Polyurethane pouring sealant as well as preparation method and application thereof

A technology of potting glue and polyurethane, which is applied in the field of polyurethane materials, can solve the problems of ignoring the low temperature resistance and bonding performance of potting glue, achieve environmental friendliness of raw materials and processes, improve mechanical strength and bonding strength, and insulate and flame retardant excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

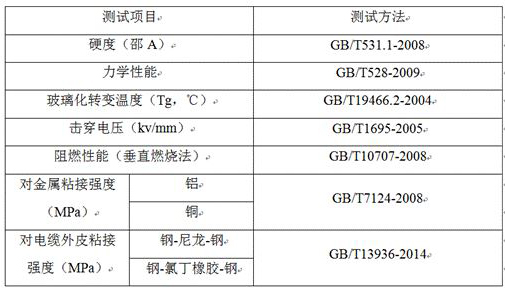

Image

Examples

Embodiment 1

[0032] Preparation of component A: Add 25g type IV hydroxyl-terminated polybutadiene, 15g plasticizer DOP and 10g polyoxypropylene diol with a molecular weight of 2000 into the reactor, vacuum dehydrate at 95-100°C, until the moisture content is <0.03%; then lower the temperature to 50-55°C, add 55g of isocyanate MDI, and keep the reaction temperature of the system at 75-80°C until the NCO% content of the system reaches 16.5%; the air bubbles can be removed, and the temperature is lowered to room temperature to obtain A component.

[0033] Preparation of component B: 30g of epoxidized special butyl hydroxy, 10g of polyoxypropylene diol with a molecular weight of 2000, 10g of plasticizer DOTP, 15g of chain extender N,N-dihydroxyisopropylaniline, 20g of retarder Flame DMMP, 5g of flame retardant aluminum hydroxide and 2g of reinforcing carbon black were added to the reactor, vacuum dehydrated at 95-100°C until the moisture content was <0.03%; then cooled to 45-50°C, and 0.5g of ...

Embodiment 2

[0036] Preparation of component A: Add 25g V-type hydroxyl-terminated polybutadiene, 15g plasticizer DOP and 10g polyethylene oxide diol with a molecular weight of 2000 into the reactor, and vacuum dehydrate at 95-100°C. until the moisture content is <0.03%; then lower the temperature to 50-55°C, add 30g of isocyanate MDI and 30g of isocyanate LMDI, and keep the reaction temperature of the system at 75-80°C until the NCO% content of the system reaches 15.5%; to room temperature to obtain component A.

[0037] Preparation of component B: 20g epoxidized special butyl hydroxy, 10g multifunctional special butyl hydroxy, 10g polymer polyol DL2000, 10g plasticizer DOTP, 5g chain extender butanediol, 20g flame retardant TCPP, 5g Flame retardant antimony oxide and 3g of wear-resistant carbon black are added to the reactor, vacuum dehydrated at 95-100°C until the moisture content is <0.03%; then the temperature is lowered to 45-50°C, and 0.5g of organotin catalyst and 0.5g Silicone de...

Embodiment 3

[0040]Preparation of component A: Add 30g type IV hydroxyl-terminated polybutadiene, 20g plasticizer DINP and 10g polytetrahydrofuran ether diol with a molecular weight of 1000 into the reactor, and dehydrate under vacuum at 95-100°C until Moisture content <0.03%; then cool down to 50-55°C, add 60g of isocyanate LMDI, keep the reaction temperature of the system at 75-80°C, until the NCO% content of the system reaches 13.0%; the bubbles can be removed, and the temperature is lowered to room temperature to obtain A components.

[0041] Preparation of component B: 30g epoxidized special butyl hydroxy, 10g polyoxypropylene diol with a molecular weight of 2000, 20g plasticizer DINP, 10g chain extender ethyl hexanediol, 20g flame retardant DMMP, 5g Flame retardant ammonium polyphosphate and 2g of reinforcing carbon black were added to the reactor, and vacuum dehydrated at 95-100°C until the moisture content was <0.03%; then the temperature was lowered to 45-50°C, and 0.5g of organic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com