Robot jitter suppression method

A vibration suppression and robot technology, applied in the direction of instruments, adaptive control, general control system, etc., can solve problems such as robot end vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

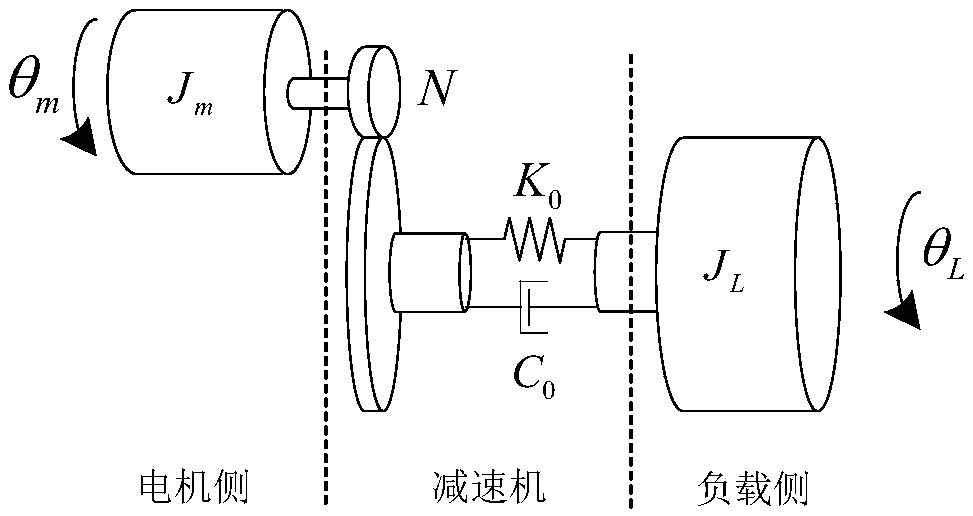

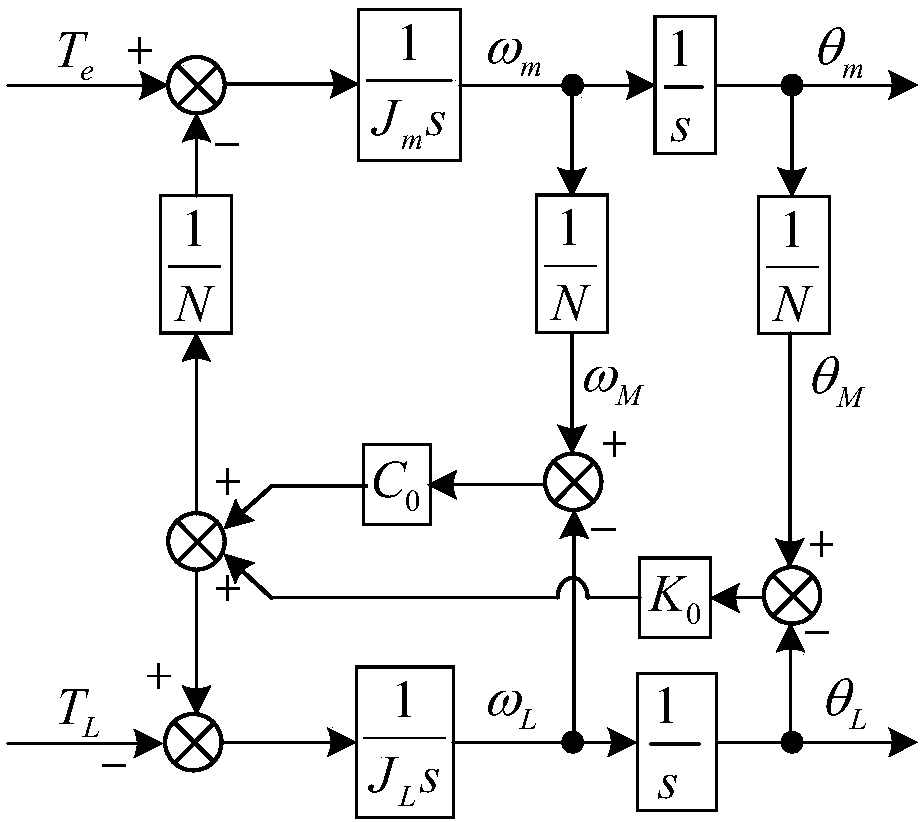

[0056] The implementation of the present invention takes a six-joint series industrial robot as an example. Each joint of the robot is controlled separately, and the shaking suppression method of the present invention is used on each joint respectively. In order to simplify the description of the vibration suppression effect, the first joint among the six joints is taken as an example. This robot joint uses a harmonic reducer as the transmission mechanism. The reduction ratio of the reducer is 121, and the stiffness coefficient is 87×10 4 Nm / rad, the damping coefficient is 15Nm / (rad / s).

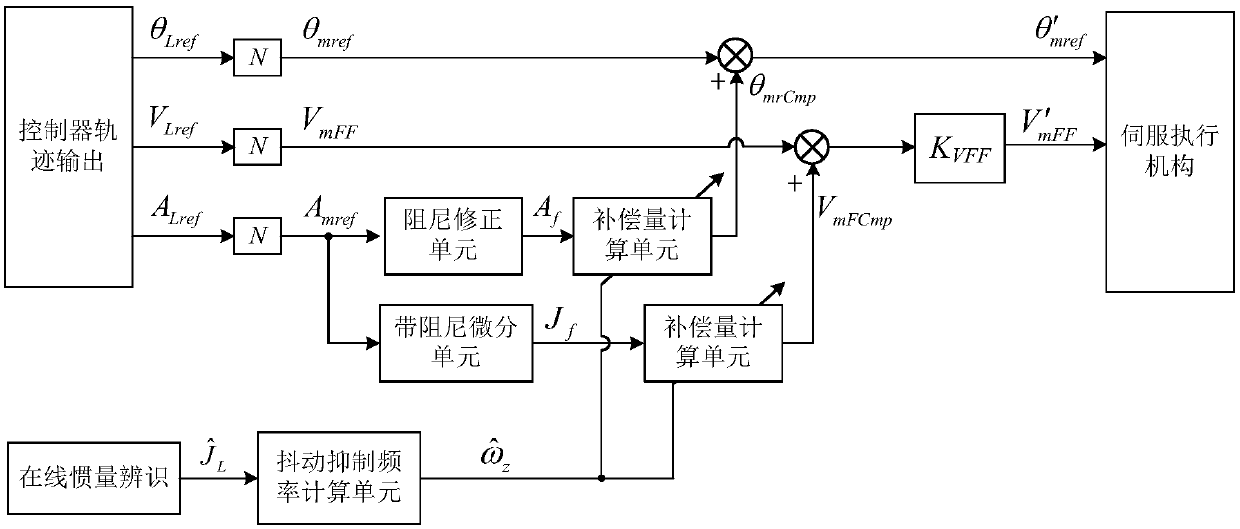

[0057] Taking a section of the path in the continuous working process of the robot as an example, the path is Figure 4 From A to B in , the action path planning is that the first joint of the robot moves from -14.836° to 7.320° within 0.8s, and the original given joint position, joint velocity, and joint acceleration are as follows: Figure 4 shown.

[0058] Step 1: The output of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com