Cutting device for thread cutting

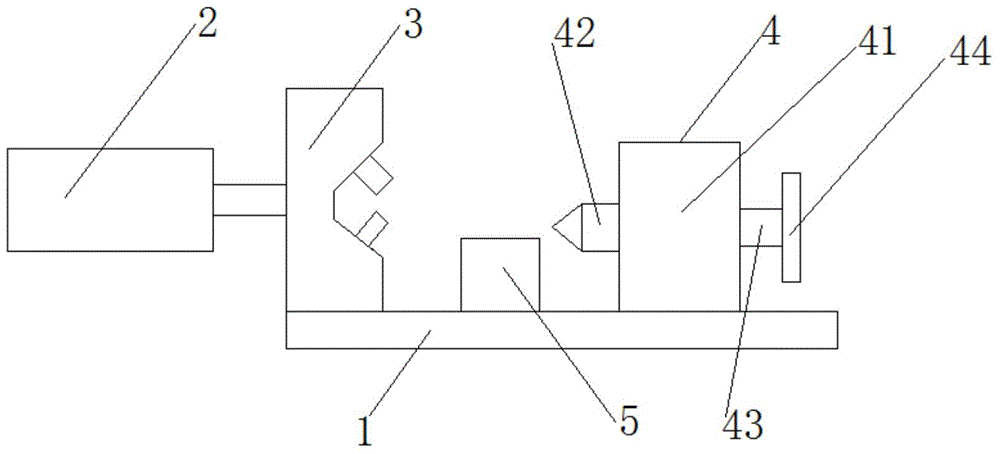

A cutting device and thread cutting technology, applied in the direction of thread cutting auxiliary equipment, tangent device, metal processing equipment, etc., can solve the problems of difficult assembly, troublesome tool replacement, burrs in threads, etc. rate, operational effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

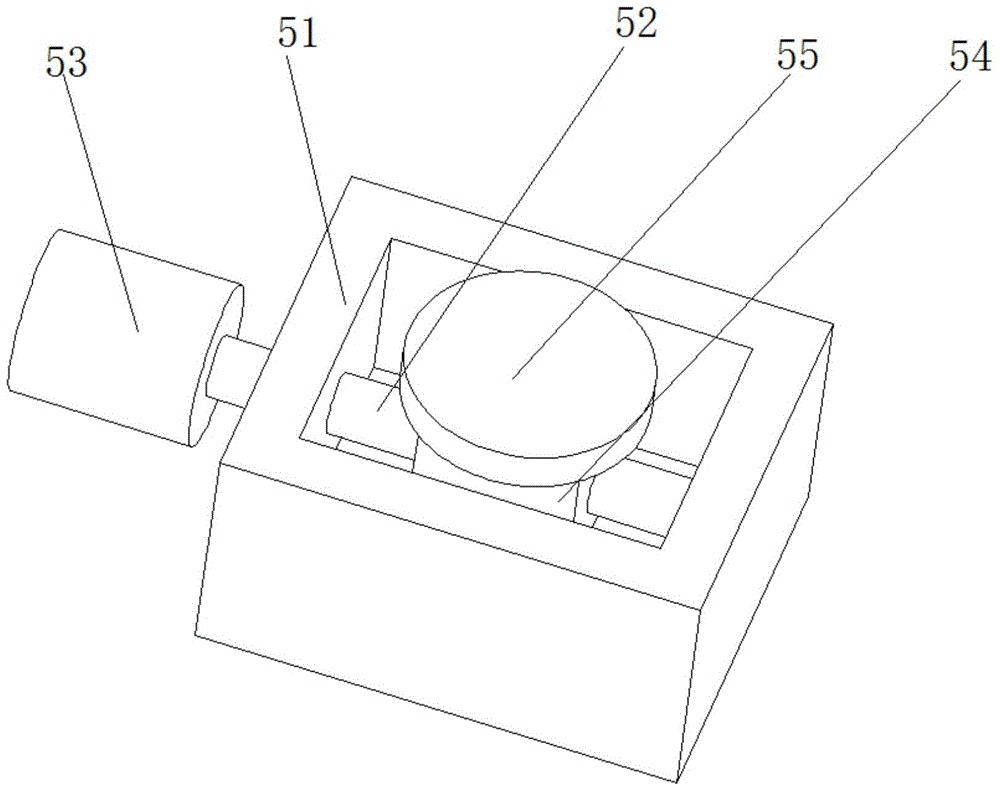

Method used

Image

Examples

Embodiment 1

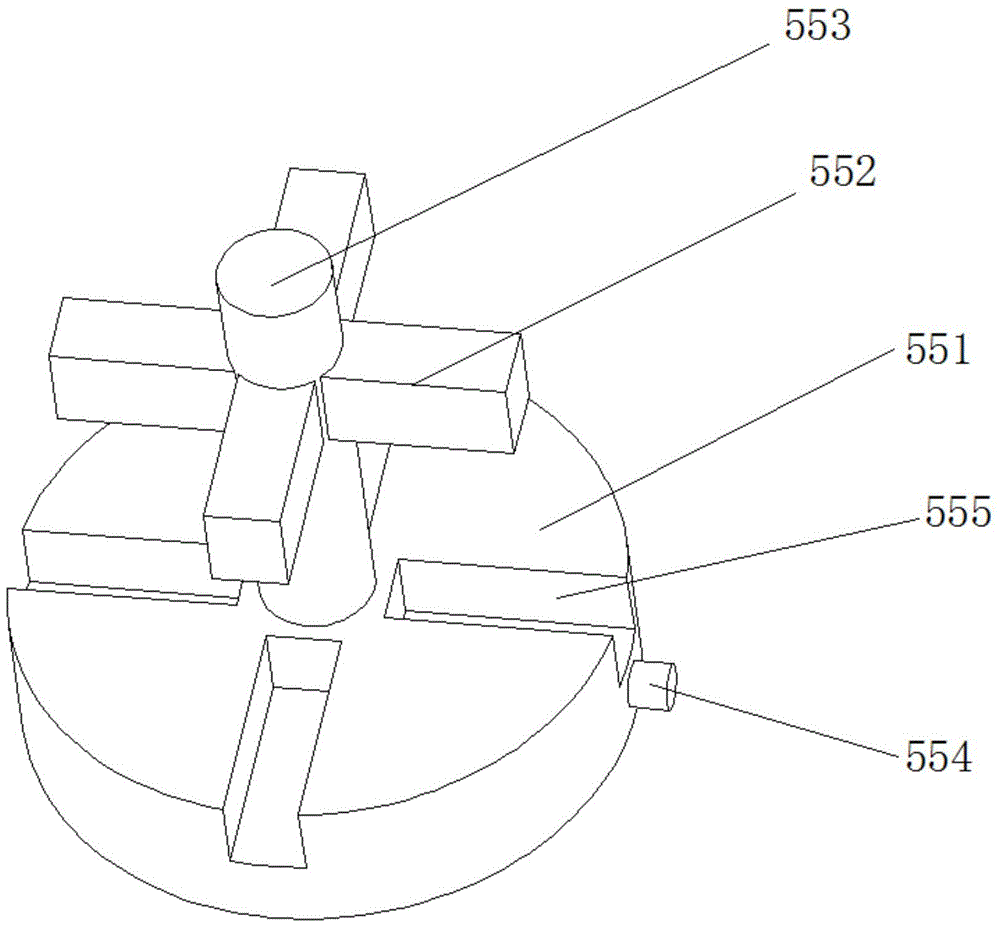

[0043] As the above-mentioned cutting device, the present embodiment is different from it in that, refer to Figure 5 As shown, it is a schematic structural diagram of Embodiment 1 of the cutting device for thread cutting according to the present invention. The cutting device also includes a detection unit 6, which is installed on the movable mechanism 5 to detect The depth of each thread on the workpiece, because the thread cutter will vibrate during the feed of the thread cutting, mainly due to the vibration of the motor in the machine tool, and after the cutting tool is used many times, the cutting edge will The given depth will change, so that the cutting depth of each thread will be inconsistent, which will make it difficult to connect the workpiece threads. Although the above-mentioned three-bar positioner 5523 can be used to adjust, because it is manually adjusted, it is always difficult. There will be deviations, so it is difficult to achieve the consistent cutting dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com