Vertical dual-sided CCD line scanning automatic detection platform for PCB (Printed Circuit Board)

A PCB circuit board and automatic detection technology, which is applied in the direction of optical testing defects/defects, can solve the problems of cumbersome mechanism, low inspection efficiency, high mechanism cost, etc., and achieve the effect of improving use stability, long service life, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawings:

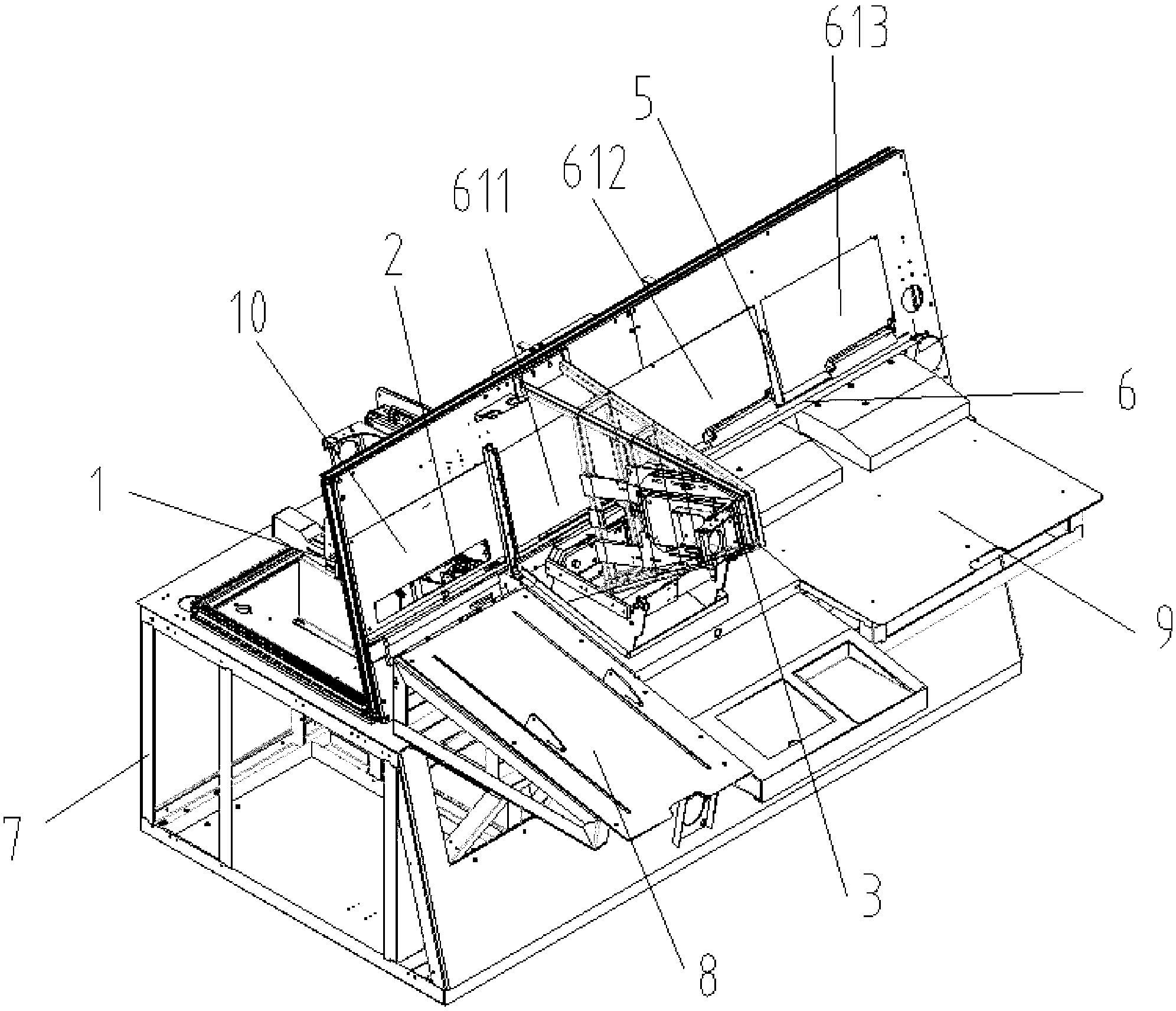

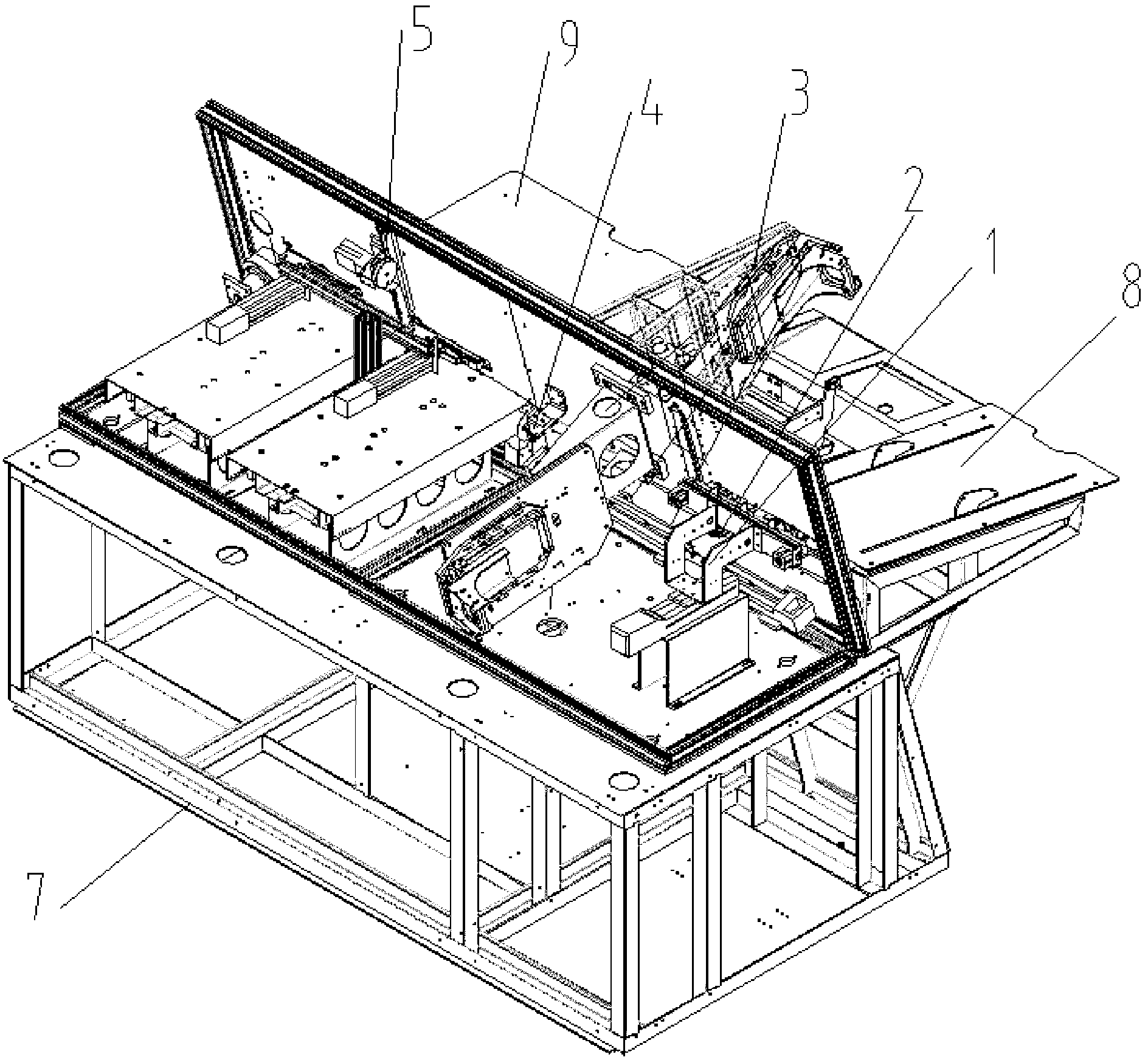

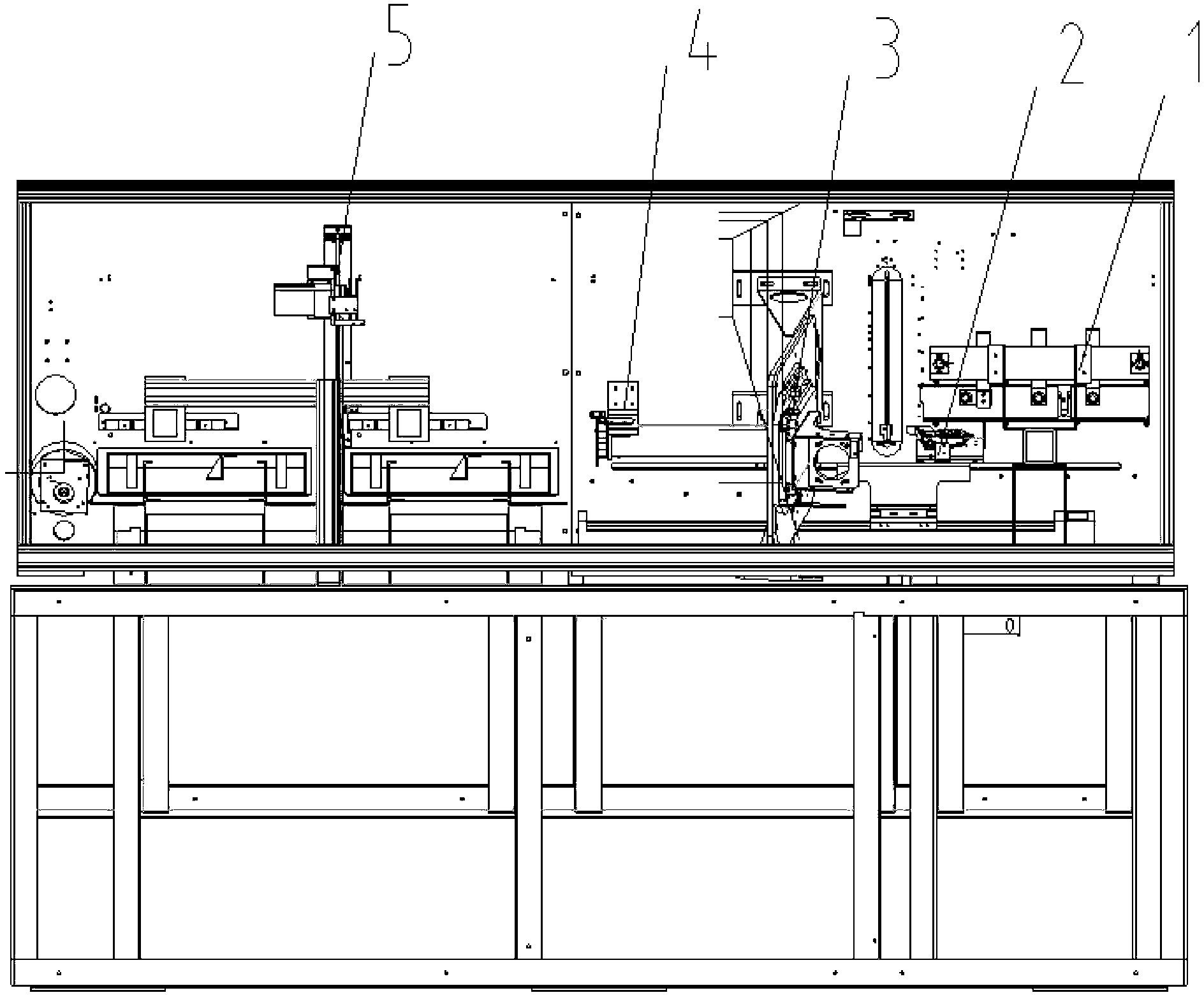

[0042] like Figures 1 to 3 , a PCB circuit board vertical double-sided CCD line scanning automatic detection platform, including a fast cylinder type suction nozzle adjustment mechanism 1, a cam arc dial positioning mechanism 2, a vertical double-sided CCD line scanning mechanism 3 in the detection area, and a cam arc Line push plate mechanism 4, cam baffle plate mechanism 5, steel belt conveying device 6, frame 7, inspection platform 8, post-inspection plate platform 9, sub-board inspection area 10, double-sided vertical line scanning area 611, defective The board rejecting area 612 and the qualified board collecting area 613, the board sub-board inspection area 10, the double-sided vertical line scanning area 611, the defective board rejecting area 612 and the qualified board collecting area 613 are arranged in a straight line on the rack 7 in sequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com