Bi-component silicone pouring sealant for LED photoelectric display device and method for manufacturing same

A photoelectric display and two-component technology, applied in semiconductor/solid-state device manufacturing, chemical instruments and methods, electrical components, etc., can solve problems such as stickiness, uncured surface of glue, catalyst poisoning, etc., to avoid damage, effective Good for potting and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

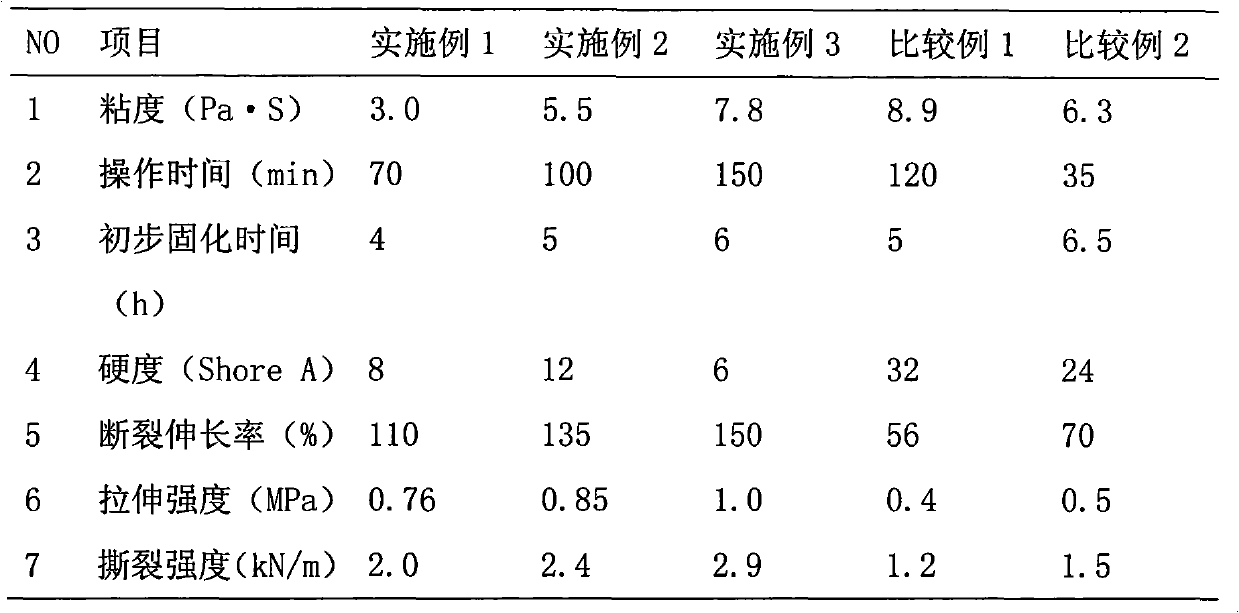

Embodiment 1

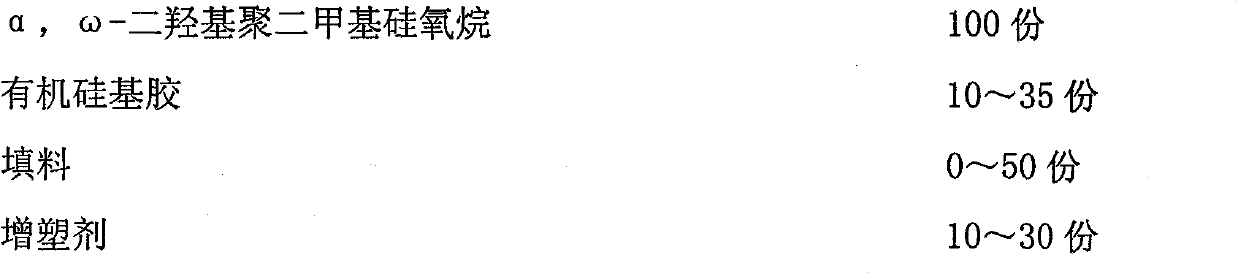

[0046] Put 100 parts of α, ω-dihydroxypolydimethylsiloxane and 5 parts of dimethyldimethoxysilane into the vacuum kneader, stir evenly, add 50 parts of precipitated white carbon black, knead at room temperature for 2 hours, Then kneading and blending at a temperature of 100° C. and a vacuum of 0.06 Mpa for 30 minutes to obtain a silicone-based rubber.

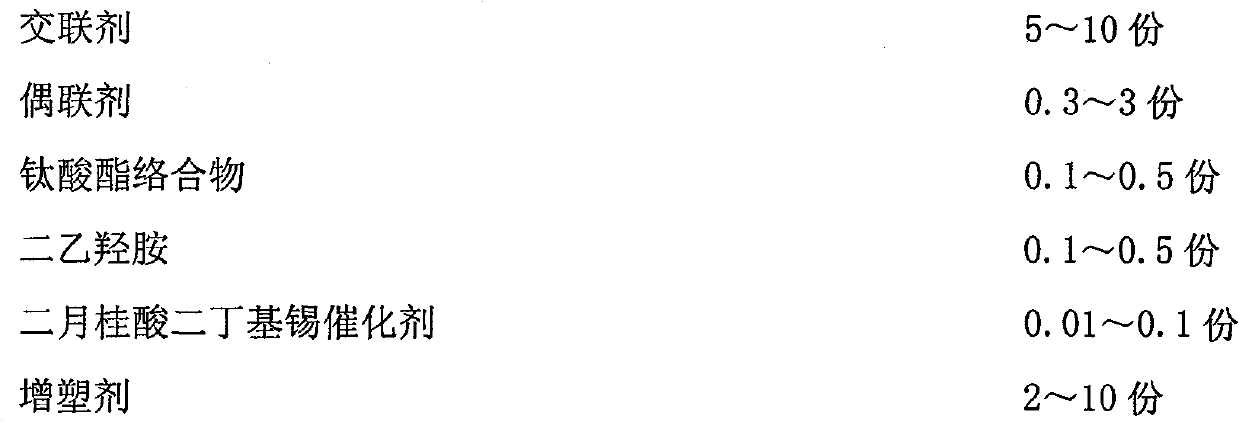

[0047]100 parts of α, ω-dihydroxy polydimethylsiloxane, 35 parts of silicone-based glue, 5 parts of α, ω-dimethyl polydimethylsiloxane, poly Add 5 parts of dimethylsiloxane into a mixer, and stir for 30 minutes under a vacuum of 0.06mpa to obtain component A. 8 parts of mixture of tetraethoxysilane and tetraethoxysilane hydrolyzate, 0.3 parts of mixture of γ-aminopropyltriethoxysilane and γ-(2,3-glycidoxy)propyltrimethoxysilane Parts, 0.5 part of diisopropoxytitanium bis(ethyl acetoacetate) chelate, 0.2 part of diethylhydroxylamine, 0.01 part of dibutyltin dilaurate catalyst, α, ω-dimethylpolydimethyl Add 2 parts of siloxane ...

Embodiment 2

[0049] Put 100 parts of α, ω-dihydroxy polydimethylsiloxane and 15 parts of hexamethyldisilazane into the vacuum kneader, after mixing thoroughly, add 150 parts of precipitated white carbon black, knead at room temperature for 4 hours, and then Kneading and blending for 200 minutes at a temperature of 150°C and a vacuum of 0.099Mpa to obtain a silicone-based rubber;

[0050] 100 parts of α, ω-dihydroxy polydimethylsiloxane, 20 parts of silicone-based glue, 40 parts of silicon powder, 10 parts of calcium carbonate, 10 parts of α, ω-dimethyl polydimethylsiloxane , 10 parts of polydimethylsiloxane with a hydroxyl group at one end and a methyl group at the other end were added to a blender, added to the blender, and stirred for 30 minutes under a vacuum degree of 0.08mpa to obtain component A. Mixture of tetraethoxysilane and tetraethoxysilane hydrolyzate 5 parts, mixture of γ-aminopropyltriethoxysilane and γ-(2,3-glycidoxy)propyltrimethoxysilane 1 Parts, 0.3 parts of diisopropox...

Embodiment 3

[0052] Put 100 parts of α, ω-dihydroxy polydimethylsiloxane and 10 parts of tetramethylammonium siloxanol and dimethyldiethoxysilane into the vacuum kneader, after mixing thoroughly, add 100 parts Precipitate white carbon black, knead at room temperature for 3 hours, then knead and blend at a temperature of 120° C. and a vacuum of 0.08 Mpa for 30 to 200 minutes to obtain a silicone-based rubber.

[0053] 100 parts of α, ω-dihydroxy polydimethylsiloxane, 10 parts of silicone-based glue, 30 parts of aluminum oxide, 15 parts of α, ω-dimethyl polydimethylsiloxane, one end is Add 15 parts of polydimethylsiloxane with a methyl group at one end of the hydroxyl group into the mixer, add it into the mixer, and stir for 30 minutes under a vacuum degree of 0.099mpa to obtain component A. 10 parts of a mixture of tetraethoxysilane and tetraethoxysilane hydrolyzate, a mixture of γ-aminopropyltriethoxysilane and γ-(2,3-glycidoxy)propyltrimethoxysilane 3 Parts, 0.1 part of diisopropoxytitan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com