Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

278results about How to "Does not affect work efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

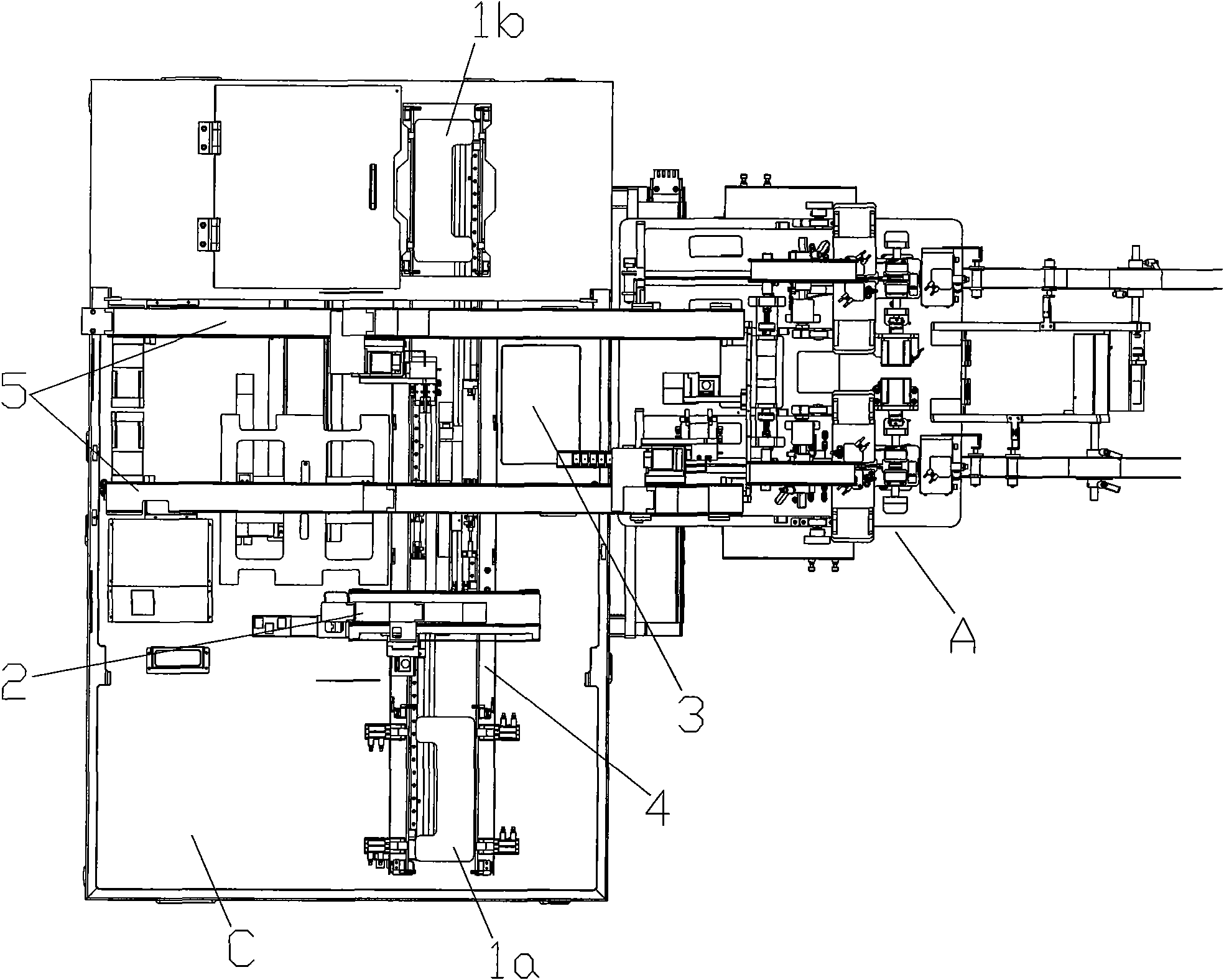

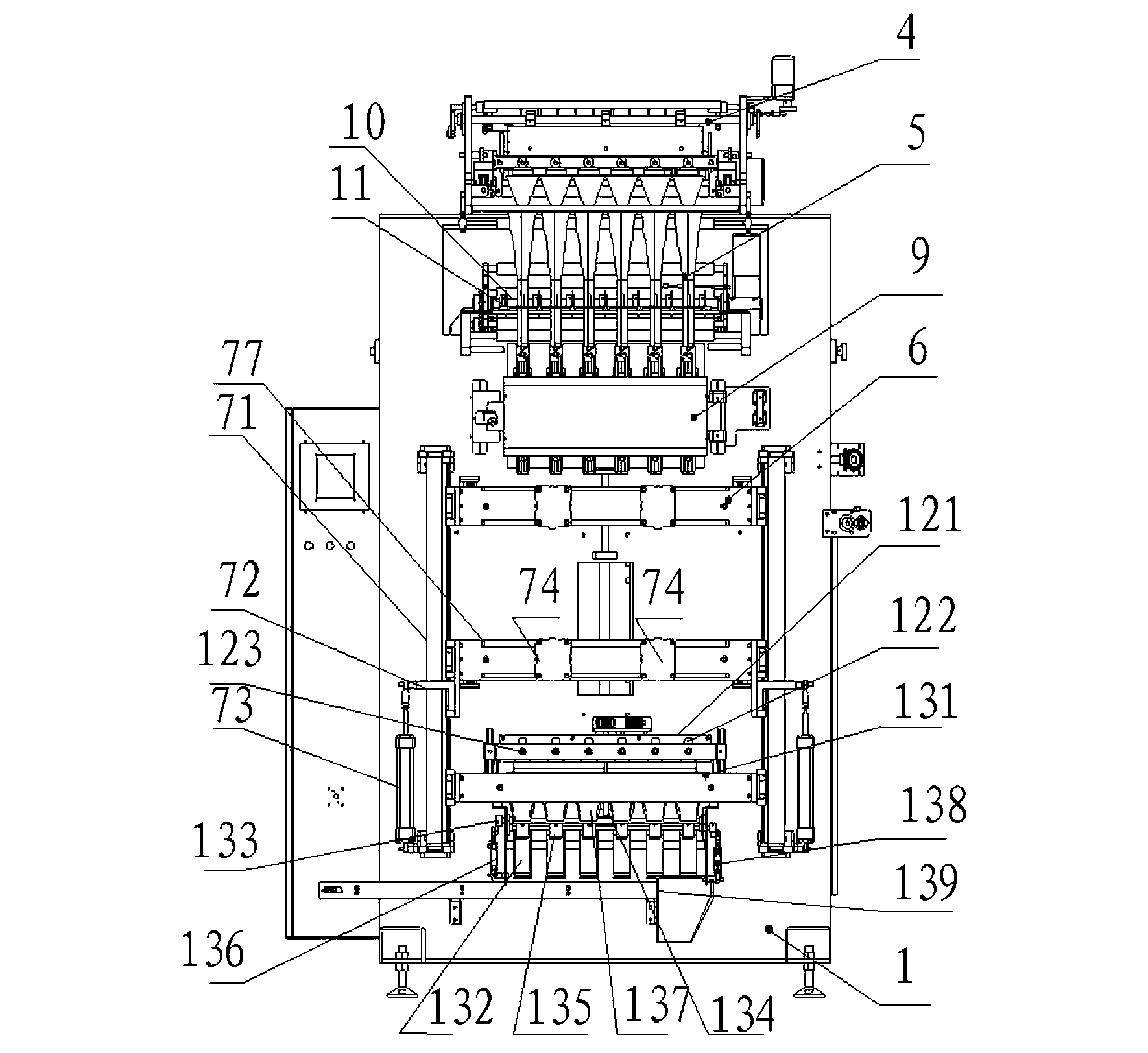

Disk-feeding braider and classified gripping method thereof

InactiveCN101920795AAvoid motion interferenceImprove pick and place efficiencyWrapping material feeding apparatusWrapper twisting/gatheringMechanical engineeringIntegrated circuit

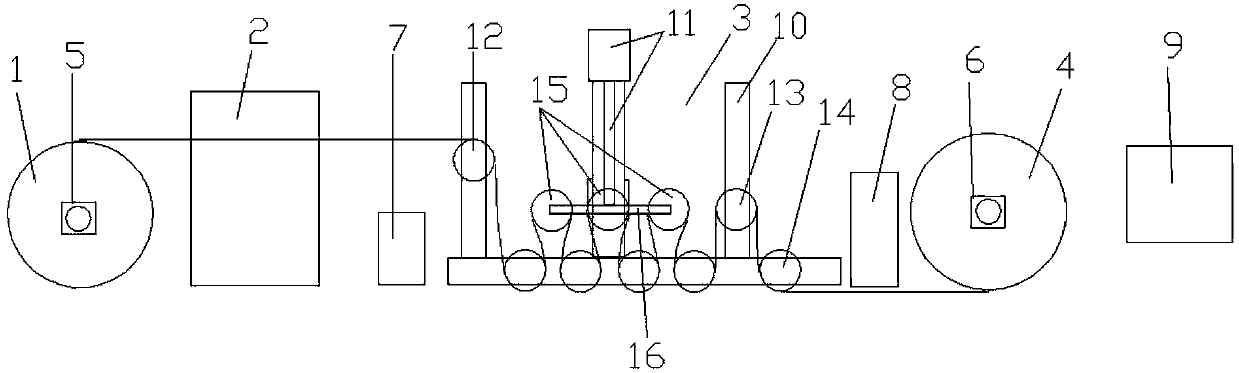

The invention discloses a disk-feeding braider and a classified gripping method thereof. The braider comprises a tray conveying device, a tray separating device, a top surface scanning surface, a three-dimensionally scanning device, a double-gripper classified gripping device, an unaccepted product collecting device, a hollow tray stacking device and a braid packaging device, wherein the tray conveying device is used for conveying a tray; the tray separating device is used for separating the tray onto the tray conveying device; the top surface scanning surface is used for scanning the top surface of an integrated circuit block in the conveyed tray; the three-dimensionally scanning device is used for three-dimensionally scanning the bottom surface and the side face of the integrated circuit board; the double-gripper classified gripping device is used for gripping the top surface-scanned and / or three-dimensionally scanned integrated circuit board in a classified way and comprises a first classified gripping device and a second classified gripping device; the unaccepted product collecting device is used for receiving the integrated circuit board of which the scanning result is unqualified; the hollow tray stacking device is used for stacking a conveyed hollow tray on which classified gripping is finished; and the braid packaging device is used for packaging and winding the integrated circuit board of which the top surface scanning and three-dimensionally scanning results are qualified. The disk-feeding braider and the corresponding classified gripping method have the characteristic of high work efficiency.

Owner:GRAND TECH SHENZHEN

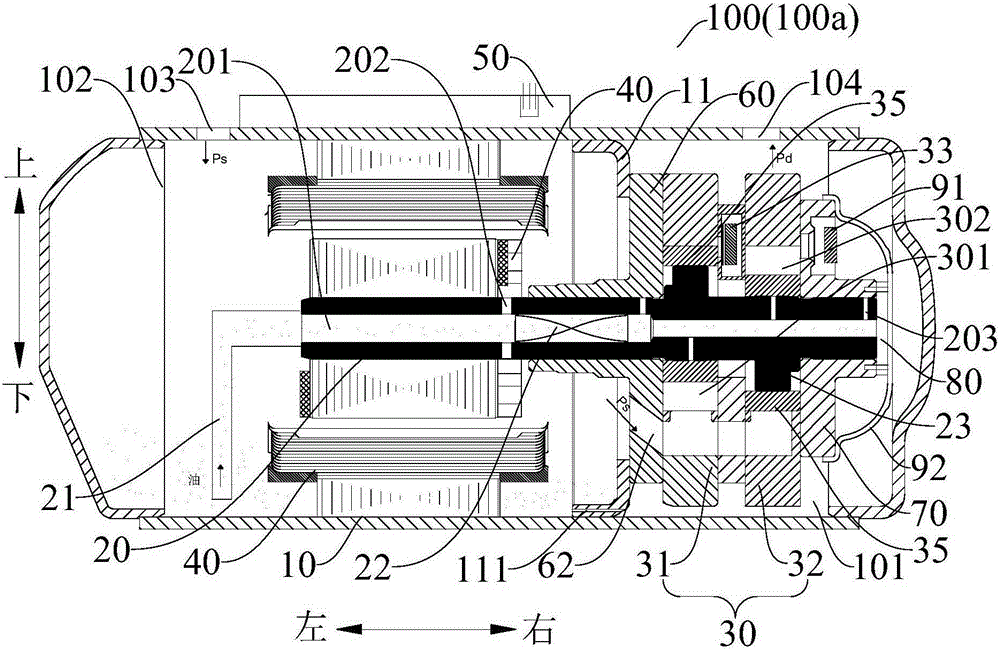

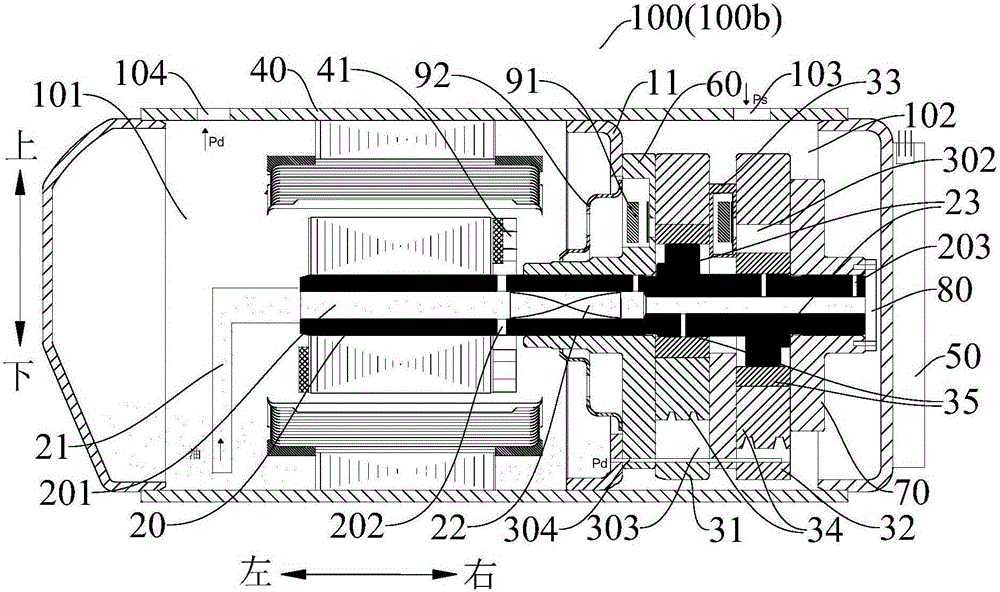

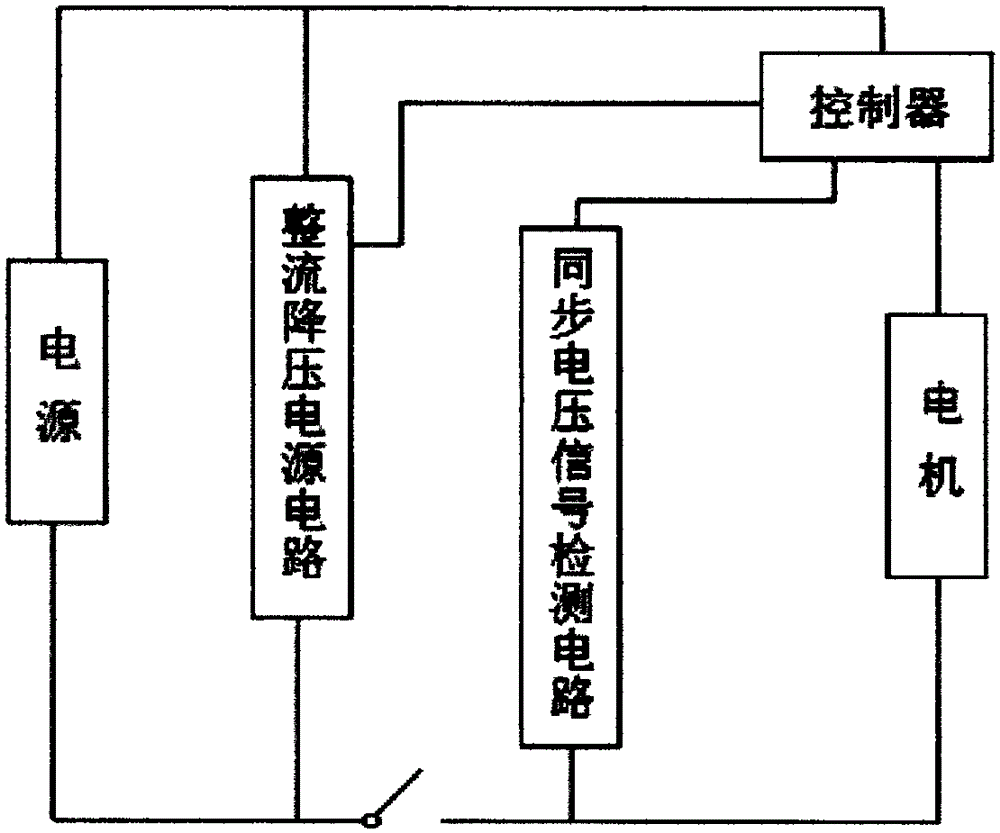

Horizontal compressor

ActiveCN105221423ADoes not affect work efficiencyImprove work efficiencyRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsWorking environmentEngineering

The invention discloses a horizontal compressor which comprises a machine shell, a crankshaft, an air cylinder, a motor and a controller. A high-pressure cavity and a low-pressure cavity which are arranged formed in the axial direction of the machine shell in a spaced manner are defined in the machine shell. The machine shell is provided with an air sucking opening and an exhaust opening. The air sucking opening is communicated with the low-pressure cavity, and the exhaust opening is communicated with the high-pressure cavity. The crankshaft is arranged in the machine shell and extends in the axial direction of the machine shell. One end of the crankshaft stretches in the high-pressure cavity, and the other end of the crankshaft stretches in the low-pressure cavity. The air cylinder and the motor are arranged on the crankshaft in a spaced manner. The air cylinder is located in one of the high-pressure cavity and the low-pressure cavity. The motor is located in the other one of the high-pressure cavity and the low-pressure cavity. The controller is arranged outside the machine shell and is connected with the outer wall, adjacent to the low-pressure cavity, of the machine shell. According to the horizontal compressor of the embodiment, under the premise that high-temperature and high-pressure air exhaust of the horizontal compressor is ensured, stability of the working environment of the controller can be improved, the working environment is prevented from being influenced by high-temperature and high-pressure air exhaust of the horizontal compressor, and therefore the energy efficiency of the horizontal compressor is improved, and the service life of the horizontal compressor is prolonged.

Owner:ANHUI MEIZHI PRECISION MFG

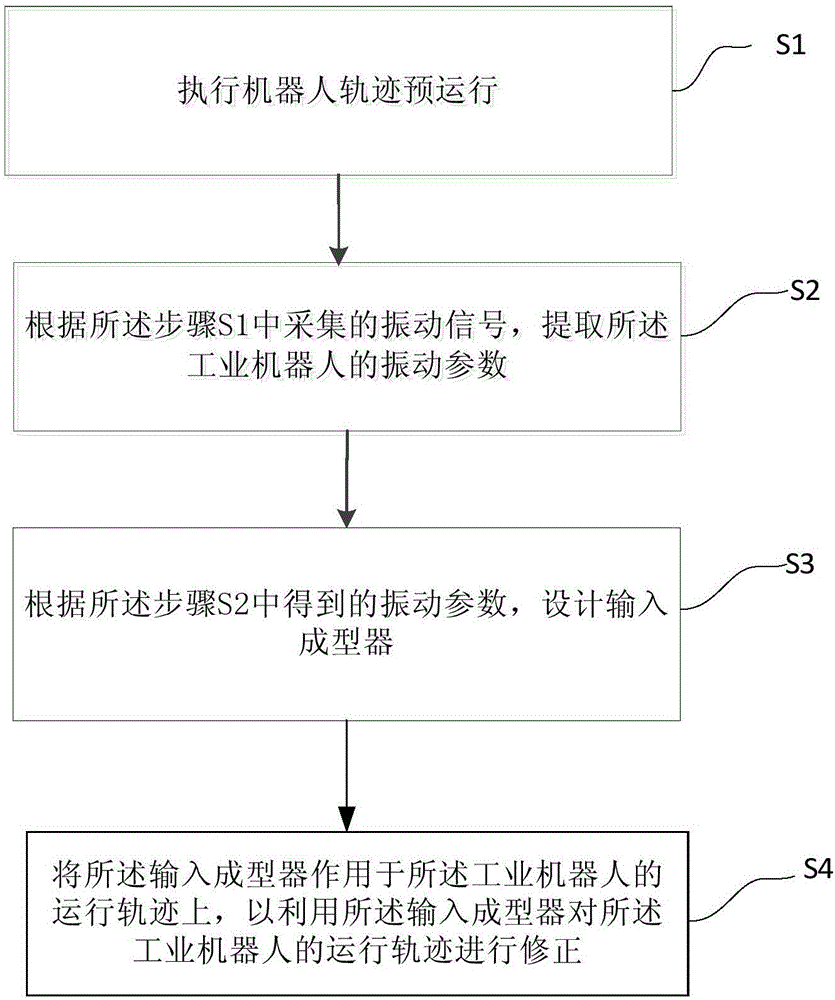

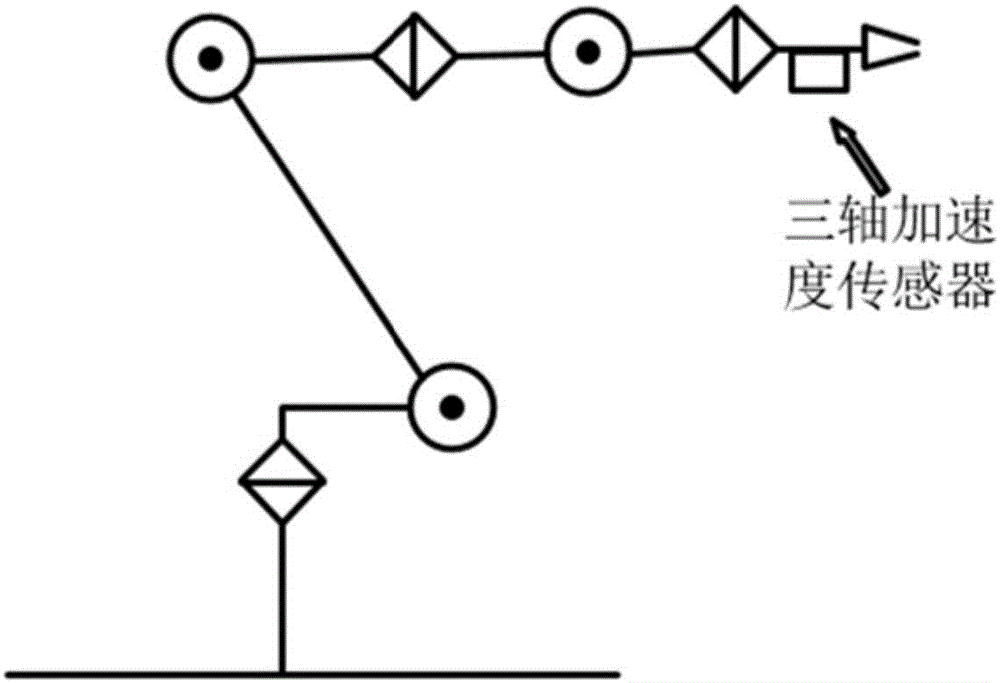

Robot vibration suppression method based on acceleration sensor

ActiveCN107433589AHigh precisionReduce the difficulty of implementationProgramme-controlled manipulatorTime lagVibratory signal

The invention provides a robot vibration suppression method based on an acceleration sensor. The robot vibration suppression method comprises the steps that robot track pre-operation is executed, specifically, the three-shaft acceleration sensor is mounted at the tail end of a robot, and vibration signals in three directions in the mounting position during pre-operation of the robot are collected; vibration parameters of the industrial robot are extracted according to the collected vibration signals; an input forming device is designed according to the obtained vibration parameters; and the input forming device acts on the operation track of the industrial robot so as to correct the operation track of the industrial robot through the input forming device. Through the method of applying input shaping to the industrial robot, the problems that input shaping parameters are difficult to obtain, and shafts move asynchronously due to the input shaping time lag are solved, vibration of the industrial robot can be suppressed, and track precision and positioning precision are improved.

Owner:ROKAE SHANDONG INTELLIGENT TECH CO LTD

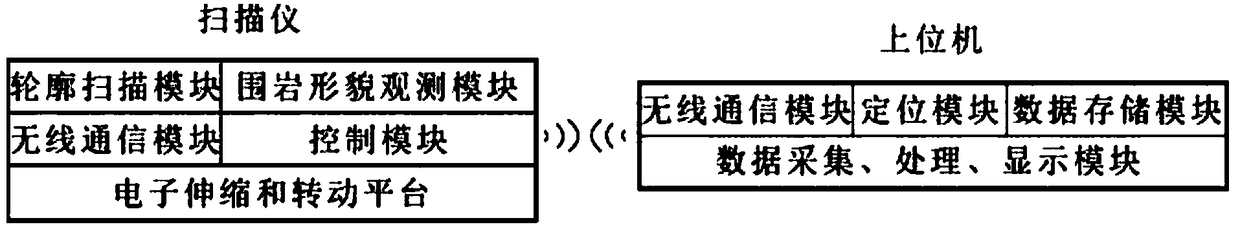

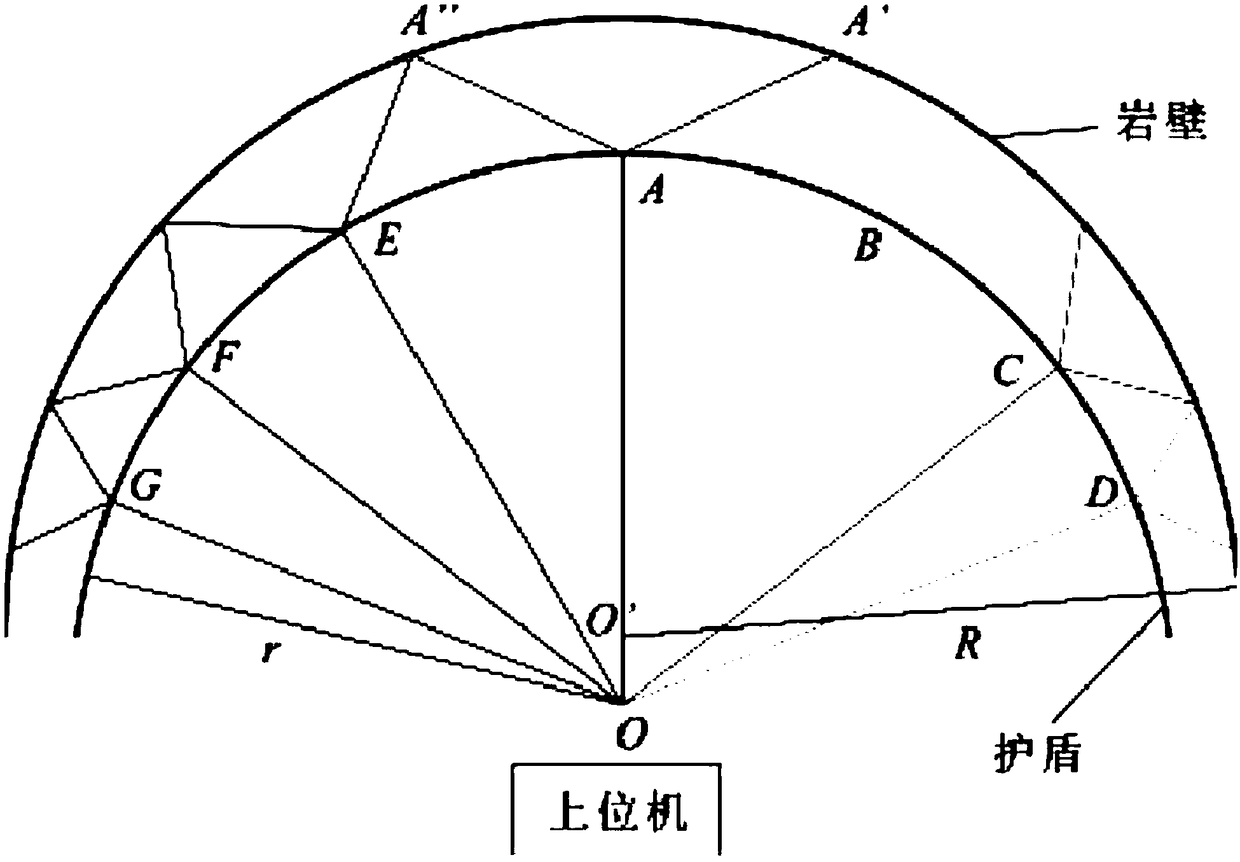

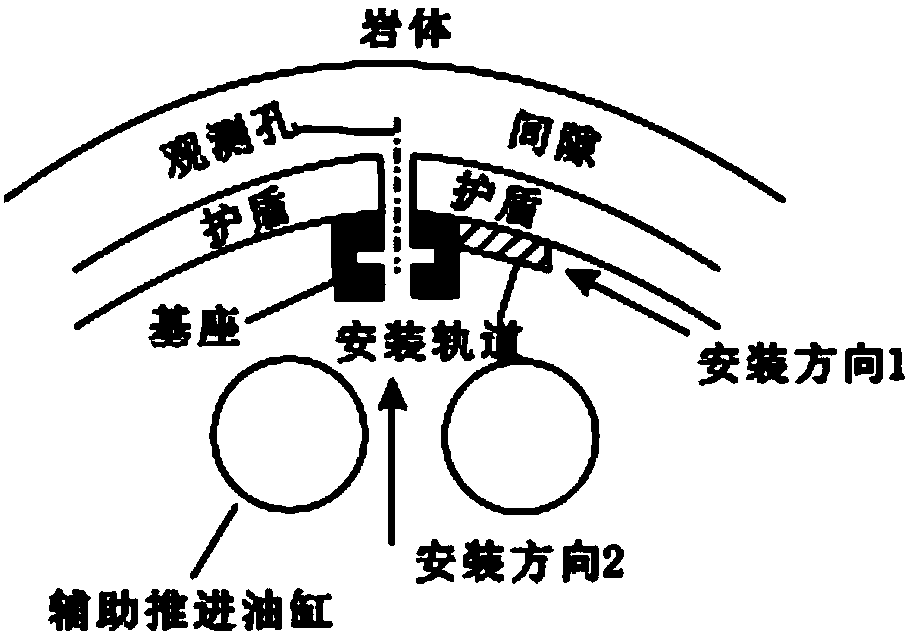

Tunnel surrounding rock scanning and observing system based on dual-shield TBM technology

ActiveCN109186480AQuick installationEasy to installEarth material testingUsing optical meansMeasurement deviceGeomorphology

The invention discloses a tunnel surrounding rock scanning and observing system based on a dual-shield TBM technology. The system comprises multiple scanners and an upper computer; the upper computeris positioned at the axis of the shield of an auxiliary propulsion oil cylinder position; the scanner is installed at each observing hole of the shield of the cross section of the auxiliary propulsionoil cylinder. According to the system provided by the invention, the scanner is installed at the preset observing hole on the rear shield to achieve direct measurement; data is collected via multiplecoordinate systems and processed in a unified manner; a scanning system for propelling observation on the profile of the tunnel surrounding rock and rock appearance by accompanying tunneling similarto well logging during drilling is formed; drawing of a two-dimensional profilogram of the cross section of a tunnel, building of a three-dimensional model of the actual excavation face of the tunnel,surrounding rock appearance imaging of the cross section of the tunnel, and three-dimensional rock appearance imaging of the actual excavation face of the tunnel within a certain angle range of the top of the whole tunnel can be achieved; in addition, the scanners and the upper computer are installed in a modularized manner, and the internal different modularized measurement devices can be changed according to needs, to achieve more functions.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

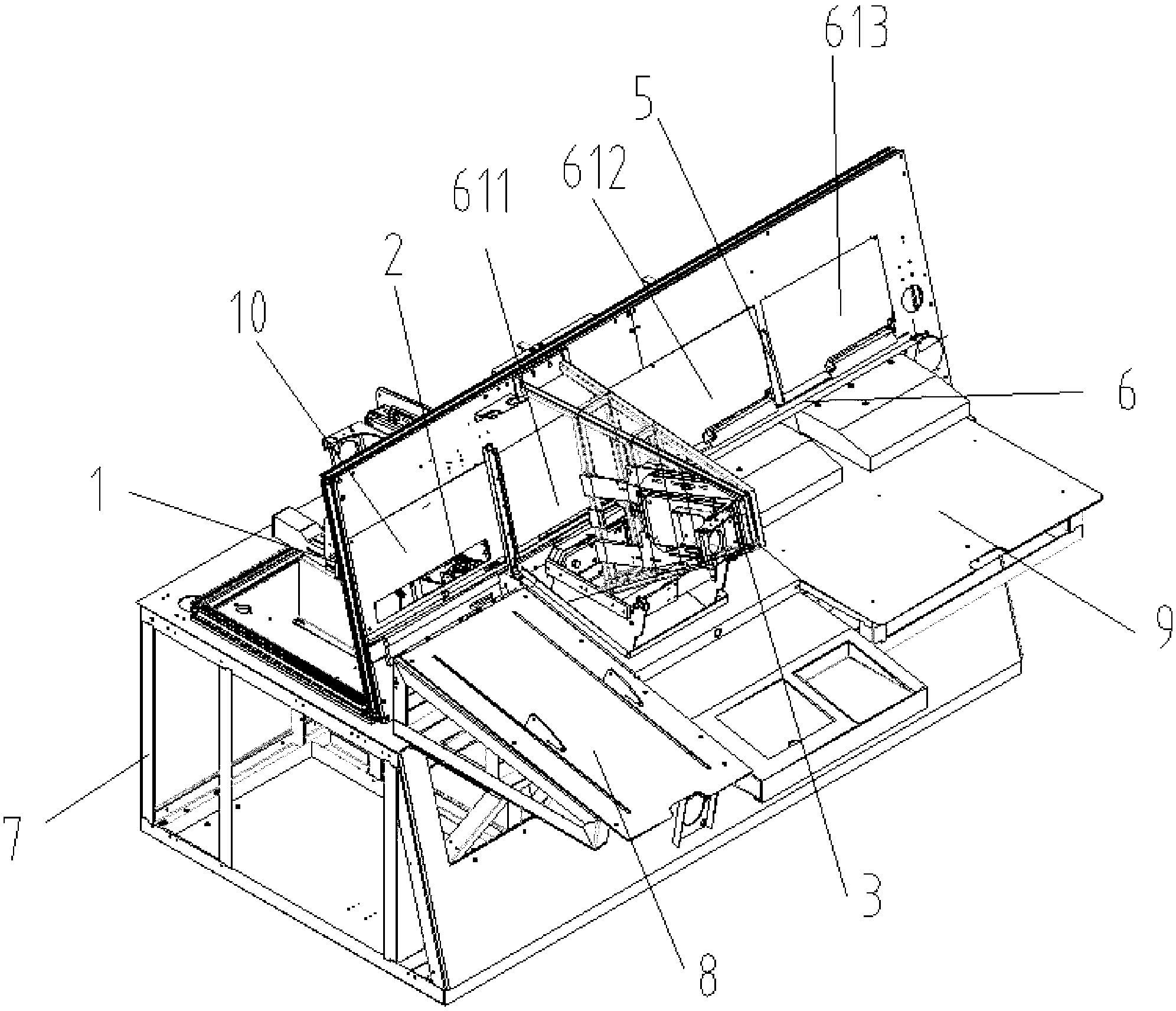

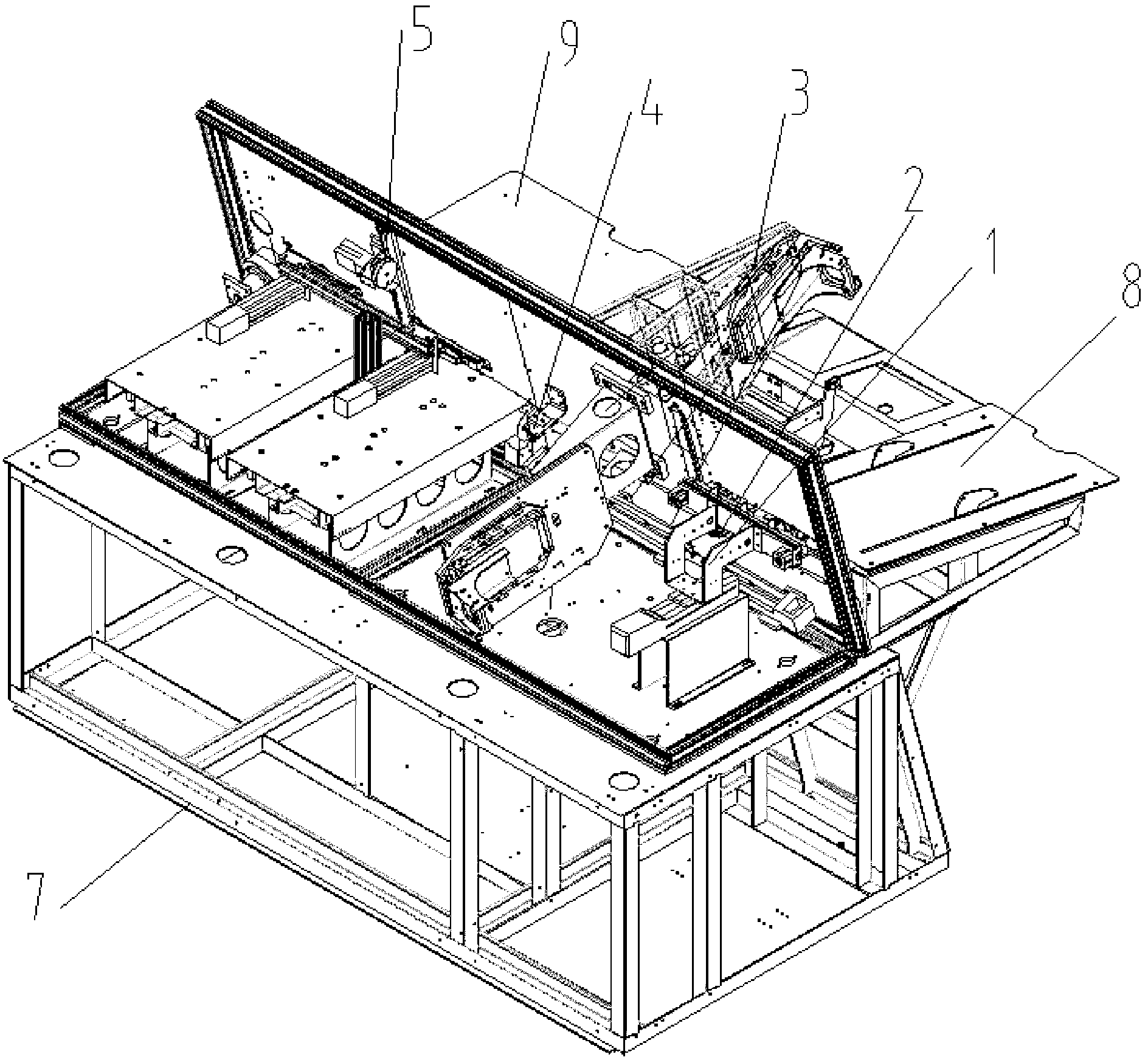

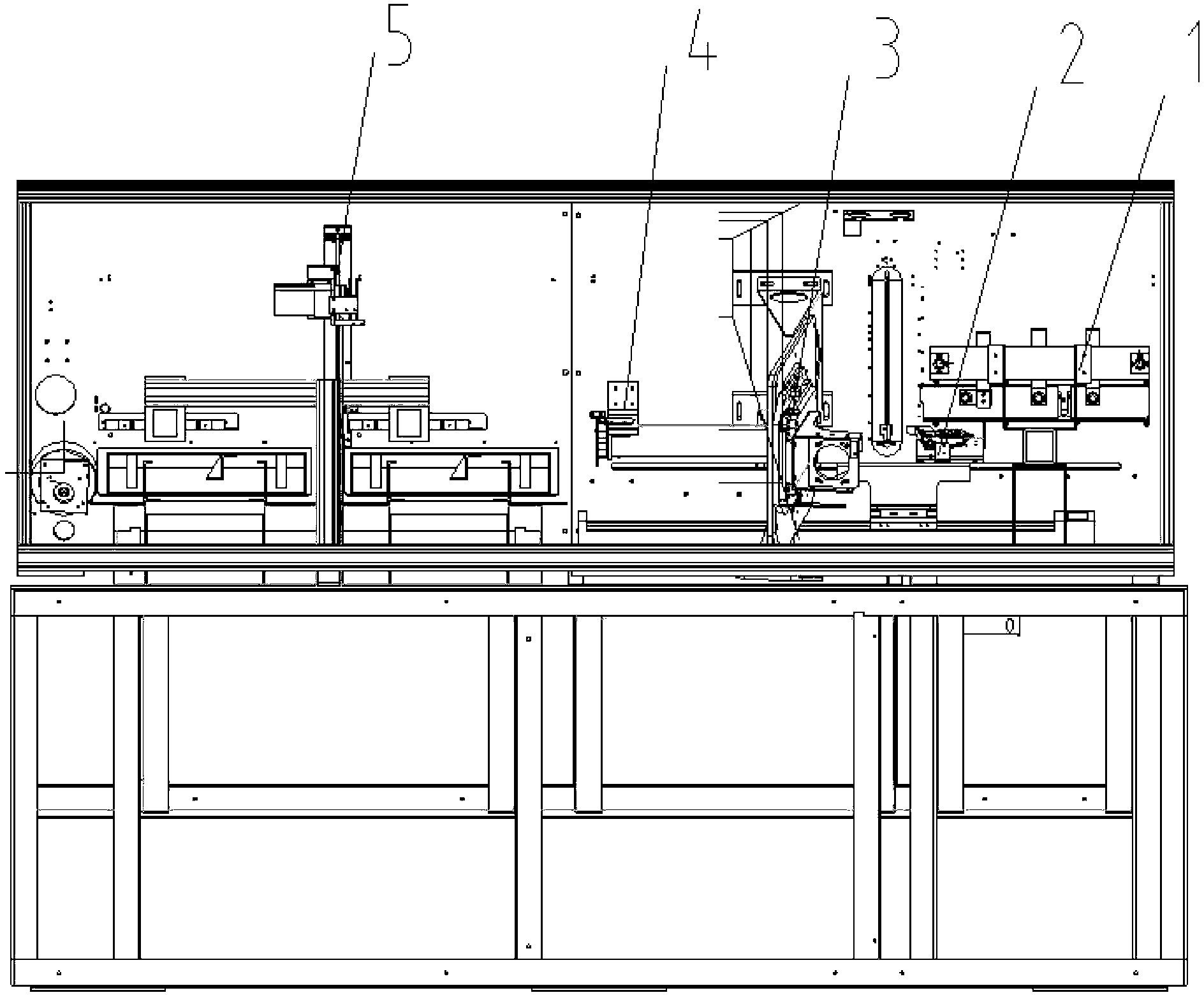

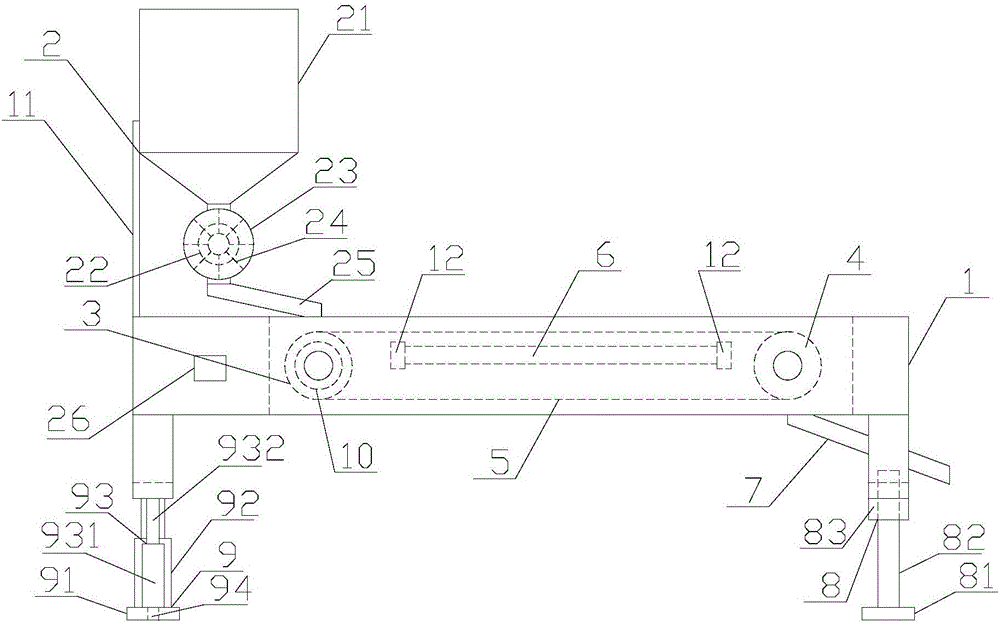

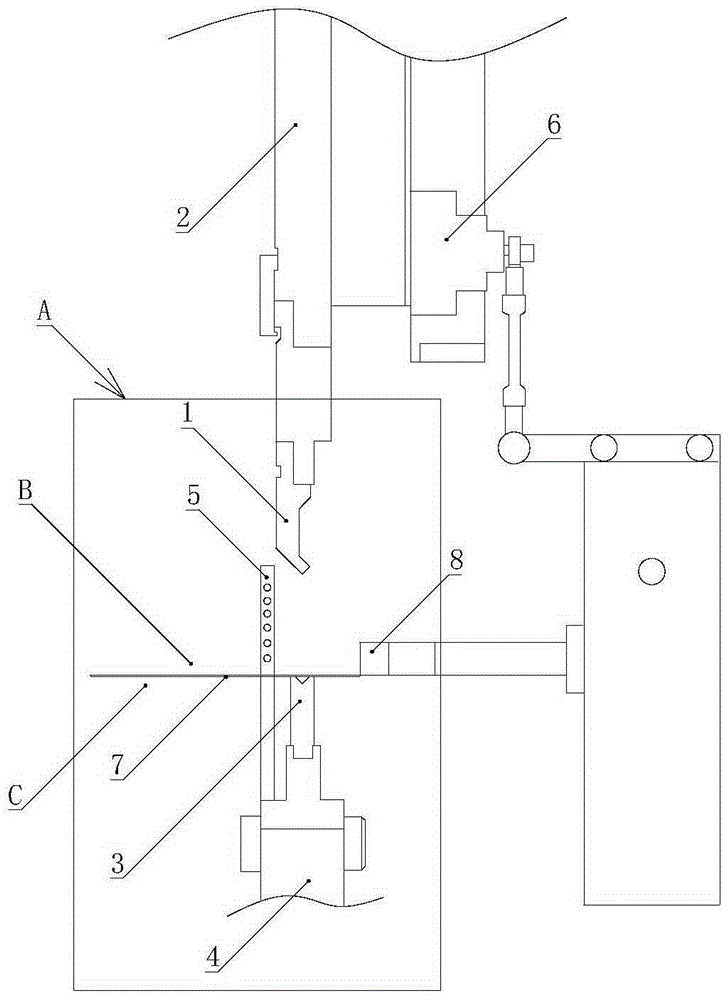

Vertical dual-sided CCD line scanning automatic detection platform for PCB (Printed Circuit Board)

InactiveCN102841101AWaste less timeAvoid damageOptically investigating flaws/contaminationEngineeringCam

The invention relates to a vertical dual-sided CCD line scanning automatic detection platform for a PCB (Printed Circuit Board). The comprises vertical dual-sided CCD line scanning automatic detection platform comprises a rapid cylinder type nozzle regulation mechanism (1), a cam arc dialing board positioning mechanism (2), a detection area vertical dual-sided CCD line scanning mechanism (3), a cam arc push plate mechanism (4), a cam baffle mechanism (5), a steel belt transport device (6), a rack (7), an inspection platform (8), an inspection post-position plate platform (9), a board distributing inspection region (10), a dual-sided vertical line scanning region (611), a bad board rejecting region (612) and a qualified board collecting region (613). According to the vertical dual-sided CCD line scanning automatic detection platform, due to the adoption of two-sided simultaneous scanning, the PCB is not needed to be overturned, thus the complexity of a mechanical structure is reduced; and because an overturning action is not needed, the efficiency reduction caused by overturning is eliminated. One time of production benefit can be increased, the volume of the vertical dual-sided CCD line scanning automatic detection platform is greatly reduced, and more vertical dual-sided CCD line scanning automatic detection platforms can be placed in same space, thus the utilization rate of a factory is effectively increased.

Owner:JOINT STARS TECH

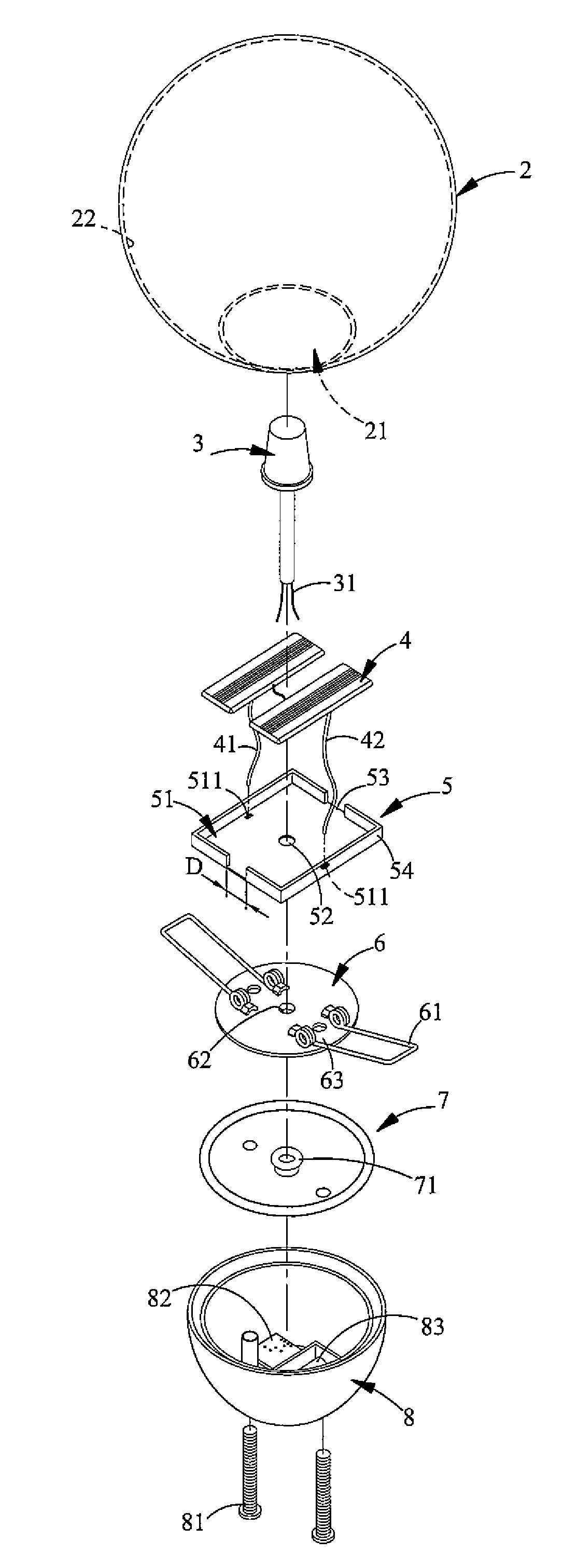

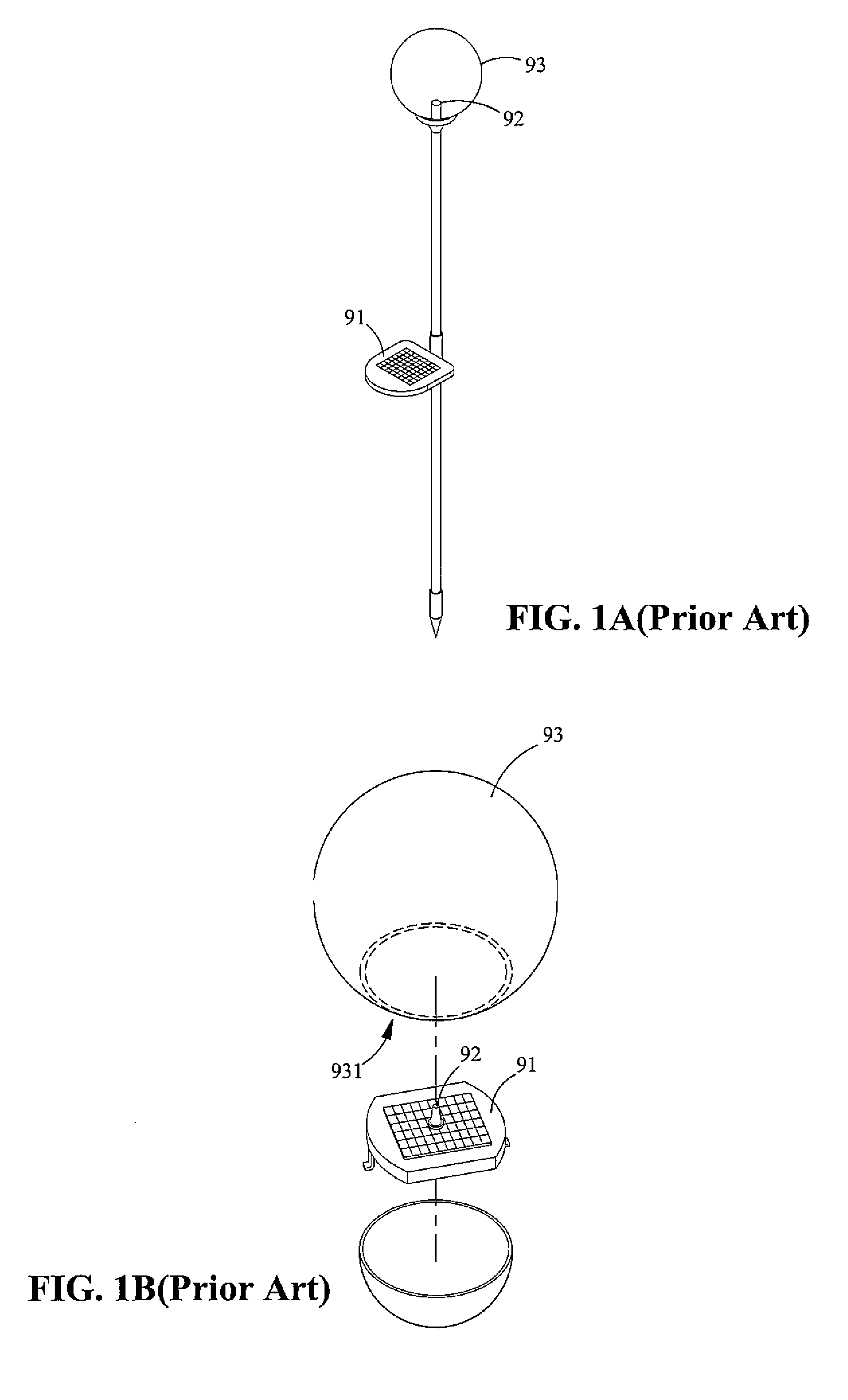

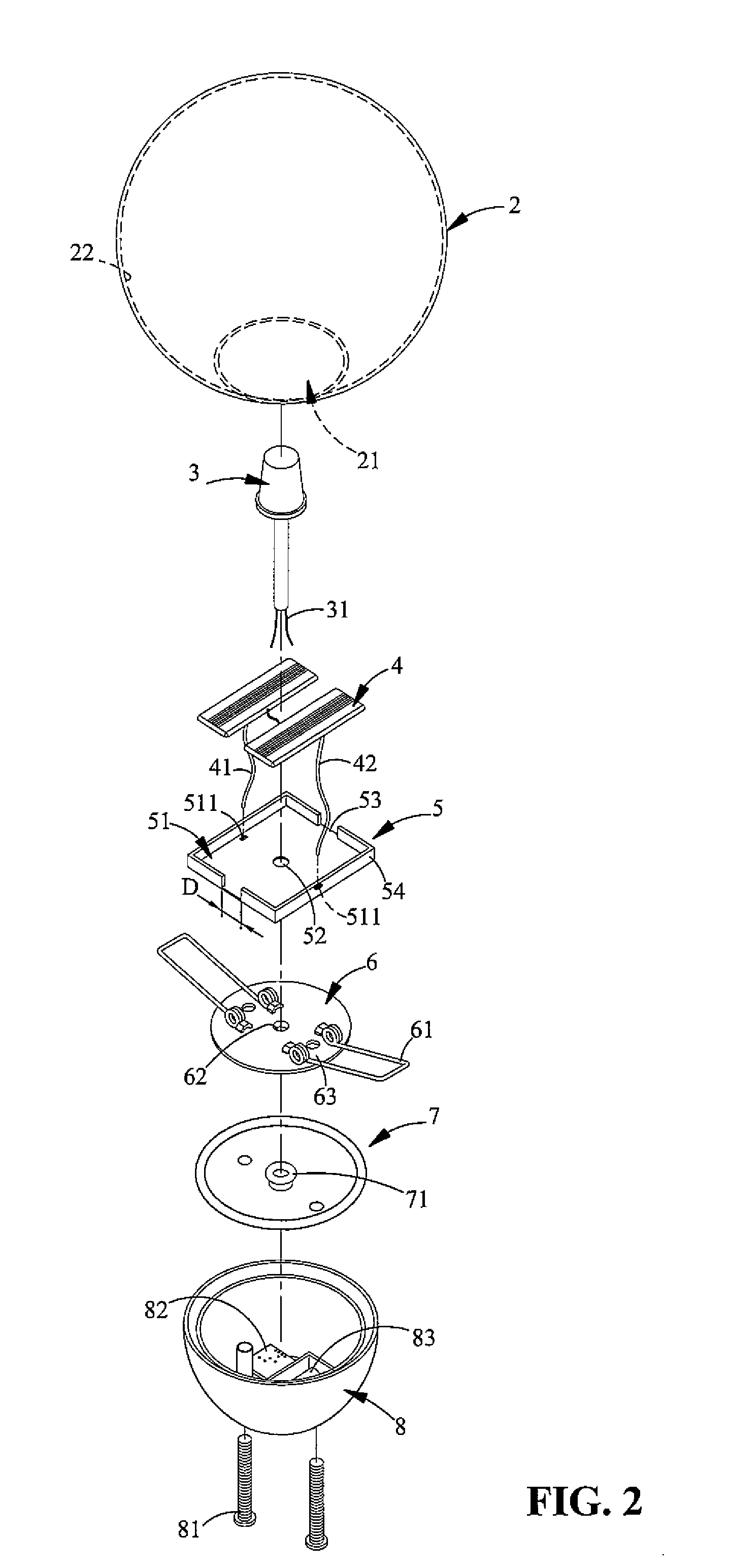

Illuminating Device Having Folding Solar Panels

ActiveUS20140133138A1Fixed securityPrevent leakageMechanical apparatusElectric circuit arrangementsEngineeringLight source

An illuminating device having folding solar panels, which comprises a lamp cover, a light source, two solar panels, and a folding holder on which the two solar panels are positioned. The opening of the lamp cover is smaller than the deployed area of the folding holder. When it is intended to place the light source, solar panels, and folding holder inside the lamp cover, the folding holder are folded by a predetermined angle so as to pass through the opening of the lamp cover. Accordingly, the illuminating device may significantly reduce the overall volume thereof without compromising the working efficiency. The illuminating device is flexible in arrangement and assembly, and is also more flexible in construction since the solar panels may be positioned at the highest portion to absorb more sunlight.

Owner:CHANG KUEI HSIANG

Smashing and cleaning mechanism

InactiveCN108437282ANot easy to break awayReduce processing timePlastic recyclingMechanical material recoveryEngineeringSlide plate

The invention relates to the technical field of plastic processing, and particularly discloses a smashing and cleaning mechanism. The smashing and cleaning mechanism comprises a motor, a rotating drumand a storage bin, wherein the motor is connected with a rotating shaft, and the storage bin is connected with a discharge pipe. The rotating shaft is provided with a plurality of cutters for cuttingplastic, a plurality of rows of clapboards are connected with the inner wall of the rotating drum, the clapboards are provided with through grooves for the cutters to pass through, and openings are formed between the adjacent clapboards on the peripheral wall of the rotating drum. Rotating plates are hinged at the openings, torsion springs are installed at the hinging positions between the rotating plates and the rotating drum, and an arc-shaped baffle plate for abutting against the rotating plates is arranged beside the rotating drum. A plurality of first through holes are formed in the sidewall of the rotating drum, and a plurality of spray heads are installed at both ends of the rotating drum. The discharge pipe is slidingly connected with an inclined T-shaped sliding plate, the T-shaped sliding plate is provided with a second through hole, and a spring is connected between the T-shaped sliding plate and the outer wall of the discharge pipe. The rotating plates can abut against the T-shaped sliding plate, and a vertical rod capable of abutting against the rotating plates is connected to the outer wall of the discharge pipe. The smashing and cleaning mechanism can simultaneously clean and cut the plastic, the smashing and cleaning mechanism can work for a long time, and the efficiency is improved.

Owner:宁波隆锐机械制造有限公司

Warehouse out-put and in-put control method

InactiveCN107527182AFully automatedRealize informatizationCo-operative working arrangementsLogisticsLogistics managementControl system

The invention provides a warehouse in-put control method comprising the warehouse in-put preparation process, the article detection process, the interruption processing process, the article warehouse in-put process and the information recording process. The invention provides a warehouse out-put control method comprising the order receiving process, the article out-put process, the out-put article detection process, the interruption processing process and the information recording process. The invention also discloses a warehouse out-put and in-put control system used for realizing the warehouse out-put and in-put control method. The warehouse out-put and in-put control system is characterized by comprising a communication control submodule, an equipment control submodule and an inquiring submodule. The inquiring submodule comprises an inquiring work module and a management work module. According to the warehouse out-put and in-put control method, logistics and information flow are integrated in an automatic logistics management center so that the integrated cost of inventory and logistics management can be reduced and the comprehensive benefits of the enterprise can be enhanced.

Owner:广州百兴网络科技有限公司

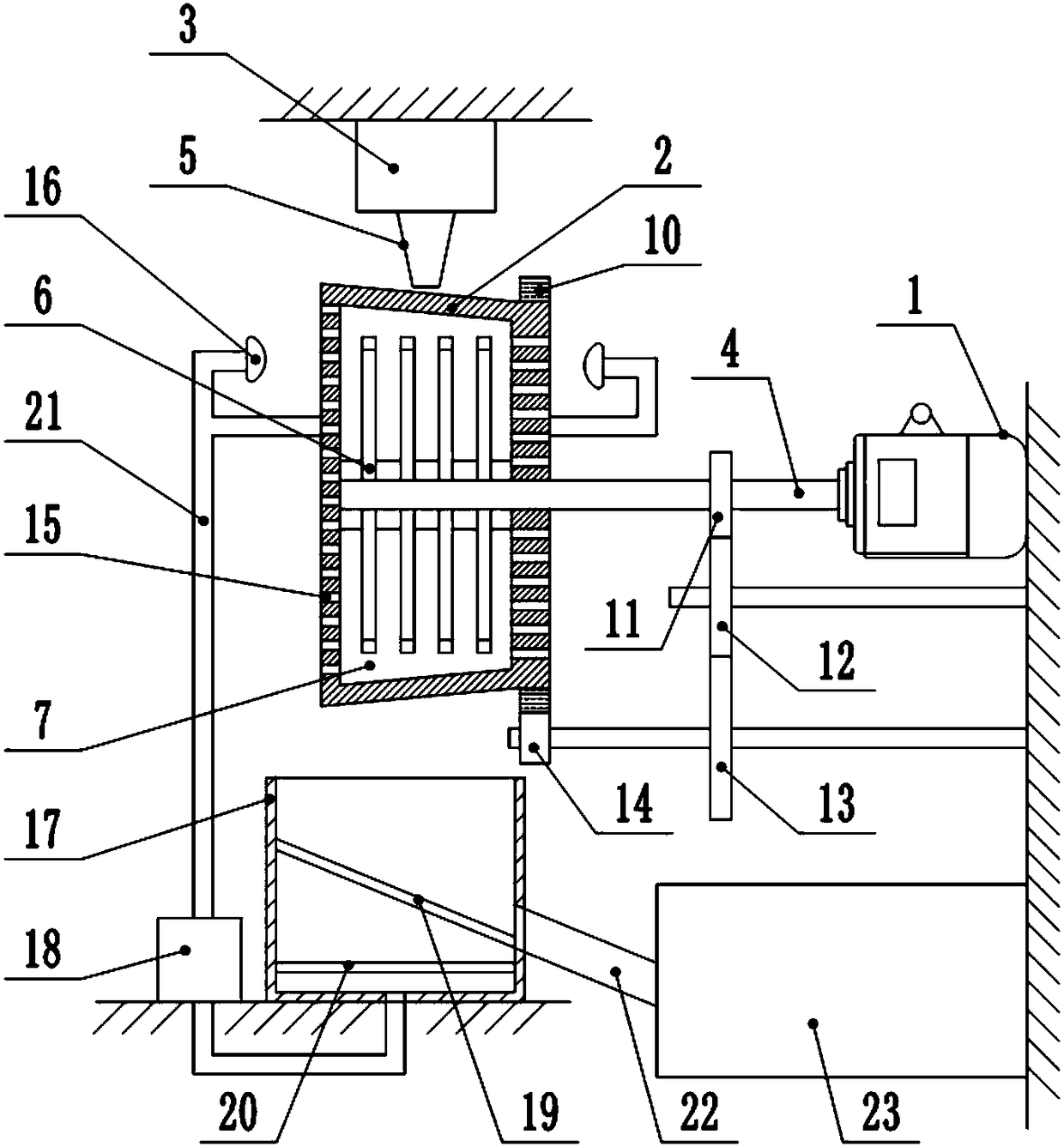

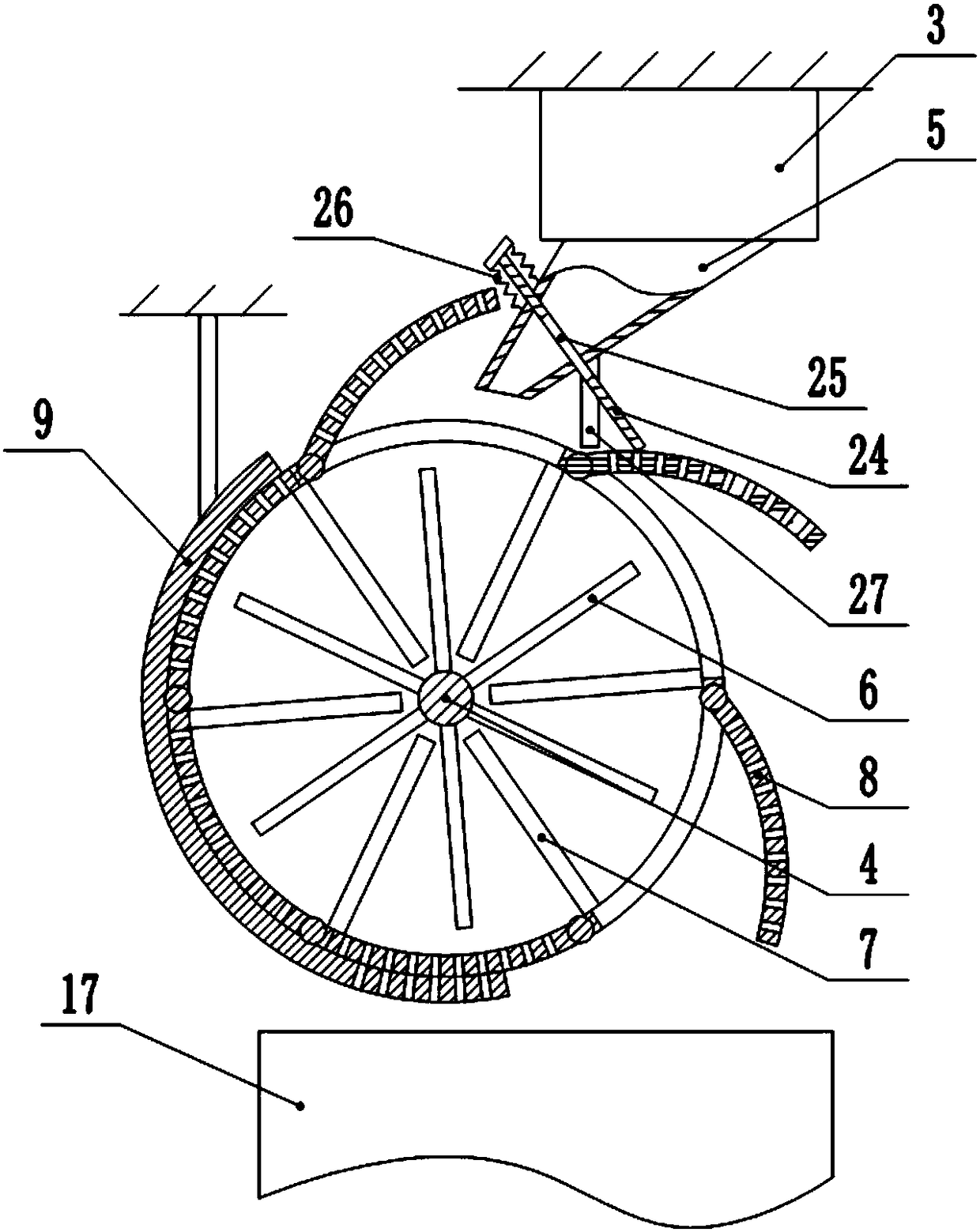

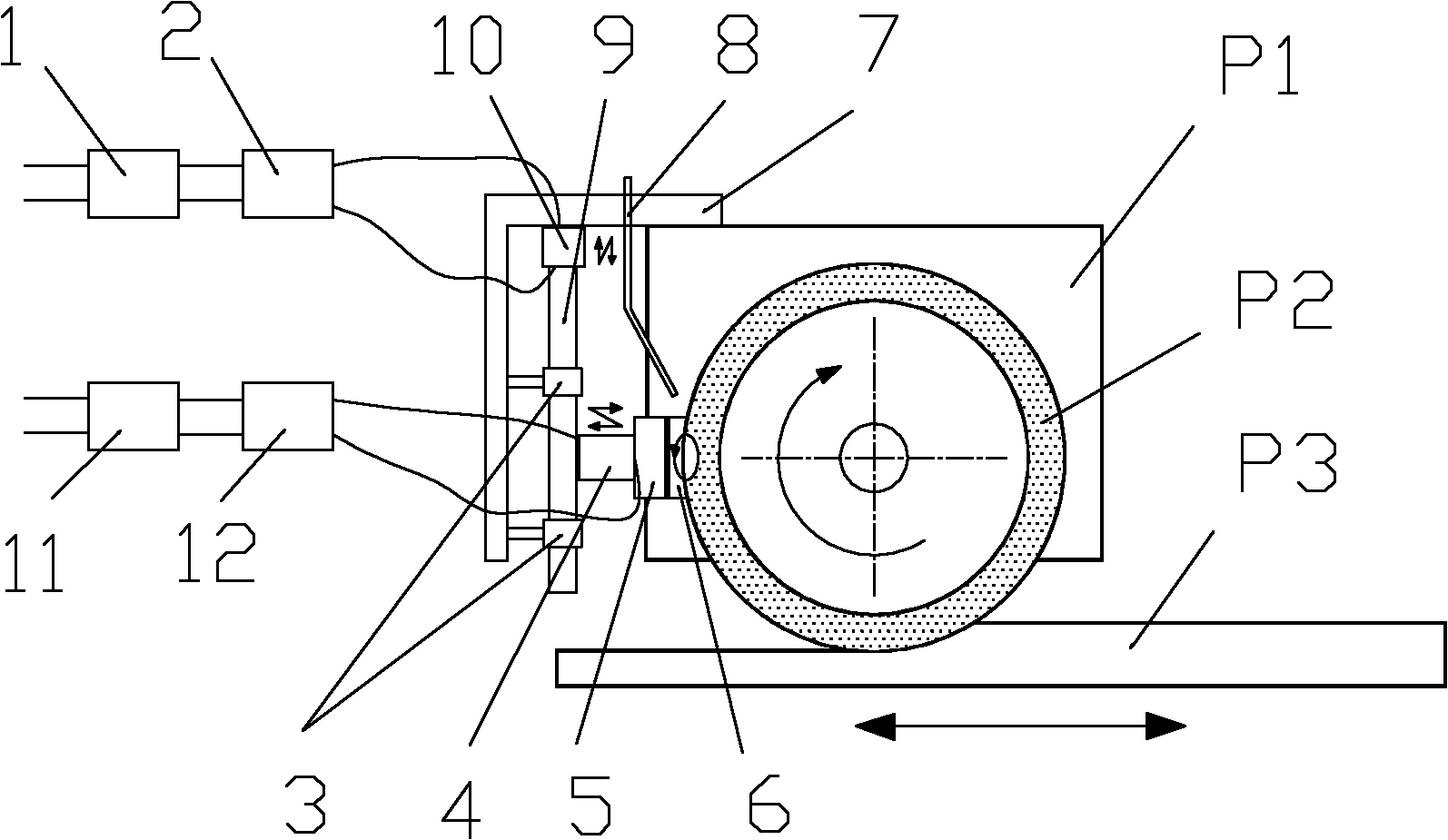

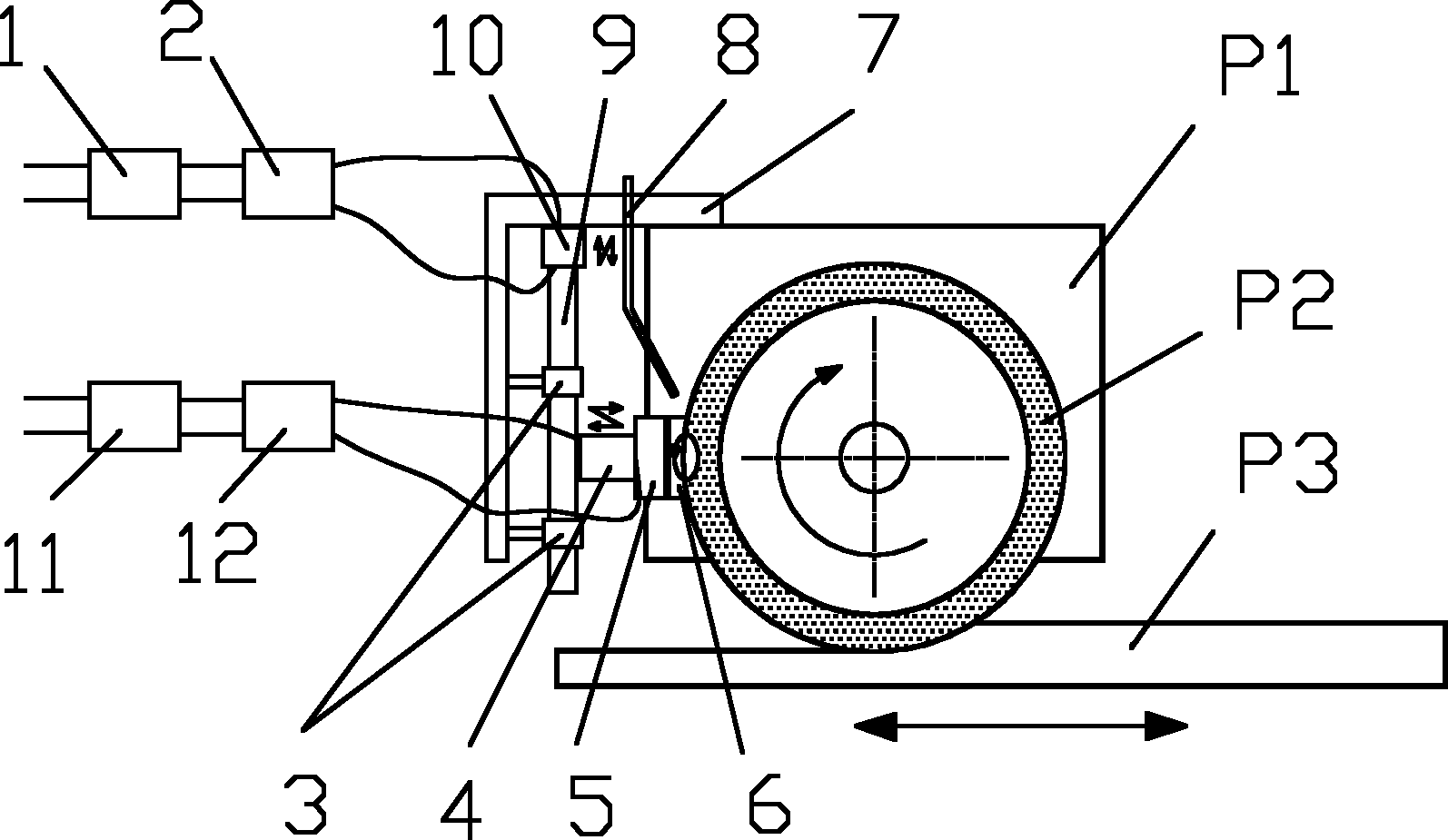

Grinding processing method and device for online grinding wheel dressing by ultrasonic vibration and

InactiveCN102152238AMeet the requirements for dressing grinding wheelsGuaranteed to proceed normallyAbrasive surface conditioning devicesGrinding/polishing safety devicesAudio power amplifierUltrasonic vibration

The invention discloses a grinding processing method and device for online grinding wheel dressing by ultrasonic vibration, relating to a grinding wheel dressing method and device. In the grinding processing device for online grinding wheel dressing by ultrasonic vibration, the structure is simple, the control accuracy is higher and the use is convenient. The device is provided with a bracket, a vibrating shaft, a longitudinal piezoelectric ceramic, a horizontal piezoelectric ceramic, a dressing block, a cooling liquid spraying pipe, a first wave function generator, a first power amplifier, a second wave function generator and a second power amplifier, wherein the vibrating shaft is arranged on the bracket; the longitudinal piezoelectric ceramic is axially connected with the vibrating shaft; the horizontal piezoelectric ceramic is radially connected with the vibrating shaft; the dressing block is arranged on the horizontal piezoelectric ceramic; the first wave function generator is connected with the first power amplifier which is connected with longitudinal piezoelectric ceramic; the second wave function generator is connected with the second power amplifier which is connected with the horizontal piezoelectric ceramic; and the cooling liquid spraying pipe is arranged on the bracket. The online grinding and dressing can be carried out on a grinding wheel by installing the bracket on a grinding machine.

Owner:XIAMEN UNIV

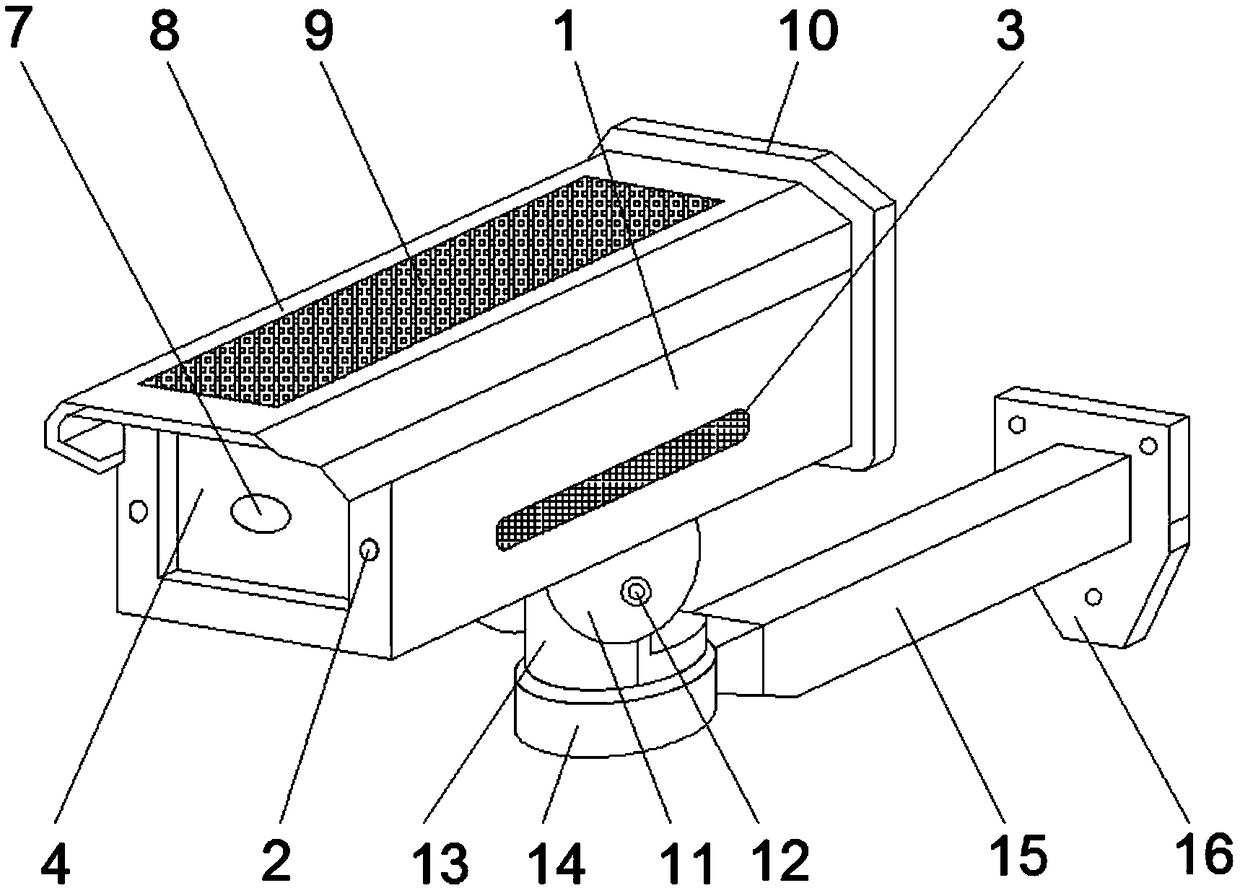

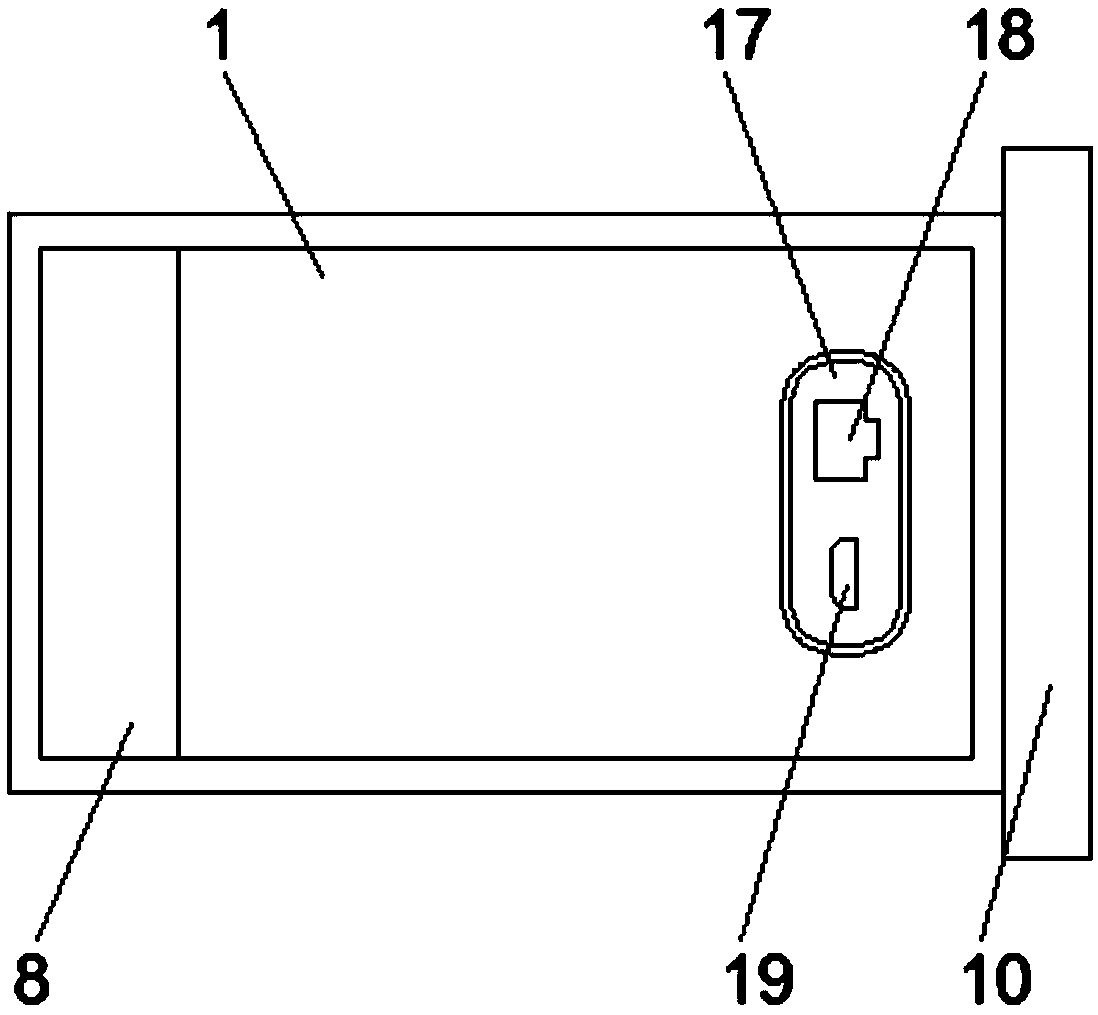

Energy-efficient outdoor surveillance camera

InactiveCN108965661ADoes not affect work efficiencyEnergy-saving effectTelevision system detailsBatteries circuit arrangementsNight visionCamera lens

The invention relates to the field of monitoring equipment and in particular to an energy-efficient outdoor surveillance camera, which comprises a camera housing, a camera body, a high-definition lens, an eave board and a movable bracket. Night vision lamps are arranged on both sides of the base surface of the camera housing. Microphones are disposed on the left and right ends of the camera housing. The camera body is disposed in the camera housing. A substrate is disposed in the camera body. The high-definition lens is fixedly mounted on the center of the base surface of the substrate. LED light sources are fixedly mounted on the base surface of the substrate and the outer side of the high-definition lens. The top of the camera housing is provided with the eave board. A solar panel is fixedly mounted in the eave board. The camera housing and the rear end of the eave board are connected to each other through a rear cover plate. The rear side of the bottom of the camera housing is provided with a connection panel. The connection panel is provided with a network cable interface and a power interface in sequence from top to bottom. The energy-efficient outdoor surveillance camera is simple in structure, has diverse functions, and has a certain promotion value.

Owner:池州市清心信息技术服务有限公司

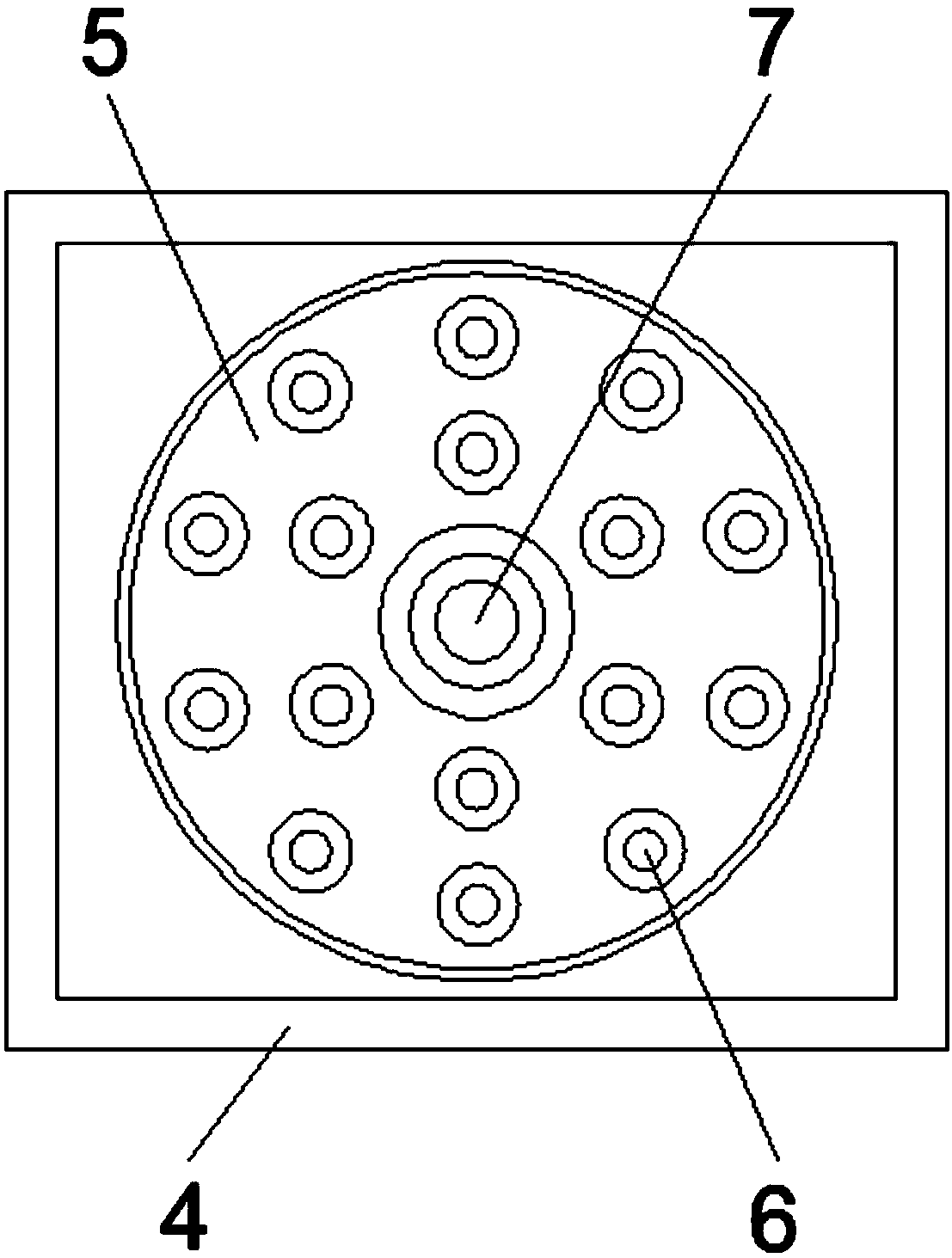

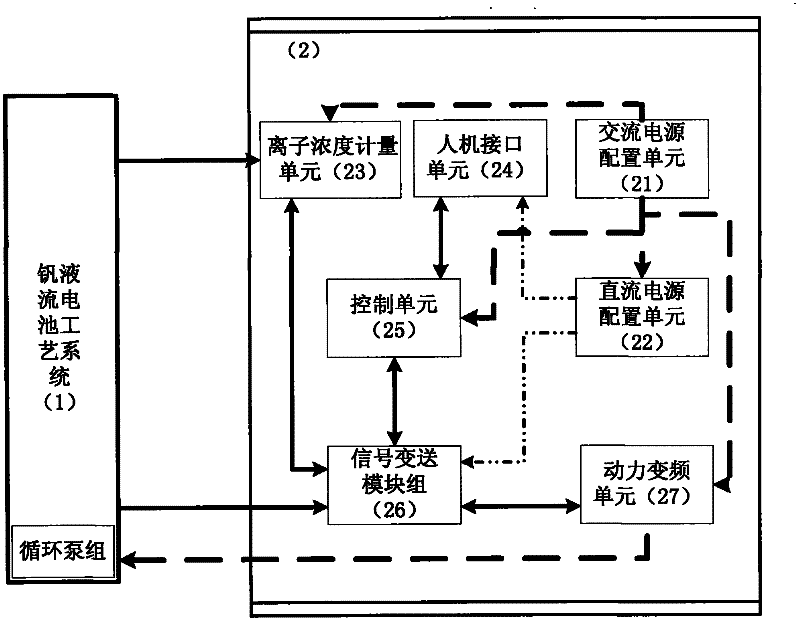

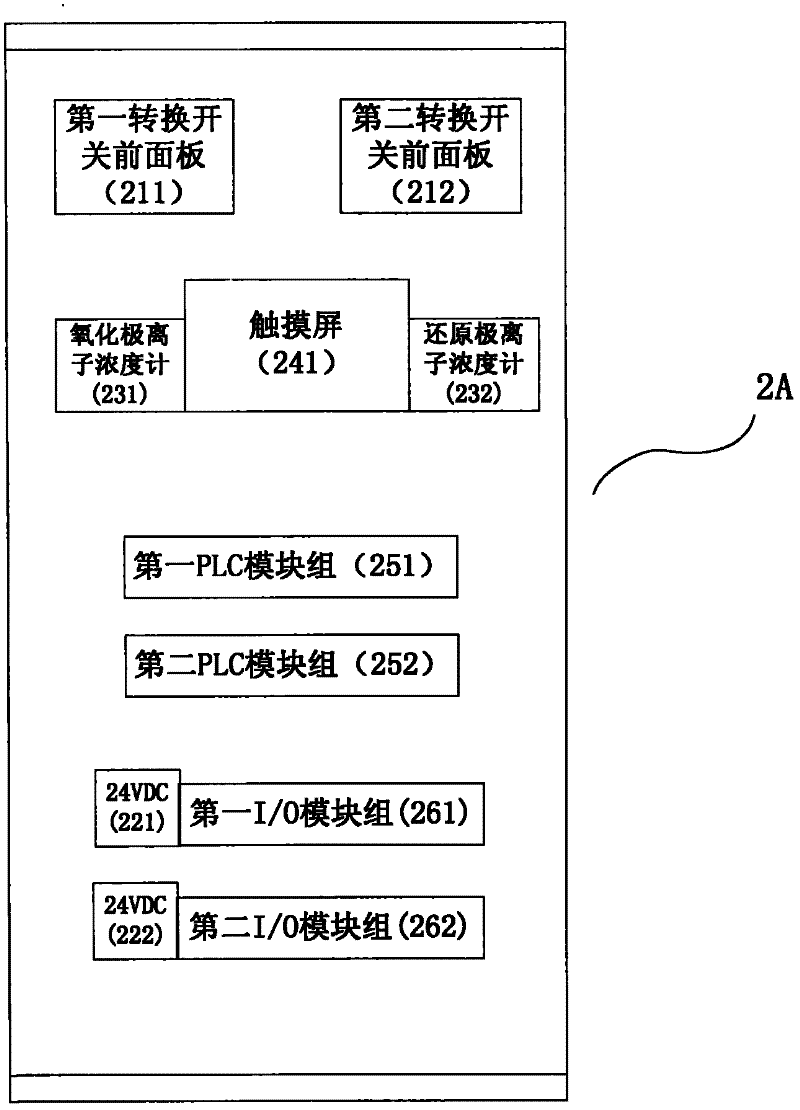

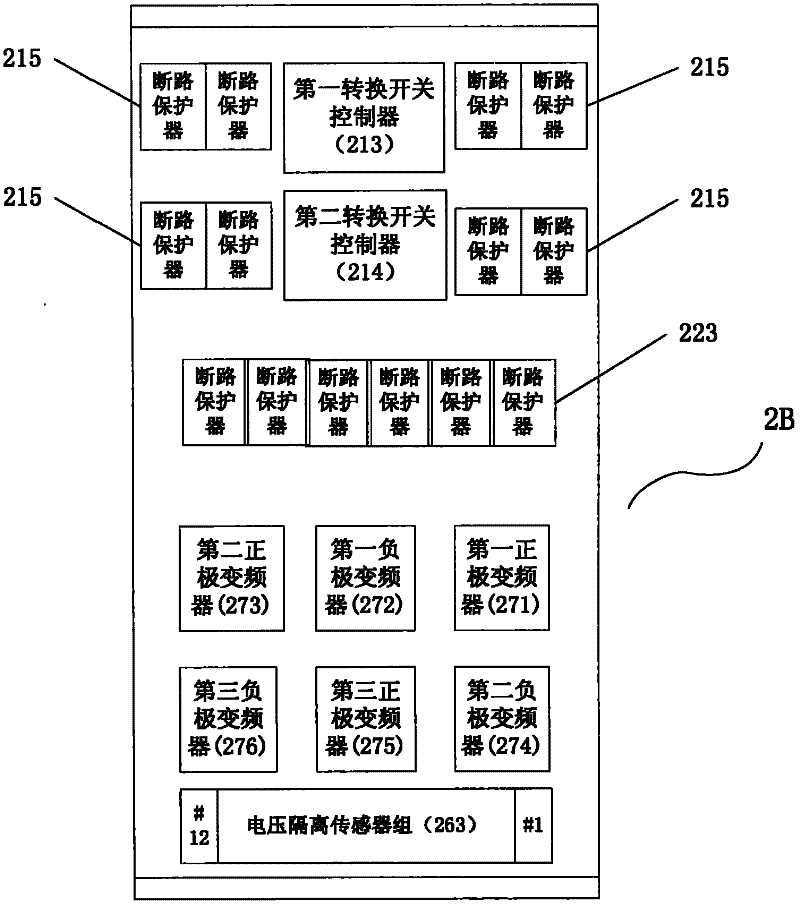

Vanadium redox flow battery control system based on PLC, control method and control device thereof

ActiveCN102315465AImprove reliabilityRealize Hot Standby RedundancyFuel cell controlProcess systemsSelf recovery

The present invention provides a vanadium redox flow battery control system based on PLC. The control system comprises a vanadium redox flow battery process system and a control cabinet. The control cabinet comprises an alternating current power supply configuration unit, a direct current power supply configuration unit, an ion concentration measurement unit, a man-machine interface unit, a control unit, a signal transmission module group and a power frequency conversion unit. According to the present invention, a power supply circuit of the control system, a PLC module group, a I / O module group, the signal transmission module group and the power frequency conversion unit are grouped and independently designed so as to realize the hot redundancy of the whole system, and greatly improve the stability and the reliability of the system. The system has a plurality of operating modes and an external four-circuit alternating current power supply, such that the charging and the discharging of the vanadium redox flow battery can be performed at any time and any place, the operation is convenient and the application is flexible; the system further has functions of self-diagnostic and self-recovery, such that the misjudgment and the missed judgment of the failure are effectively avoided, the reliability and the availability of the system are improved so as to indeed realize unattended operation; in addition, with the man-machine interface, the related parameters can be monitored and adjusted so as to meet the requirements of various operating conditions.

Owner:TIANJIN BINHAI ENERGY STORAGE TECH

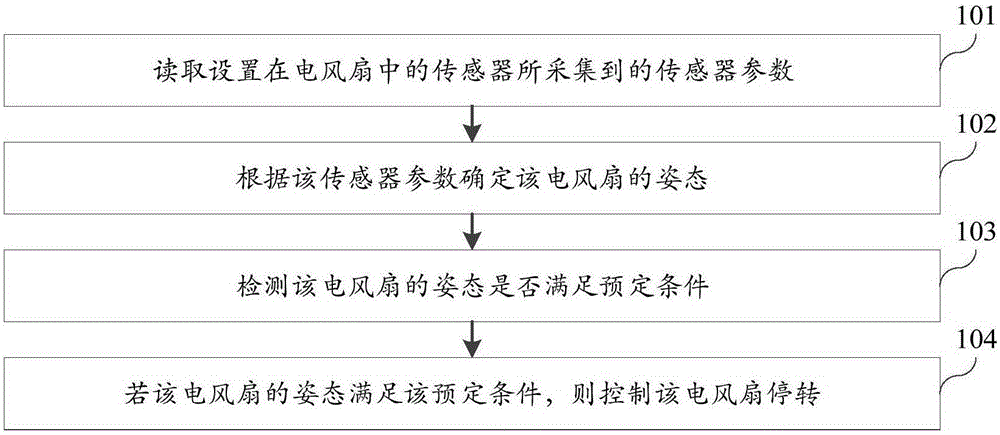

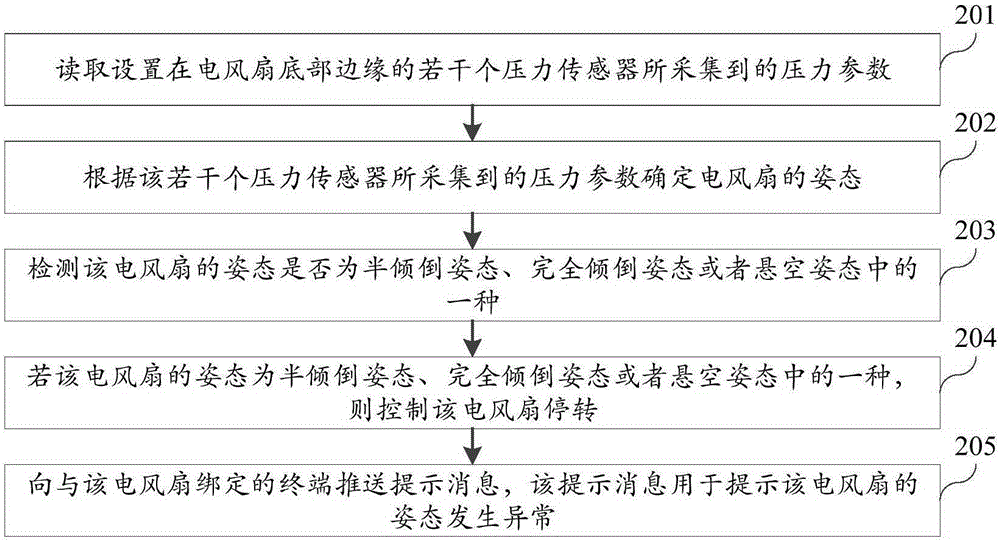

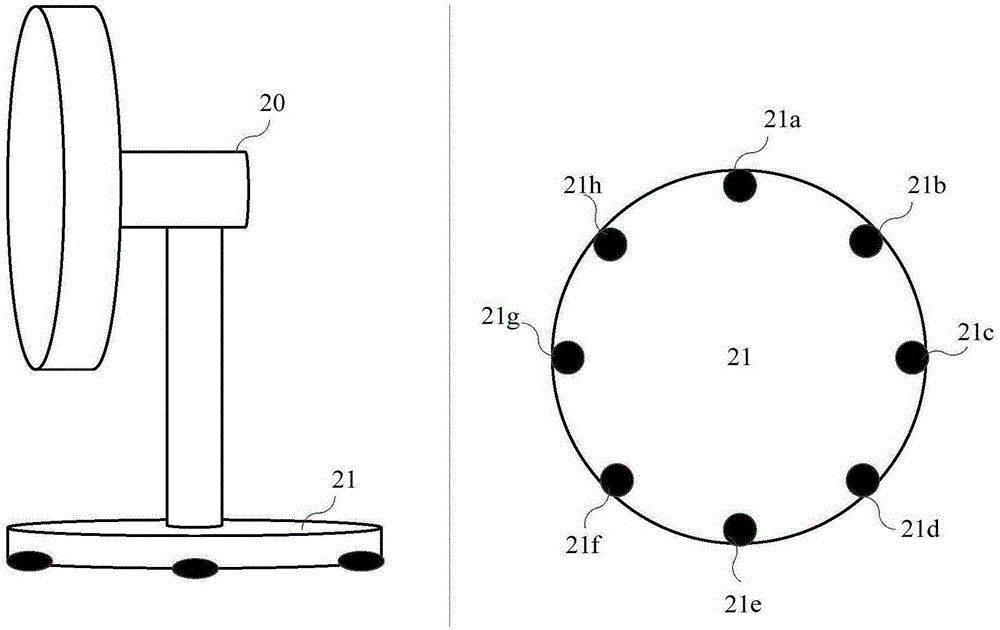

Electric fan control method and device

ActiveCN105179286AEnsure safetyDoes not affect work efficiencyPump controlNon-positive displacement fluid enginesEmbedded system

Owner:XIAOMI INC +1

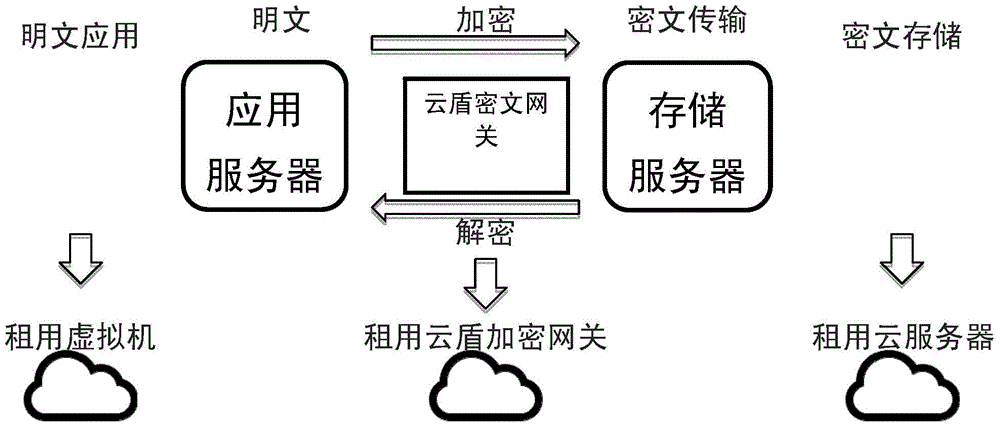

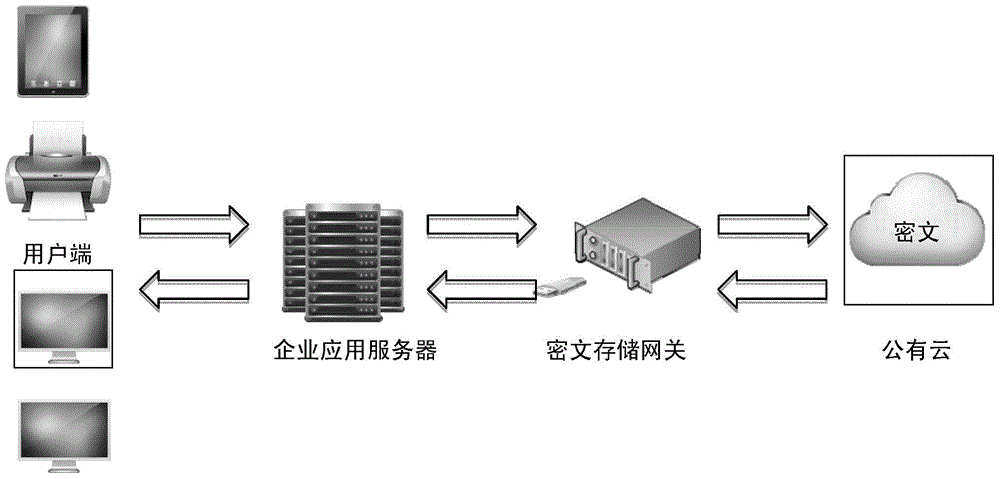

Method for encrypting and decrypting information by means of ciphertext storage gateway

InactiveCN104092672ASolve data security issuesDoes not affect work efficiencyTransmissionComputer hardwarePlaintext

The invention relates to a method for encrypting and decrypting information by means of a ciphertext storage gateway. According to the method for encrypting and decrypting information by means of the ciphertext storage gateway, data read by a client side are in a plaintext form, and the data are stored in a storage server in a ciphertext mode through the ciphertext storage gateway; the data are read out from the storage server in a ciphertext mode and are converted into data in a plaintext form on the client side application server through the ciphertext storage gateway. The method for encrypting and decrypting information by means of the ciphertext storage gateway specifically comprises the steps that (1) a storage space is mounted to the ciphertext storage gateway; (2) the ciphertext storage gateway is mounted to a cloud computing server; (3) a driving program is installed on the ciphertext storage gateway, and the driving program is called during access to all / mnt / oss files. The method for encrypting and decrypting information by means of the ciphertext storage gateway has the advantages that the cloud shield ciphertext storage gateway is used by enterprises for encrypting data during data storage, and data encryption is independent of carriers and containers; data leakage protection and enterprise application systems are combined perfectly, and the data security of the enterprises are effectively guaranteed; the method can be flexibly applied to various complicated kinds of network architecture more effectively and more flexibly.

Owner:安徽云盾信息技术有限公司

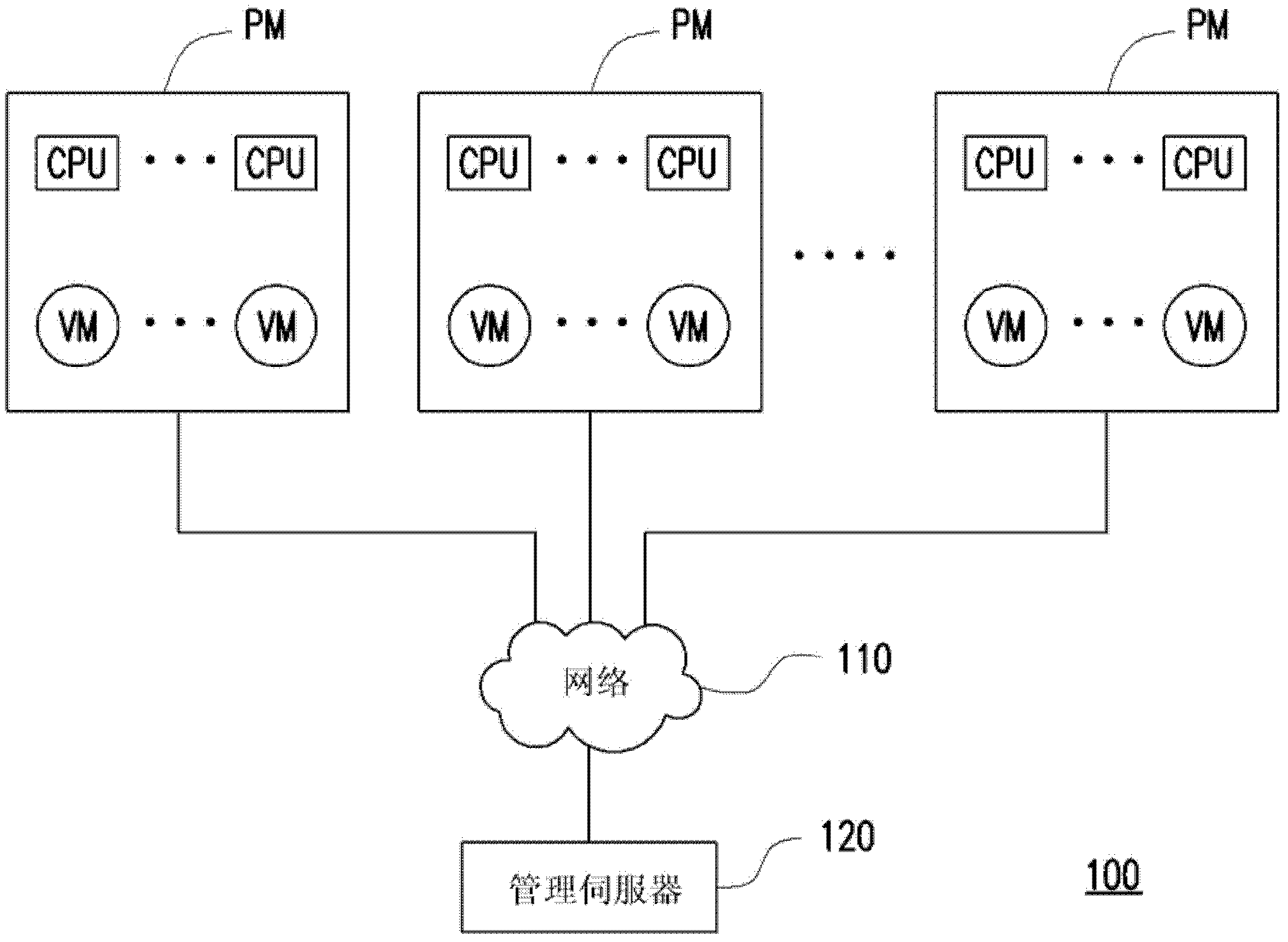

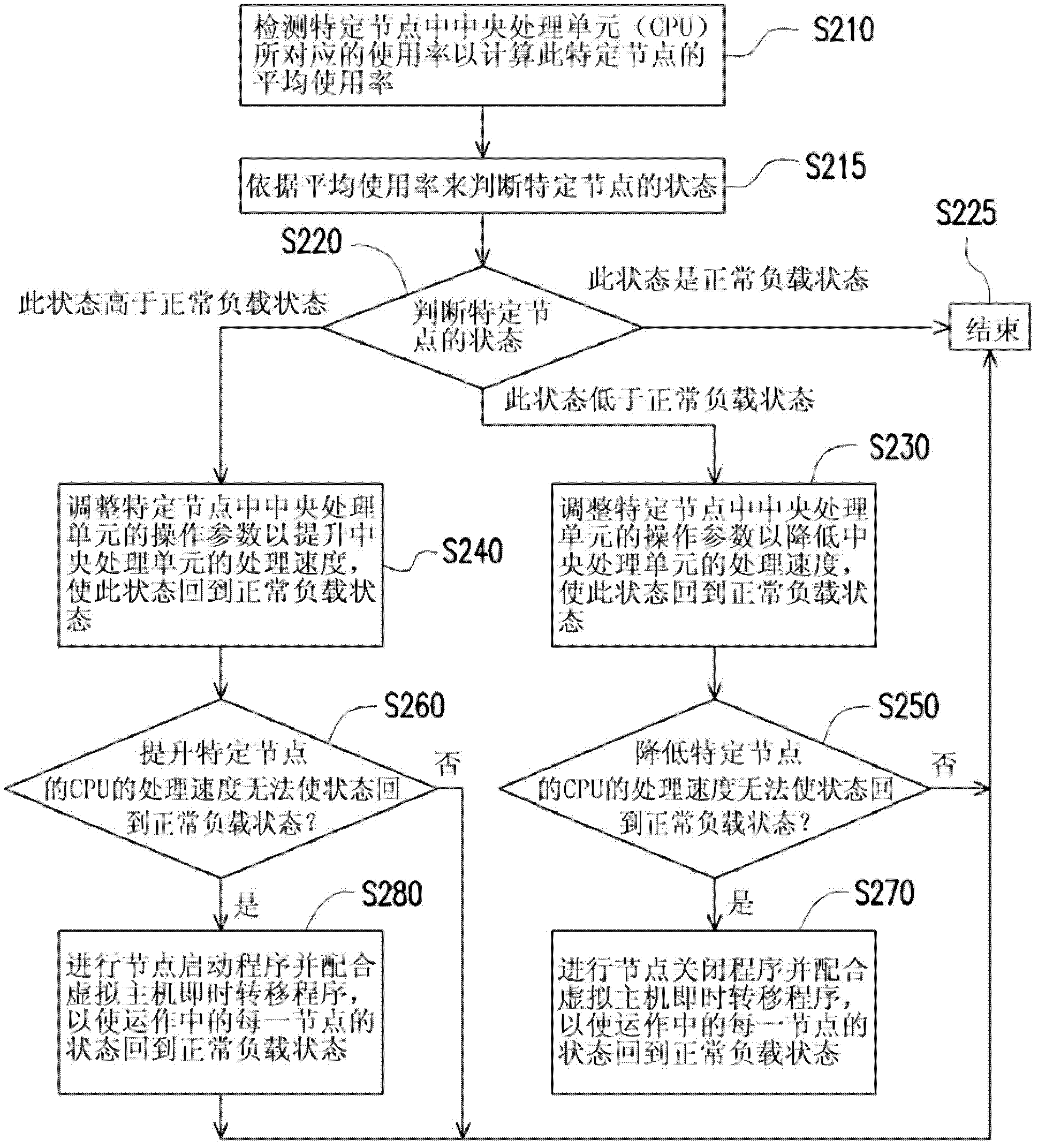

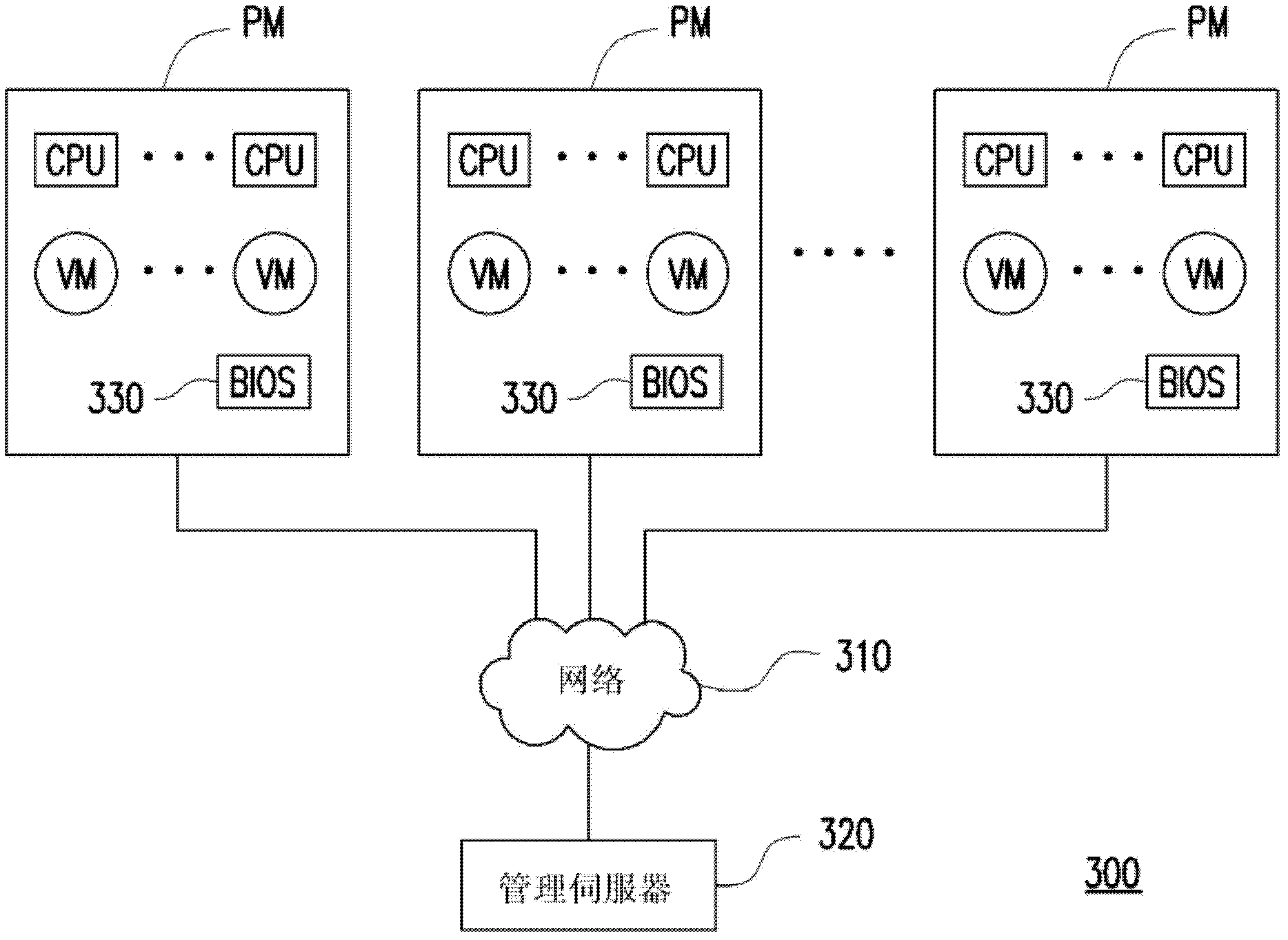

Server system and power management method thereof

InactiveCN103034539AReduce consumptionDoes not affect work efficiencyResource allocationPower supply for data processingNormal loadWork cycle

Disclosed are a server system and a power management method thereof. The power management method of the server system comprises the following steps: a usage rate corresponding to at least one central processing unit (CPU) in a specific node is detected so as to calculate an average service rate of the specific node. A state of the specific node is judged according to the average service rate. When the state is lower than a normal load state, an operation parameter of the CPU is adjusted so as to reduce processing speed of the CPU, and when the state is higher than the normal load state, the operation parameter of the CPU is adjusted so as to improve the processing speed of the CPU, and therefore the state of the specific node can be in the normal load state. According to the power management method, operating efficiency and working period of the CPU are adjusted dynamically based on the usage rate of the CPU of the specific node so that power supply consumption is saved without affecting work efficiency of a virtual host machine.

Owner:INVENTEC CORP

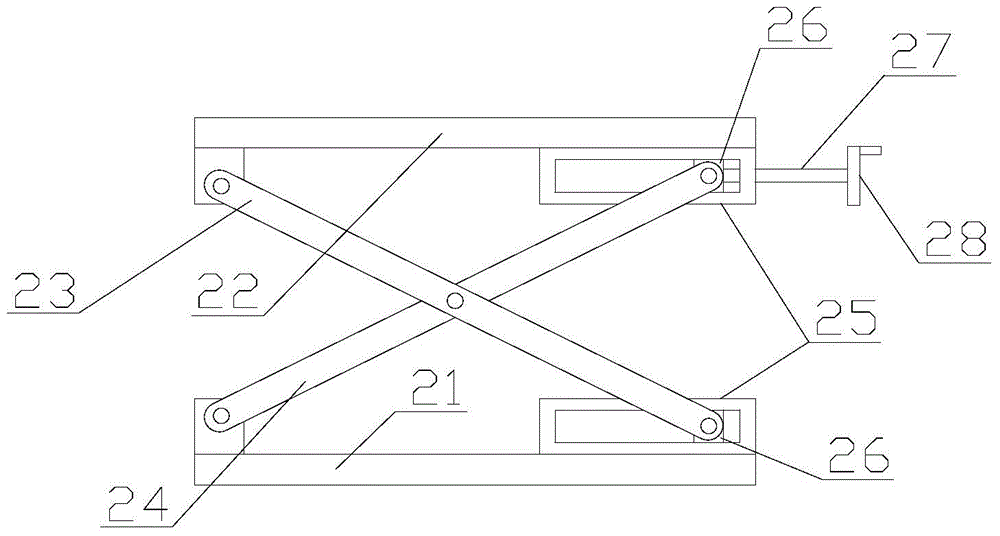

Semi-automatic separation device used for capsule production

InactiveCN105173635AAvoid the disadvantages caused by the plugboard to control the capsule flowAvoid the disadvantages of capsule flow controlConveyor partsSemi automaticEngineering

The invention discloses a semi-automatic separation device used for capsule production. The semi-automatic separation device comprises a machine frame, a lifting mechanism, a driving roller, a driven roller, a conveyor belt, an illumination lamp, a chute, a frame body, a conveying pipe and a hopper. The driving roller, the driven roller, the illumination lamp and the frame body are arranged in a rectangular cavity of the machine frame. The driving roller is in transmission connection with a motor. The driving roller and the driven roller are sleeved with the conveyor belt. The frame body is arranged over the front portion of the conveyor belt. A notch for outputting capsules is formed in the lower end of a rear frame of the frame body. The chute is arranged on the portion, below the driven roller, of the machine frame. The hopper is arranged at the front end of the machine frame. The input end of the conveying pipe is connected with the output end of the hopper. The output end of the conveying pipe is arranged in the frame body. The lifting mechanism is arranged at the bottom of a supporting body of the machine frame. Compared with the prior art, the semi-automatic capsule separation device can be conveniently used, the feeding reliability is high, the work efficiency is not influenced, the physical comfort degree is met in the operation process, and the semi-automatic capsule separation device has more user-friendly beneficial effects and is convenient to adjust.

Owner:ZHEJIANG HUILI CAPSULES

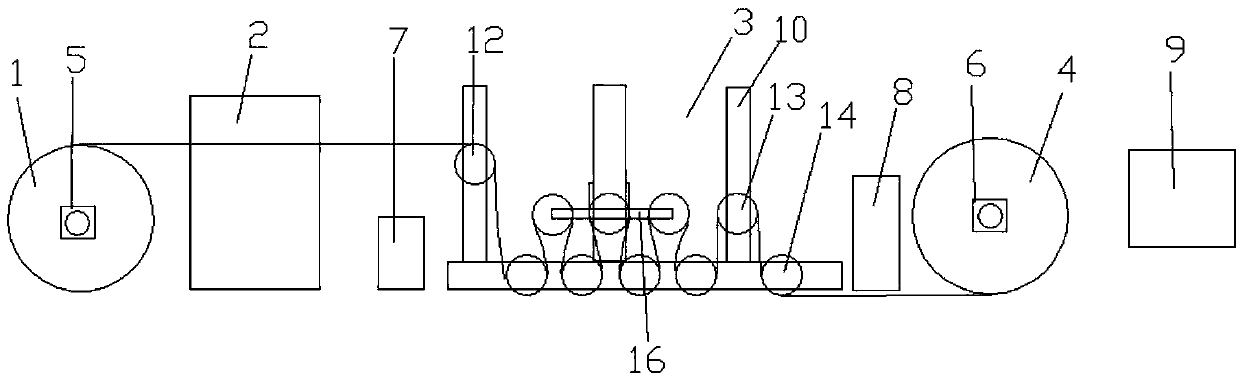

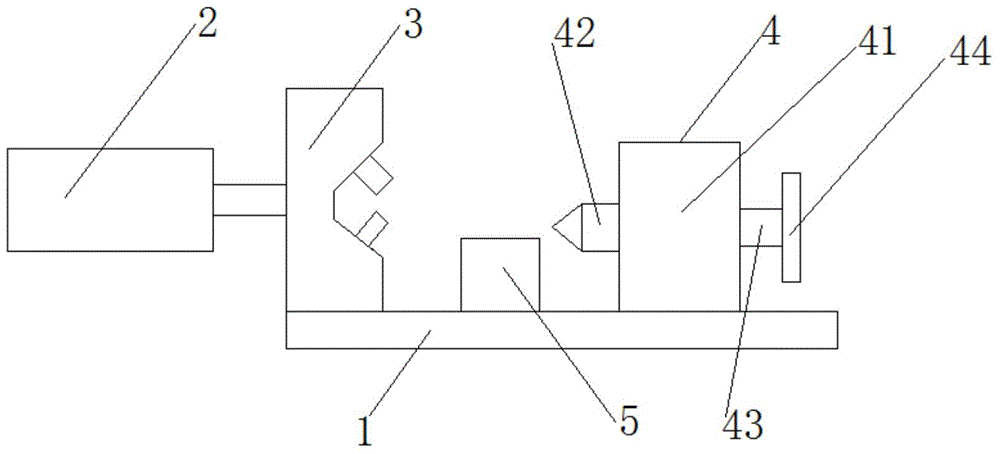

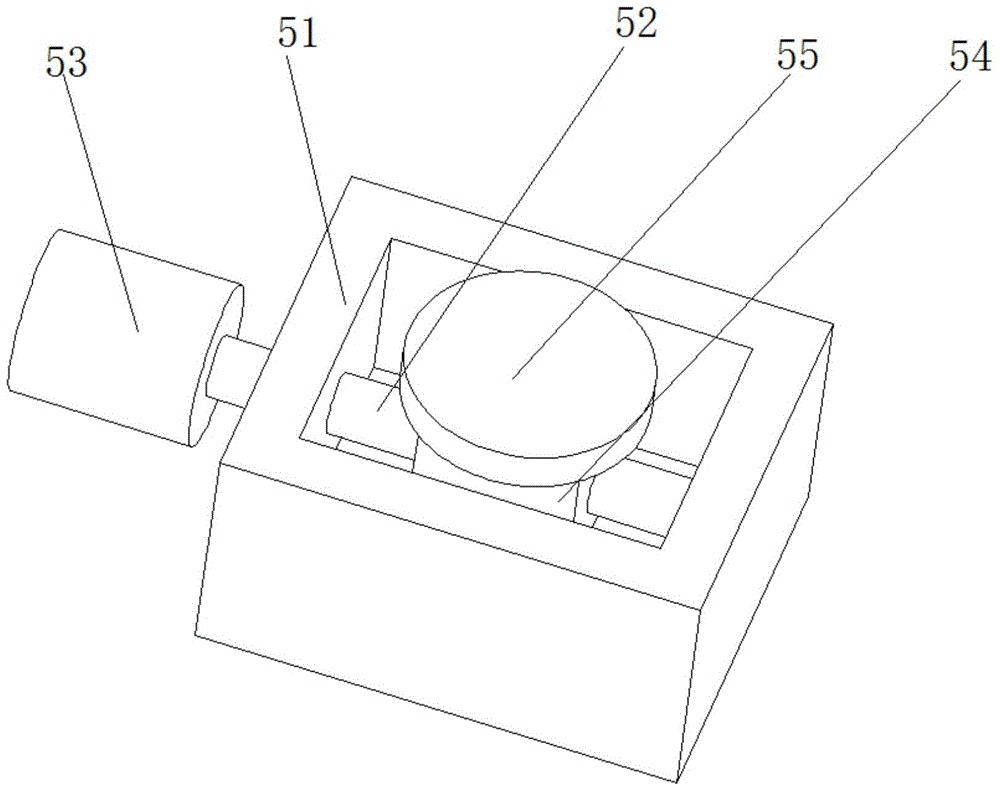

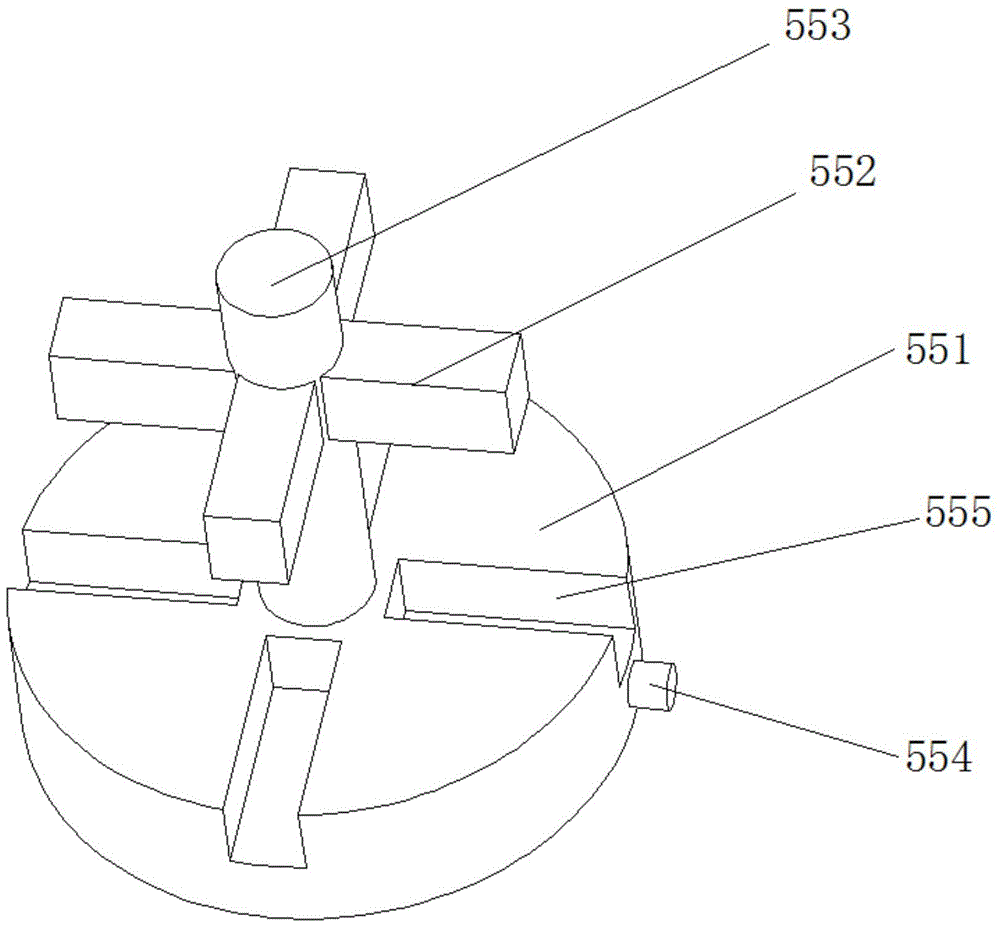

Automatic adjusting device for coating thickness of electroplated wire and adjusting method thereof

The invention discloses an automatic adjusting device for the coating thickness of an electroplated wire. The automatic adjusting device comprises an unwinding assembly, an electroplating assembly, adriving roller assembly and a winding assembly, wherein the unwinding assembly, the electroplating assembly, the driving roller assembly and the winding assembly are sequentially arranged; the unwinding assembly is driven by a first speed regulation motor; and the winding assembly is driven by a second speed regulation motor. The automatic adjusting device is characterized by further comprising acontroller; an automatic coating thickness gauge is arranged between the driving roller assembly and the winding assembly, is electrically connected to the controller and is used for uploading the actual coating thickness value of the electroplated wire wound on the driving roller assembly in real time; and the controller is electrically connected to the first speed regulation motor and the secondspeed regulation motor and is used for adjusting the transmission speed of the electroplated wire according to the actual coating thickness value. According to the automatic adjusting device for thecoating thickness of the electroplated wire, the coating thickness can be ensured to be uniform, the cost can be saved, and the automation degree is high. In addition, the invention further provides an automatic adjusting method for the coating thickness of the electroplated wire.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

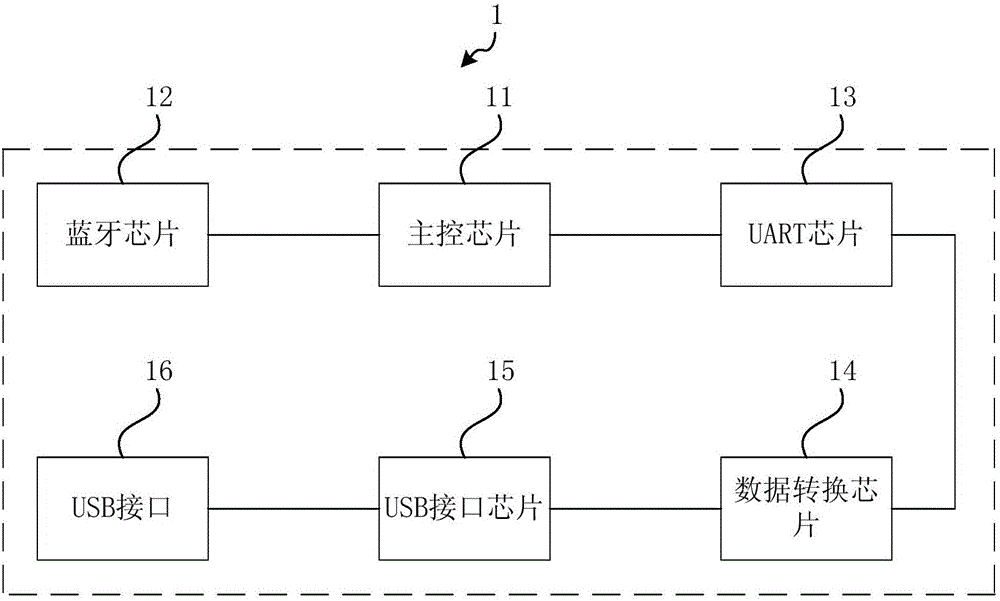

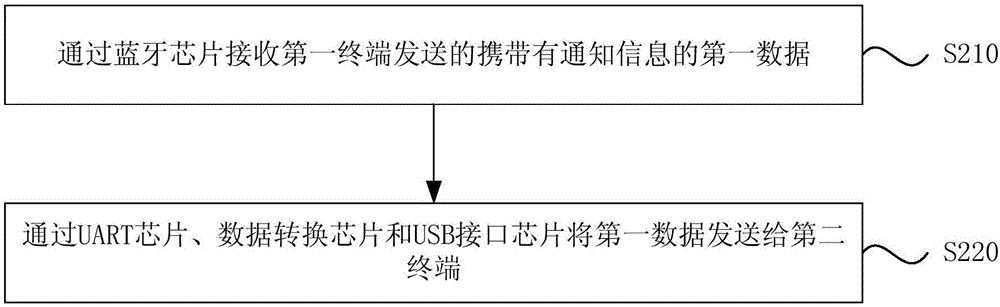

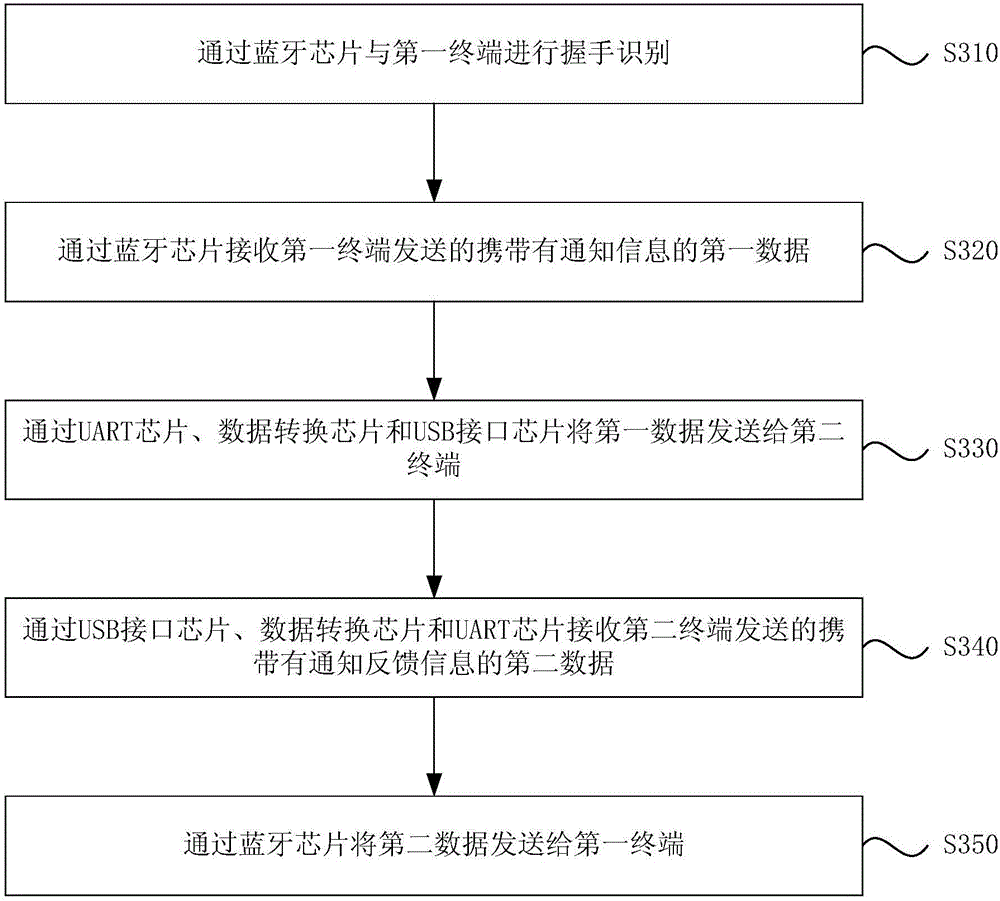

External equipment, data transmission method, device and system

InactiveCN106453906ARealize mutual data transferDoes not affect work efficiencySubstation equipmentComputer terminalUniversal asynchronous receiver/transmitter

The embodiments of the invention disclose external equipment, a data transmission method, device and system. The external equipment comprises a main control chip, a Bluetooth chip, an UART (Universal Asynchronous Receiver Transmitter) chip, a data conversion chip and a USB interface chip, wherein the main control chip is connected with the Bluetooth chip and the UART chip respectively, and the data conversion chip is connected with the UART chip and the USB interface chip respectively. The external equipment transmits data to a first terminal via the Bluetooth chip, and transmits data to a second terminal via the UART chip, the data conversion chip and the USB interface chip, thereby realizing data transmission between the first terminal and the second terminal, e.g., realizing data transmission between a smart phone and a computer under various systems; the external equipment has good compatibility, so that a user working with a computer can know notification messages received by a mobile phone without frequently viewing the mobile phone; corresponding notification feedback information can be input to the computer, so that the working efficiency of the user is not influenced; and the external equipment, which adopts Bluetooth communication and does not depend on a wifi router, is applicable to the scenes without wifi signals and low in power consumption.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

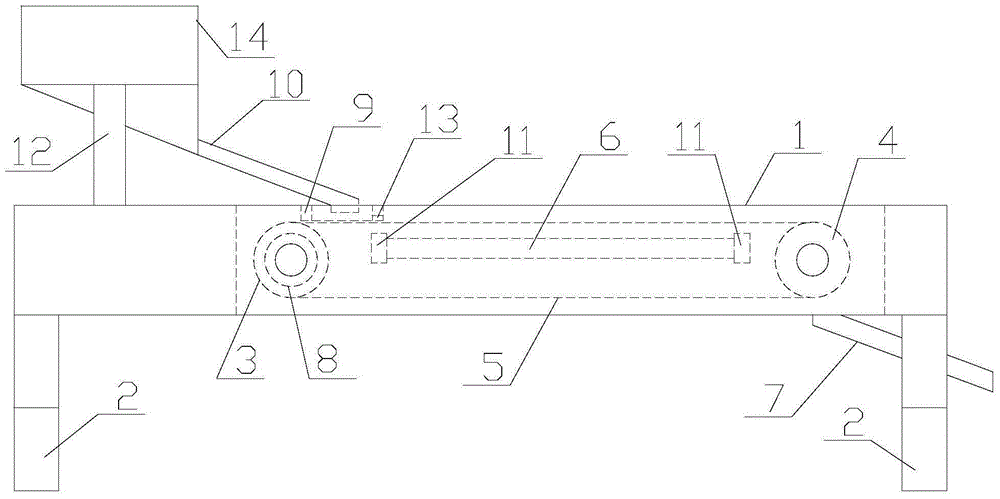

Improved sorting apparatus for capsules

InactiveCN104964988AEasy to useEasy to adjustOptically investigating flaws/contaminationSortingEngineeringMechanical engineering

The invention discloses an improved sorting apparatus for capsules. The improved sorting apparatus comprises a frame, a material feeding mechanism, a driving roller, a driven roller, a conveyer belt, an illuminating lamp, a material sliding groove, a supporting mechanism and an elevator mechanism, wherein the driving roller, the driven roller and the illuminating lamp are arranged in a rectangular cavity of the frame, the driving roller is in transmission connection with a first motor, the driving roller and the driven roller are sleeved by the conveyer belt, the illuminating lamp is arranged below the upper belt body of the conveyer belt, the frame is provided with the material sliding groove at a position below the driven roller, the bottom of a rear support of the frame is provided with the supporting mechanism, the bottom of a front support of the frame is provided with the elevator mechanism, and the front end of the frame is provided with the material feeding mechanism. Compared with the prior art, the invention has the following advantages: the improved sorting apparatus is convenient to use and reliable in feeding, does not influence work efficiency, has a high physiological comfort level in operation, is more humanized and can be easily adjusted.

Owner:ZHEJIANG HUILI CAPSULES

A freezing rain prevention, snow dissolution and freezing power transmission line

InactiveCN101241783AImprove insulation performanceDoes not affect work efficiencyOverhead installationInsulated cablesElectric power transmissionElectric power system

The present invention provides an electric power transmission line which can prevent the ice rain and the freezing of the dissolved snow. An electric heating line is arranged when the electric power transmission line (mainly the aluminum stranded wire and the aluminum cable steel reinforced and the like for overhead electric power transmission) is produced. The electric heating line coats the organic composite material which has excellent electric insulating property and high thermal conduction coefficient for replacing one or a plurality of steel wires in the aluminum cable steel reinforced and using as a bearing wire. In the normal meteorological condition, the electric heating wire has the advantages of non-conducting, no working, no effect to the operating efficiency of the electric network, no increasing the loss of the system and functioning for bearing the steel wire in the aluminum cable steel reinforced. When the heavy weathers of ice rain, snowstorm and the like occur and the electric network line is generated with ice rain, dissolve-snow freezing, the power transmission line has the advantages of supplying power for the electric heating line, providing heat to the electric transmission line through the electric heating wire, sustaining the surface temperature of the electric power transmission line above zero, melting the ice bear by the electric power transmission line, preventing the refreezing of the ice rain and the dissolved snow on the electric power transmission line and preventing the generation of the overloading accident of the circuit bearing ice. In this way, though the electric power loss of the electric network in the heavy weathers of ice rain, snowstorm and the like is increased, the safety of the electric facility is guaranteed. The normal operation of the electric facility in heavy meteorological condition is guaranteed.

Owner:尹克胜

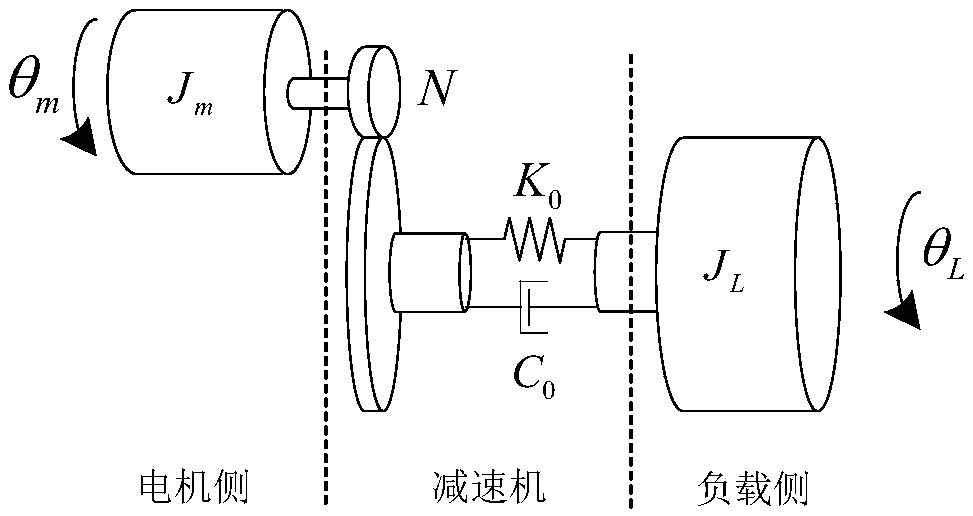

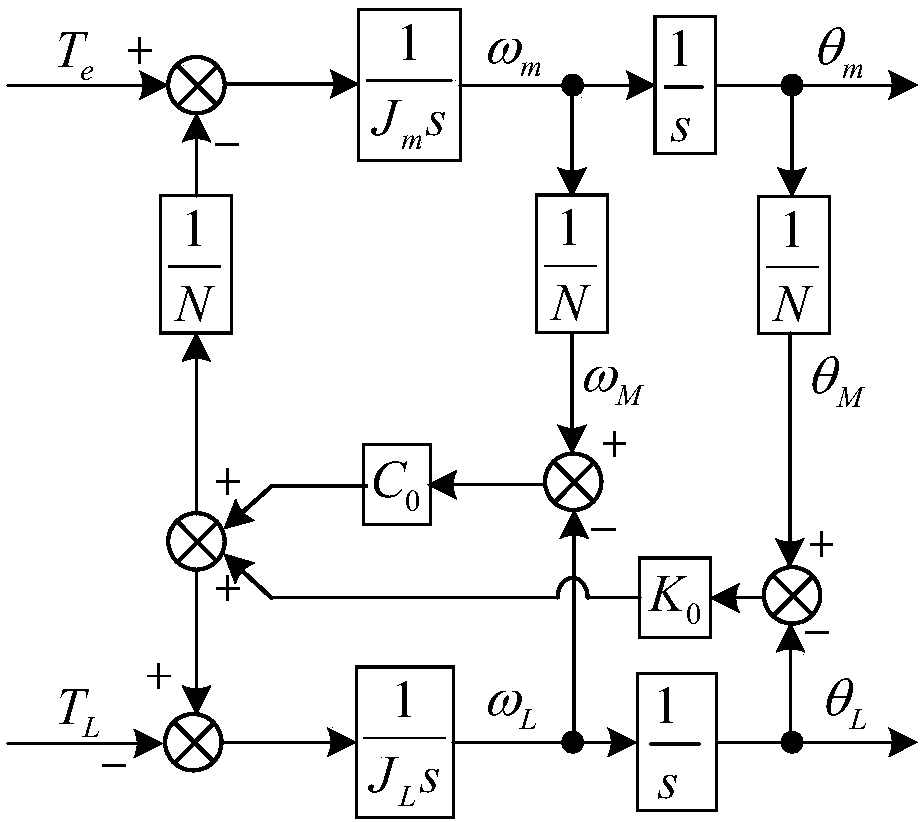

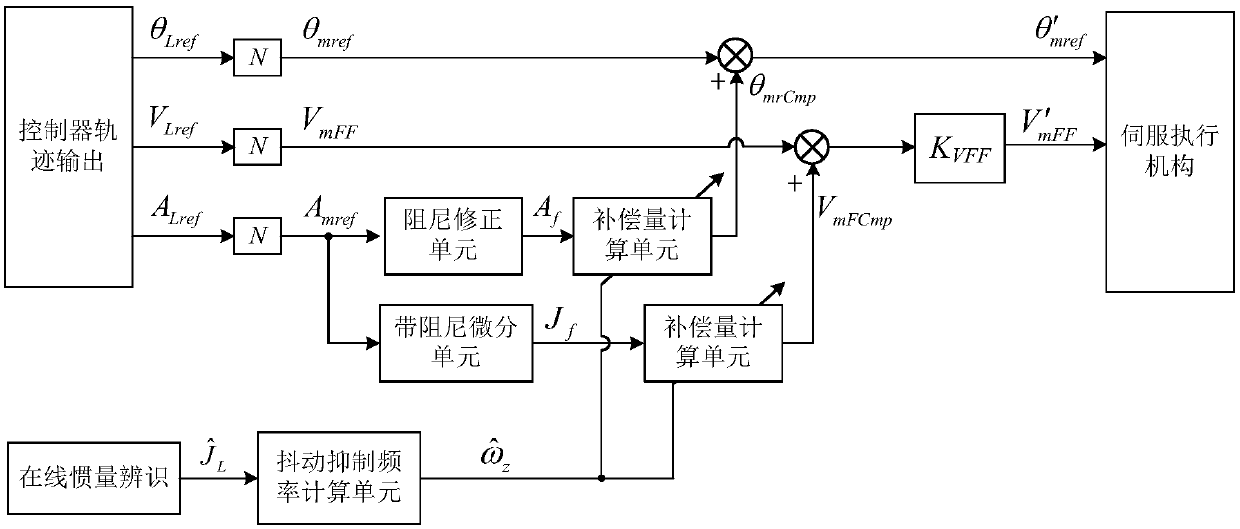

Robot jitter suppression method

ActiveCN107942680AAvoid noise effectsDoes not affect work efficiencyAdaptive controlTrajectory planningAcceleration Unit

The invention discloses a robot jitter suppression method, which is characterized in that joints of the robot are controlled separately; for each joint, a robot flexible joint part is indirectly replaced with a two-mass system; a corrected position tutoring and feed feedforward of a motor end are solved according to a two-mass system model, the solved corrected position tutoring of the motor end is used as a new position given signal of the motor end, and the solved corrected speed feedforward of the motor end is used as new speed feedforward of the motor end. According to the robot jitter suppression method provided by the invention, starting from the tutoring sent from an upper computer to the motor, using planning of the trajectory of a load end as the objective, and the original planned trajectory of the upper computer is optimized, thereby achieving the purpose of suppressing tail end jitter of the robot. At the same time, to prevent noise influence of second-order differential inan algorithm implementation process, an acceleration signal generated by the upper computer trajectory planning is utilized to realize adjustment of the position tutoring.

Owner:NANJING ESTUN AUTOMATION CO LTD

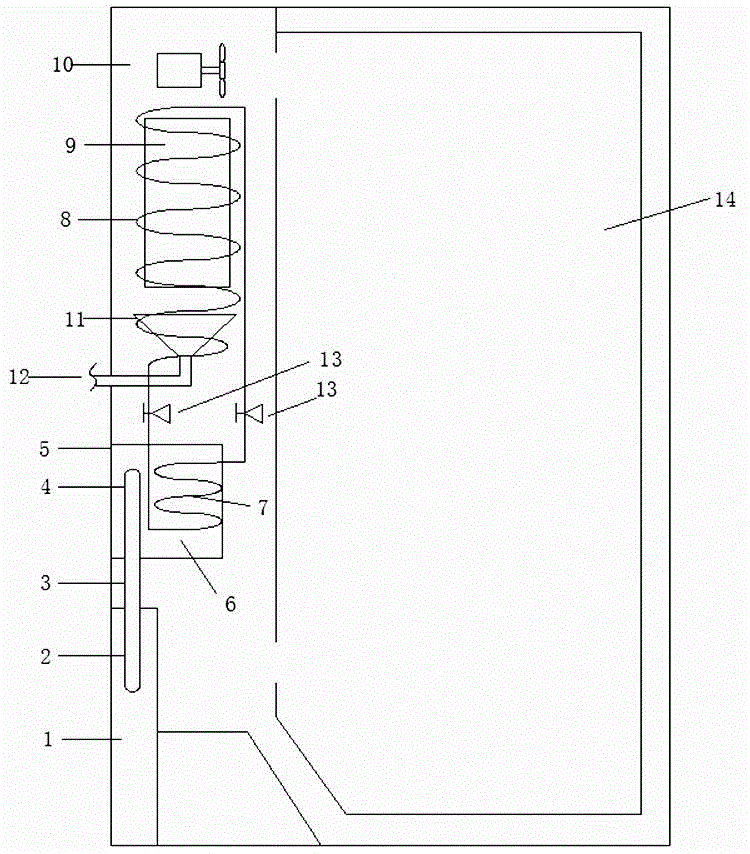

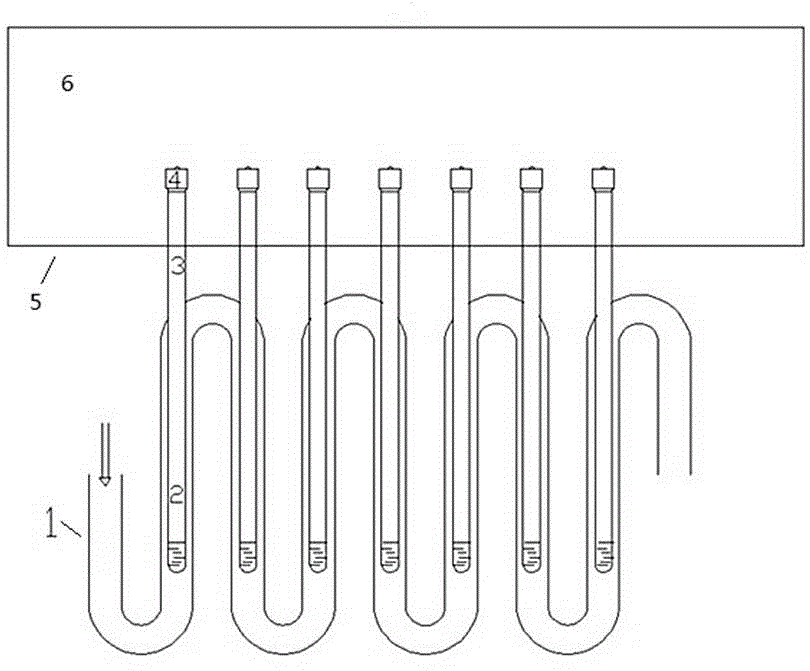

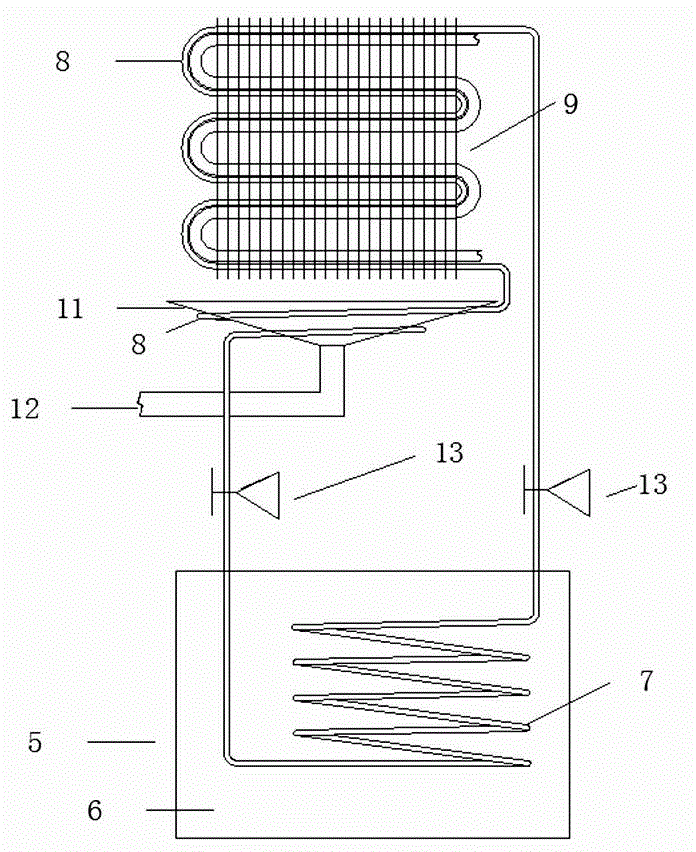

Air-cooled type refrigerator with heat pipe type heat storage and frost removal mechanism

InactiveCN104697276AReduce energy consumptionTo achieve the effect of energy saving and emission reductionLighting and heating apparatusDefrostingFrostEvaporation

The invention relates to an air-cooled type refrigerator with a heat pipe type heat storage and frost removal mechanism. The air-cooled type refrigerator comprises a refrigerator body, a condenser, an evaporator, a fan, a water receiving tray, a water drain pipe, more than one gravity assisted heat pipe and an annular heat pipe, wherein a heat storage chamber is formed in the refrigerator body between the condenser and the evaporator and is filled with a phase change heat storage material; a gravity assisted heat pipe evaporation section of each of the more than one gravity assisted heat pipe is inserted in a condenser coil of the condenser, a condensation section of each of the more than one gravity assisted heat pipe extends into the heat storage chamber and is wrapped with the phase change heat storage material; an evaporation section of the annular heat pipe is located in the heat storage chamber, one part of a condensation section of the annular heat pipe is attached to the evaporator and used for removing frost on the evaporator of the refrigerator, and the other part is attached to the water receiving tray and used for heating the water receiving tray. According to the air-cooled type refrigerator, waste heat released by the condenser is stored by the phase change heat storage material and used for efficiently removing frost on the evaporator of the air-cooled refrigerator, so that the energy consumption of the refrigerator is effectively reduced.

Owner:HEFEI UNIV OF TECH

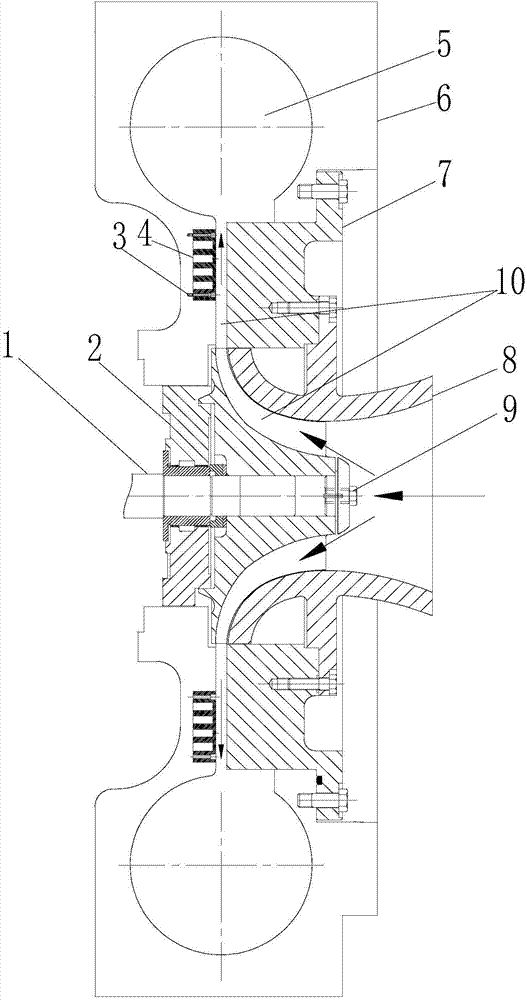

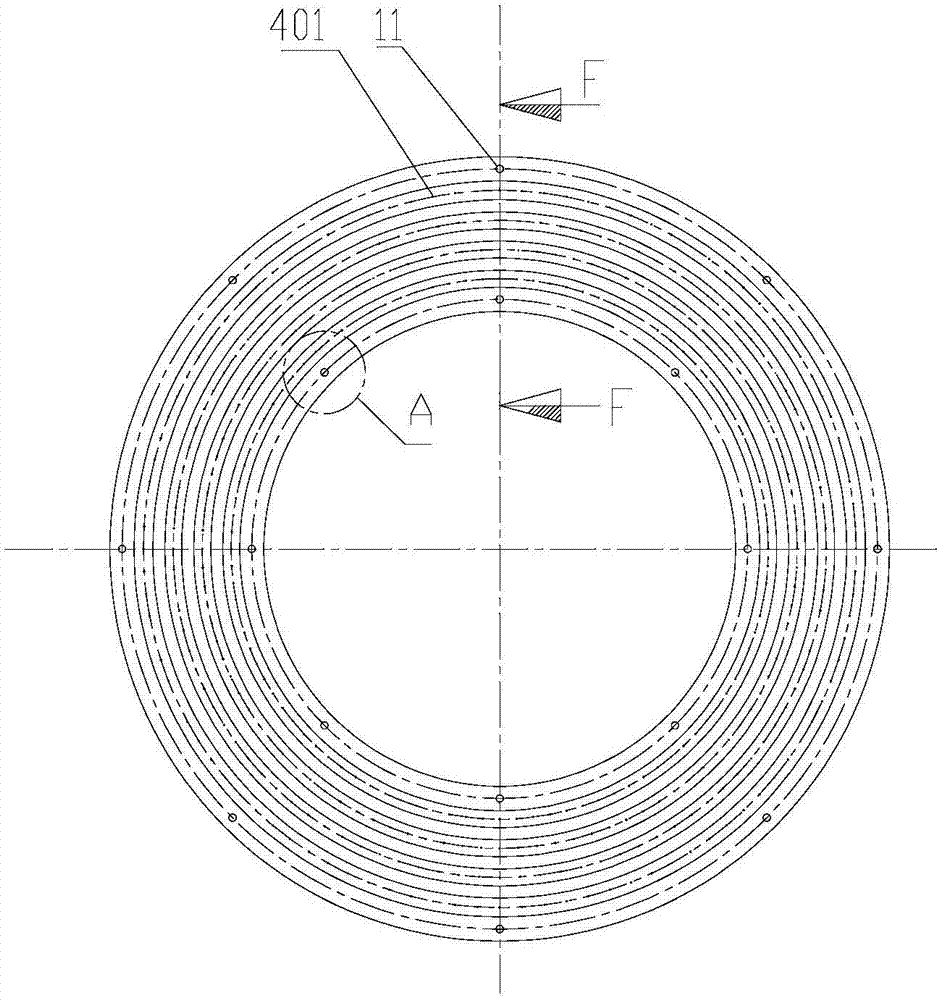

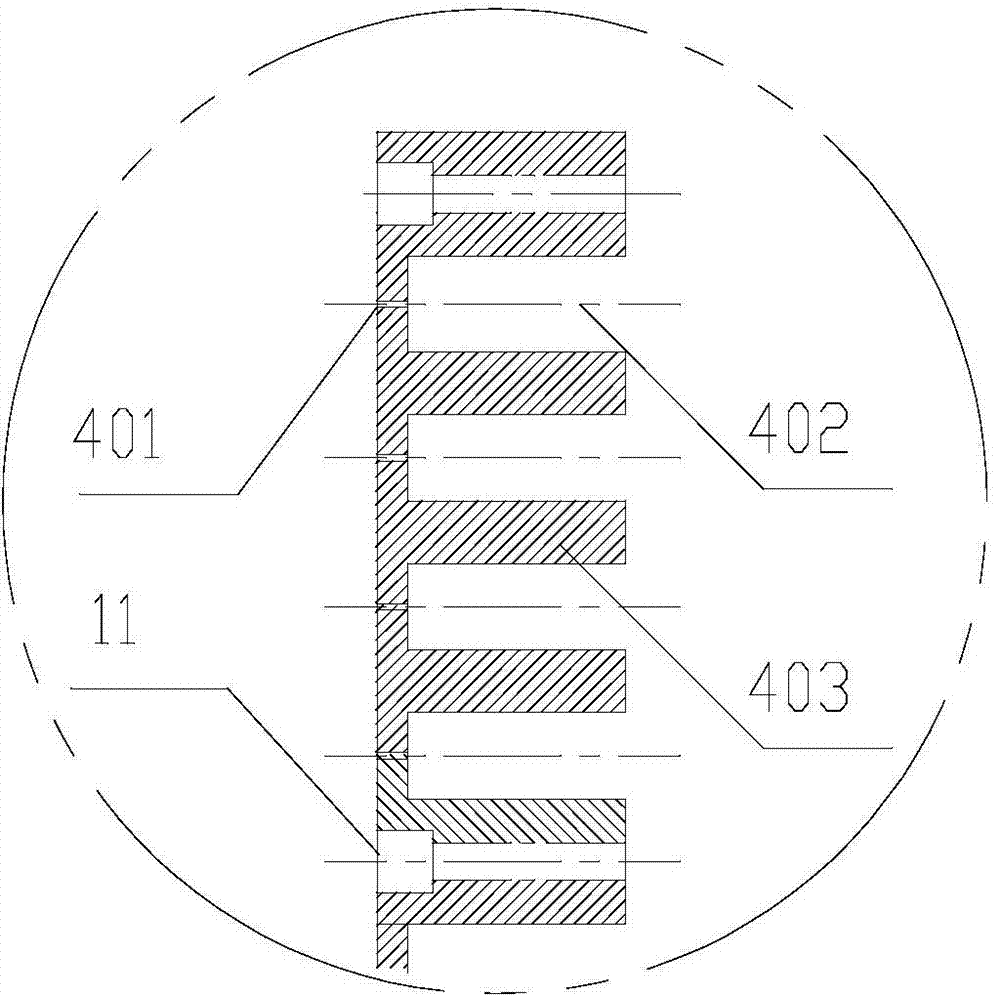

Silencer of centrifugal compressor

InactiveCN103498818AReduce noiseDoes not affect work efficiencyPump componentsPumpsEngineeringCentrifugal compressor

The invention relates to a silencer, in particular to a technology of a centrifugal compressor. The silencer of the centrifugal compressor comprises a shaft, a bearing, an impeller and an impeller cover, the shaft is arranged on a volute casing through the bearing, the tail end of the shaft is fixedly connected with the impeller, the impeller cover is arranged on the outer side of the impeller, the impeller cover is arranged on a diffuser, the diffuser is contained in the volute casing, the interior of the volute casing is hollow to form a volute casing channel, the volute casing is separated from the diffuser through an exhaust passage, the impeller cover is separated from the impeller through the exhaust passage, the exhaust passage is communicated with the volute casing channel, a porous plate is arranged on the volute casing, and the porous plate is arranged on the side wall of the exhaust passage. The silencer has the advantages that a plurality of cavity structures are formed by annular ribs in the porous plate and the volute casing, and the noise of the centrifugal compressor is greatly reduced. The silencer is simple in structure, easy to achieve and wide in applicability, and does not influence the overall working efficiency of the centrifugal compressor.

Owner:乐金空调(山东)有限公司

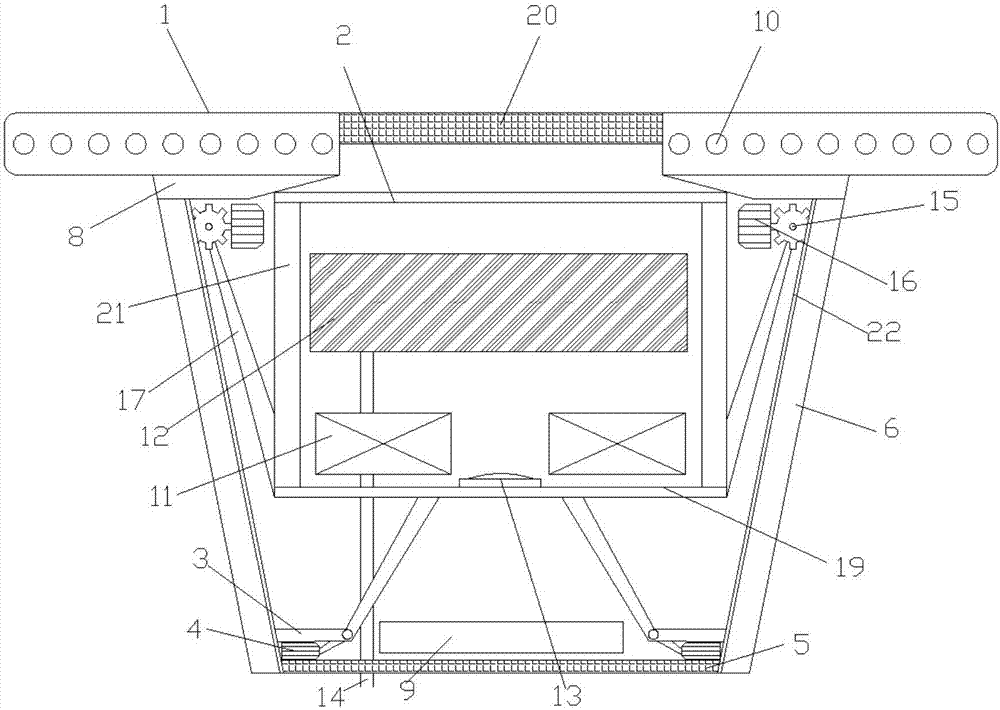

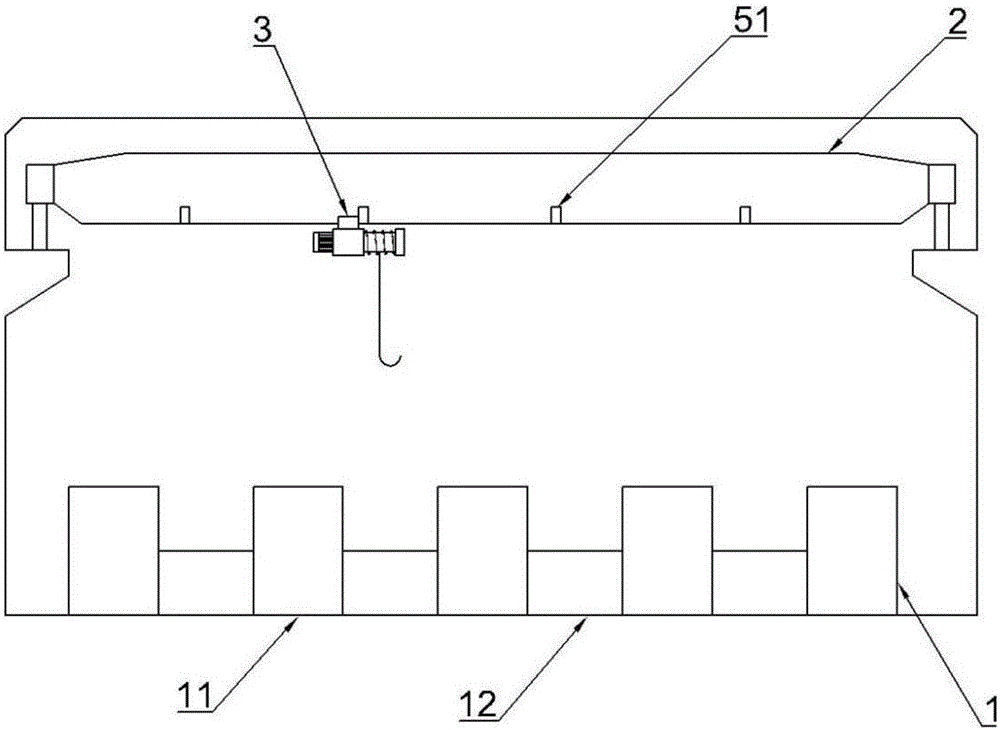

Air conditioner indoor unit hidden in round table

InactiveCN107314442ADoes not affect work efficiencySpace heating and ventilation safety systemsLighting and heating apparatusAir volumeEngineering

The invention discloses an air conditioner indoor unit hidden in a round table. The air conditioner indoor unit comprises a rotary round table board, a supporting column and an air conditioner indoor unit body. The rotary round table board is installed on the supporting column. The air conditioner indoor unit body is arranged in the supporting column. A rotation mechanism is arranged below the rotary round table board. An air inlet is formed in the bottom of the supporting column. An air outlet lifting plate is arranged in the center of the rotary round table board. An air outlet is formed in the air outlet lifting plate. A limiting ring is arranged on the periphery of the bottom of the air outlet lifting plate. A lifting platform is arranged in the supporting column. According to the air conditioner indoor unit hidden in the round table, light induction coils on the periphery of the rotary round table is used for inducing the number of people, and the rotation mechanism rotates to drive the lifting platform to ascend or descend, so that the distance between the air conditioner indoor unit body and the air outlet as well as the distance between the air conditioner indoor unit body and the air outlet are controlled, regulation and control over the air volume and the ventilation volume are achieved, the air conditioner indoor unit and the round table are integrated, and while the attractiveness is achieved by hiding the air conditioner indoor unit in the round table, the working efficiency of an air conditioner is not affected.

Owner:SHENZHEN WOHAISEN TECH CO LTD

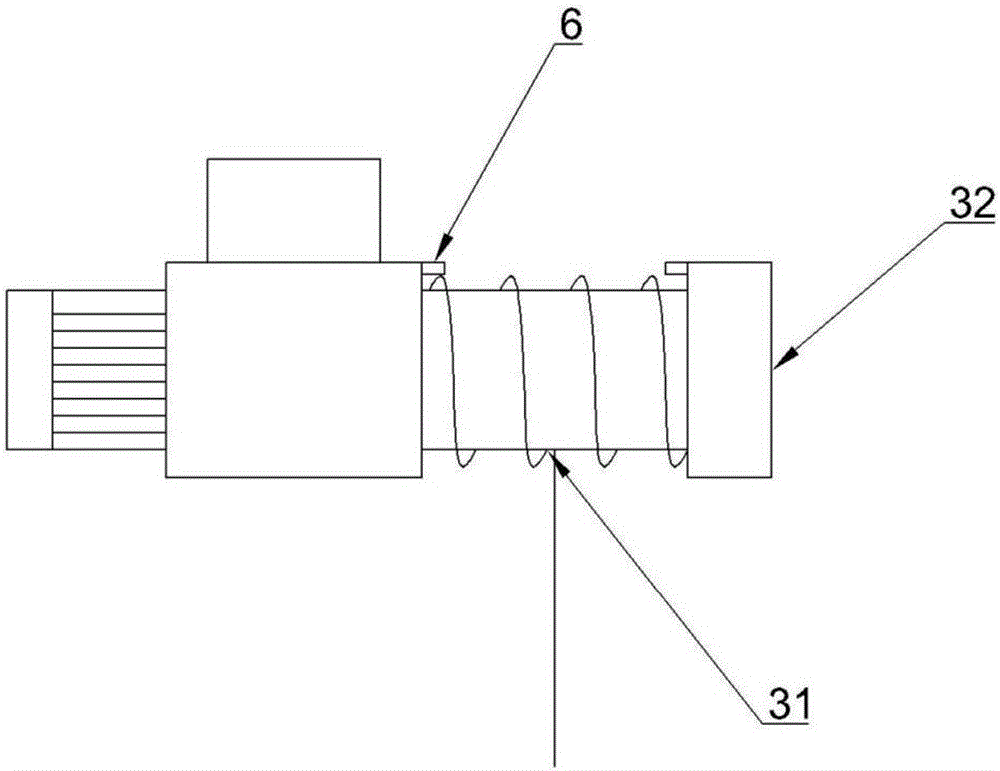

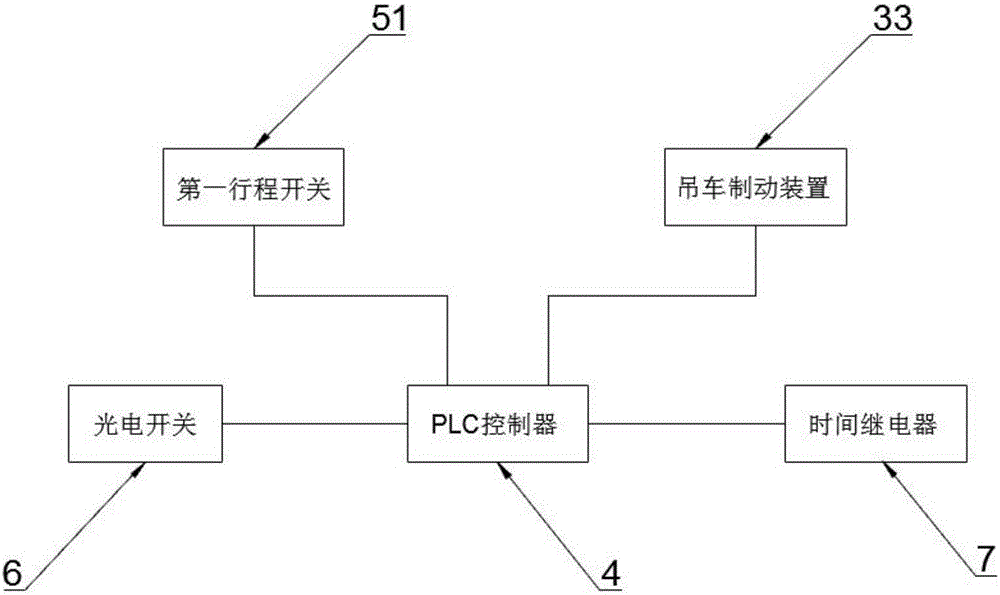

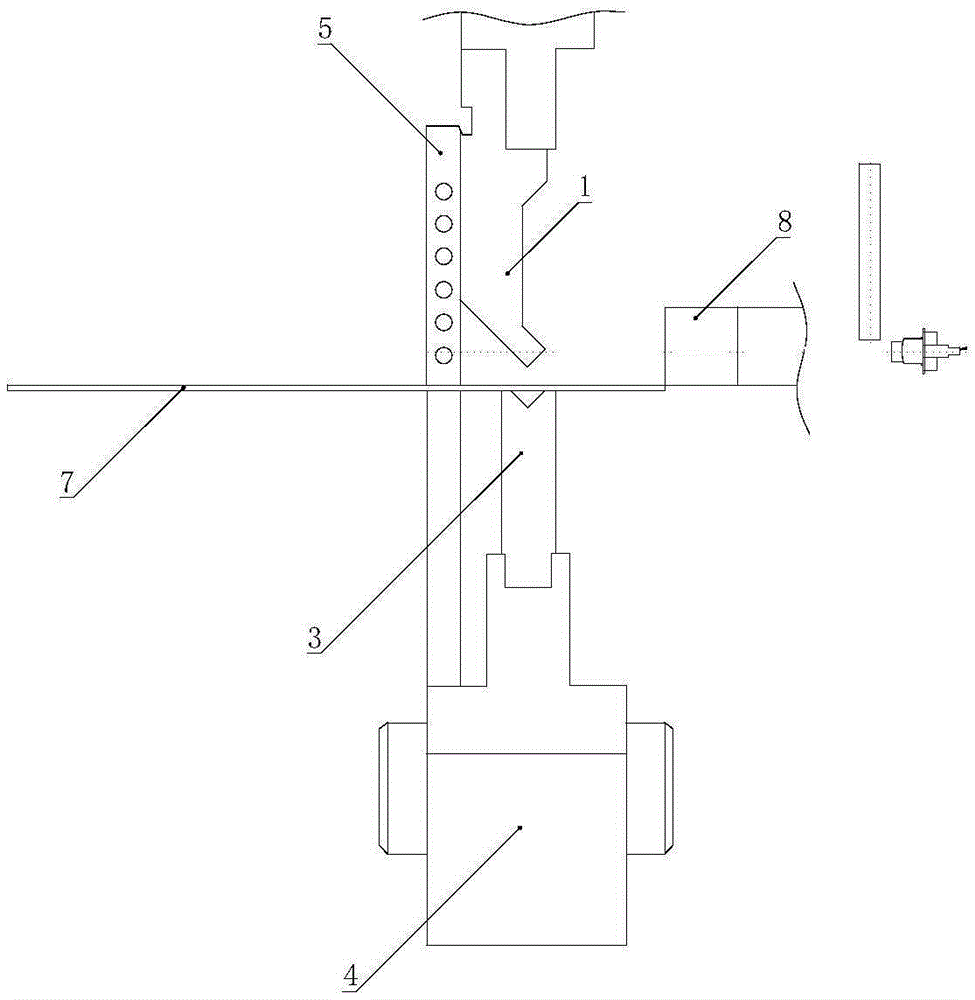

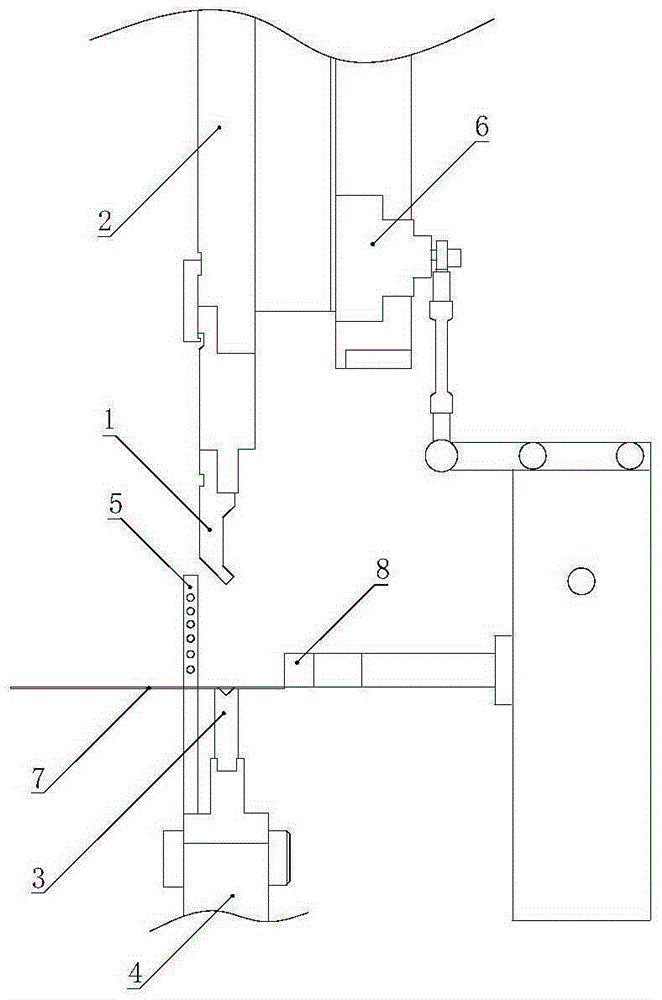

Aluminum profile surface treatment bath solution stability control system and control method thereof

ActiveCN106319595AWaste liquid treatment is simpleReduce pollutionAnodisationCellsSurface finishingTreatment system

The invention discloses an aluminum profile surface treatment bath solution stability control system and a control method thereof and relates to the technical field of aluminum profile production equipment. The aluminum profile surface treatment bath solution stability control system comprises a surface treatment system formed by sequentially arranging a plurality of process tanks in a line, a trolley track which is arranged above the surface treatment system in parallel, a crane which is driven by a power mechanism and can walk on the trolley track and a PLC controller; a water liquid tank is also formed between every two process tanks; first travel switches for determining the stopping position of the crane are also arranged on the trolley track; and the first travel switches are arranged above the water liquid tanks and are connected with a crane braking device and the PLC controller respectively. According to the aluminum profile surface treatment bath solution stability control system, the addition quantity of a medicine and water consumption of a material per ton can be effectively lowered.

Owner:南京鸿发有色金属制造股份有限公司

Numerical control bending machine with smart safety light curtain and safety protection device and method

ActiveCN105234312AProtection securityFix bugsShaping safety devicesNumerical controlMechanical engineering

The invention discloses a numerical control bending machine with a smart safety light curtain and a safety protection device. The numerical control bending machine comprises an upper die, a sliding block, a lower die, a work table and the safety light curtain, wherein the upper die is arranged on the sliding block, the lower die is arranged below the upper die and is located on the work table, and the safety light curtain is arranged on the work table. The numerical control bending machine further comprises a linear displacement sensor or an angular displacement sensor. The sliding block is provided with the linear displacement sensor used for directly measuring the movement speed, direction and position of the sliding block or is provided with the angular displacement sensor used for indirectly measuring the movement speed, direction and position of the sliding block. According to the invention, the defects of common safety light curtains special for bending machines in the market are overcome, the safety of operation personnel can be protected in the bending process, and the work efficiency will not be influenced. In addition, the numerical control bending machine is simple in structure and highly practical.

Owner:GUANGZHOU XINYUE CNC CO LTD

Cutting device for thread cutting

ActiveCN104942383ASimple structureIncrease usageThread cutting auxillary apparatusTool bitEngineering

The invention provides a cutting device for thread cutting. The cutting device comprises a rack and a movable mechanism. The movable mechanism is connected with the rack. The movable mechanism can slide on the rack. The movable mechanism comprises a rotating mechanism which is installed on the movable mechanism and used for switching thread cutting tools and repairing threads. The cutting device is simple in structure and convenient to operate, tool blades in the cutting device can be replaced easily, and different threads can be produced by replacing the different tool bits; burrs on the surfaces of the threads can be repaired, the tool blades which conduct polishing many times can be used for many times only by adjusting a three-rod positioner, and the utilization rate of the tool blades is increased.

Owner:XIANGSHAN HUAYANG MACHINE TOOL ACCESSORIES FACTORY

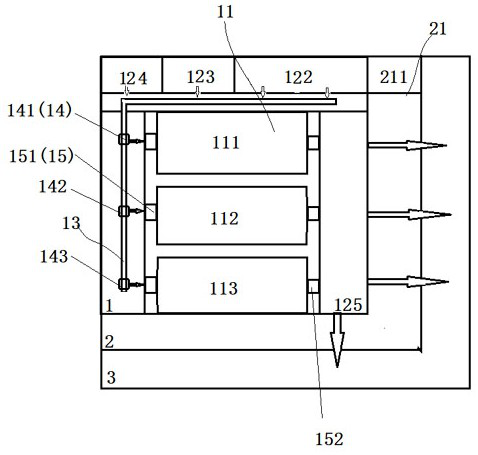

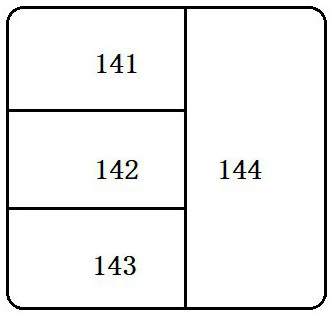

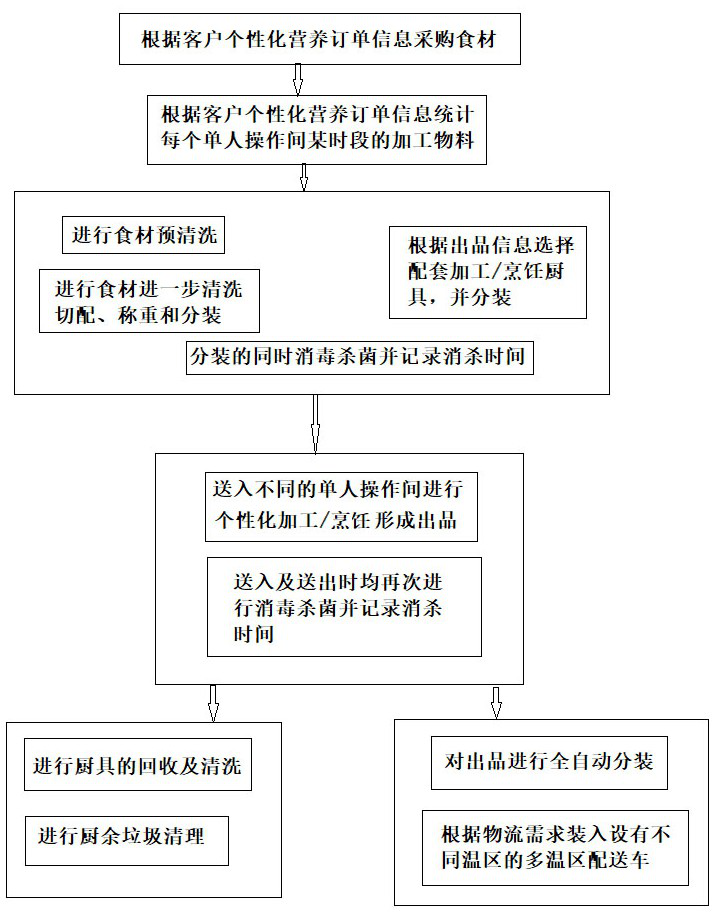

Personalized customized central kitchen capable of accurately tracing and management method thereof

ActiveCN111681135ADoes not affect the stable, safe and clean stateGuaranteed personalized and flexible operationDeodrantsBuying/selling/leasing transactionsPersonalizationProcess engineering

The invention relates to a personalized customization central kitchen capable of accurately tracing and a management method thereof. A clean area capable of reaching the food processing safety standard is adopted; air in the single-person operation room is not communicated with air in an external automatic processing space; an operator does not need to wear protective clothing or monkey clothing when entering a single-person operation room; when most of the products are cooked, operators only need to prove that the products are healthy people under the strictest food and health quarantine requirements at the moment and then carry out conventional disinfection and sterilization; the stable, safe and clean state except for a single-person operation room is not affected, personalized flexibleoperation of operators can be fully guaranteed, and personalized education live broadcast, feeding and breeding and other work can be conveniently carried out. And all articles entering and exiting the single-person operation room can be subjected to disinfection operation and disinfection time is recorded before entering, the single-person operation room and operators for producing products canbe accurately traced, and accurate tracing to seconds and individuals is realized on the basis of fully ensuring the processing safety.

Owner:北京德润良品健康科技有限公司

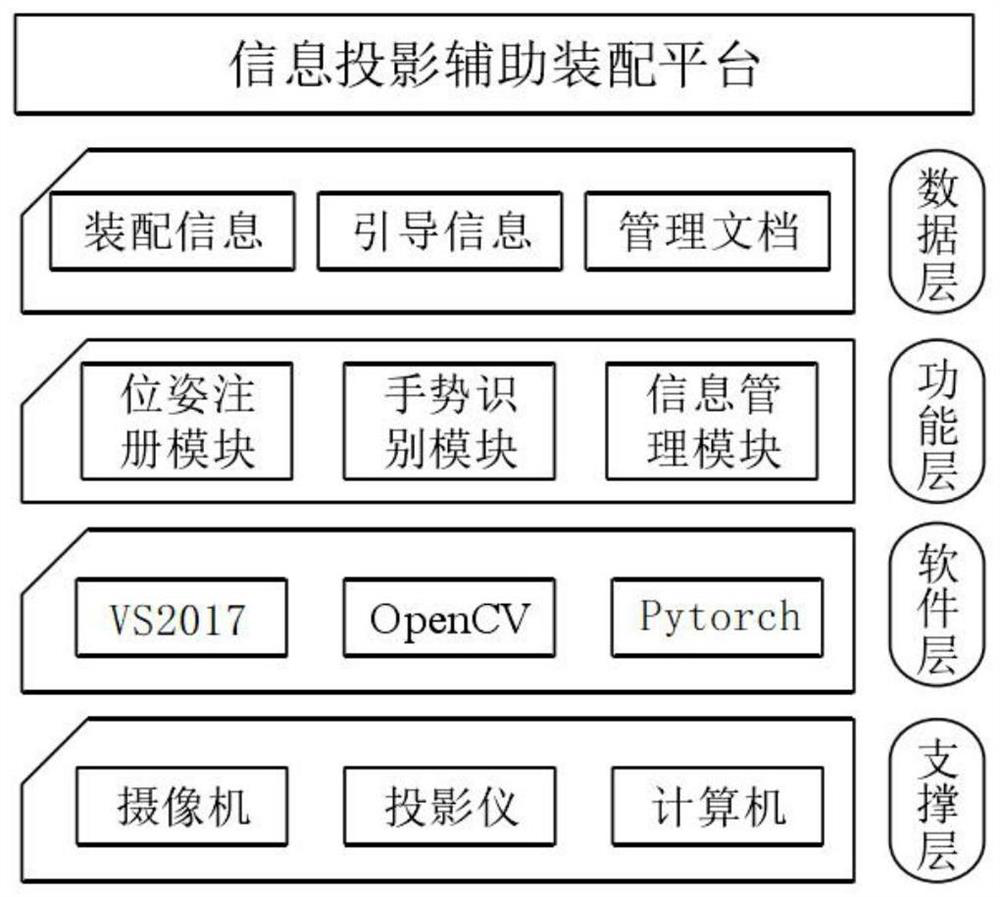

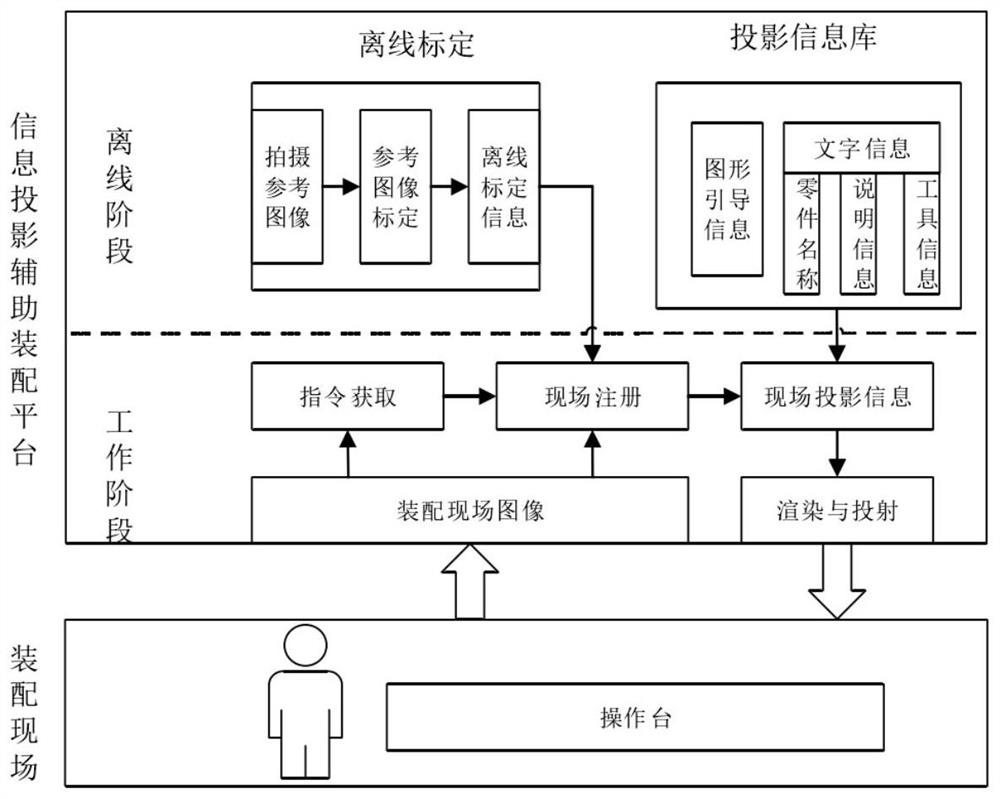

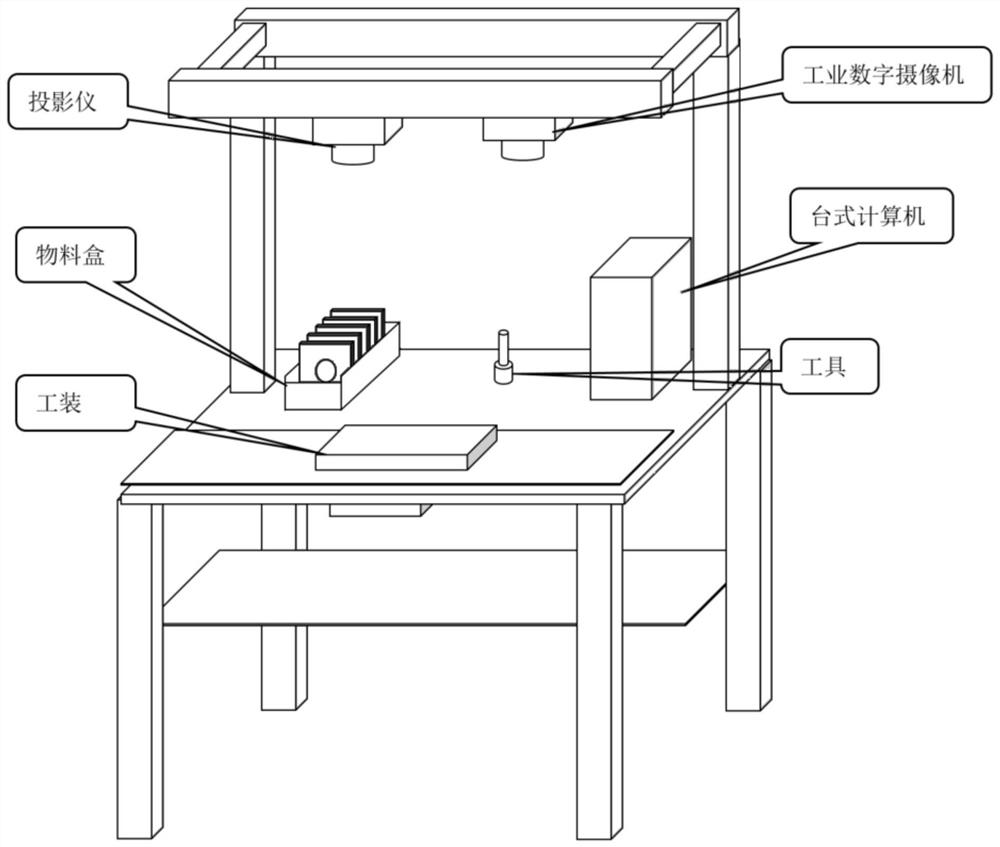

Projection type operation guiding method and system

PendingCN113393535ADoes not affect work efficiencyGuaranteed pass rateInput/output for user-computer interactionImage analysisMixed realitySimulation

The invention discloses a projection type operation guiding method and system, relates to the technical field of augmented reality, and aims to solve the problems that according to an existing assembly guiding method, a virtual assembly scene needs to be constructed, then virtuality and reality are fused through mixed reality equipment, and finally assembly guiding needs to be achieved by means of wearable equipment,the immersion feeling is realized, however, the burden of an operator is invisibly increased, so that the information auxiliary assembly platform comprises: an information auxiliary assembly platform and a data layer; a functional layer; a software layer; and a support layer. According to the invention, man-machine interaction is realized in a projection mode, and the working efficiency of operators is not affected; according to the invention, a large amount of operation process information can be collected, and product tracing, information system display, assembly process optimization and the like can be served; and according to the invention, the gesture state of the operator is captured in real time, so that the qualified rate of finished products can be ensured, and the loss is reduced.

Owner:SHENZHEN INST OF ARTIFICIAL INTELLIGENCE & ROBOTICS FOR SOC

Multi-column strip vertical packing machine

ActiveCN103287630AIncrease productivityLow costPackaging automatic controlStructural engineeringElectrical and Electronics engineering

The invention relates to a packing machine which comprises a framework, a film supply device, a film feeding device, a feeding hopper, a plurality of collar forming devices, a horizontal sealing device, a plurality of vertical sealing devices, a slitting device, a detection device and a separation device. The horizontal sealing device comprises two upright guide rails, two sliders, two cylinders, two touch cylinders, front pressing pieces, rear pressing pieces and a support, and the two sliders are matched with the guide rails; the two sliders are respectively mounted on the two guide rails, and inner sides of the two sliders are fixedly connected with the support; outer sides of the two sliders are respectively connected with telescopic arms of the two cylinders, the front pressing pieces are fixedly mounted on telescopic arms of the two touch cylinders, and the two touch cylinders are fixedly mounted on the front side of the support. The packing machine in a multi-column design has the advantages that the production efficiency is greatly improved, a mechanical structure is simplified, and the product percent of pass is guaranteed owing to the additional detection device and the additional separation device.

Owner:瑞派克智能包装科技(昆山)有限公司

Power-off protection method and device

InactiveCN106207971ADoes not affect work efficiencyEmergency protective circuit arrangementsComputer moduleEngineering

The invention discloses a power-off protection method and device, relates to the technical field of power-off protection, and aims at solving the problems that control of the prior art is inaccurate and the reliability is low. The power-off protection method comprises the steps as follows: power interruption information of a motor is continuously monitored through a power-off protection module; when the power interruption duration is smaller than 80ms, the power-off protection module does not start protection and the motor normally works after being powered up; when the power interruption duration is greater than 80ms, the power-off protection module starts protection, the motor does not work after being powered up, and the power-off protection module returns to initialization; and if a motor switch is in an off state, the motor does not work and the motor can be started by turning off the motor switch and then turning on the motor switch. By the power-off protection method and device, whether the motor is normally powered off or abnormally powered off can be accurately judged; the work efficiency is not affected; and the power-off protection method and device are safe and reliable.

Owner:PANAN JIARUN ELECTRICAL APPLIANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com