Organic silicon pouring sealant and preparation method thereof

A technology of silicone potting glue and hydrogen-containing silicon, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., and can solve the problems of inability to meet flame retardancy requirements, low tracking resistance, and long service life. Low-level problems, to achieve the effects of easy potting, improved flame retardancy, fluidity and excellent foam release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

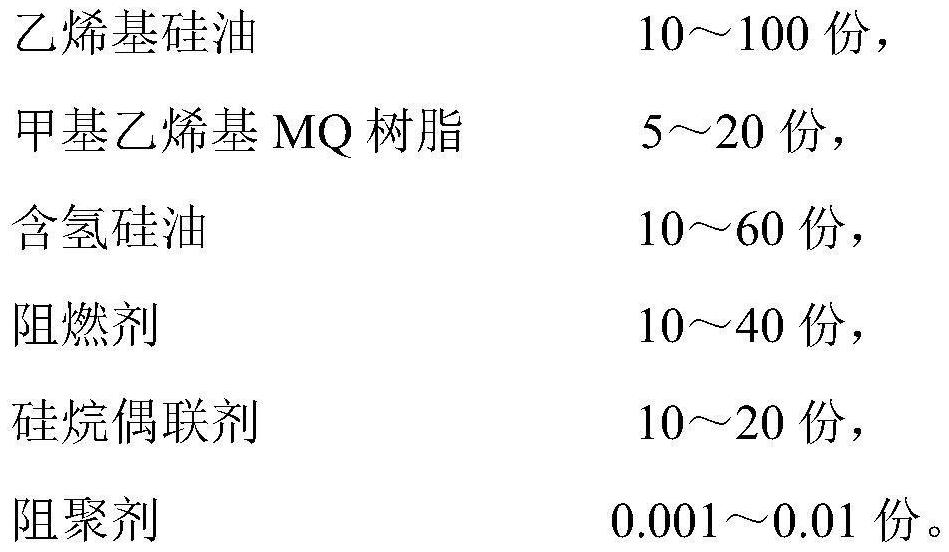

[0035] A silicone potting compound of the present invention, comprising A component and B component with a mass ratio of 2:1, wherein A component includes the following components:

[0036]

[0037]

[0038] Component B includes the following components:

[0039]

[0040] The preparation method of the silicone encapsulant of the present embodiment comprises the following steps:

[0041] (1) Preparation of component A:

[0042] Add 80g of terminal vinyl silicone oil, 10g of methyl vinyl MQ resin and 0.01g of catalyst into the reaction kettle, disperse at low speed for 0.5 hours (rotating speed is 500r / min), then add 10g of modified polyaryletherketone, and disperse at high speed for 30min ( Rotating speed is 1200r / min), finally vacuum defoaming 20min, makes A component;

[0043] (2) Preparation of component B:

[0044] Add 50g of terminal vinyl silicone oil, 10g of methyl vinyl MQ silicone resin and 0.01g of polymerization inhibitor into the reactor, disperse at low...

Embodiment 2

[0048] A silicone potting compound of the present invention, comprising a component A and a B component with a mass ratio of 3:1, wherein the A component comprises:

[0049]

[0050] Component B includes:

[0051]

[0052]

[0053] The preparation method of the silicone encapsulant of the present embodiment comprises the following steps:

[0054] (1) Preparation of component A:

[0055]Add 70g of terminal vinyl silicone oil, 15g of methylvinyl MQ resin and 0.05g of catalyst into the reactor, disperse at low speed for 0.5 hours (rotating speed is 500r / min), then add 15g of modified polyaryletherketone, and disperse at high speed for 30min ( Rotating speed is 1200r / min), finally vacuum defoaming 20min, makes A component;

[0056] (2) Preparation of component B:

[0057] Add 40g of terminal vinyl silicone oil, 20g of methyl vinyl MQ silicone resin and 0.03g of polymerization inhibitor into the reactor, disperse at low speed for 0.5 hours (rotating speed is 500r / min), ...

Embodiment 3

[0061] A silicone potting compound of the present invention comprises A component and B component with a mass ratio of 1:1, wherein A component comprises:

[0062]

[0063] Component B includes:

[0064]

[0065] The preparation method of the high-performance silicone encapsulant of the present embodiment comprises the following steps:

[0066] (1) Preparation of component A:

[0067] 60g vinyl-terminated silicone oil (vinyl content 0.23%, viscosity 2000mpa s), 40g vinyl-terminated silicone oil (vinyl content 0.57%, viscosity 300mpa s), 5g methyl vinyl MQ resin and 0.02g catalyst Add it into the reaction kettle, disperse at low speed for 0.5 hours (rotating speed: 500r / min), then add 20g of modified polyaryletherketone, disperse at high speed for 30min (rotating speed: 1200r / min), and finally vacuum defoam for 20min to obtain component A ;

[0068] (2) Preparation of component B:

[0069] 40g vinyl-terminated silicone oil (vinyl content 0.57%, viscosity 300mpa s), 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com