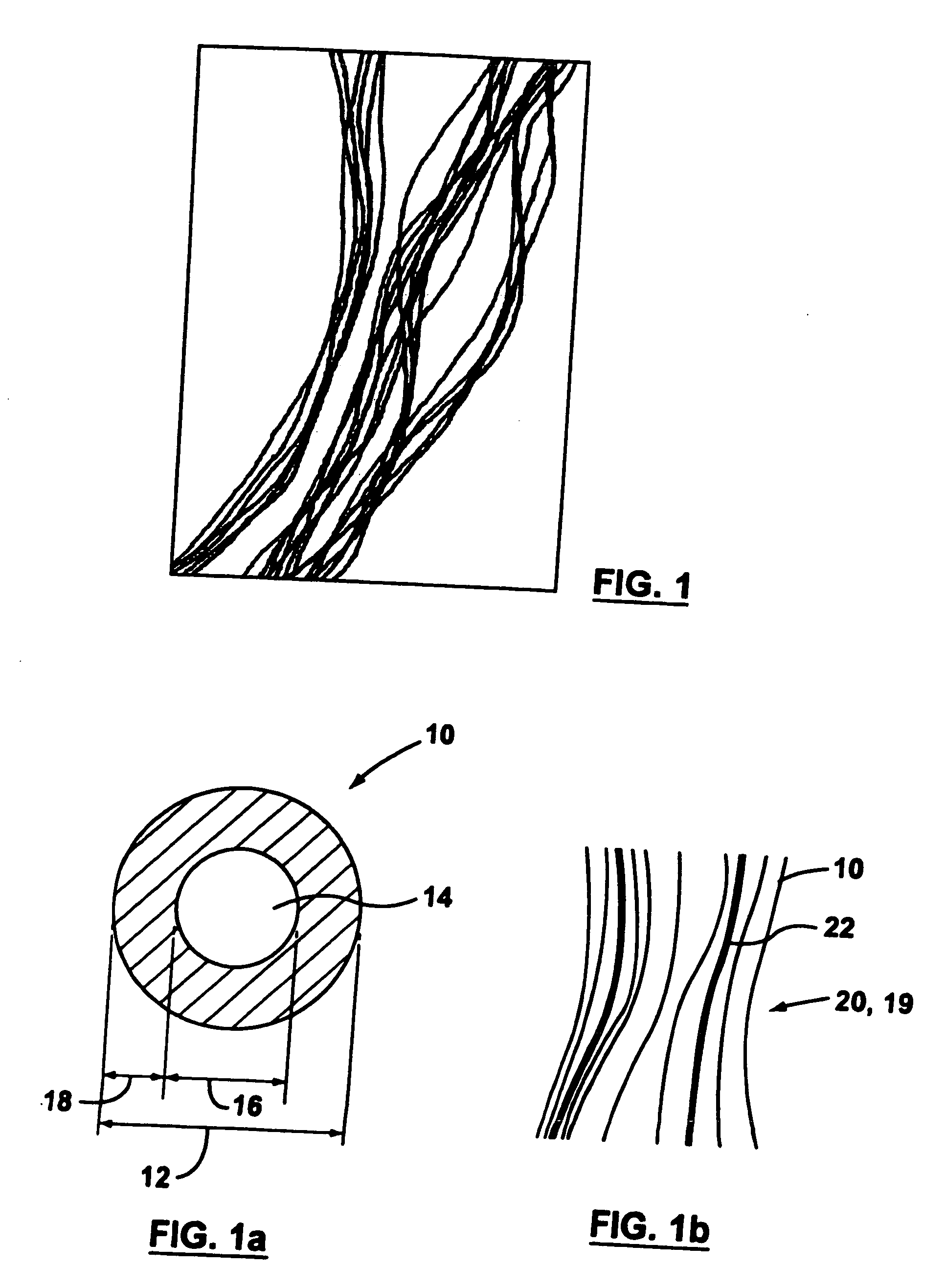

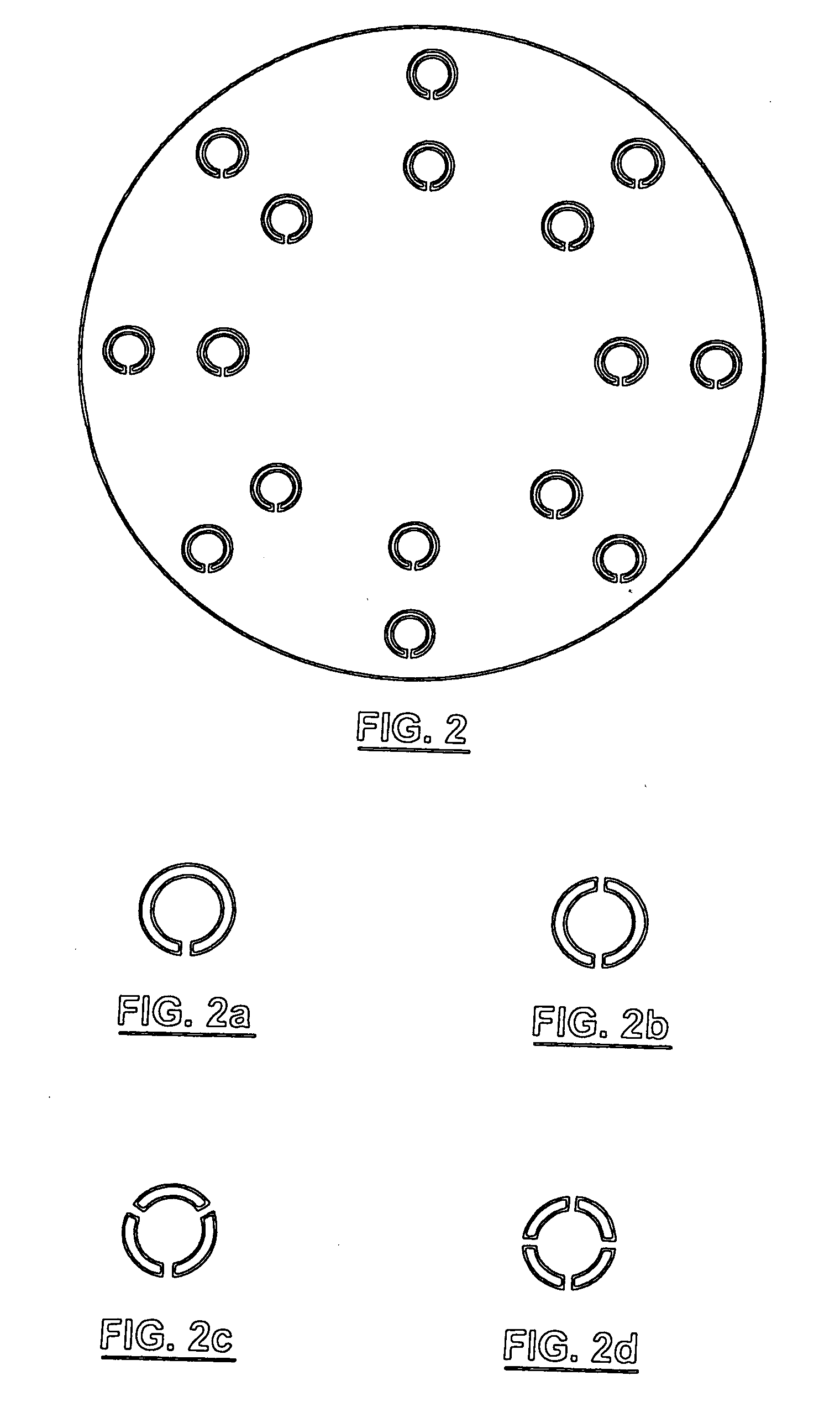

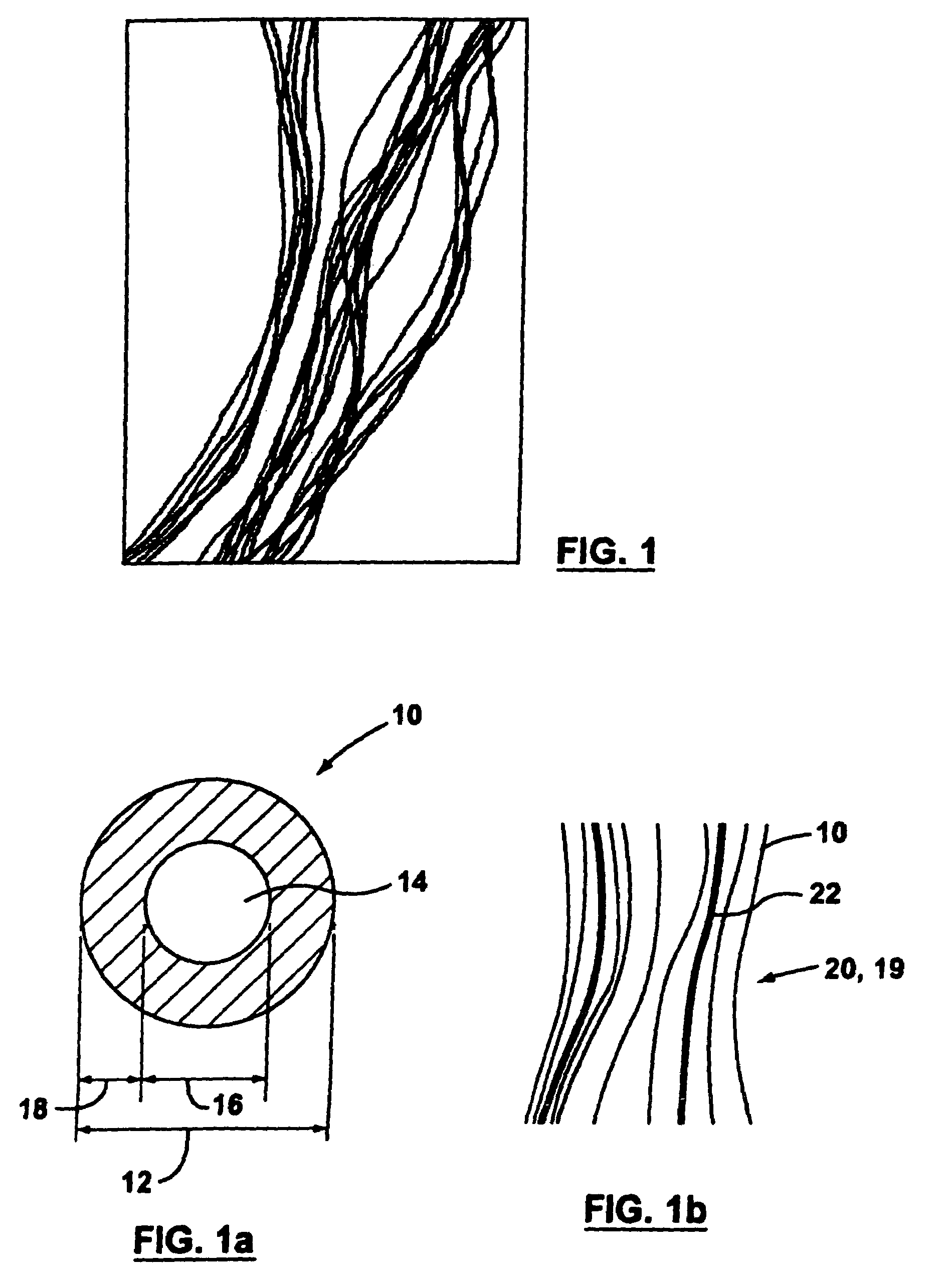

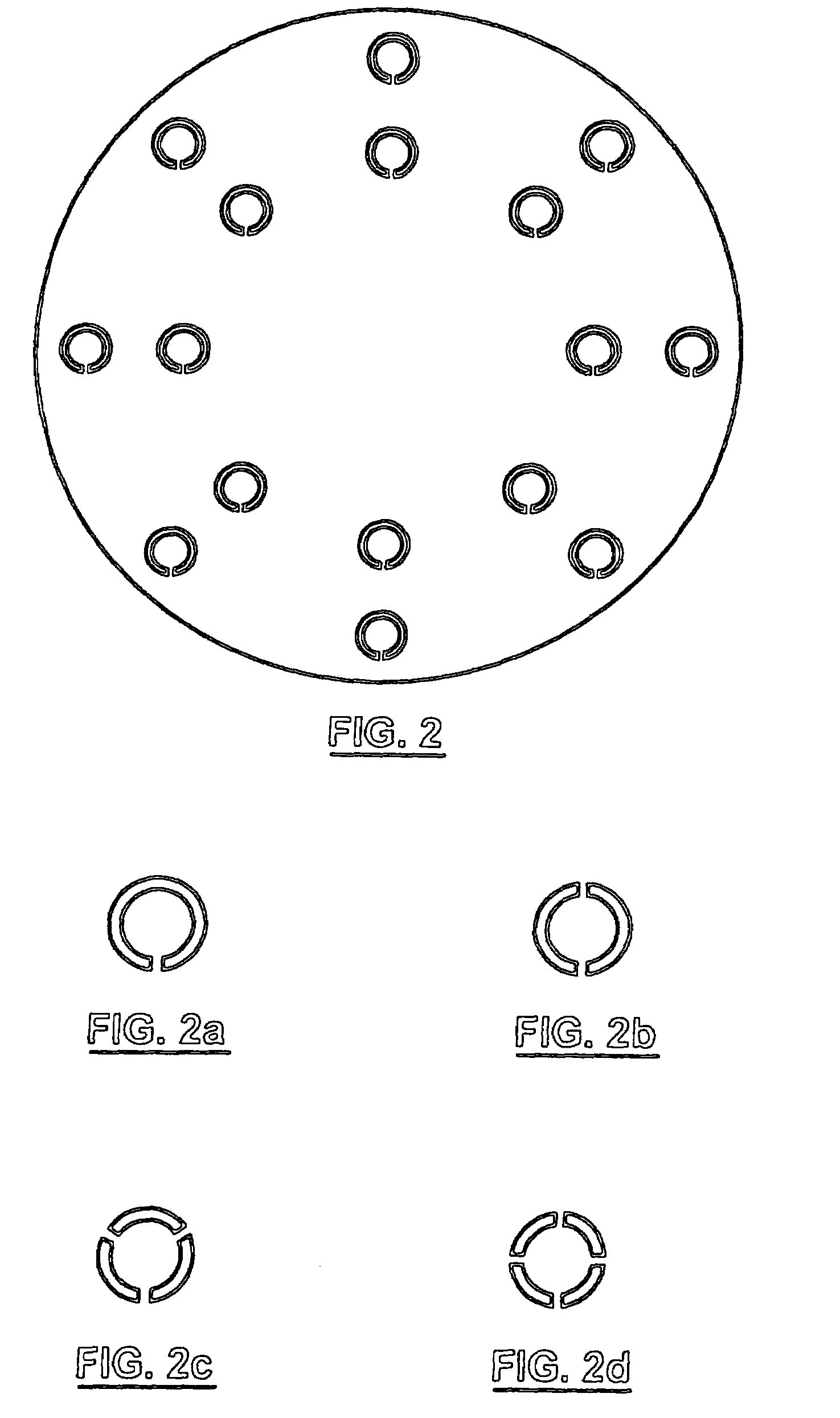

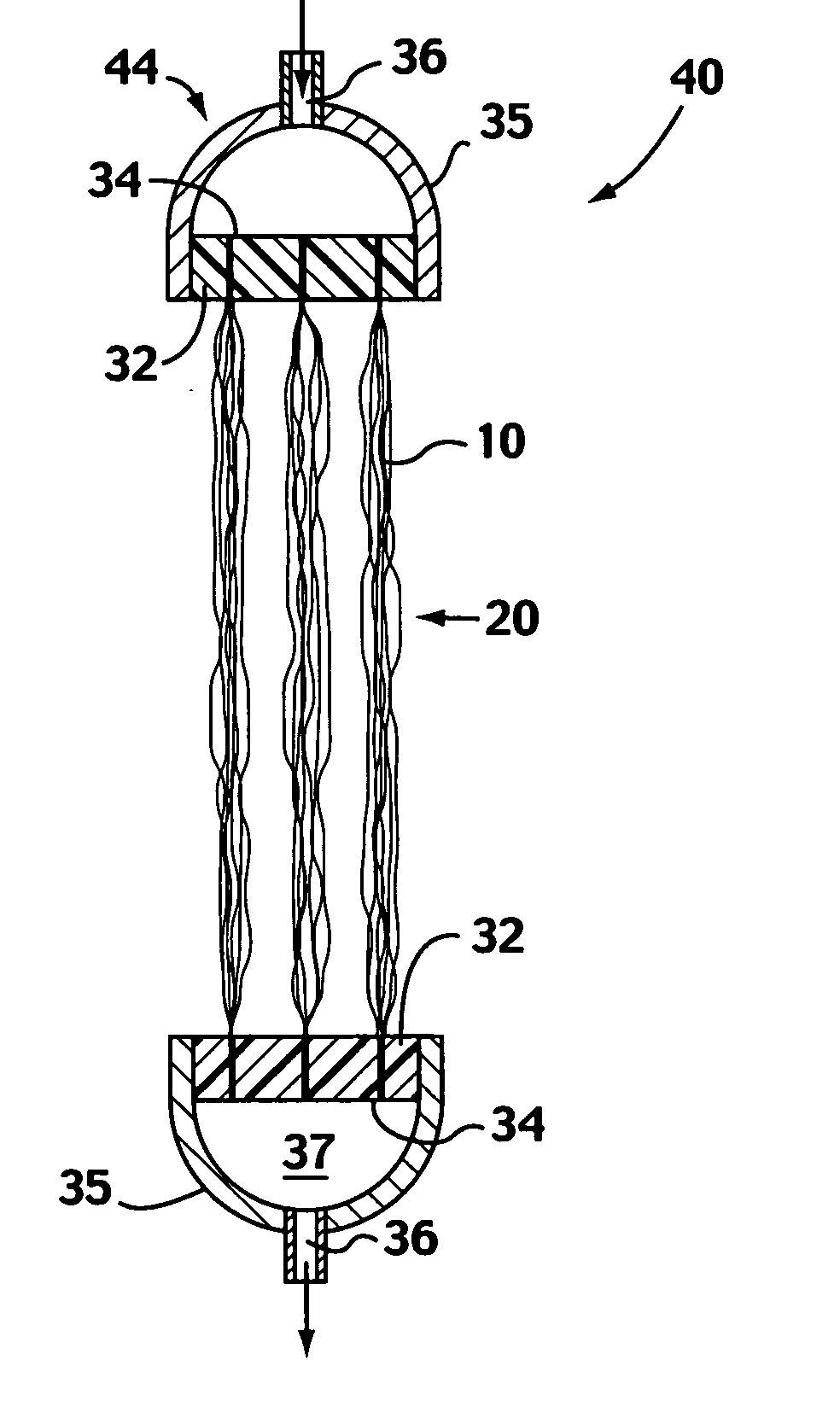

A membrane supported biofilm reactor uses modules having fine, hollow fibres, for example, made from melt spun thermoplastic polymers treated after spinning to increase their permeability to oxygen, used, for example, in tows or formed into a fabric. In one module, one or more sheets of the fabric are potted into a module to enable oxygen containing gas to be supplied to the lumens of the hollow fibres. Various reactors and processes, for example to treat wastewater, using such modules are described. In one process, oxygen travels through fibers, optionally through an attached biofilm, to oxygenate surrounding water. Mechanical, chemical and biological methods, for example endogenous respiration, are used to control the thickness of the biofilm.

Owner:ZENON TECH PARTNERSHIP

Supported biofilm apparatus

InactiveUS7300571B2High gas transfer rateIncrease the areaSemi-permeable membranesTransportation and packagingBiofilmFiber

A membrane supported biofilm reactor uses modules having fine, hollow fibers, for example, made from melt spun thermoplastic polymers treated after spinning to increase their permeability to oxygen, used, for example, in tows or formed into a fabric. In one module, one or more sheets of the fabric are potted into a module to enable oxygen containing gas to be supplied to the lumens of the hollow fibers. Various reactors and processes, for example to treat wastewater, using such modules are described. In one process, oxygen travels through fibers, optionally through an attached biofilm, to oxygenate surrounding water. Mechanical, chemical and biological methods, for example endogenous respiration, are used to control the thickness of the biofilm.

Owner:ZENON TECH PARTNERSHIP

Supported biofilm apparatus and process

ActiveUS20060163157A1High gas transfer rateIncrease the areaSemi-permeable membranesTransportation and packagingFiberHollow fibre

A membrane supported biofilm reactor uses modules having fine, hollow fibres, for example, made from melt spun thermoplastic polymers treated after spinning to increase their permeability to oxygen, used, for example, in tows or formed into a fabric. In one module, one or more sheets of the fabric are potted into a module to enable oxygen containing gas to be supplied to the lumens of the hollow fibres. Various reactors and processes, for example to treat wastewater, using such modules are described. In one process, oxygen travels through fibers, optionally through an attached biofilm, to oxygenate surrounding water. Mechanical, chemical and biological methods, for example endogenous respiration, are used to control the thickness of the biofilm.

Owner:ZENON TECH PARTNERSHIP

Supported biofilm apparatus and process

ActiveUS7303676B2High gas transfer rateIncrease the areaMembranesSemi-permeable membranesHollow fibreFiber

A membrane supported biofilm reactor uses modules having fine, hollow fibres, for example, made from melt spun thermoplastic polymers treated after spinning to increase their permeability to oxygen, used, for example, in tows or formed into a fabric. In one module, one or more sheets of the fabric are potted into a module to enable oxygen containing gas to be supplied to the lumens of the hollow fibres. Various reactors and processes, for example to treat wastewater, using such modules are described. Mechanical, chemical and biological methods, for example endogenous respiration, are used to control the thickness of the biofilm.

Owner:ZENON TECH PARTNERSHIP

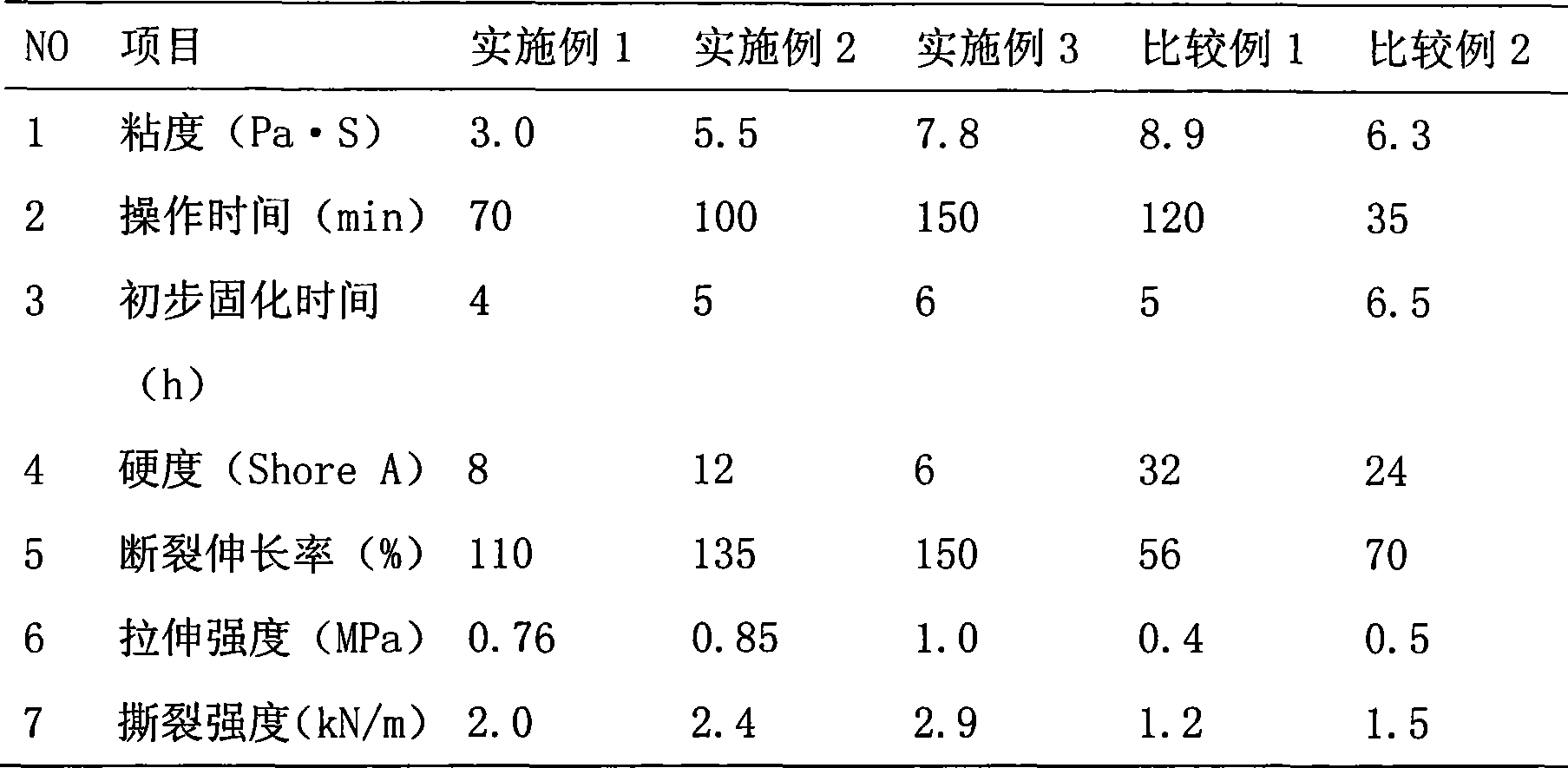

Double-component epoxy resin embedding adhesive and its preparation method and can sealing technique

ActiveCN101235269ALow viscositySave operating timeOther chemical processesEpoxy resin adhesivesEpoxyAlcohol

Bi-component epoxy resin pouring sealant and the preparation and the potting technology are disclosed, which comprises an epoxy resin A component and a cursing agent B component, wherein the curing agent B component at least comprises the mixing curing agent of cashew shell oil modified amine curing agent and fatty amine curing agent. The potting technology comprises mixing and stirring evenly the epoxy resin A component and the curing agent B agent to conduct the potting, and spraying a layer of absolute alcohol on the surface of the pouring sealant after 10-15 minutes. The advantages are that gel time is prolonged through adopting the mixing curing agent of cashew shell oil modified amine curing agent and fatty amine curing agent, the requirement of operation time is fulfilled, and the operation time can reach 20-30 minutes, thereby being beneficial for the encapsulation of housing with large capacity, and the pouring sealant of the invention has the effect of fast curing, wherein the curing time is 1-3 hours, and defoaming is accelerated through spraying a layer of absolute alcohol on the surface of colloid after pouring, thereby making the solid gel surface bright and flat after curing.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

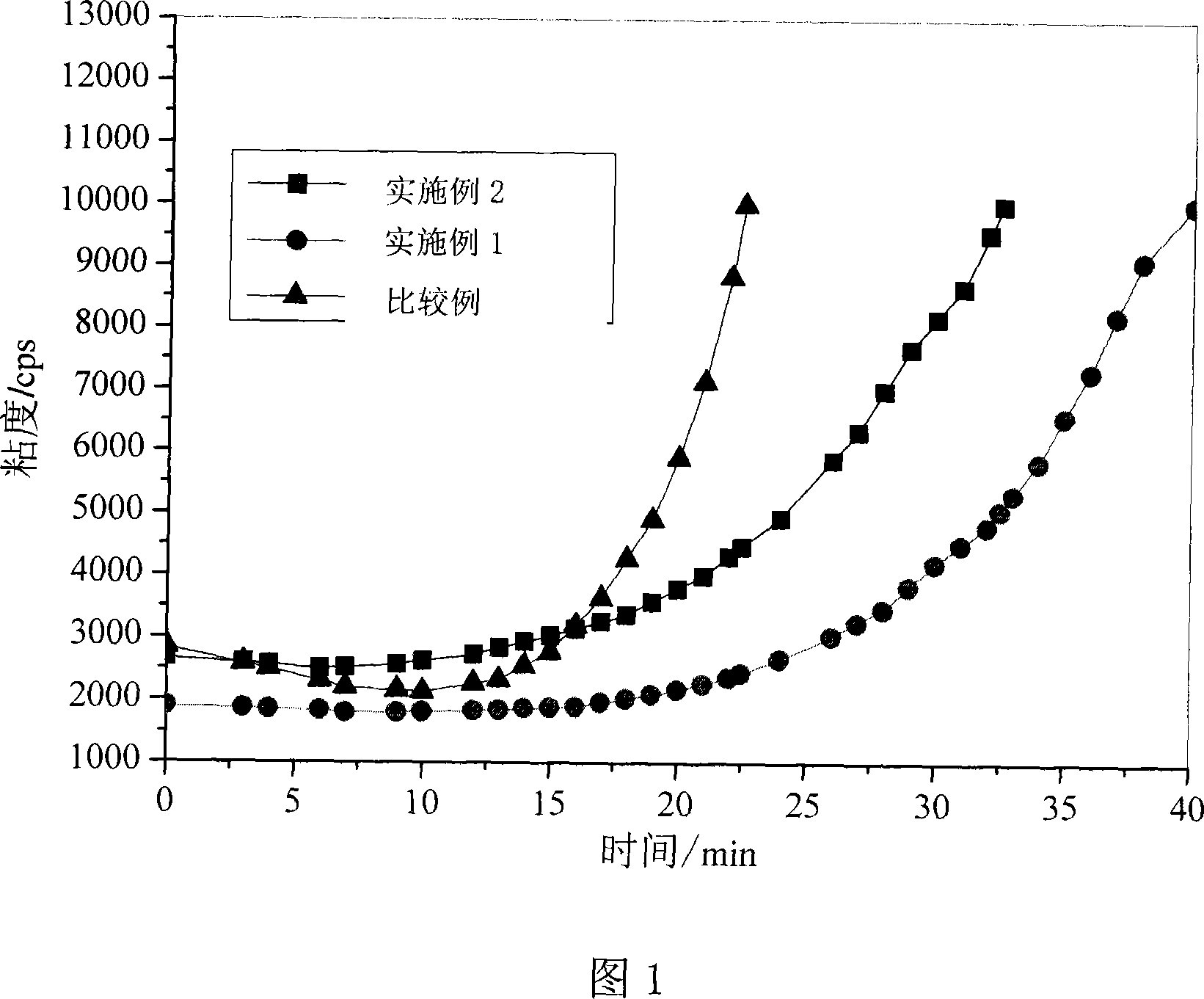

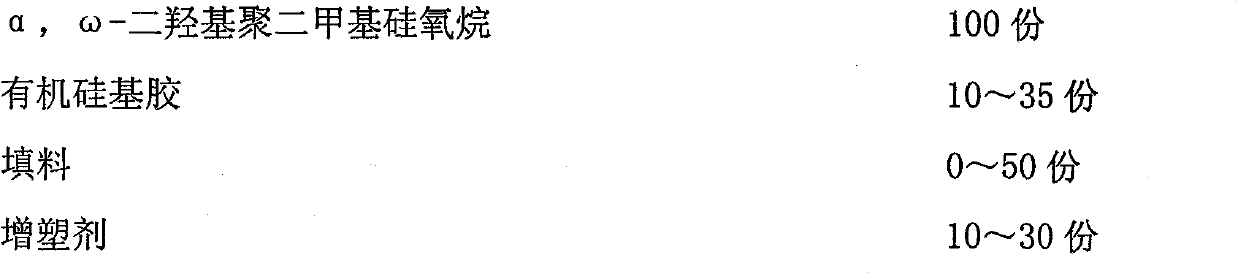

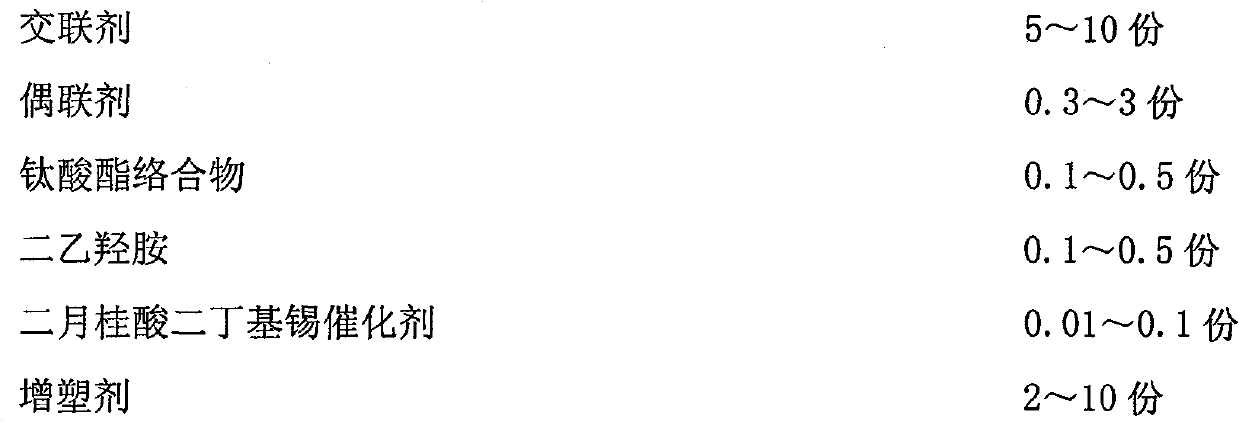

Bi-component silicone pouring sealant for LED photoelectric display device and method for manufacturing same

ActiveCN101544881AAvoid thickeningSimple processOther chemical processesSemiconductor/solid-state device manufacturingHydroxylamineDisplay device

The invention relates to a bi-component silicone pouring sealant for an LED optoelectronic display device and a method for manufacturing the same. The bi-component silicone pouring sealant is characterized in that the sealant is obtained through the reaction of components A and B by using alpha,omega-dihydroxy polydimethylsiloxane of which the structural formula shown on the right as a main material. The component A is prepared from the following components by weight portion through mixing: 100 portions of the alpha,omega-dihydroxy polydimethylsiloxane, 10 to 35 portions of organosilicon based gel, 0 to 50 portions of stuffing, and 10 to 30 portions of plasticizer; and the component B is prepared from the following components in portion by weight through mixing: 5 to 10 portions of cross-linking agent, 0.3 to 3 portions of coupling agent, 0.1 to 0.5 portion of titanate complex, 0.1 to 0.5 portion of diethyl hydroxylamine, 0.01 to 0.1 portion of dibutyltin dilaurate catalyst, and 2 to 10 portions of plasticizer. The silicone pouring sealant prepared by the method has the advantages of simple process flow, good adhesive property, excellent temperature and weather resistant properties, and good flow property, and can be widely applicable for embedding electronic devices such as the LED optoelectronic display device and the like.

Owner:CHENGDU GUIBAO SCI & TECH

Pouring method for pouring molding of special-shaped coil former

The invention relates to a pouring method for pouring molding of a special-shaped coil former. The method includes the following steps that first, pretreatment of adhesives is performed, the adhesives are subject to defoaming treatment in stirring and pressure drop modes, and stirring under vacuumizing and stirring under ordinary pressure are carried out alternately; second, workpiece installation is conducted, and the coil former is placed into a molding tool; and third, filling and sealing are carried out, and a four-opening synchronous filling and sealing tool is used for pouring the four surfaces of the coil former at the same time. By the adoption of the tool and the pouring method thereof, the molding quality of coil pouring of a seeker product is guaranteed, reliable performance of the product is ensured, and production efficiency is improved.

Owner:XIAN NORTH ELECTRO OPTIC TECH DEFENSE

Encapsulating material of new energy automobile battery and preparation method thereof

The invention discloses an encapsulating material of a new energy automobile battery. The encapsulating material is prepared from the following components in parts by weight: 100 parts of vinyl-terminated silicone oil, 2 to 6 parts of hydrogen-containing silicone oil, 150 to 300 parts of modified aluminum oxide, 0.05 to 0.15 part of a platinum catalyst, 20 to 50 parts of a halogen-free flame retardant, 2 to 5 parts of white carbon black, 0.5 to 1 part of hexamethyl disilazane, 1 to 5 parts of a peroxide vulcanizing agent and 0.5 to 3 parts of a plasticizer, wherein the peroxide vulcanizing agent is prepared from dibenzoyl peroxide and bis(tert-butyl peroxy isopyl)benzene. The encapsulating material prepared through invention formula disclosed by the invention is nontoxic, has no release ofan irritant gas and is environment-friendly and safe, and not only excellent high / low temperature resistance, excellent weather resistance and excellent electric insulation performance are obtained,but also excellent mechanical performance and excellent heat conduction are obtained; during a working process, an effective protection function on a battery is achieved, heat of the battery can be dissipated in time, high-security protection can be provided for the new energy automobile battery, the safety of the battery is increased, the service life of the battery is increased, and occurrence of the accidents of catching a fire and blasting of the new energy automobile battery can be effectively reduced.

Owner:清远市敬威能源开发有限公司

Pouring sealant for filling gap between warhead charge and shell

InactiveCN103205229AEasy pottingAvoid volume shrinkageNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesHydroxyl-terminated polybutadieneChemistry

The invention discloses a pouring sealant for filling a gap between a charge and a shell of a warhead. The pouring sealant comprises hydroxyl-terminated polybutadiene, a curing agent, a plasticizer and a curing catalyst, wherein mol ratio of R=[NCO] in the curing agent to [OH] in the hydroxyl-terminated polybutadiene is 0.8-1.2, content of the plasticizer is 0-1.5 times that of the hydroxyl-terminated polybutadiene, and the content of the curing catalyst is 0-0.01wt% that of the hydroxyl-terminated polybutadiene. The pouring sealant disclosed by the invention can be used for effectively solving the problem of an inherent gap between the charge and the shell of the warhead of the conventional weapon, so that use safety performance of the warhead and penetration stability to a target are greatly improved; and by adopting the pouring sealant disclosed by the invention, fabricated charging can be carried out without prefabricating a grain, so that the warheads in various sizes and shapes are directly poured and moulded, the mass production capability is greatly improved and the charging process cost is greatly reduced.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

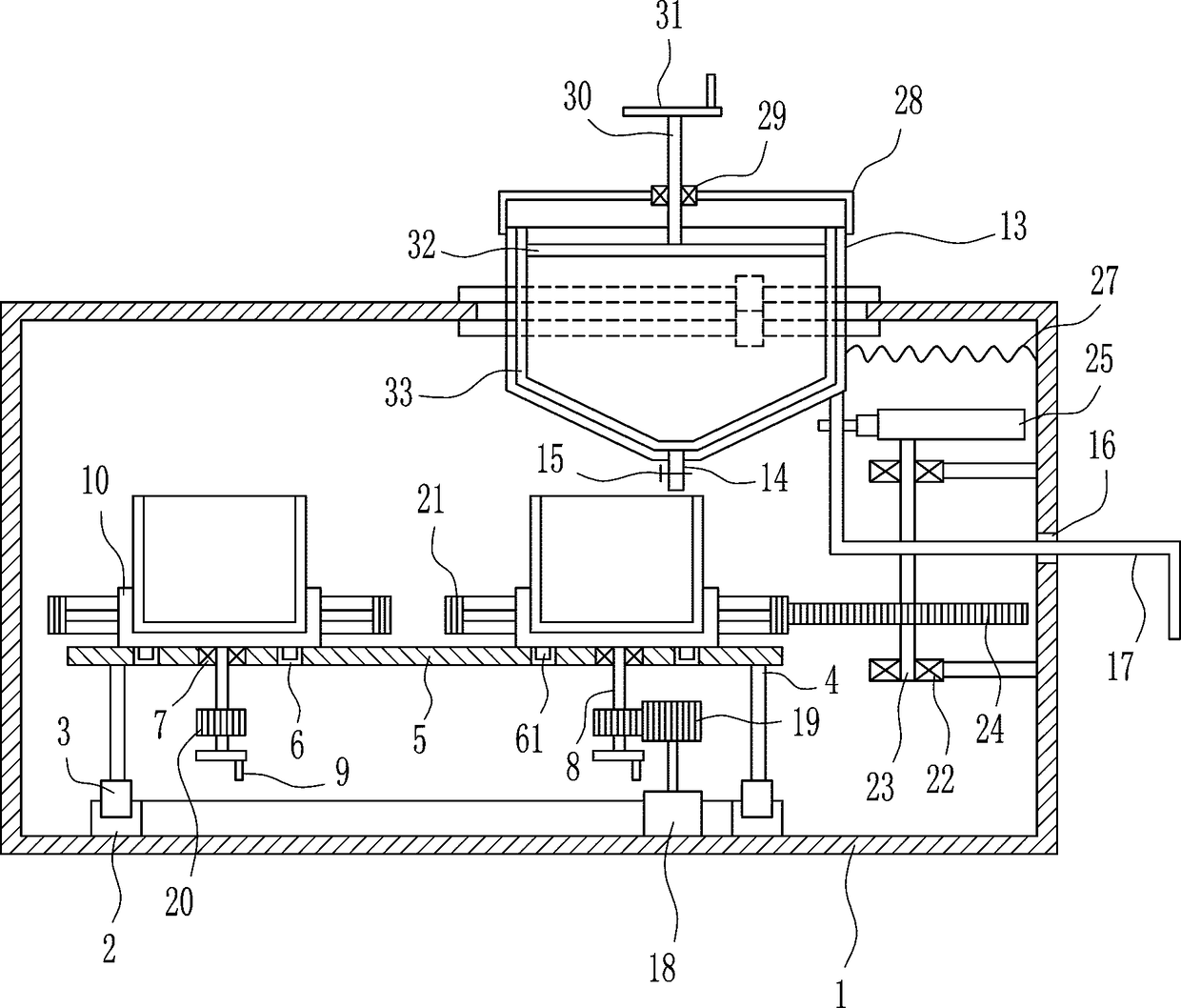

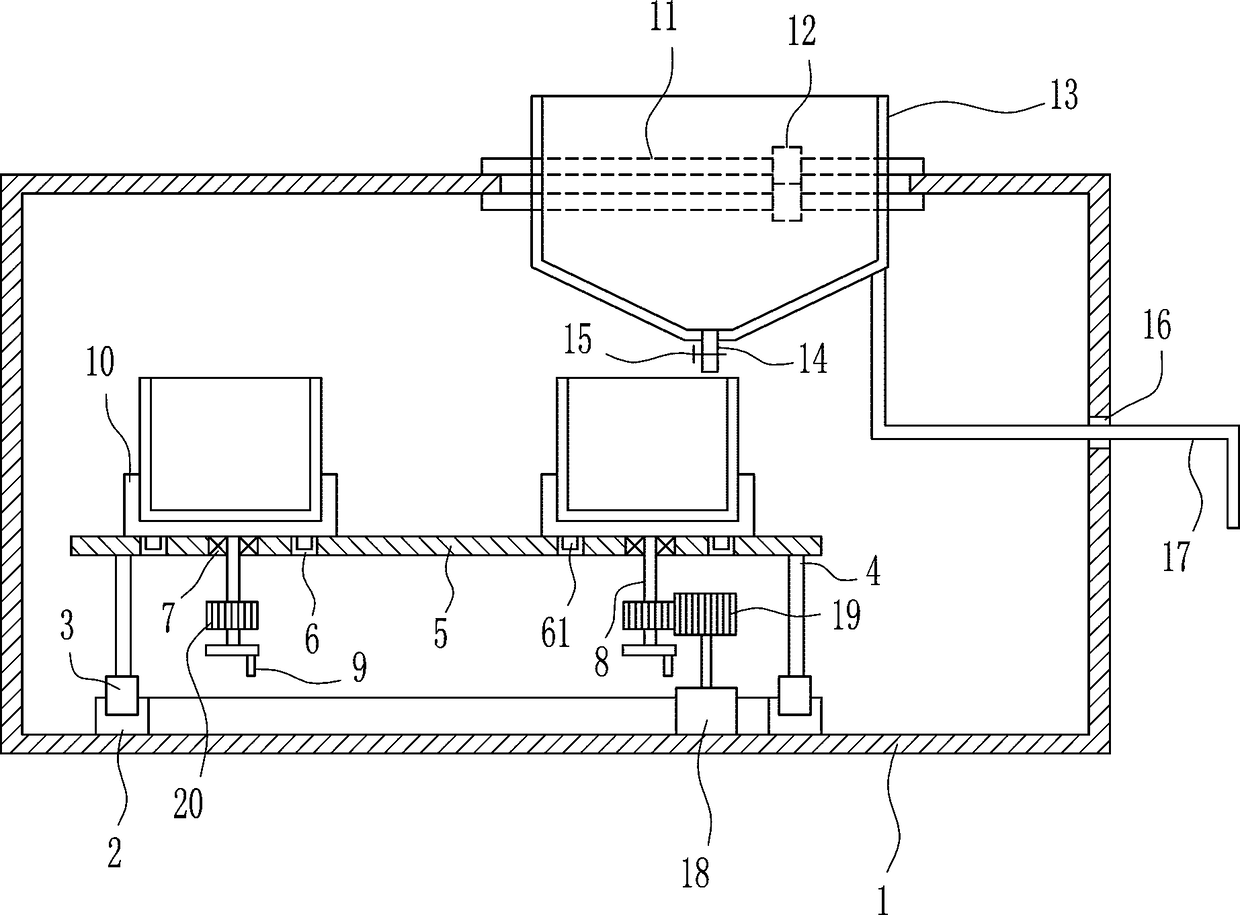

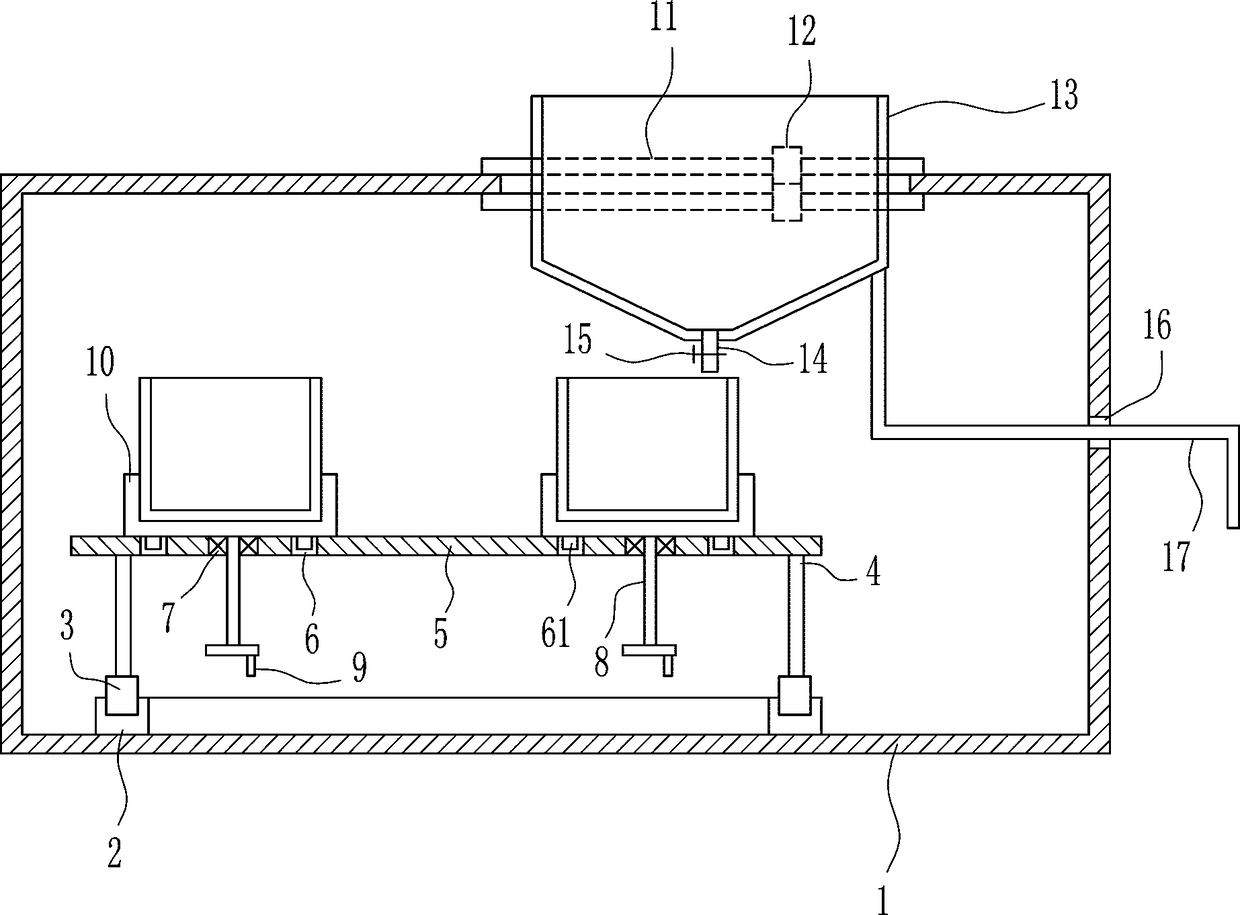

Rotary black adhesive filling and sealing equipment for electronic transformer manufacturing

The invention relates to black adhesive filling and sealing equipment for electronic transformer manufacturing, in particular to rotary black adhesive filling and sealing equipment for electronic transformer manufacturing. According to the rotary black adhesive filling and sealing equipment for electronic transformer manufacturing, a plurality of square frames are conveniently subjected to black adhesive filling and sealing, and labor is saved. According to the technical scheme, the rotary black adhesive filling and sealing equipment for electronic transformer manufacturing comprises a mounting frame, a first annular sliding rail, a first sliding block, a first connecting rod, a disc, a second annular sliding rail, a second sliding block, a first bearing seat, a first rotating rod and thelike; and the first annular sliding rail is connected to bottom in the mounting box. The effects that the multiple square frames are conveniently subjected to black adhesive filling and sealing, and the labor is saved are achieved; the square placement frames on the disc can rotate and thus are convenient to replace during black adhesive filling and sealing, and the square placement frames can rotate; and a discharge box can move left and right so that a black adhesive can be evenly filled.

Owner:李纪民

Flexible insulation pouring sealant based on modified epoxy resin

InactiveCN105623592AGood thermal conductivity and insulationLow viscosityNon-macromolecular adhesive additivesOther chemical processesDefoamerToluene

The invention discloses a flexible insulation pouring sealant based on modified epoxy resin. The flexible insulation pouring sealant comprises the following components by mass percentage: 20-30% of a methyl vinyl silicone rubber, 15-25% of modified epoxy resin, 10-15% of gamma-(methacrylic acyloxy)propyl trimethoxy silane, 5-9% of boron oxide, 3-5% of a flexible additive, 0-2% of toluene, 0-1% of an antifoaming agent, 25-30% of an active diluent, 0.5-1.5% of a coupling agent, and 0.5-1.5% of a curing agent. The flexible insulation pouring sealant has good heat conduction and insulating properties, the viscosity of the pouring sealant is greatly reduced by adopting the reactive diluent containing a plurality of active end groups, the viscosity of the pouring sealant is low, so that the pouring sealant is beneficial for pouring; usage of the flexible additive increase flexibility of pouring sealant matrix, and the pouring can be easily realized during a pouring process.

Owner:NANJING AILU NEW ENERGY TECH CO LTD

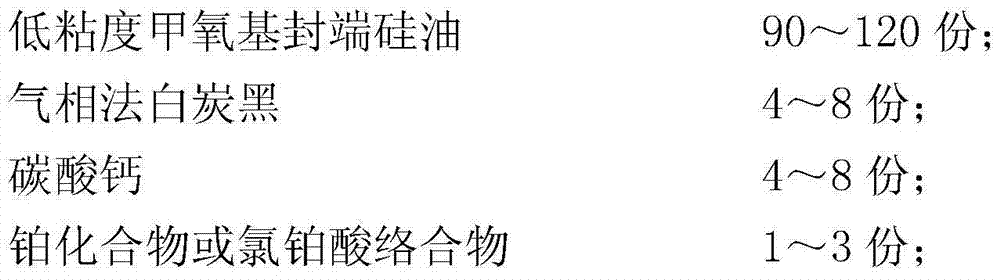

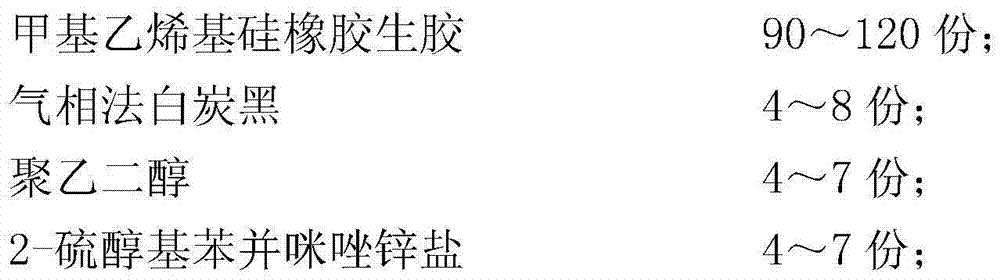

Low-velocity liquid silicon rubber and preparation method thereof

The invention discloses low-velocity liquid silicon rubber which consists of a component A and a component B in a weight ratio or volume ratio of 1:1, wherein the component A comprises the following components in parts by weight: 90-120 parts of low-velocity methoxy end capping silicon oil, 4-8 parts of fumed silica, 4-8 parts of calcium carbonate, and 1-3 parts of a platinum compound or chloroplatinic acid complex; the component B comprises the following components in parts by weight: 90-120 parts of methylvinyl unvulcanized silicone rubber, 4-8 parts of fumed silica, 4-7 parts of polyethylene glycol, 4-7 parts of 2-thiol benzimidazole zinc salt, 3-6 parts of an inhibitor, 8-10 parts of methyl hydrogen-containing polysiloxane and 10-20 parts of an additive. The low-velocity liquid silicon rubber disclosed by the invention is high in transparence, low in velocity, relatively high in strength after being cured, relatively high in flowability and machinability, and can be conveniently filled to seal complex electronic components, and the velocity of the low-velocity liquid silicon rubber is kept being about 4000cps.

Owner:SUZHOU JIN TENG ELECTRONICS TECH

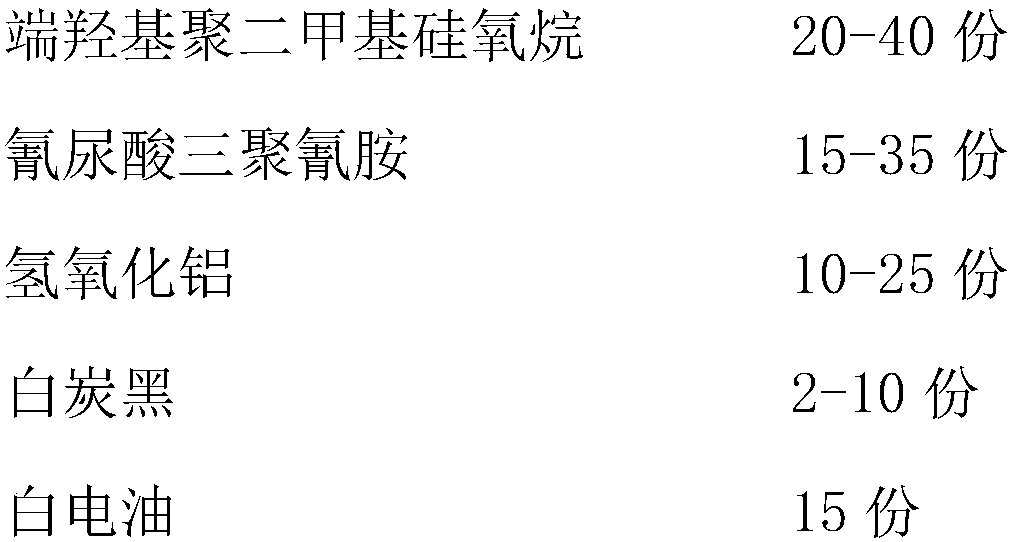

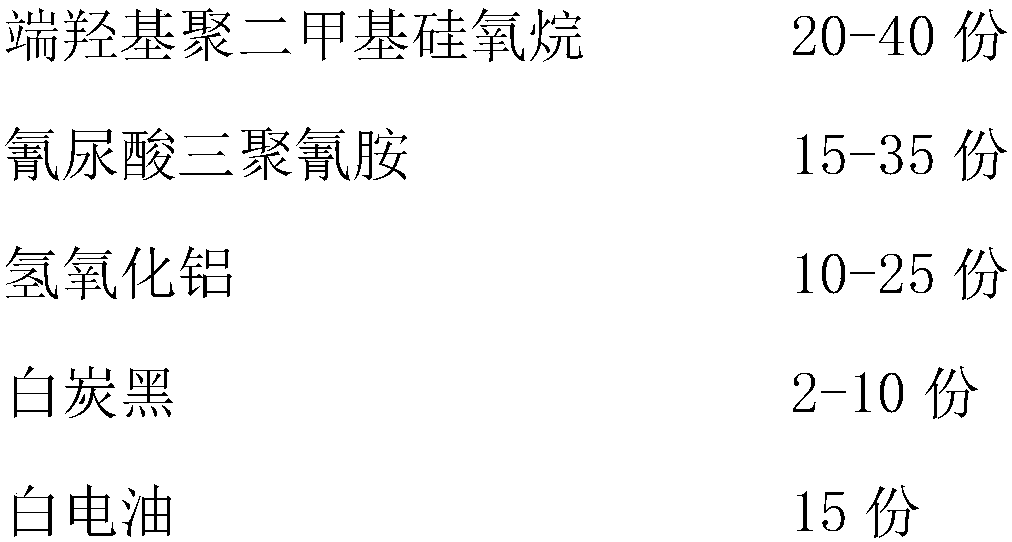

Low-viscosity display screen flame-retardant surface mounting pouring sealant

InactiveCN107663443ALow densityLow oil absorptionNon-macromolecular adhesive additivesLiquid viscositySealant

The invention discloses the technical field of a pouring sealant, and particularly relates to the field of a low-viscosity display screen flame-retardant surface mounting pouring sealant. The low-viscosity display screen flame-retardant surface mounting pouring sealant is prepared from an ingredient A and an ingredient B according to the ratio of 10:1, wherein the ingredient A is prepared from hydroxyl-terminated polydimethylsiloxane, melamine cyanurate, aluminum hydroxide, white carbon black and white gas; the ingredient B is prepared from gamma-aminopropyltriethoxysilane, tetraethoxysilane and dibutyltin dilaurate; the melamine cyanurate and the aluminum hydroxide are matched to be used as flame-retardant agents; the flame-retardant stage of UL94V0 can be reached at low consumption; thecorresponding construction requirements can be met; the white gas is used as diluents, and can fast reduce the glue liquid viscosity; no influence on lamp beads, printed circuit boards and LED masks is caused, so that the glue liquid circulation performance is good; the pouring and sealing can be convenient; a phenomenon of bubbling since glue liquid cannot fast immerge into electronic devices canbe avoided.

Owner:广东和天新材料科技有限公司

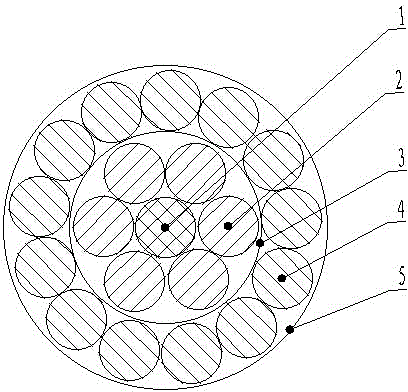

Abrasion-resistant steel wire rope

The invention discloses an abrasion-resistant steel wire rope, relating to the technical field of manufacture of steel wire ropes. The abrasion-resistant steel wire rope comprises a rope core, outside of which inner-layer steel wire ropes, an inner-layer abrasion-resistant layer, outer-layer steel wire ropes and an outer-layer abrasion-resistant layer are sequentially arranged. The multiple strands of inner-layer steel wire ropes are arranged and wrapped outside the rope core. The multiple strands of outer-layer steel wire ropes are arranged and wrapped outside the inner-layer abrasion-resistant layer. The outer-layer abrasion-resistant layer is wrapped outside the multiple strands of outer-layer steel wire ropes. The inner-layer abrasion-resistant layer and the outer-layer abrasion-resistant layer are both polyurethane resin layers. The rope core is a metal wire rope core. Compared with a conventional steel wire rope, the abrasion-resistant steel wire rope helps to solve problems of the conventional steel wire rope such as poor abrasion-resistant performance and short service lifetime.

Owner:LIUZHOU PUYA TRADE

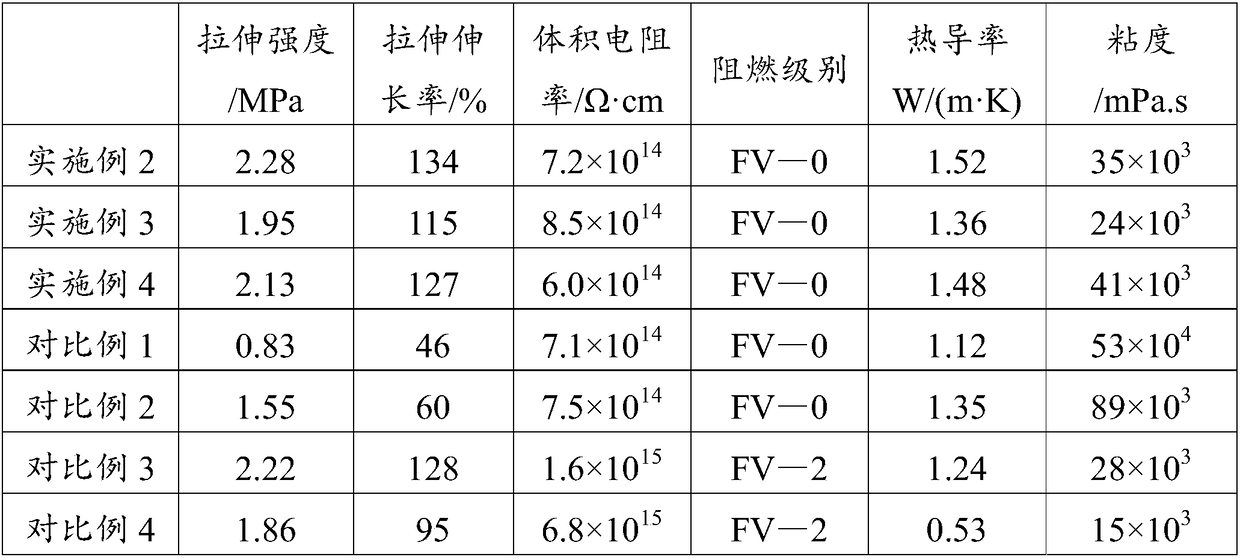

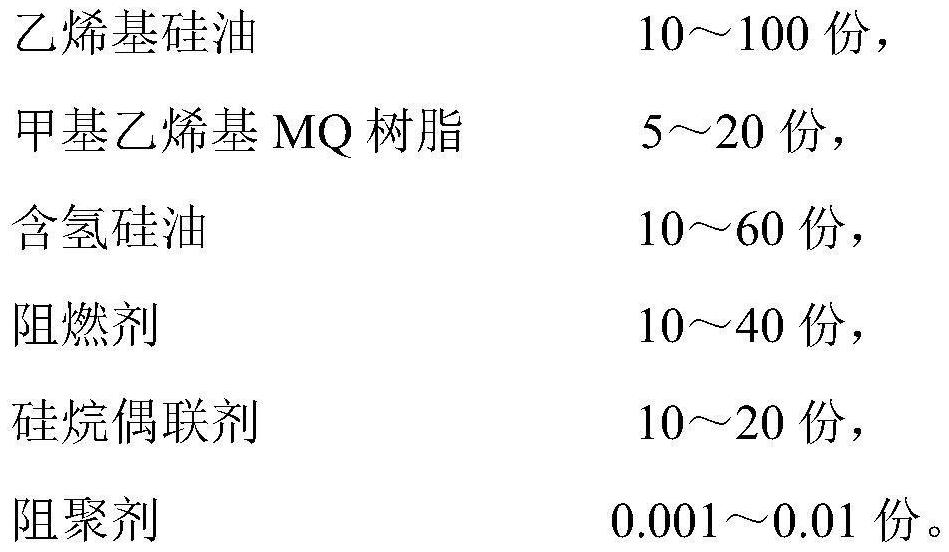

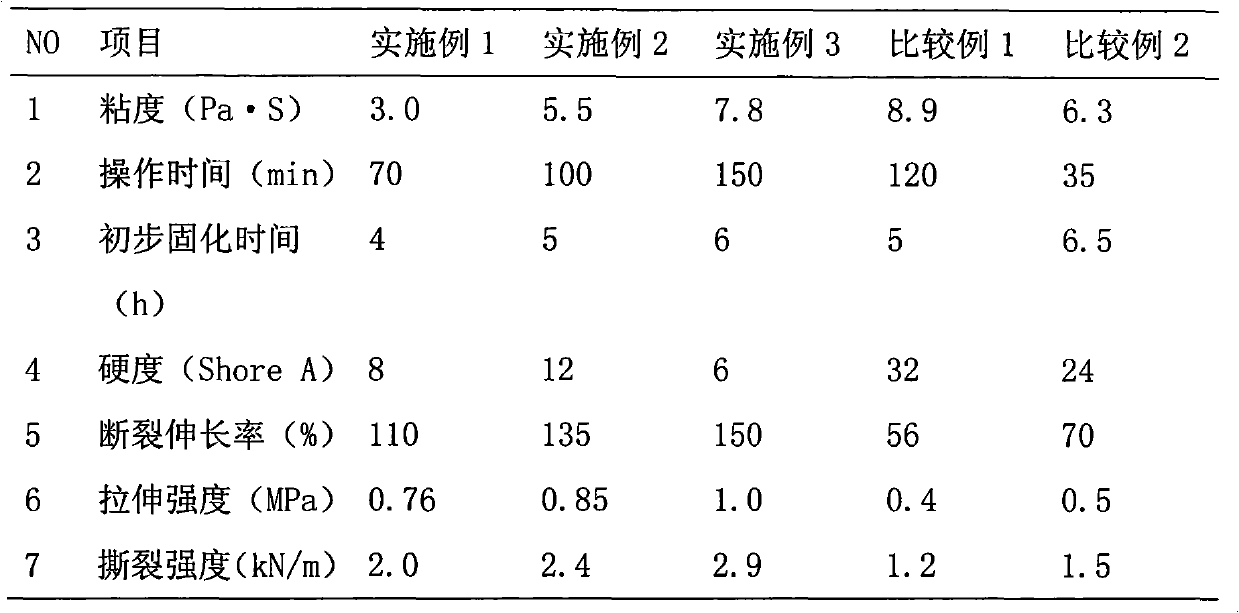

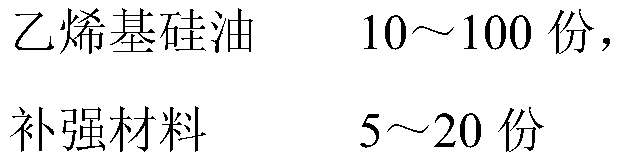

Organic silicon pouring sealant and preparation method thereof

PendingCN112778968AImprove the tracking coefficient compared toInhibition formationNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses an organic silicon pouring sealant which comprises two components including a component A and a component B. The component A comprises vinyl, methyl vinyl MQ resin, a reinforcing filler and a catalyst. The component B comprises vinyl silicone oil, methyl vinyl MQ resin, hydrogen-containing silicone oil, a flame retardant, a silane coupling agent and a polymerization inhibitor. The preparation method comprises the following steps of: adding vinyl silicone oil, methyl vinyl MQ resin and a catalyst into a reaction kettle, dispersing at a low speed, adding a reinforcing filler, dispersing at a high speed, and defoaming in vacuum to obtain a component A; and adding vinyl silicone oil, methyl vinyl MQ resin and a polymerization inhibitor into a reaction kettle, dispersing at a low speed, adding hydrogen-containing silicone oil and a silane coupling agent, dispersing at a low speed, adding a flame retardant, dispersing at a high speed, and defoaming in vacuum to obtain a component B; The comparative tracking coefficient (CTI) of the organic silicon pouring sealant is larger than or equal to 600V, and the organic silicon pouring sealant is free of oil leakage, excellent in flame retardant property, small in viscosity and easy to pour.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Bi-component silicone pouring sealant for LED photoelectric display device and method for manufacturing same

ActiveCN101544881BAvoid thickeningSimple processOther chemical processesSemiconductor/solid-state device manufacturingHydroxylamineDisplay device

Owner:CHENGDU GUIBAO SCI & TECH

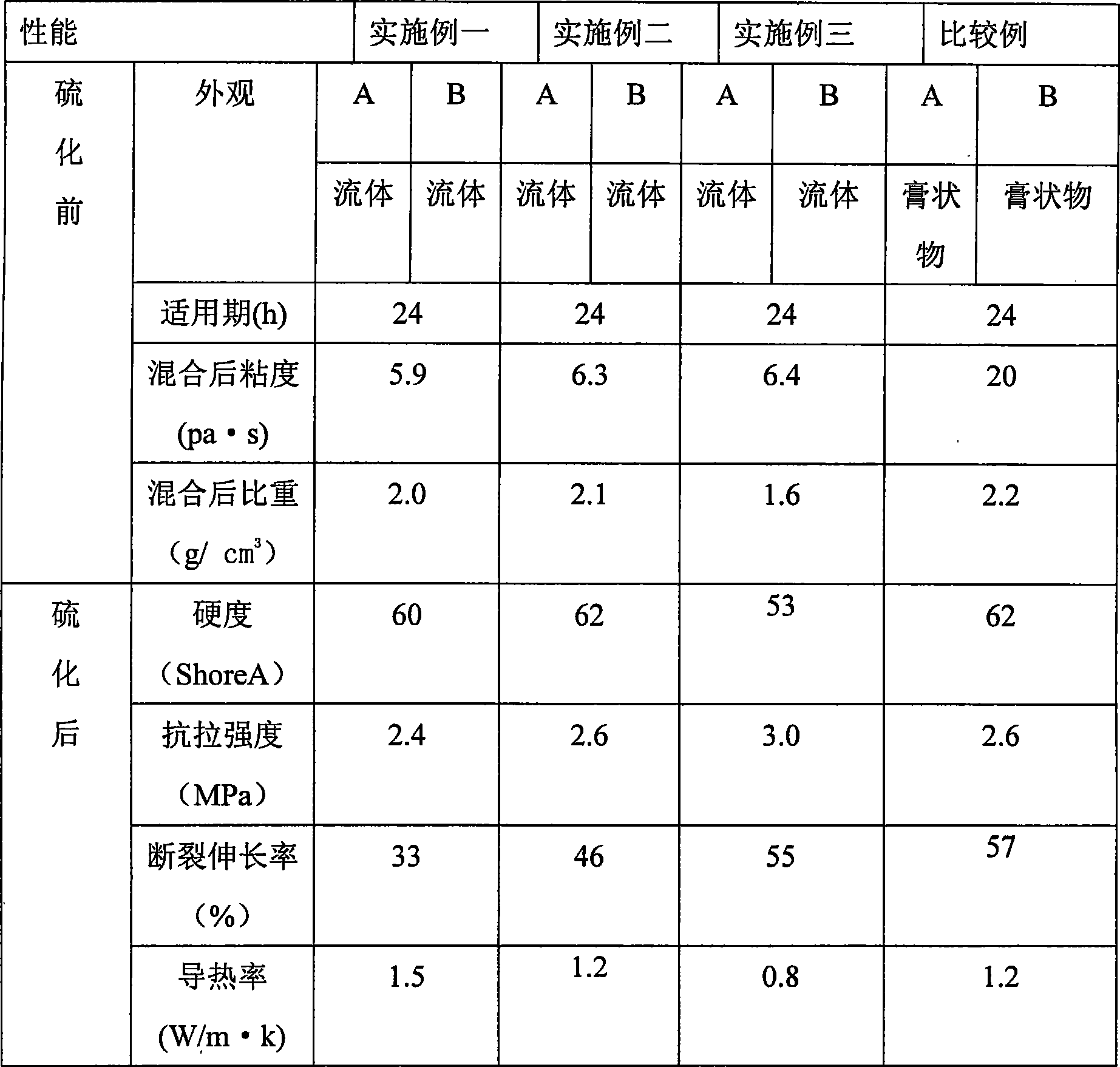

Addition type heat conducting silicon rubber and manufacturing method thereof

The invention relates to an addition type heat-conducting silicone rubber and a preparation method thereof. The addition type heat-conducting silicone rubber is characterized in that 100 weight portions of vinyl silicone oil and 200 weight portions to 500 weight portions of heat-conducting material are dewatered and mixed in a vacuum kneader for 30 to 200 minutes with the temperature of 100 to 150 DEG C and the vacuum degree of 0.06 to 0.099 MPa so as to obtain base material; under normal temperature, 0.5 weight portion to 1.5 weight portions of hydrogeneous silicone oil, 0.01 weight portion to 0.06 weight portion of inhibitor and 3 weight portions to 10 weight portions of diluent are added and stirred in a stirrer for 15 to 40 minutes so as to obtain A glue; 100 weight portions of base material are taken, 0.25 weight to 0.75 weight portion of platinum catalyst and 3 weight portions to 10 weight portions are added and stirred in the stirrer for 15 to 40 minutes so as to obtain B glue.The A glue and the B glue with the same weight portions are taken, mixed evenly and defoamed for 3 to 10 minutes at the vacuum degree of 0.06 to 0.09 MPa so as to obtain addition type heat-conductingsilicone rubber. The heat-conducting silicone rubber is cured at normal temperature or low temperature, has good flow property and convenient use, has higher heat conductivity after fluidization and can be used for the components with the need of heat dissipation and heat transmission in the electronic appliance field.

Owner:CHENGDU GUIBAO SCI & TECH

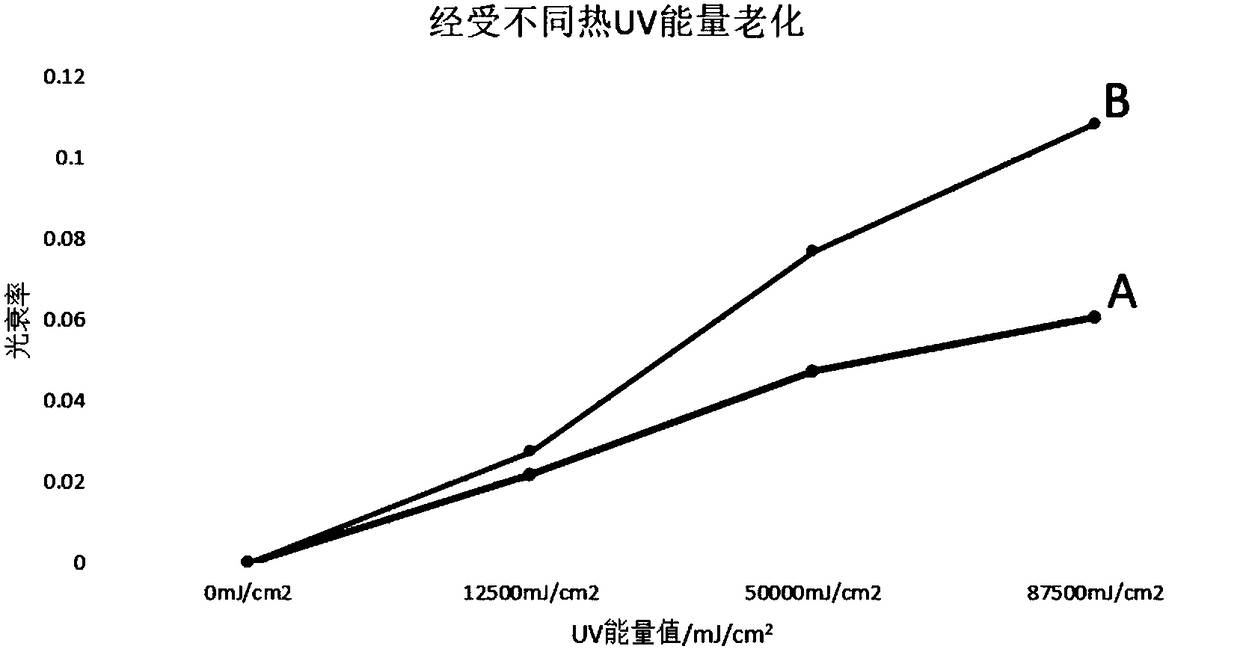

Yellowing resistant bi-component room-temperature curing transparent epoxy glue and preparation method thereof

InactiveCN108300391AImprove heat resistanceExcellent resistance to UV aging yellowing performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyComposition B

The invention discloses yellowing resistant bi-component room-temperature curing transparent epoxy glue. The epoxy glue consists of a composition A and a composition B, wherein the composition A and the composition B are mixed in proportion at the mass ratio of 2 to 1; the composition A consists of the following components in percentages by weight: 88.0% to 92.0% of epoxy resin, 0.3% to 1.0% of adefoaming additive, 4.0% to 6.0% of an antioxidant and 3.0% to 7.0% of benzyl alcohol; and the composition B consists of the following components in percentages by weight: 99.0% to 99.5% of a curing agent and 0.5% to 1.0% of an epoxy resin yellowing resistant agent. The invention also discloses a preparation method of the yellowing resistant bi-component room-temperature curing transparent epoxy glue. The yellowing resistance of the epoxy glue can be improved effectively, the problem that a plate becomes warped by curing when a digital tube advertisement light-emitting word plate is manufactured is avoided, and the service life of the digital tube advertisement light-emitting word plate is prolonged more effectively.

Owner:广州惠利电子材料有限公司

High-heat-conductivity insulation low-viscosity epoxy resin pouring sealant and preparation method thereof

ActiveCN103087665BLow viscosityImprove thermal conductivityNon-macromolecular adhesive additivesOther chemical processesPolymer scienceEnd-group

The invention discloses a high-heat-conductivity insulation low-viscosity epoxy resin pouring sealant and a preparation method thereof. The pouring sealant comprises a component A and a component B, wherein the component A is prepared by blending an epoxy resin, a reactive diluent, an antifoaming agent and an inorganic heat conductivity filler which is treated by a silane coupling agent; and the component B is a curing agent. According to the pouring sealant, aluminum oxide and zinc oxide are adopted to provide high heat conductivity and insulation properties, the heat conductivity coefficient can be 1.75-2.23W.m.K, the volume resistivity is 3.25-5.91*10<15>omega / cm, the viscosity of the pouring sealant is greatly reduced by adopting the reactive diluent containing a plurality of active end groups, and the viscosity of the pouring sealant is 19,800-29,800mPa.s (25 DEG C), so that the pouring sealant is beneficial for pouring; and by using a modified acid anhydride as the curing agent, the operable time of the pouring sealant at 25 DEG C can be more than 8h.

Owner:HEFEI UNIV OF TECH

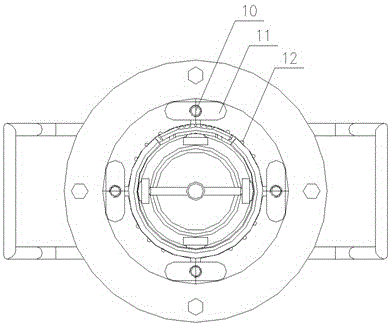

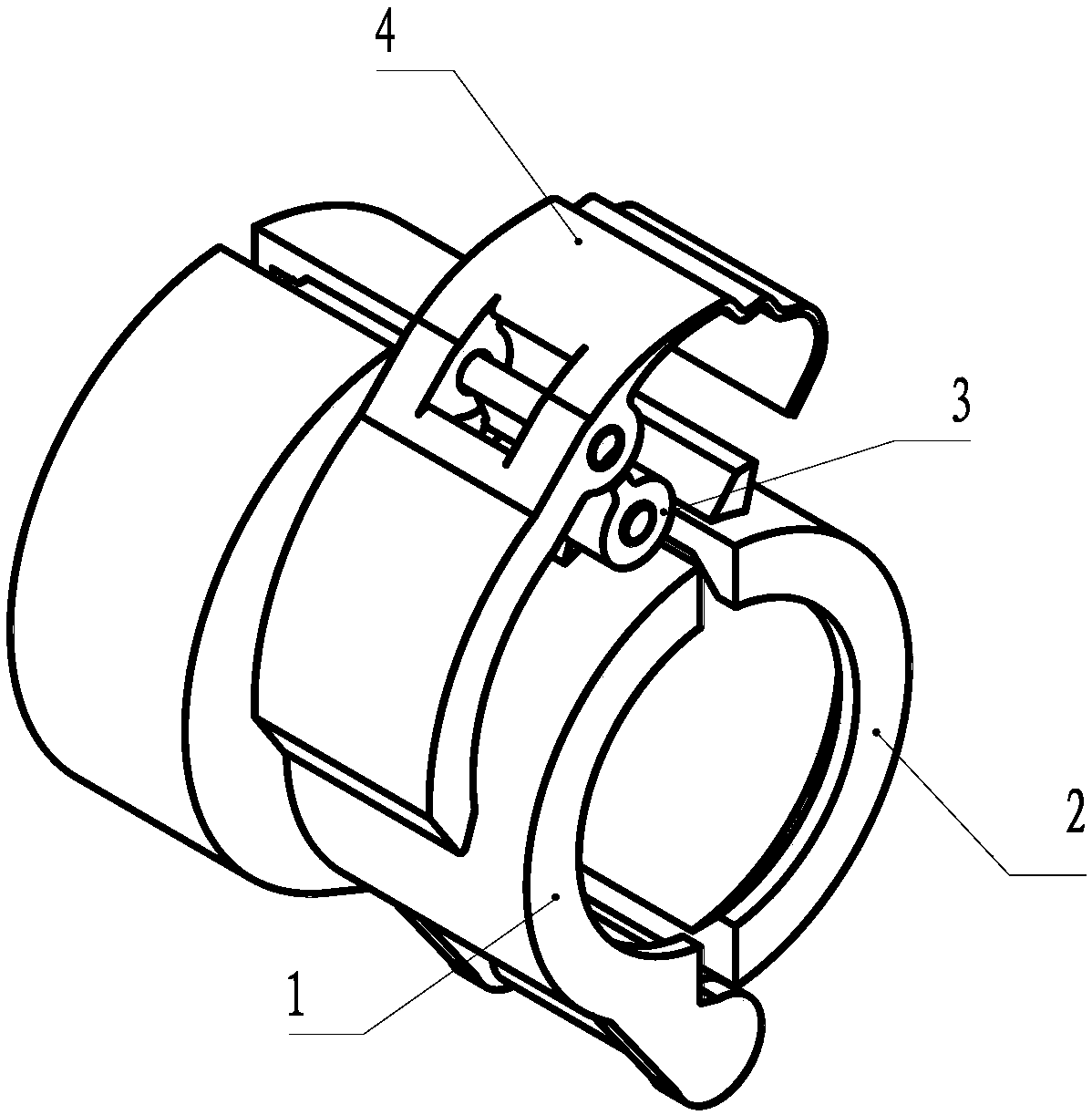

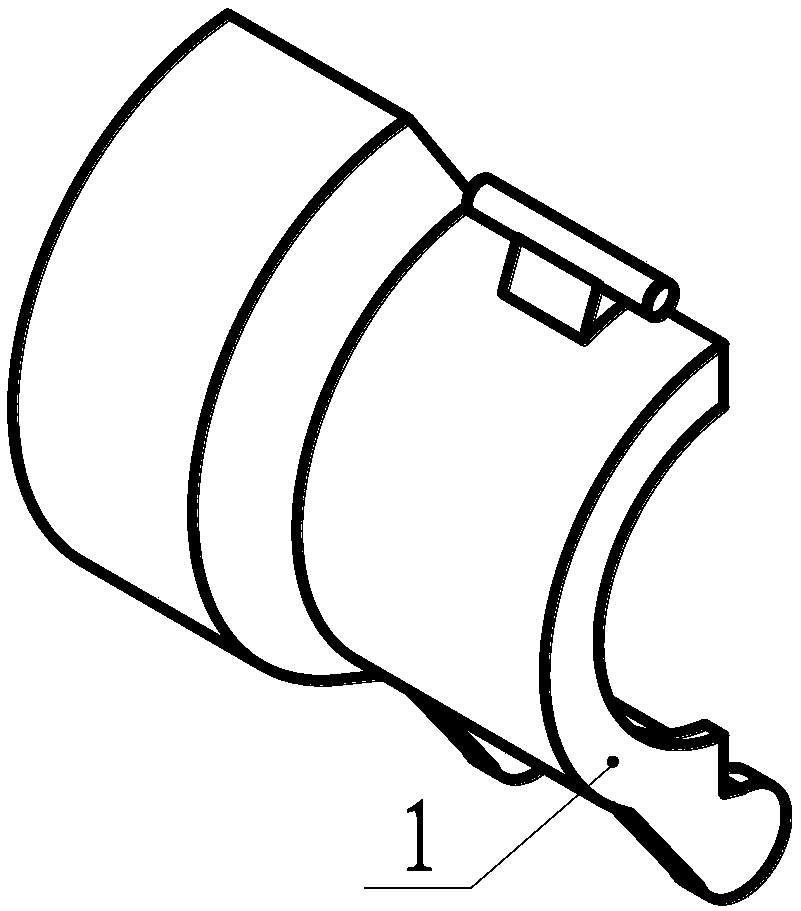

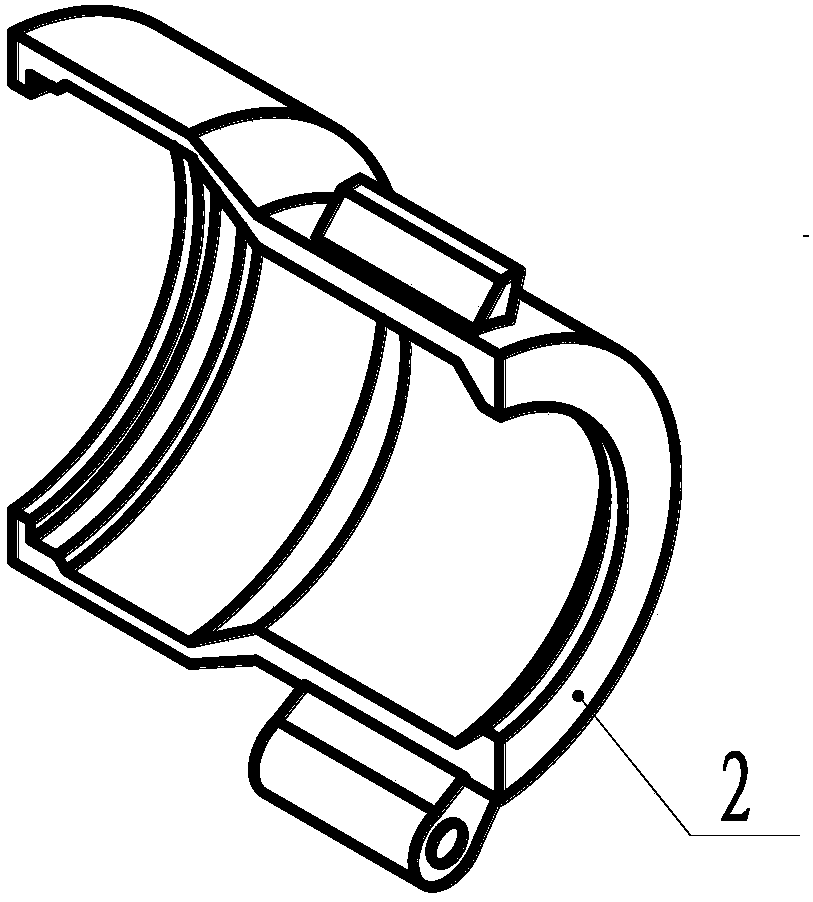

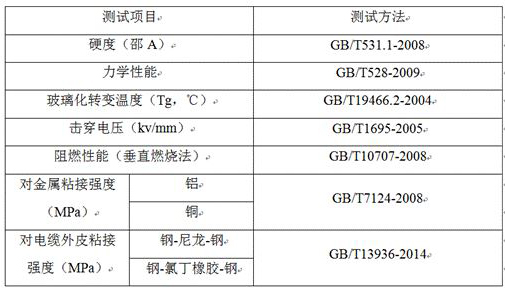

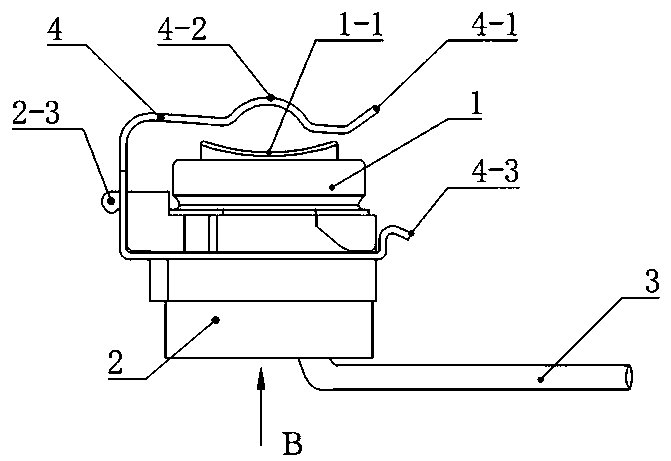

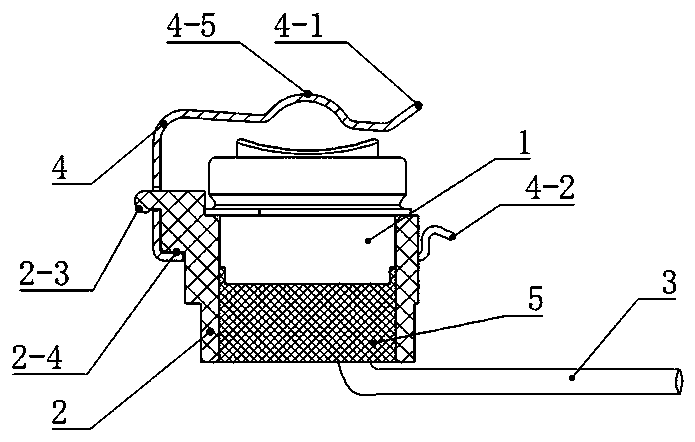

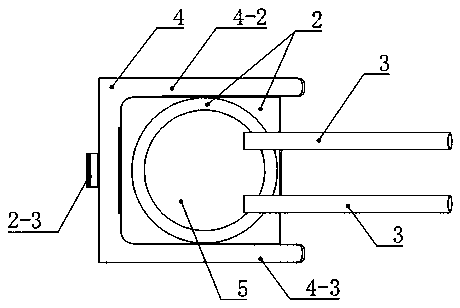

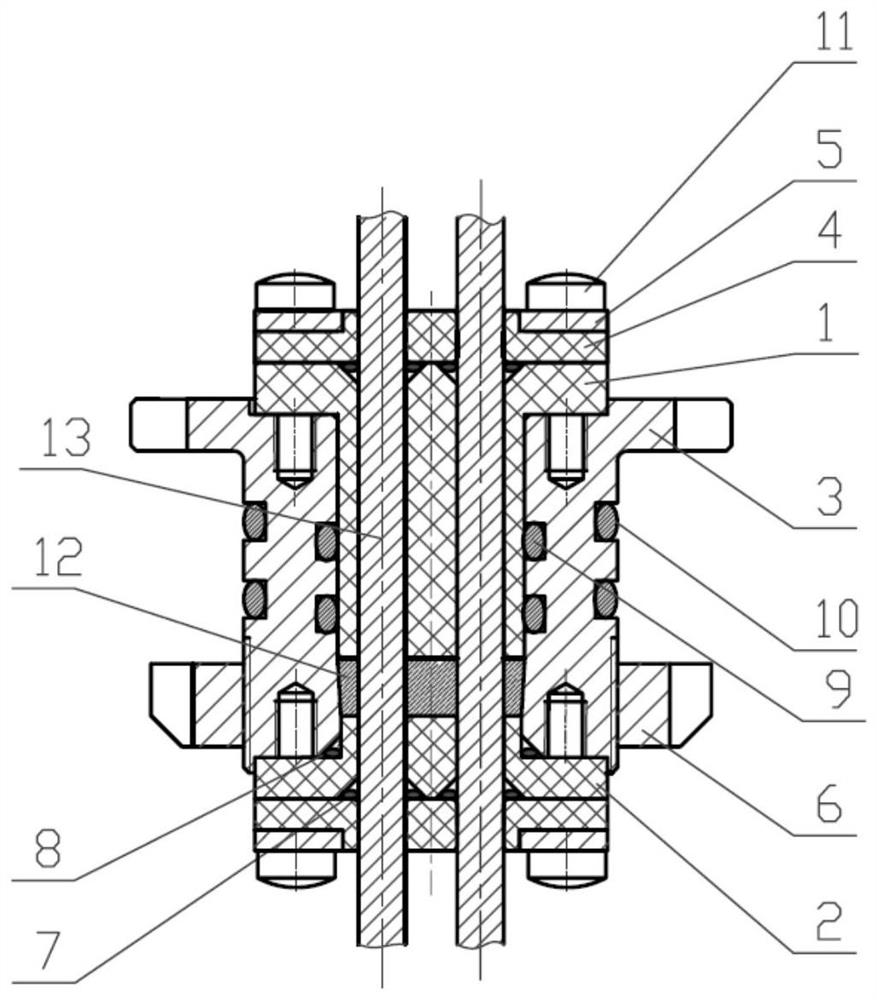

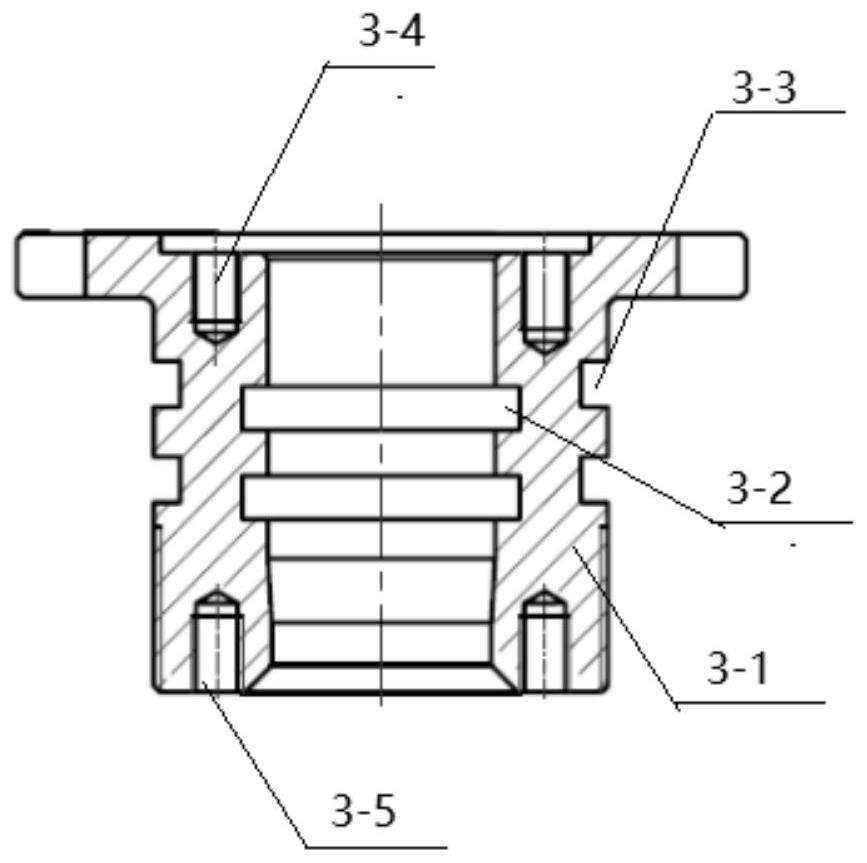

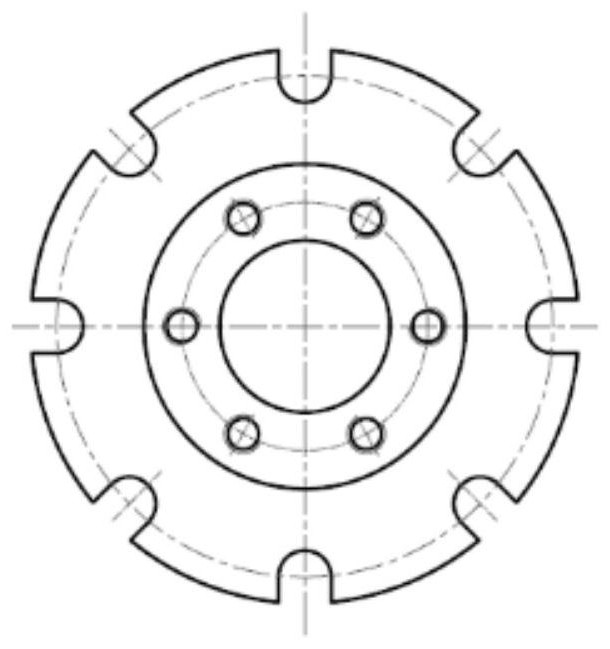

Potting positioning and clamping device of circular electric connector and use method of potting sealing and positioning device

ActiveCN107834341AEasy to pottingAchieve precise positioningContact member cases/bases manufactureBiomedical engineeringSkill level

The invention relates to a potting positioning and clamping device of a circular electric connector. The device comprises a first half clamp ring, a second half clamp ring, a support and a clamp head.The first half clamp ring is movably connected with the second half clamp ring. The support is fixed on the first half clamp ring in a pivoted manner. One end of the clamp head is pivoted to the support and the other end of the clamp head is movably buckled to the second half clamp ring. Meanwhile, the invention also relates to a use method of the potting sealing and positioning device. Accordingto the invention, precise positioning and clamping of a sol ring and the front end of an electric connector during potting of the circular electric connector are achieved; labor intensity of an operator and dependency on the skill level of the operator are reduced; and the yield and the efficiency of the potting ar improved.

Owner:BEIJING MECHANICAL EQUIP INST

Polyurethane pouring sealant as well as preparation method and application thereof

ActiveCN114316878AEasy to synthesizeHigh elongationNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention relates to a polyurethane pouring sealant and a preparation method and application thereof.The polyurethane pouring sealant is composed of a component A and a component B. The mass ratio of the component A to the component B is 40-60: 100, and the component A is prepared from, by weight, 10-40 parts of hydroxyl-terminated polybutadiene A, 5-20 parts of polymer polyol, 5-30 parts of plasticizer and 35-75 parts of isocyanate; the component B comprises the following raw materials in parts by weight: 20-60 parts of hydroxyl-terminated polybutadiene B, 5-30 parts of polymer polyol, 5-30 parts of a plasticizer, 5-25 parts of a chain extender, 5-40 parts of a flame retardant, 0.5-5 parts of carbon black, 0.01-1 part of a catalyst and 0.1-1 part of a defoaming agent; the hydroxyl-terminated polybutadiene A is a special hydroxyl-terminated polybutadiene with low functionality; the hydroxyl-terminated polybutadiene B is polyfunctional special hydroxyl-terminated polybutadiene and / or epoxidized special hydroxyl-terminated polybutadiene. The pouring sealant disclosed by the invention has the characteristics of high mechanical property, good adhesive property, excellent insulation and flame retardance and low-temperature resistance, and can be used for pouring and sealing electronic components such as cables.

Owner:LIMING RES INST OF CHEM IND

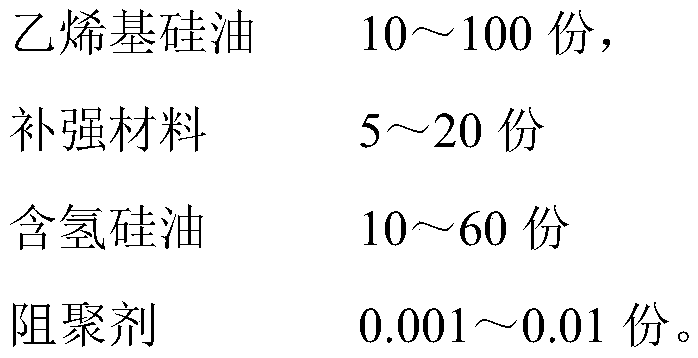

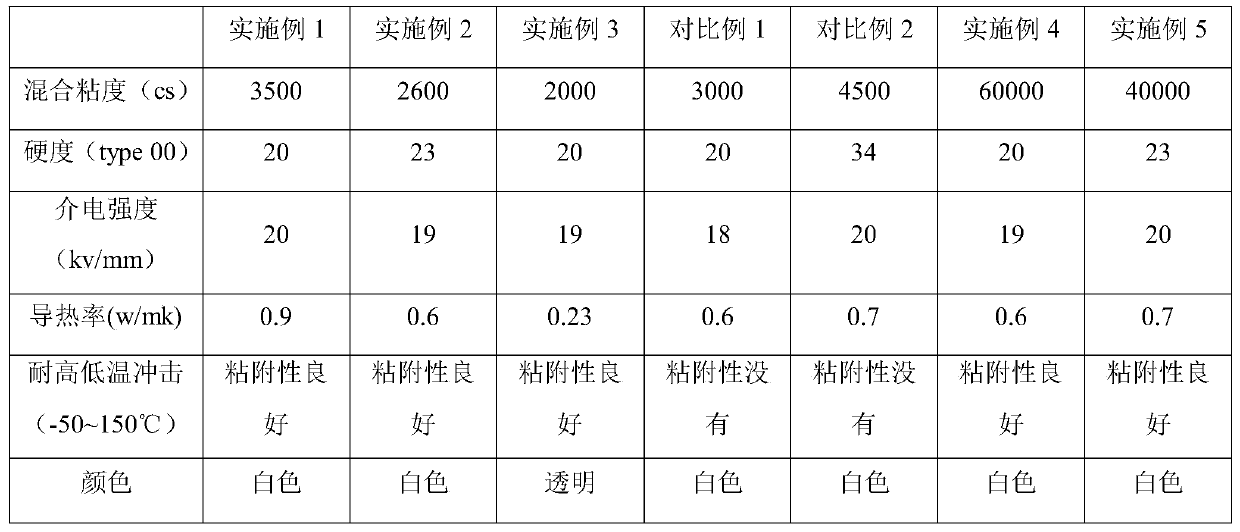

High pressure resistant silicone gel for IGBTs and preparation method thereof

InactiveCN110862692AHigh dielectric strengthSolve the technical problems that cannot meet the potting requirements of IGBT high-voltage modulesSilicone GelsPolymer science

The invention discloses high pressure resistant silicone gel for IGBTs. The silicone gel includes multiple components which are an A component and a B component with the mass ratio being (1 : 1)-(6 :1); the A component includes vinyl silicone oil, modified silicone oil and a catalyst; and the B component includes the vinyl silicone oil, a reinforcing material, hydrogen-containing silicone oil anda polymerization inhibitor. A preparation method of the silicone gel is also disclosed. The dielectric strength of the silicone gel is high (the dielectric strength is greater than or equal to 30 KV / mm), so that the technical problems, that silicone gel on the market cannot satisfy the encapsulation requirements of IGBT high-voltage modules, can be solved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Waterproof snap-action thermostat with buckle frame

PendingCN110648881AEasy to pottingFirmly connectedThermal switch detailsClassical mechanicsStructural engineering

A waterproof snap-action thermostat with a buckle frame comprises a snap-action thermostat, an outer sleeve and the buckle frame, the outer sleeve is provided with a cavity and a first positioning surface, and is integrated with the snap-action thermostat in a matching and encapsulating manner, and the outer sleeve is further provided with a second positioning surface and a convex hook table, andis movably connected with the elastic buckle frame in a matching and hooking mode. The snap-action thermostat and the outer sleeve are encapsulated, and then elastic buckle frame is movably mounted, so tool clamps are greatly reduced, the operation difficulty is reduced, the production efficiency is improved, the production cost is reduced, and the adaptability of the product is improved.

Owner:佛山市通宝华龙控制器有限公司

A wire high pressure sealing structure

ActiveCN112331978BGuaranteed sealing reliabilityGuaranteed structural strengthEngine sealsCell sealing materialsBattery cellMaterials science

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Transformer encapsulating material as well as preparation method and application thereof

The invention discloses a transformer encapsulating material as well as a preparation method and an application thereof. The preparation method comprises the steps as follows: (1), resin, quartz powder and an organic solvent are mixed to obtain a mixture M1; and (2), a curing agent is added into the mixture M1 for mixing so as to obtain the transformer encapsulating material. For 100 parts by weight of the resin, 10-50 parts by weight of quartz powder, 50-100 parts by weight of the organic solvent and 10-40 parts by weight of the curing agent are used. The organic solvent is added in the resin material, so that the liquidity of the resin material is greatly improved, and then the prepared resin material can facilitate transformer encapsulation; and besides, the quartz powder in certain proportion is added, the insulation performance of the material can be increased, meanwhile, the curing agent is matched, and accordingly, the prepared encapsulating material has better curing performance and is more suitable for being used in actual production.

Owner:ANHUI LANXIANG ELECTRICAL EQUIP

Low stress thermally conductive silicone gel composition

ActiveCN106753215BWith thermal conductivity and flame retardant propertiesImprove cooling efficiencyNon-macromolecular adhesive additivesMacromolecular adhesive additivesSilicone GelsAdhesion force

The invention discloses a low-stress thermal-conductive silicone gel composition which comprises vinyl-containing polydiorganosiloxane, a functional filler, hydrosiloxane, an extender and an adhesion promoter, and is crosslinked and formed under action of a catalyst. The low-stress thermal-conductive silicone gel composition has advantages of low stress, strong adhesion force, thermal conductivity and flame retardancy, and can protect electronic components under mechanical stress and thermal stress.

Owner:宁波聚力新材料科技有限公司

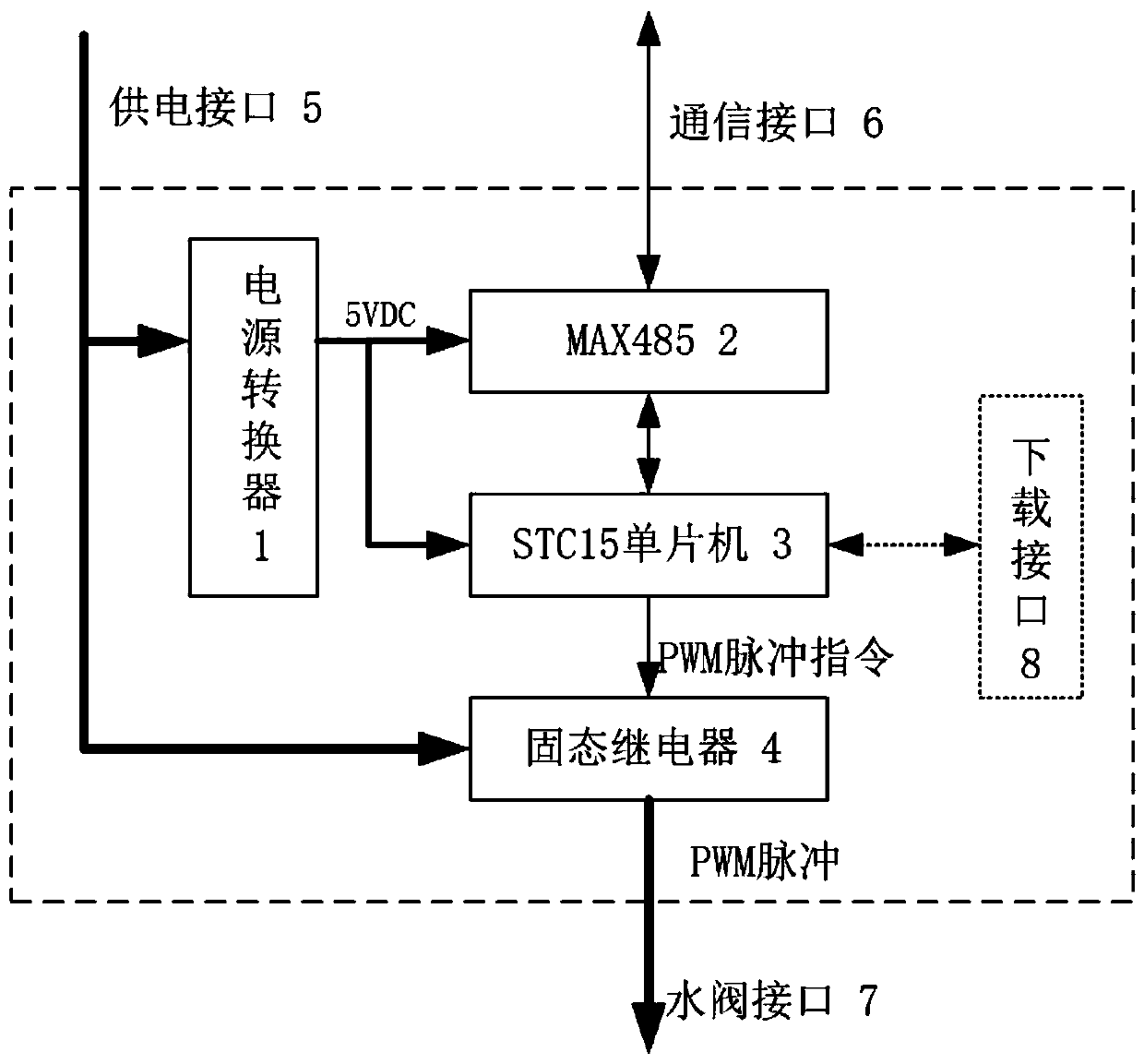

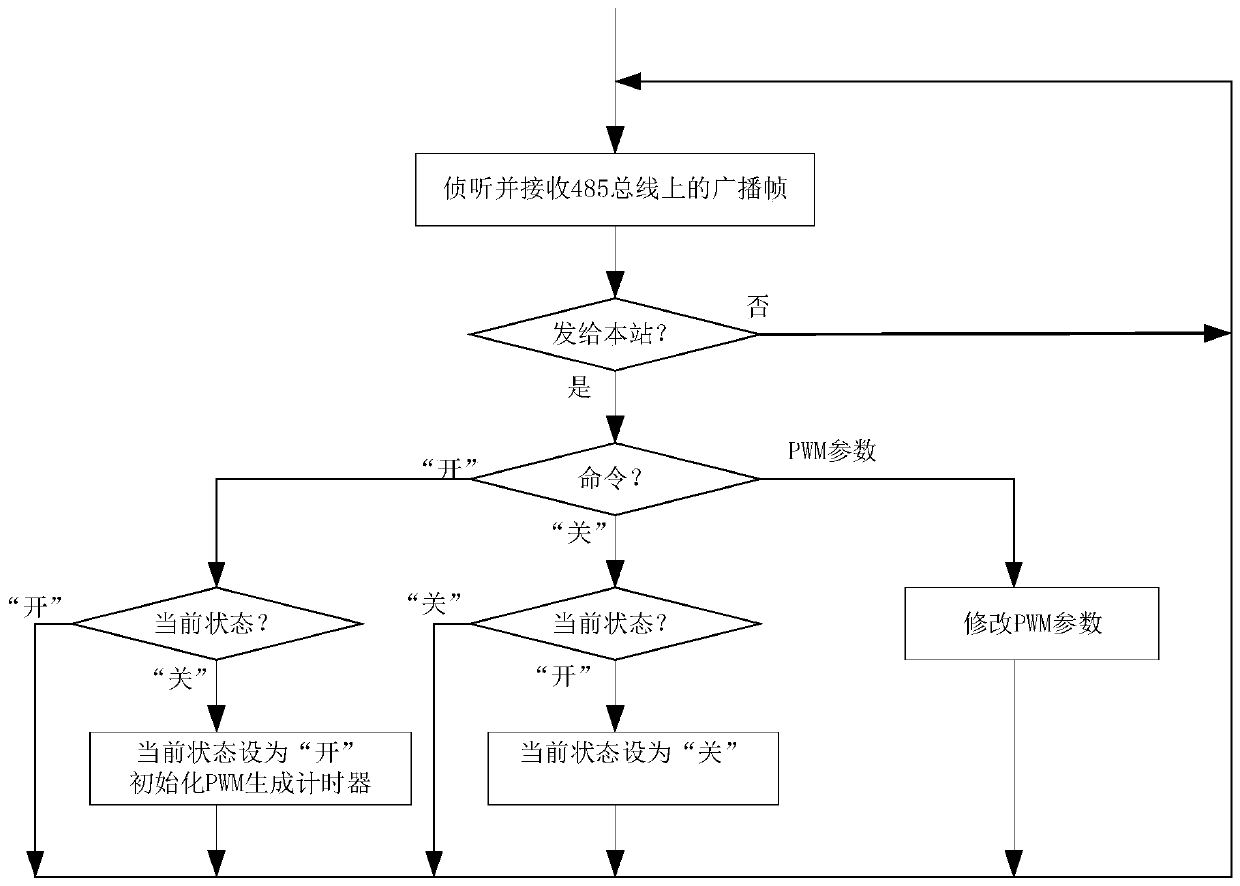

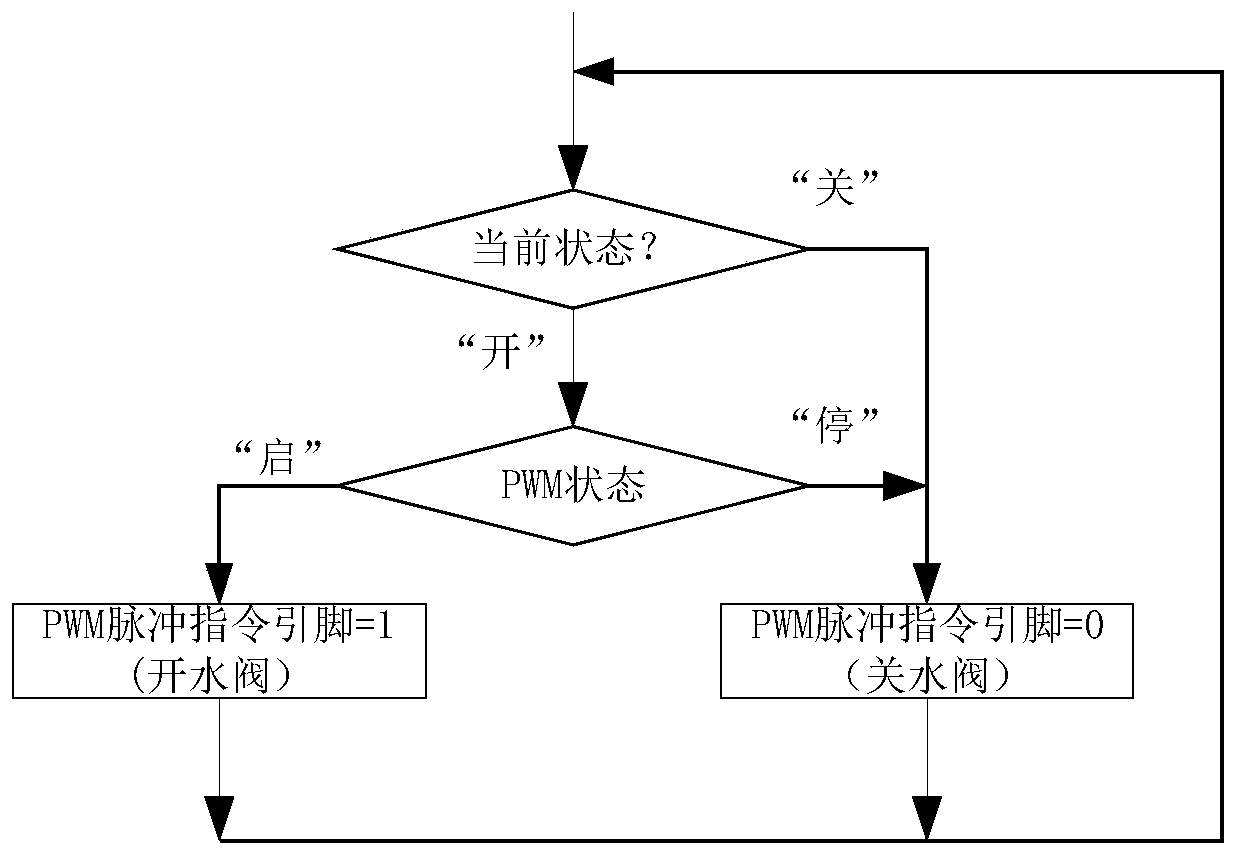

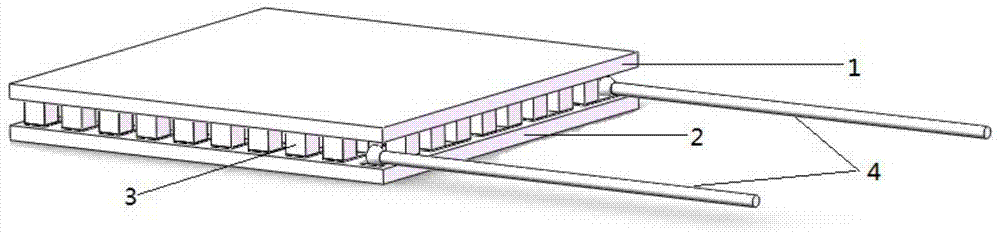

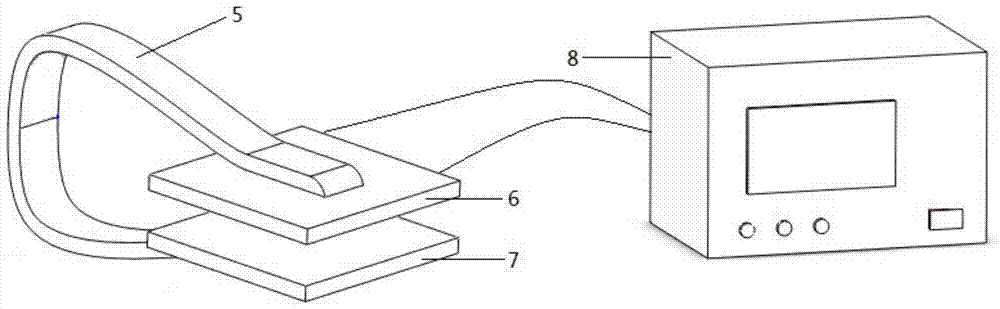

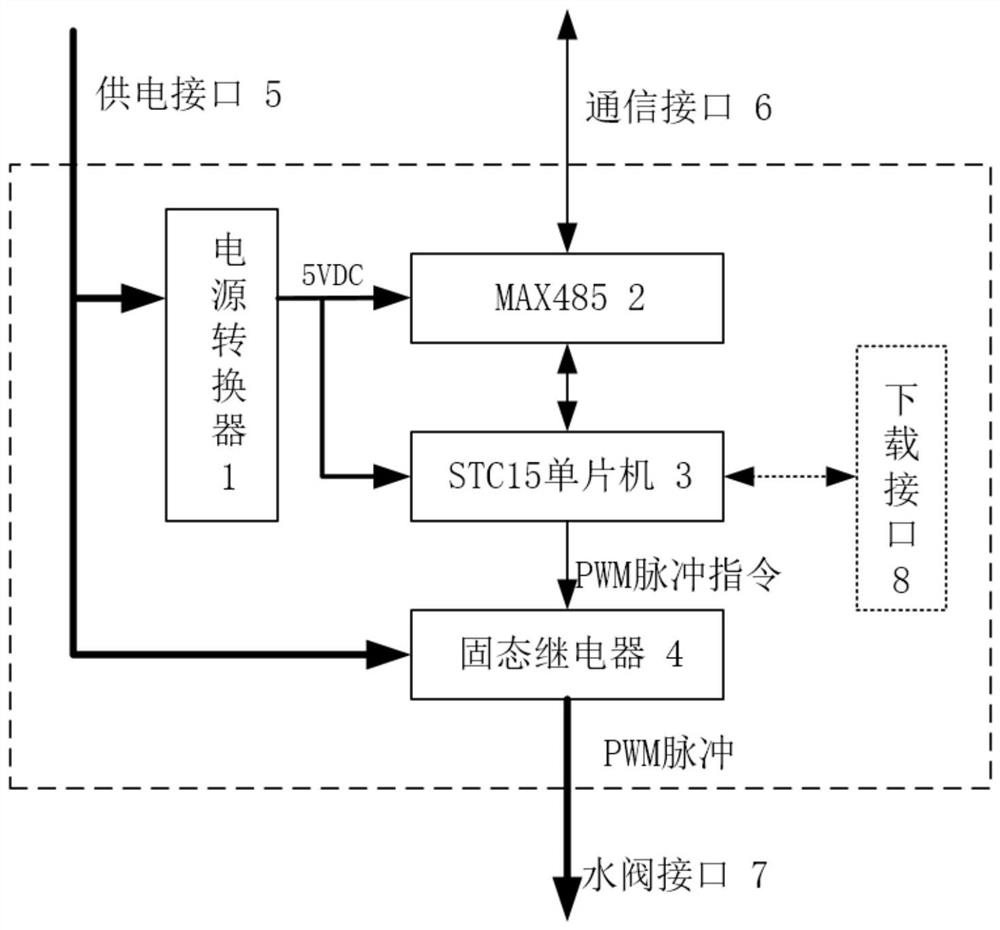

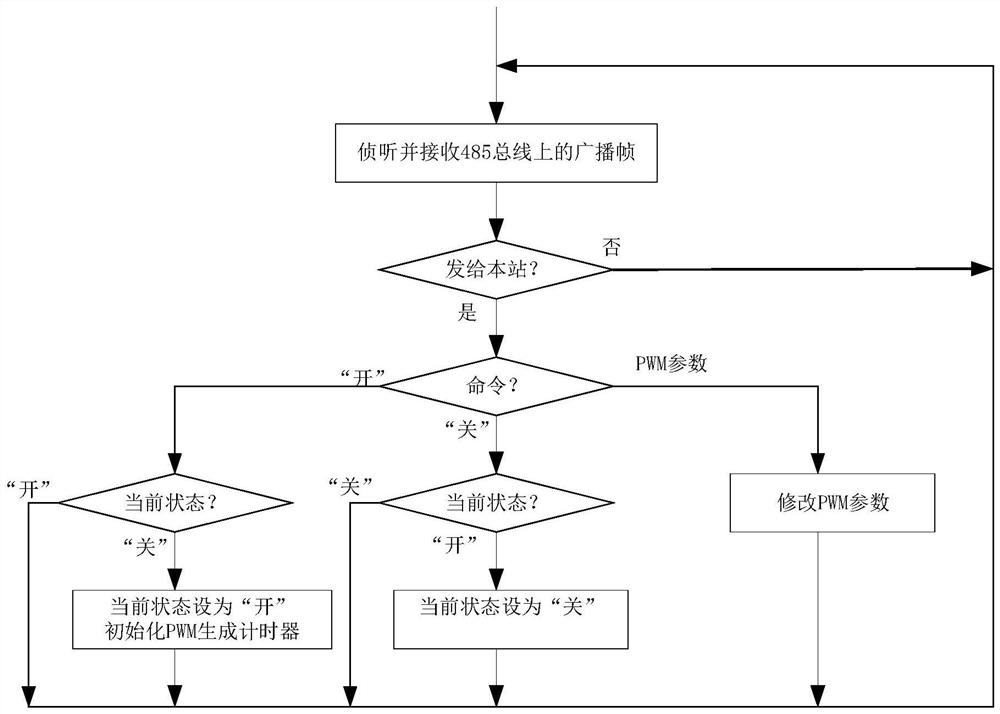

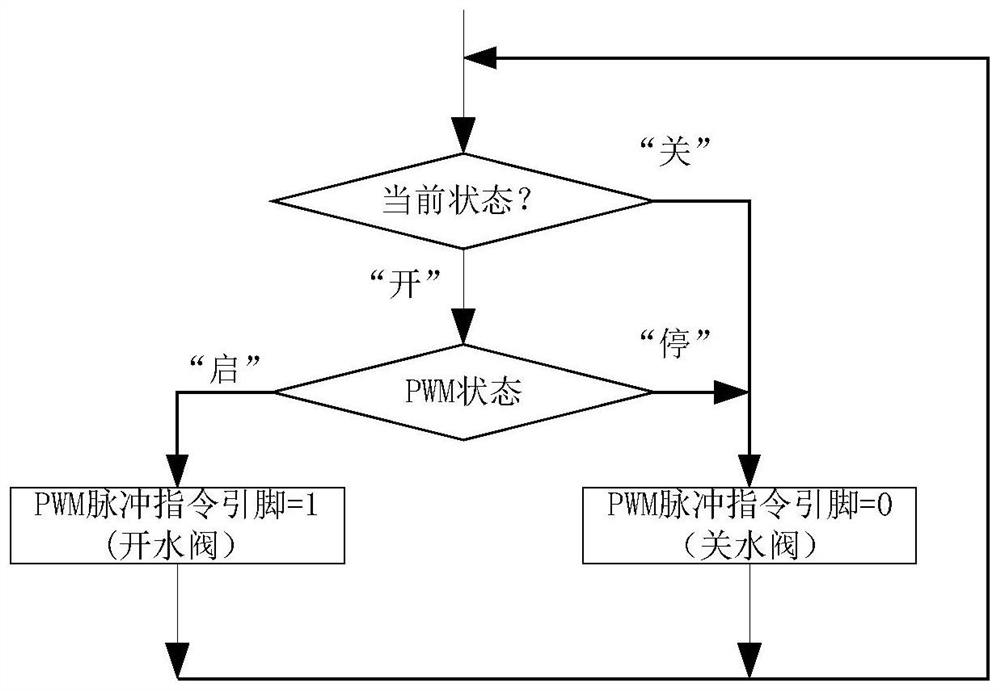

Single-valve pulse width modulation controller for large-scale variable sprinkling irrigation machine

ActiveCN110161912AReduce control tasksReduce communication real-time requirementsProgramme controlComputer controlMaster controllerSingle chip

The invention provides a single-valve pulse width modulation controller for a large-scale variable sprinkling irrigation machine. The single-valve pulse width modulation controller comprises a power converter (1), an MAX485 chip (2), an STC15 single-chip microcomputer (3) and a solid-state relay (4); the power converter (1) is connected with the MAX485 chip (2) and the STC15 single-chip microcomputer (3) separately; the MAX485 chip (2) is connected with the STC15 single-chip microcomputer (3); and the STC15 single-chip microcomputer (3) is connected with the solid-state relay (4). By virtue of485 bus control, the multi-water valve and long-distance requirements of the sprinkling irrigation machine are met; and in addition, PWM pulse is generated independently, so that the control tasks ofthe main controller of the sprinkling irrigation machine are reduced, and the communication instantaneity requirements of the whole system are lowered.

Owner:SHANGHAI JIAO TONG UNIV

The method of improving the anti-overload shock capacity of semiconductor refrigerator

InactiveCN105222392BPrevent overflowImprove anti-overload performanceMachines using electric/magnetic effectsBismuth tellurideEngineering

The invention provides a method for improving the overload resistance impact capacity of a semiconductor cooler. By the adoption of the method, the overload resistance impact capacity of the semiconductor cooler can be remarkably improved. According to the following technical scheme, the method includes the steps that firstly, the edges of bismuth telluride grains of three peripheral edges of the semiconductor cooler are covered and protected through epoxy glue, and vent holes are reserved in the bottom edge; a glue filling port of the semiconductor cooler is formed upwards, and the semiconductor cooler is vertically placed in a special tool so as to be heated; a glue injection needle cylinder is used for injecting the epoxy glue into the semiconductor cooler from the glue filling port under assistance of compressed air; after encapsulation is completed, the semiconductor cooler with the epoxy glue encapsulated and cooling fins of the semiconductor cooler are continuously heated, so that the epoxy glue fully flows in the cooling fins to soak all the bismuth telluride grains and the inner walls of ceramic boards, and air bubbles in the semiconductor cooler are exhausted; and finally, the cooling fins are taken out from the special tool and vertically placed so as to be naturally solidified for at least 24 h. By the adoption of the method, the problem that bismuth telluride grains are easy to break when bearing force or ceramic boards are damaged in the high overload environment in the prior art is solved.

Owner:SOUTH WEST INST OF TECHN PHYSICS

A kind of mixed gum chewable soft capsule and preparation method thereof

InactiveCN104721170BHigh transparencyGood flavor releasePharmaceutical non-active ingredientsCapsule deliveryAdditive ingredientGlycerol

The invention discloses a mixed gum chewing type soft capsule and a preparation method thereof. The capsule skin of the soft capsule is prepared from the following raw materials in percentage by mass: 20-40% of gellan gum, 10-15% of dextrin, 5-15% of gelatin, 15-30% of glycerol, 4-10% of a thickening agent, 10-20% of deionized water and 10-15% of a flavoring agent; and the content of the capsule is liquid or a semisolid medicament, a health food or a food. The capsule skin of the capsule disclosed by the invention takes a mixed gum consisting of the gellan gum, the gelatin and the dextrin as a gum base, wherein the gellan gum is the main component and is compounded with the gelatin to obtain the gum base, the gelling performance of the gum base has a synergistic effect, and the dextrin is beneficial for forming a gel with a stable structure; and the thickening agent is used for controlling syneresis and reducing the brittleness of the gum base, and the flavoring agent is used for increasing the mouthfeel and good smell while solving a hydration problem of the gellan gum. The mixed gum chewing type soft capsule is good in temperature resistance, suitable in capsule skin strength, thickness and toughness, and good in chewing property and mouthfeel, is difficult to deform and generate adhesion and oil leakage, and is high in stability and convenient to store and transport, and the product shelf life is prolonged.

Owner:GUANGZHOU ZHAIJIA COMMODITY

Single-Valve Pulse Width Modulation Controller for Large Variable Variable Sprinkler

ActiveCN110161912BReduce control tasksReduce communication real-time requirementsProgramme controlComputer controlMicrocontrollerConverters

The invention provides a single-valve pulse width modulation controller for a large-scale variable sprinkler irrigation machine, comprising: a power converter (1), a MAX485 chip (2), an STC15 single-chip microcomputer (3) and a solid-state relay (4); The power converter (1) is respectively connected with the MAX485 chip (2) and the STC15 single-chip microcomputer (3), the MAX485 chip (2) is connected with the STC15 single-chip microcomputer (3), and the STC15 single-chip microcomputer (3) is connected with the solid-state relay (4). The 485 bus control of the present invention meets the requirement of multiple water valves and long distances of the sprinkler irrigation machine, and the independent generation of PWM pulses of the present invention reduces the control task of the main controller of the sprinkler irrigation machine and reduces the real-time communication requirements of the entire system.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com