High pressure resistant silicone gel for IGBTs and preparation method thereof

A technology of organosilicon and high-voltage resistance, which is applied in the field of high-voltage-resistant organosilicon gel for IGBT and its preparation. The effect of anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

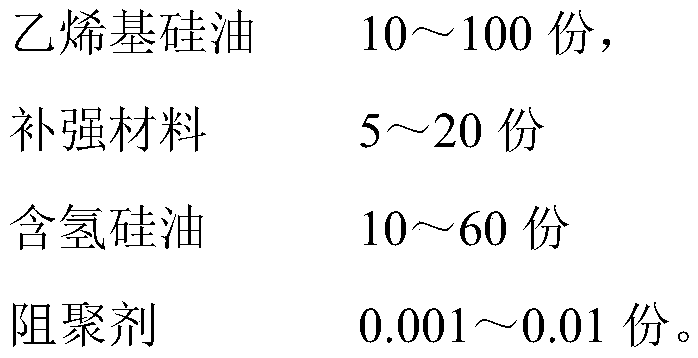

[0038] A high-pressure-resistant silicone gel for IGBTs of the present invention includes component A and component B with a mass ratio of 4:1, wherein component A includes the following raw materials in parts by mass:

[0039] Vinyl-terminated silicone oil (vinyl content 0.1%, viscosity 1000mpa·s at 25°C) 80g,

[0040] γ-(2,3 glycidoxy) propyltrimethoxysilane 10g,

[0041] Catalyst chloroplatinic acid-vinylsiloxane complex 0.01g;

[0042] B component comprises each raw material of following mass parts:

[0043]

[0044] The preparation method of the high-voltage resistant silicone gel for the IGBT of the present embodiment comprises the following steps:

[0045] (1) Preparation of component A:

[0046] Add 80g of vinyl-terminated silicone oil, 10g of γ-(2,3 glycidoxy) propyltrimethoxysilane and ion adsorbent (nano-activated carbon, pore size 0.8nm to 2nm) into the reaction kettle, at 80°C at a low speed Disperse for 4 hours (rotating speed: 500r / min), add 0.01g of cata...

Embodiment 2

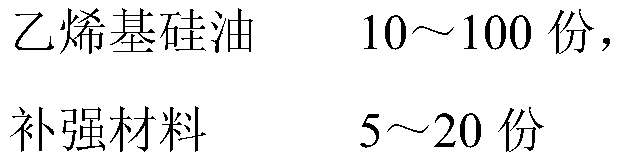

[0052] A high-pressure-resistant silicone gel for IGBTs of the present invention includes component A and component B with a mass ratio of 4:1, wherein component A includes the following raw materials in parts by mass:

[0053]

[0054] B component comprises each raw material of following mass parts:

[0055]

[0056] The preparation method of the high-voltage resistant silicone gel for the IGBT of the present embodiment comprises the following steps:

[0057] (1) Preparation of component A:

[0058] 60g terminal vinyl silicone oil (vinyl content 0.1%), 5g gamma-(2,3 glycidoxy) propyltrimethoxysilane, 8g hydroxyl silicone oil and ion adsorbent chitosan are added in the reactor, Disperse at 90°C for 3 hours (rotating speed: 500r / min)), add 0.05g catalyst after filtration, disperse at high speed for 20min (rotating speed: 1200r / min), and vacuum degassing for 20min to obtain component A;

[0059] (2) Preparation of component B:

[0060] 40g terminal vinyl silicone oil (vin...

Embodiment 3

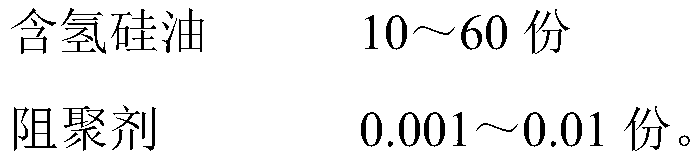

[0064] A high-pressure-resistant silicone gel for IGBTs of the present invention includes component A and component B with a mass ratio of 4:1, wherein component A includes the following raw materials in parts by mass:

[0065]

[0066] B component comprises each raw material of following mass parts:

[0067]

[0068] The preparation method of the high-voltage resistant silicone gel for the IGBT of the present embodiment comprises the following steps:

[0069] (1) Preparation of component A:

[0070] Add 60g vinyl silicone oil (vinyl content 0.1%), 40g vinyl silicone oil (vinyl content 0.2%), 5g gamma-(2,3 glycidoxy) propyltrimethoxysilane and ion adsorbent nano silica gel Put it into the reactor, disperse at 100°C for 2 hours (rotating speed is 500r / min)), filter and then add 0.05g of catalyst, disperse at high speed for 20min (rotating speed is 1200r / min), and vacuum degassing for 20min to obtain component A .

[0071] (2) Preparation of component B:

[0072] 40g v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com