The method of improving the anti-overload shock capacity of semiconductor refrigerator

A technology of shock capacity and refrigerator, applied in the operation mode of the machine, refrigerator, refrigeration and liquefaction, etc., can solve the problems of difficult application, and achieve the effect of easy process control, high reliability, and good temperature shock resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

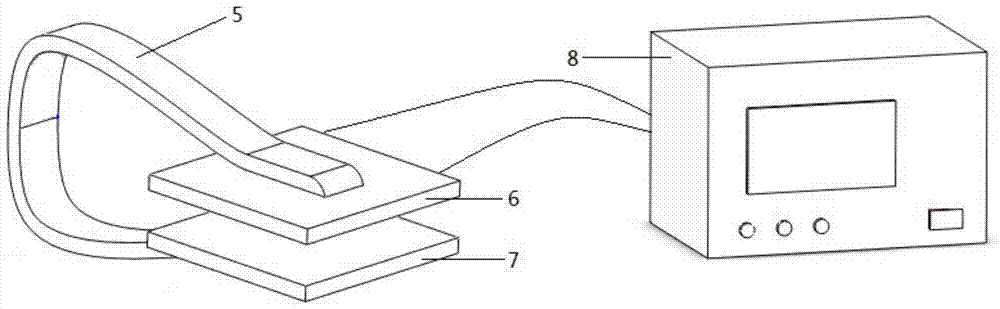

[0016] Attached below figure 2 The implementation of the present invention will be described in further detail.

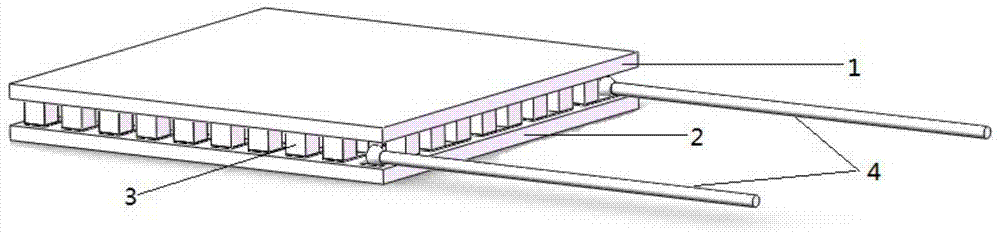

[0017] refer to figure 1 . The semiconductor refrigerator includes bismuth telluride crystal grains 3 sandwiched between a cold-side ceramic plate 1 and a hot-side ceramic plate 2 and distributed in an array, and electrode leads 4 drawn from both sides of the hot-side ceramic plate.

[0018] According to the present invention, the following steps are adopted to improve the anti-overload impact capability of semiconductor refrigerators:

[0019] (1) Before potting, use alcohol to clean the semiconductor refrigerator 1 or 2 times to remove organic dirt adhering to the ceramic plate and crystal grains, and then bake it in an oven at 80°C for 20 to 30 minutes.

[0020] (2) Potting Use DG-4 epoxy glue to pot the semiconductor refrigerator, and pour the epoxy glue into the inside of the refrigeration chip. Prepare DG-4 epoxy glue, the volume ratio of the A and B com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com