Pouring method for pouring molding of special-shaped coil former

A technology for infusion molding and special-shaped coils, applied in the field of infusion and infusion molding of special-shaped coil bobbins, can solve problems such as difficulty in infusion molding of special-shaped coil bobbins, and achieve the effect of ensuring integrity, infusion quality and smooth surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A perfusion method for perfusion forming a special-shaped coil skeleton, characterized in that: the method specifically includes the following steps:

[0032] Step 1, pretreat the adhesive, and degas the adhesive by means of agitation and pressure drop, that is, alternately vacuumize and normal pressure;

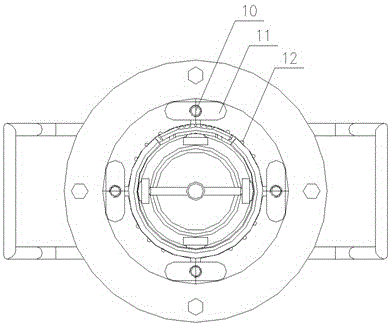

[0033] Step 2, install the workpiece, take out the four positioning modules 2 of the molding tool, apply a thin layer of grease to all parts that can touch the adhesive, and check the first glue hole 8 and the second glue hole of the molding tool The smoothness of holes 9 and exhaust holes 12; place the unencapsulated coil bobbin 18 at the center of the molding tooling, wrap the coil bobbin 18 with four positioning modules 2 and initially position it; place the four positioning modules 2 through the pressure ring 4 Compaction and close contact; use four rubber plugs 7 to block the central hole of the coil skeleton; seal the connection between the top of the coil skele...

Embodiment 2

[0036] A perfusion method for perfusion molding of a special-shaped coil skeleton, specifically comprising the following steps:

[0037] Step 1, pretreat the adhesive, and degas the adhesive by means of agitation and pressure drop, that is, alternately vacuumize and normal pressure;

[0038] The specific steps of alternately carrying out vacuuming and normal pressure are as follows: first, place the adhesive under the electric mixer in the vacuum box, and use a lifting platform to place the stirring rod in the material box containing the adhesive; Stir the adhesive for 2 to 5 minutes, then pump the pressure to 0.05 to 0.06 MPa, keep it for 1 to 4 minutes, and slowly lower it to normal pressure. After the extracted air bubbles subside, continue to vacuum and stir slowly. Repeat this process. The adhesive is defoamed; finally, put the stirred adhesive into a high-temperature box and keep it warm for 10-15 minutes at a temperature of 40-70°C, and wait for potting. The adhesive i...

Embodiment 3

[0047] On the basis of Example 2, the adhesive is composed of components A, B and C in a mass ratio of 50: (1-5): (5-8); the A Components are liquid polysulfide rubber with a molecular weight of 1200-3000 and liquid epoxy resin mixed at a mass ratio of 1:1; component B is triethylenetetramine; component C is silicon micropowder of 1200-2000 mesh.

[0048] The preparation method of adhesive is:

[0049] 1) Weigh components A, B and C according to the mass ratio of 50:(1-5):(5-8);

[0050] 2) After mixing the components A and B of the formula amount evenly, a mixed solution is formed;

[0051] 3) Add the formula amount of component C to the mixture in step 2), and stir evenly.

[0052] The adhesive of the invention adopted can ensure the bonding effect, and meanwhile, the fluidity of the adhesive is optimal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com