Chemical mechanical grinding method

A technology of chemical machinery and grinding method, which is applied in the direction of grinding devices, grinding machine tools, and parts of grinding machine tools, etc., which can solve problems such as surface scratches, and achieve the effect of avoiding scratches and preventing significant increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

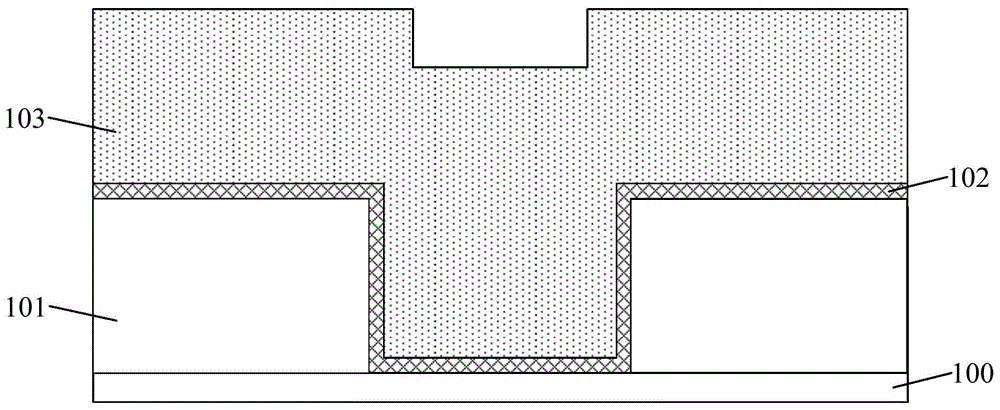

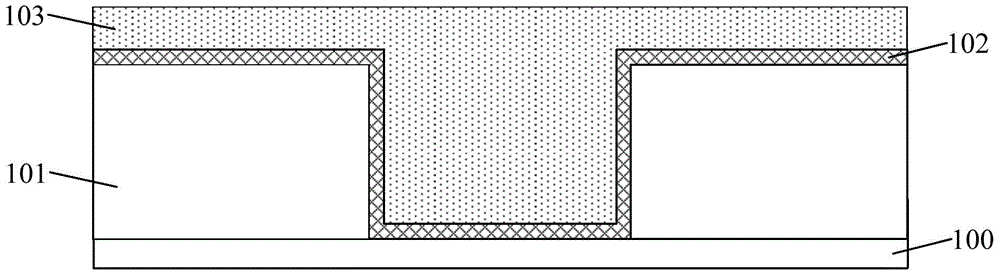

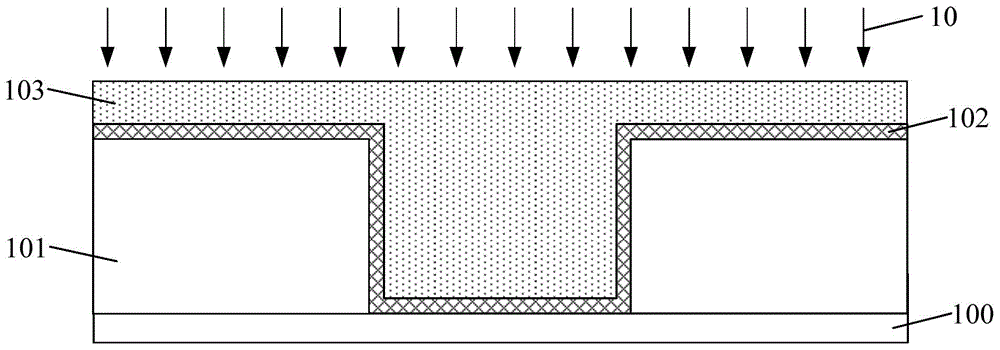

[0034] It can be seen from the background art that in the prior art, after chemical mechanical polishing is performed on the wafer to be polished, there are scratches on the surface of the wafer to be polished, and the scratches lead to a low production yield of the semiconductor structure.

[0035] It has been found through research that common grinding liquids include abrasives, reactants and deionized water, and the abrasives are generally silica or alumina. Microscopic particles (microscopic particles) can be produced in the grinding liquid itself. When the particulate matter is suspended in the grinding liquid, the particles repel or attract each other, so that a charged layer is formed in the grinding liquid, so that the wafer to be ground The surface develops a zeta potential, which is either positive or negative.

[0036] When the wafer to be ground is ground, at least the following steps are included: step S1, the surface of the wafer to be ground is first ground, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com