Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

130results about How to "Different colors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

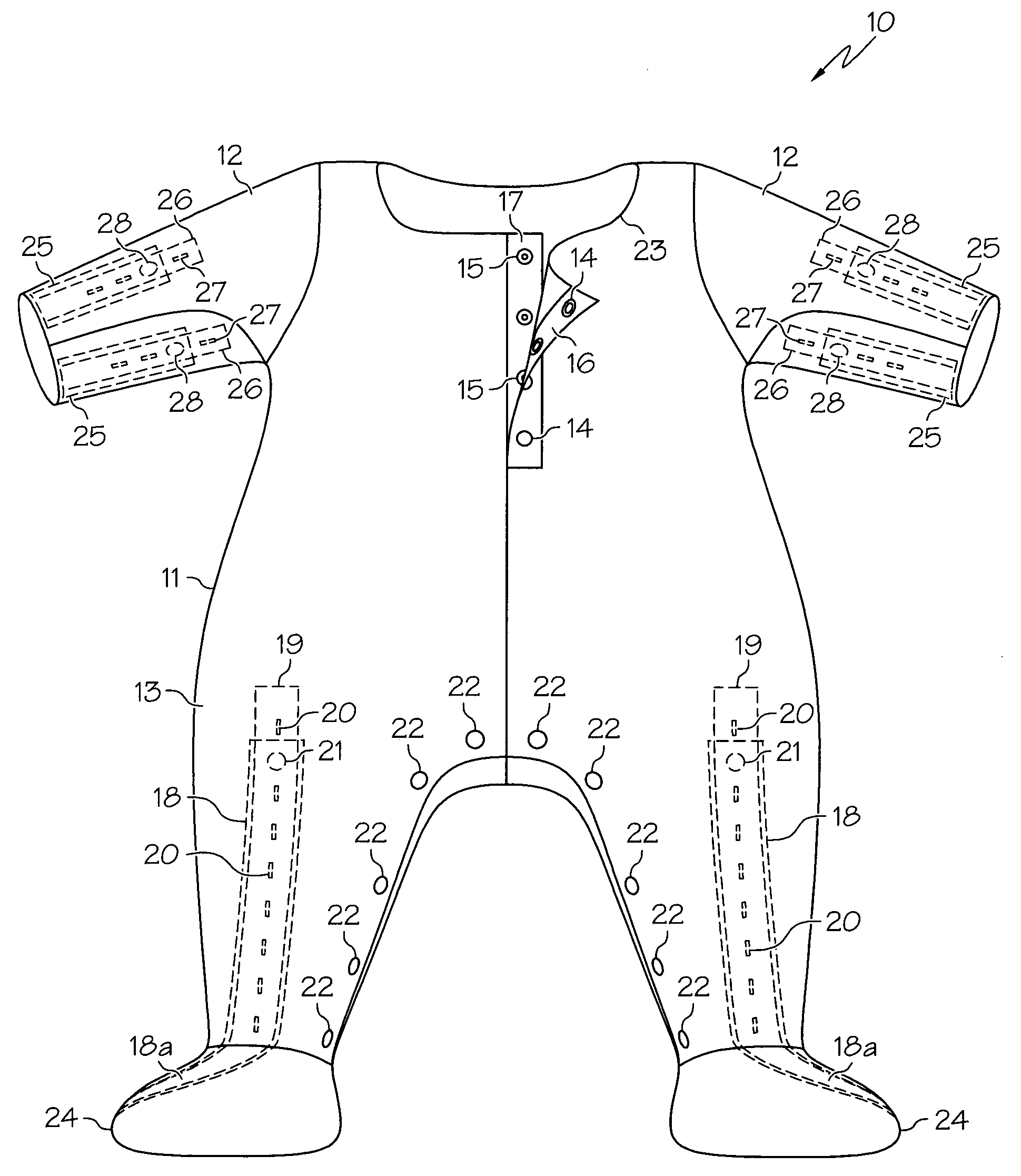

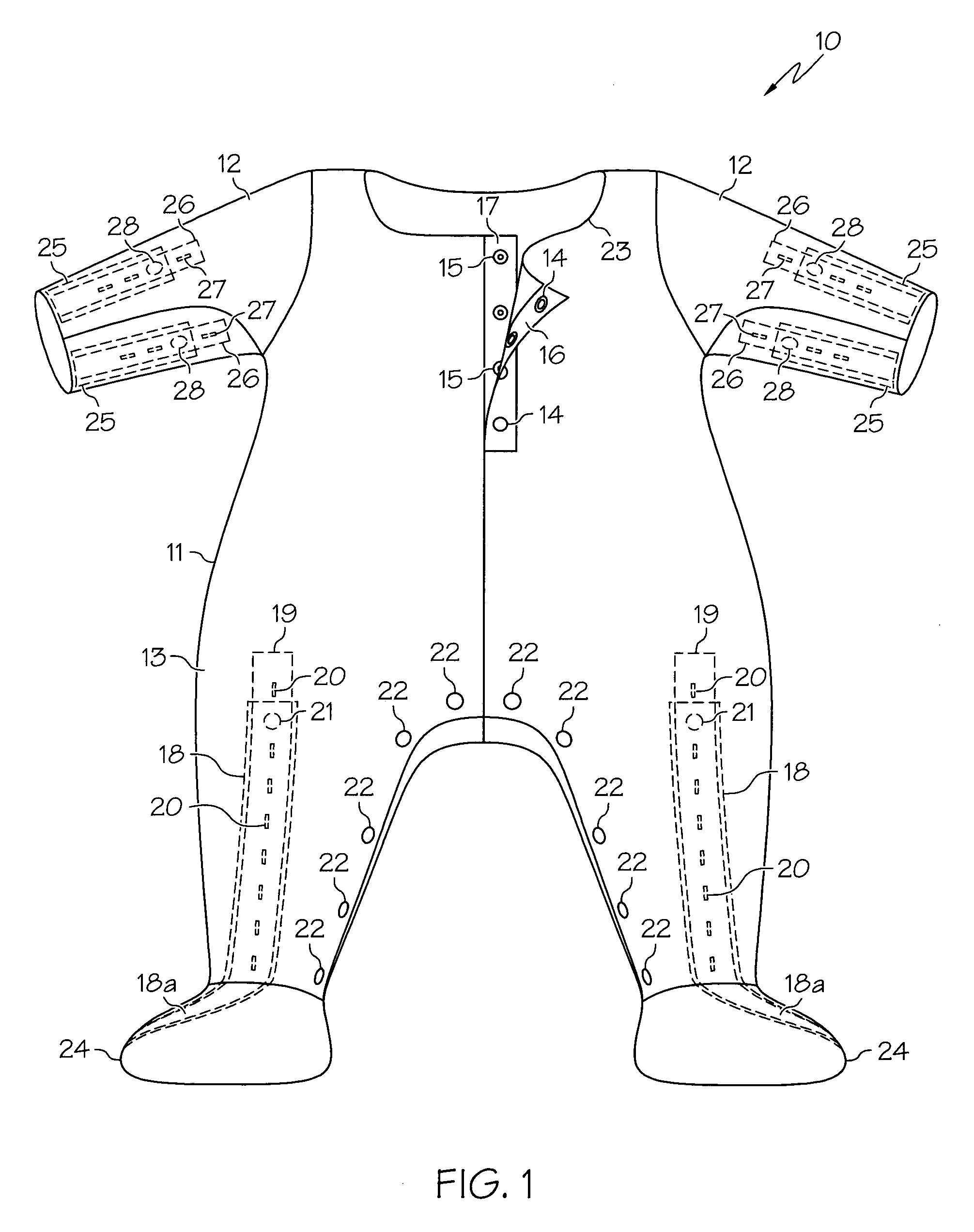

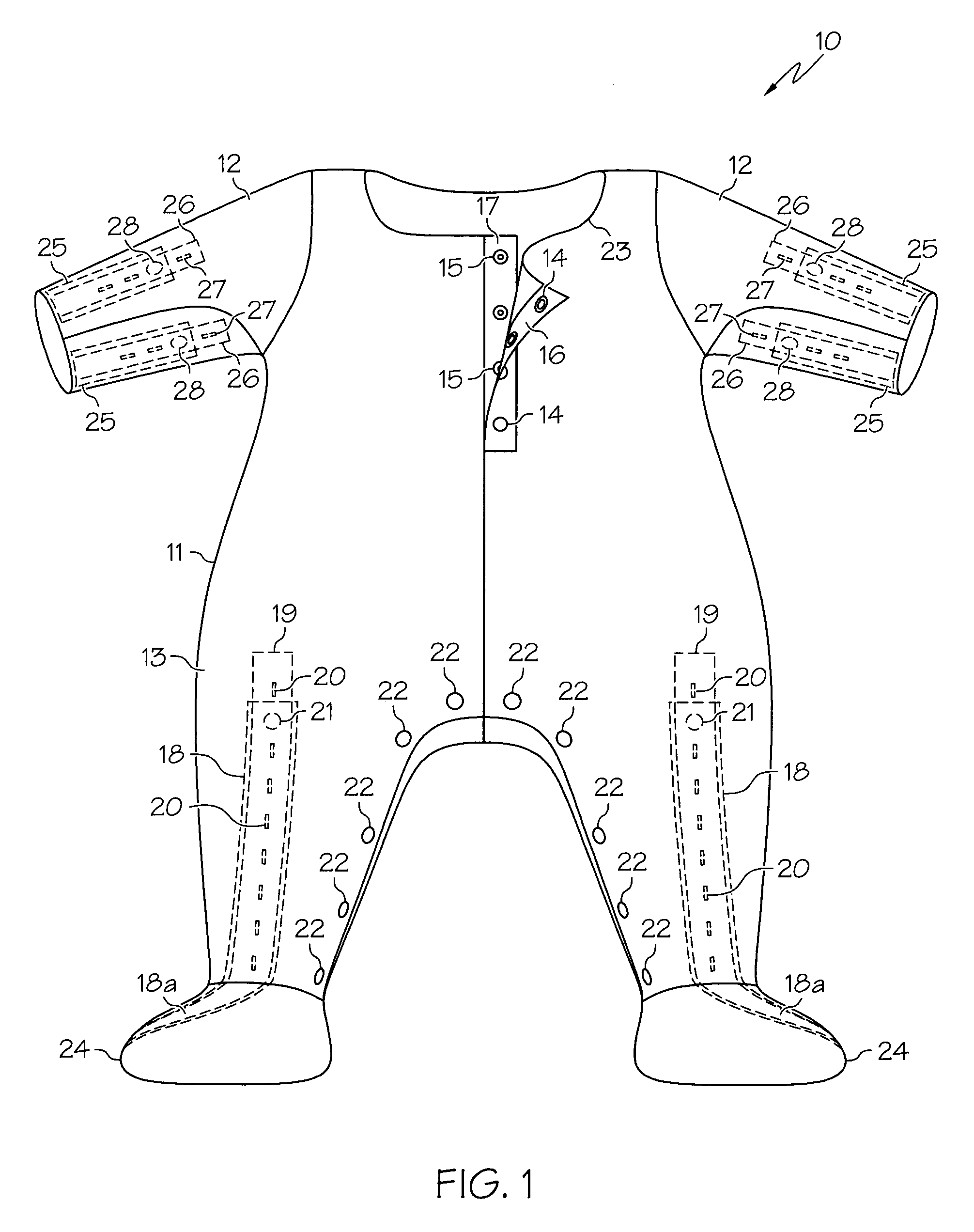

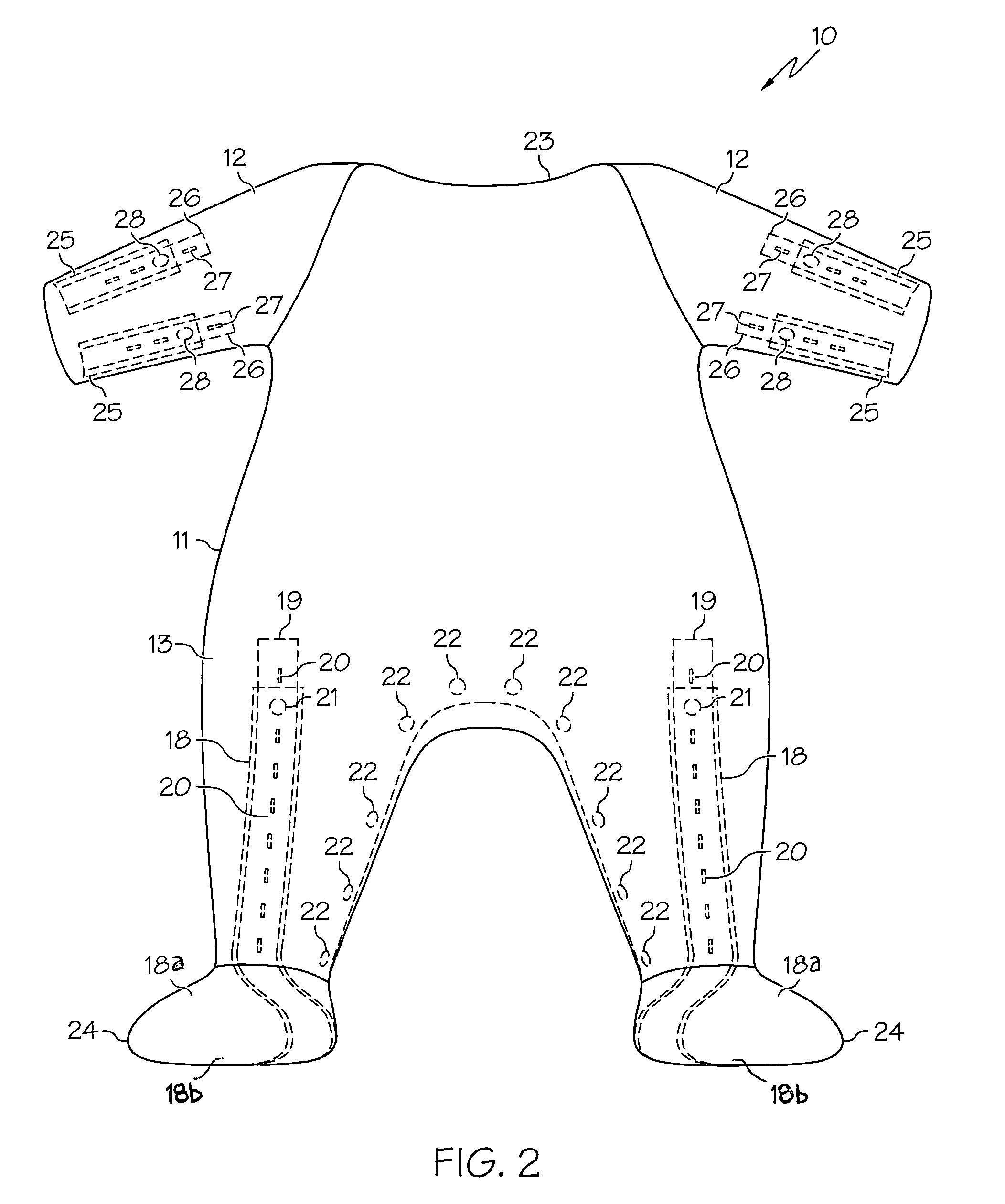

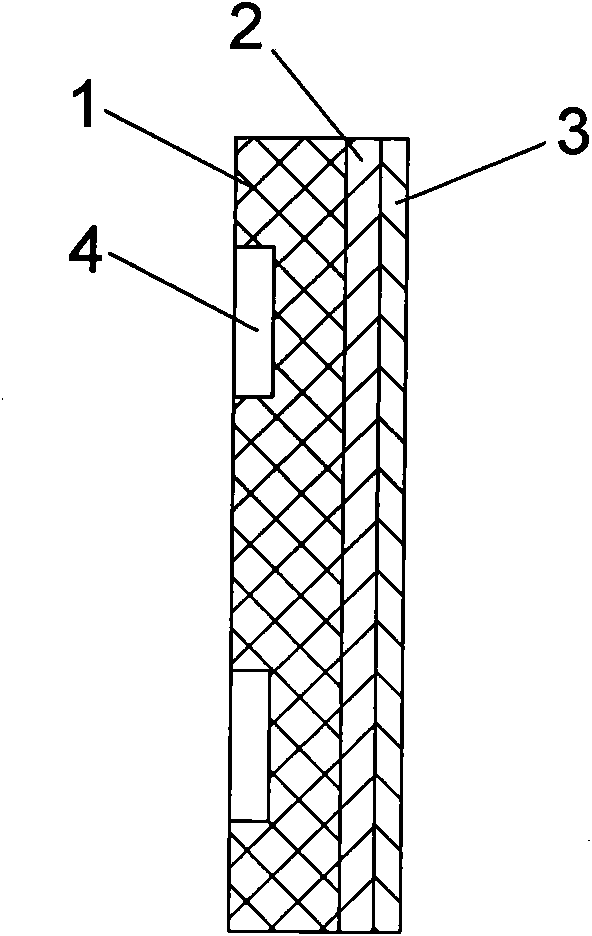

Expandable children garment with an improved adjustable feature

ActiveUS20100299802A1Prevent slippage and slidingReduce materialGarment suspendersConvertible garmentFastenerEngineering

An adjustable garment includes an article of clothing and a plurality of improved and unique adjustment features. The improved adjustment features includes a plurality of spaced apart pockets and elastic band members disposed along sleeves, inseams and interior front and back portions of a shirt body portion, pants inseams, interior front and back pants leg portions, waist section of pants, interior portions of foot or bootie portions and associated extended body portions on one-piece garments. The spaced apart pockets include a lower closed end and an upper open end with a fastener adjacent thereto. The elastic band having a first end cooperating with the lower closed end and a second end extending partially out of the open end with a plurality of fastener holes thereon. Adjustment of the garment is achieved by pulling the second end to connect a desired fastener hole with the pocket fastener.

Owner:BAILEY TERESA +2

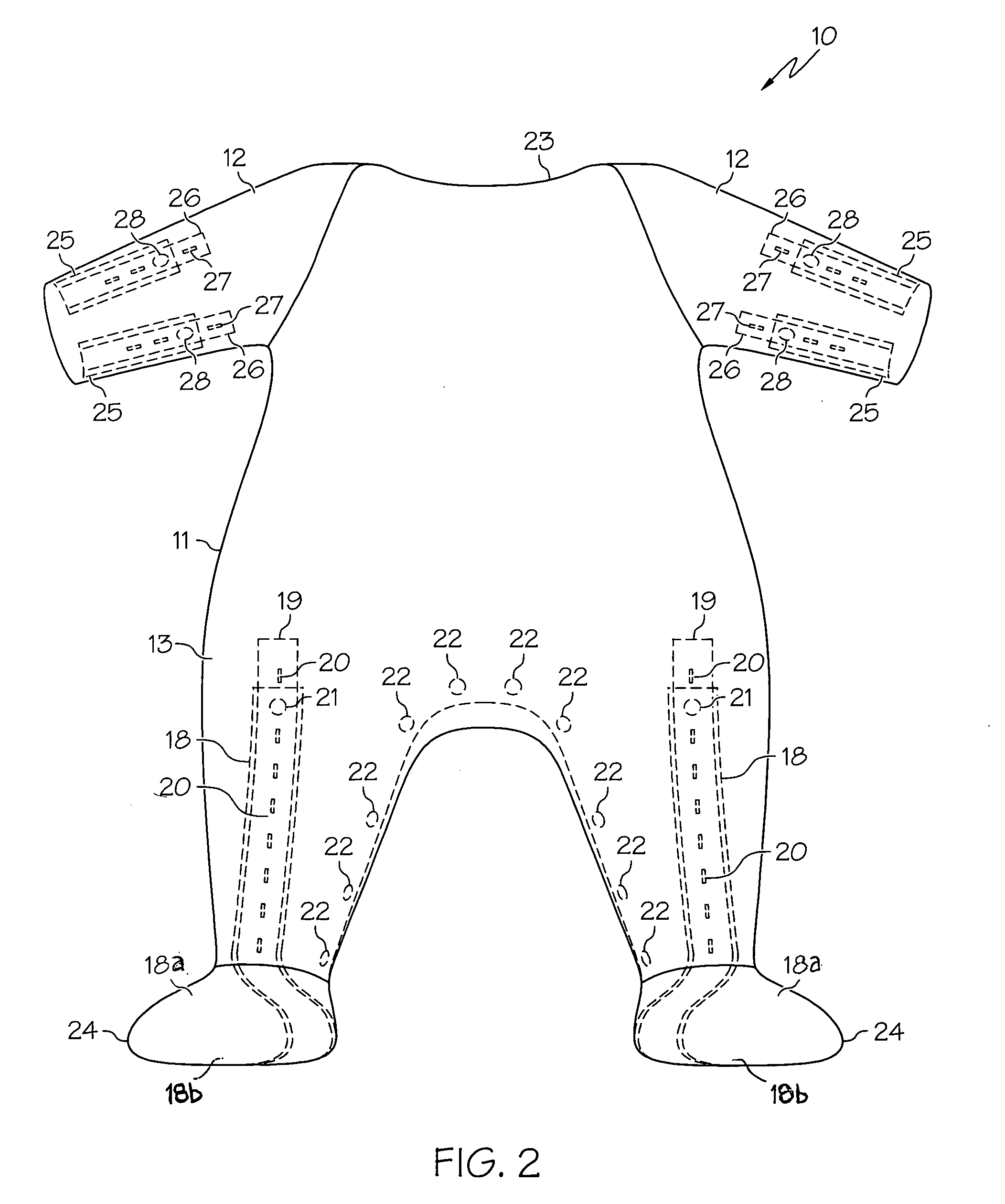

Ultraviolet light crosslinked polymer material used for 3D printing, and preparation method and application thereof

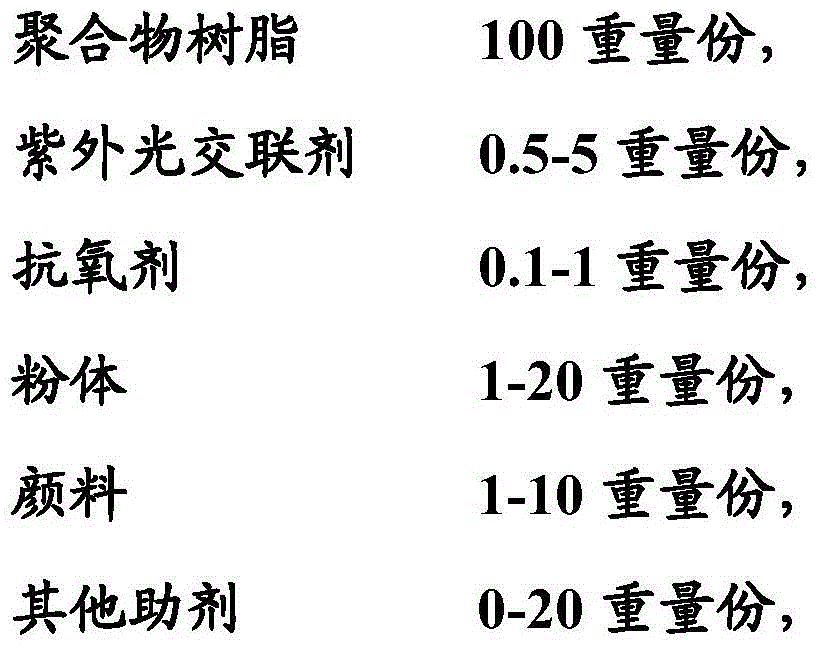

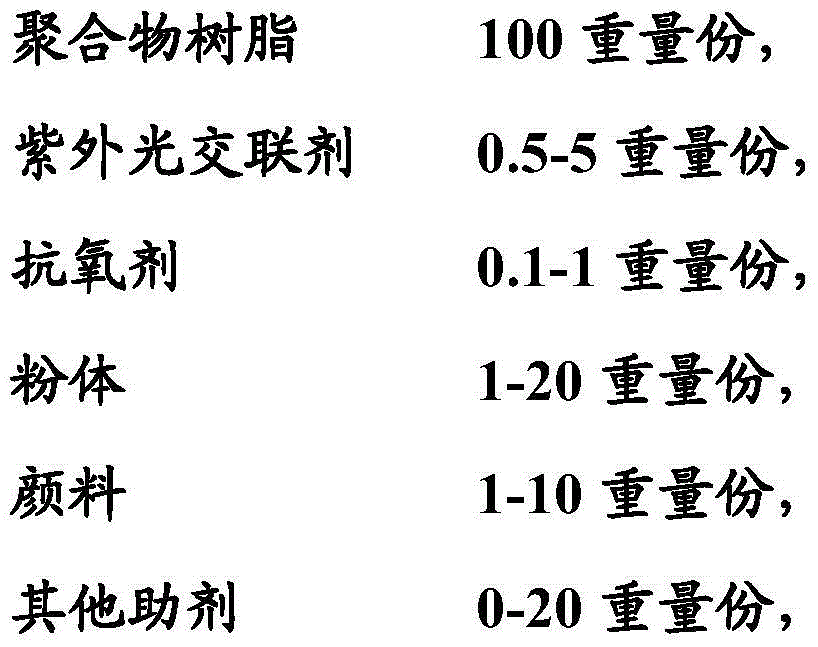

The invention relates to an ultraviolet light cross-linked polymer material used for 3D printing, and a preparation method and an application thereof. Raw materials of the material comprise, by weight, 100 parts of polymer resin, 0.5-5 parts of an ultraviolet light cross-linking agent, 0.1-0.5 parts of an antioxidant, 1-20 parts of powder, 1-10 parts of a pigment and 0-20 parts of other assistant. The light cross-linking agent absorbs ultraviolet lights with specific wavelengths under ultraviolet light irradiation to generate high molecular chain free radicals, so a series of a rapid polymerization reaction is generated to the polymer resin crosslink in a 3D printing process in order to form a three-dimensional net structure. The heat resistance, the chemical corrosion resistance and the mechanical strength of the cross-linked polymer material are greatly improved, so the polymer resin has a wide application prospect in 3D printing materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Ultra violet radiation cross-linking polymeric material for 3D printing and preparation method and product thereof

ActiveCN103980594AImprove heat resistanceGood chemical resistance3D object support structuresCross-linkAntioxidant

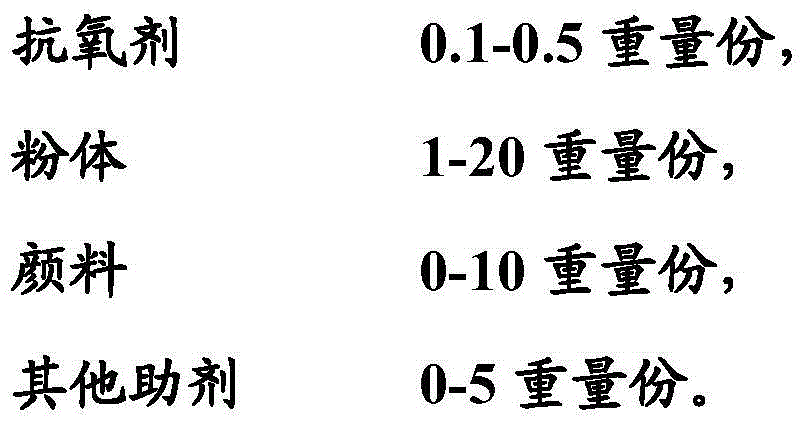

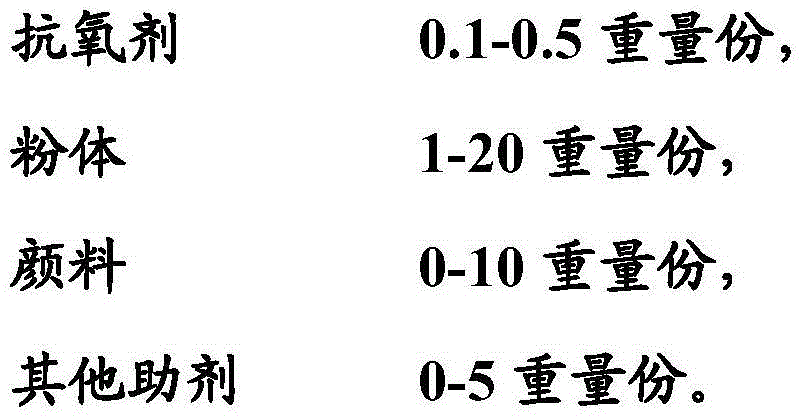

The invention discloses an ultra violet radiation cross-linking polymeric material for 3D printing and a preparation method and a product thereof. Main components of the material contain, by weight, 100 parts of unsaturated resin and 0.5-5 parts of an UV cross-linking agent. In addition, the material also contains, by weight, 0.1-0.5 part of an antioxidant, 1-20 parts of a powder, 0-10 parts of a pigment and 0-5 parts of other auxiliary agents, which help enhance a printing effect of the material. With the addition of the UV cross-linking agent and by the utilization of ultraviolet irradiation, unsaturated resin is subjected to crosslinking after 3D printing extrusion so as to form a three-dimensional net structure. Heat resistance, resistance to chemical corrosion and mechanical strength of a moulding material are all raised to a large extent. Thus, unsaturated resin has a wider application prospect in 3D printing materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

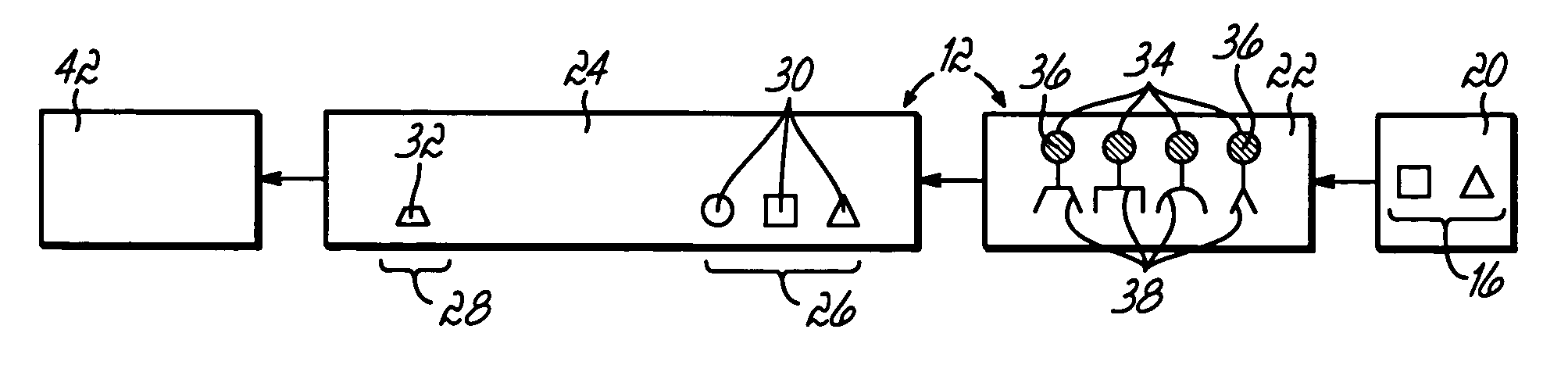

Hyperlinks as visualizations of standing queries

InactiveUS20060155707A1Well formedDifferent colorsDigital data processing detailsSpecial data processing applicationsHyperlinkWeb site

The subject invention provides a unique system and method that facilitate readily identifying that content associated with a hyperlink has been modified or changed in some way that may be of interest to the user. In particular, the target or active sites associated with a plurality of hyperlinks can be monitored for content changes. A user can determine the conditions for which the changes must satisfy before the user is notified of the changes. Various actions can be taken to notify the user of the change via the site's hyperlink when the conditions or queries are satisfied. In addition to general site monitoring, the user can specify specific locations of a site to monitor so that only the desired content on the page is monitored.

Owner:MICROSOFT TECH LICENSING LLC

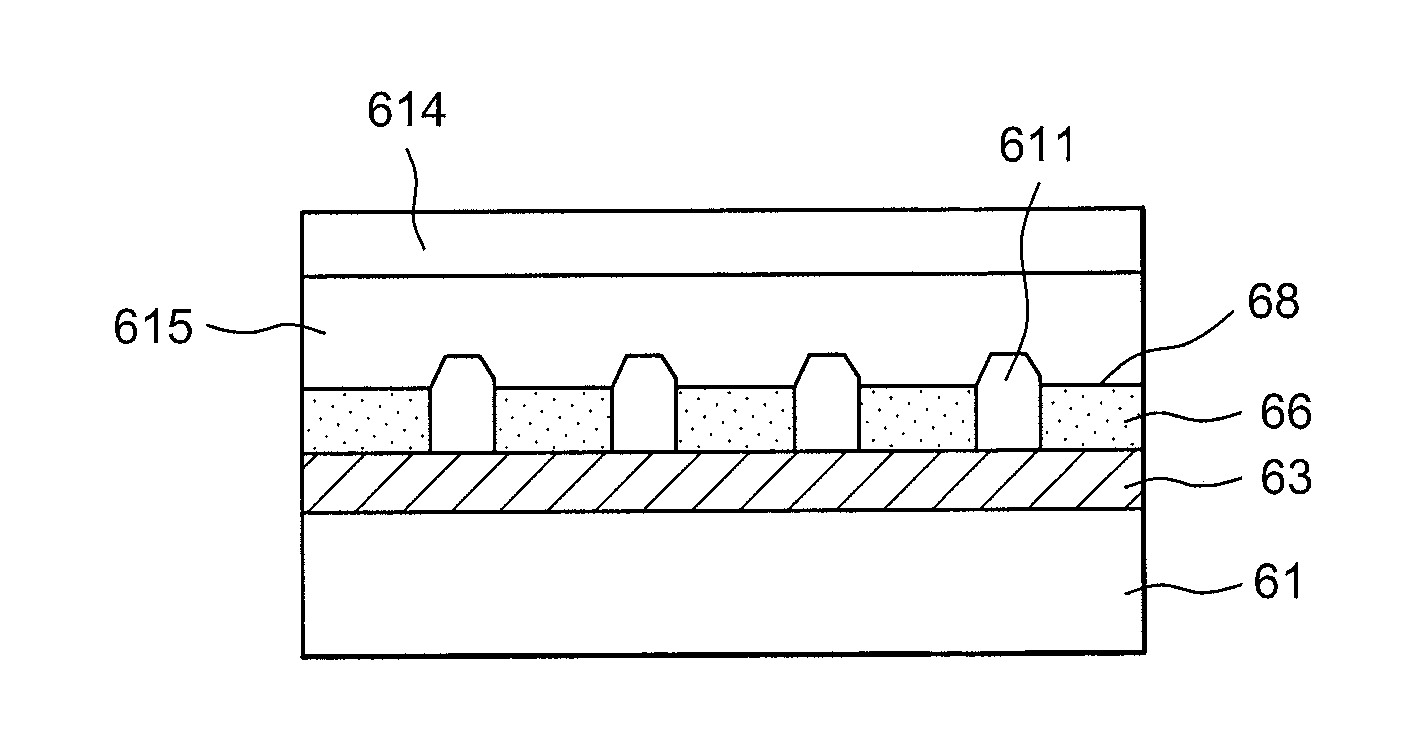

Method for manufacturing a metal and dielectric nanostructures electrode for colored filtering in an OLED and method for manufacturing an OLED

InactiveUS20110151607A1Avoid disadvantagesSimple processSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsNanostructure

A method for manufacturing an OLED and an electrode for an OLED, said electrode comprising a surface comprising a first dielectric nanostructuration and a second metal nanostructuration, on a substrate, wherein the following successive steps are carried out:a) a metal layer is deposited on a planar surface of a substrate;b) on the metal layer, a dielectric layer comprising said first dielectric nanostructuration which includes cavities which extend from the upper surface of the dielectric layer as far as the upper surface of the metal layer, is prepared;c) the cavities of the first dielectric nanostructuration are at least partially filled with a metal, whereby the second metal nanostructuration is obtained.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

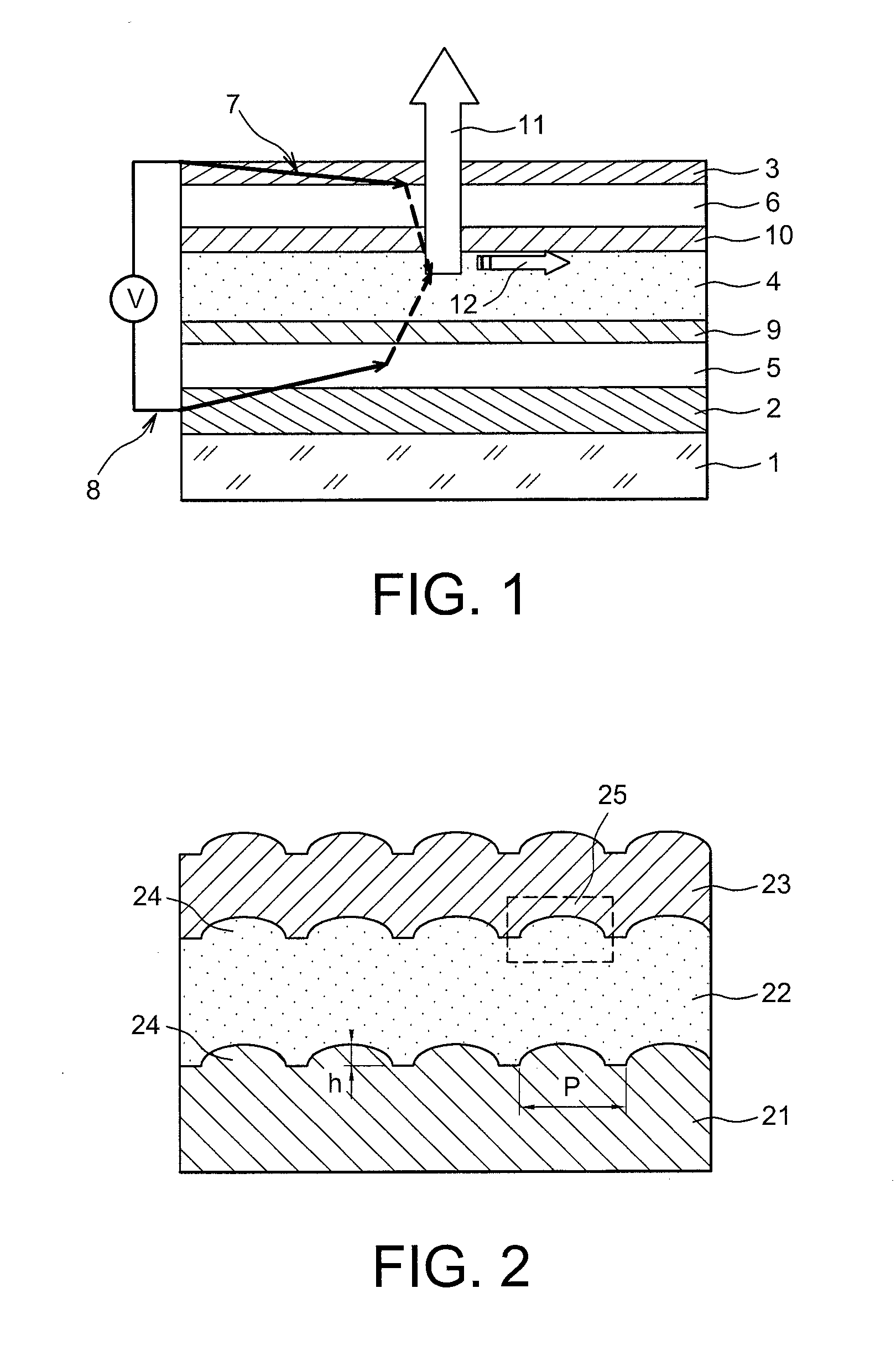

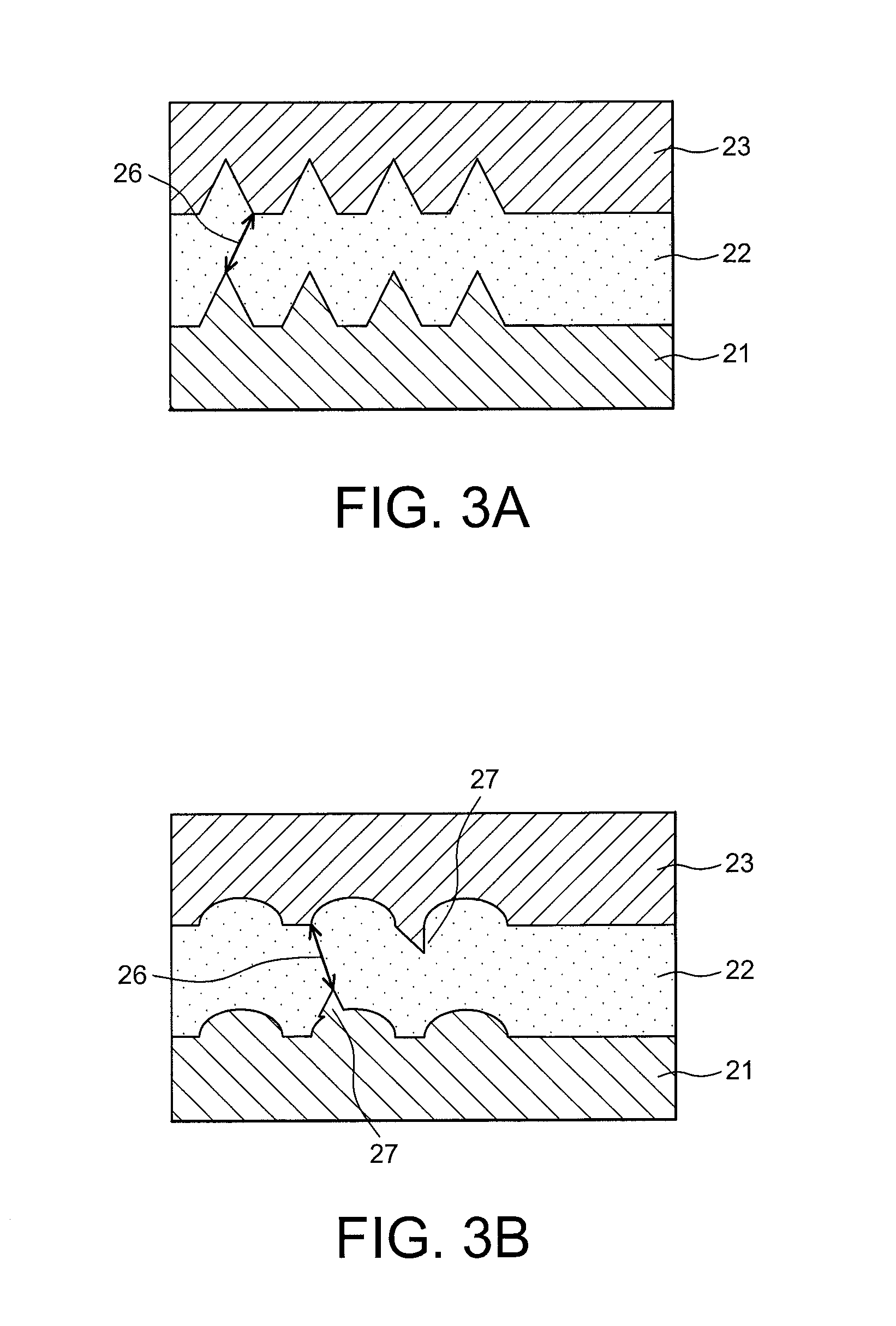

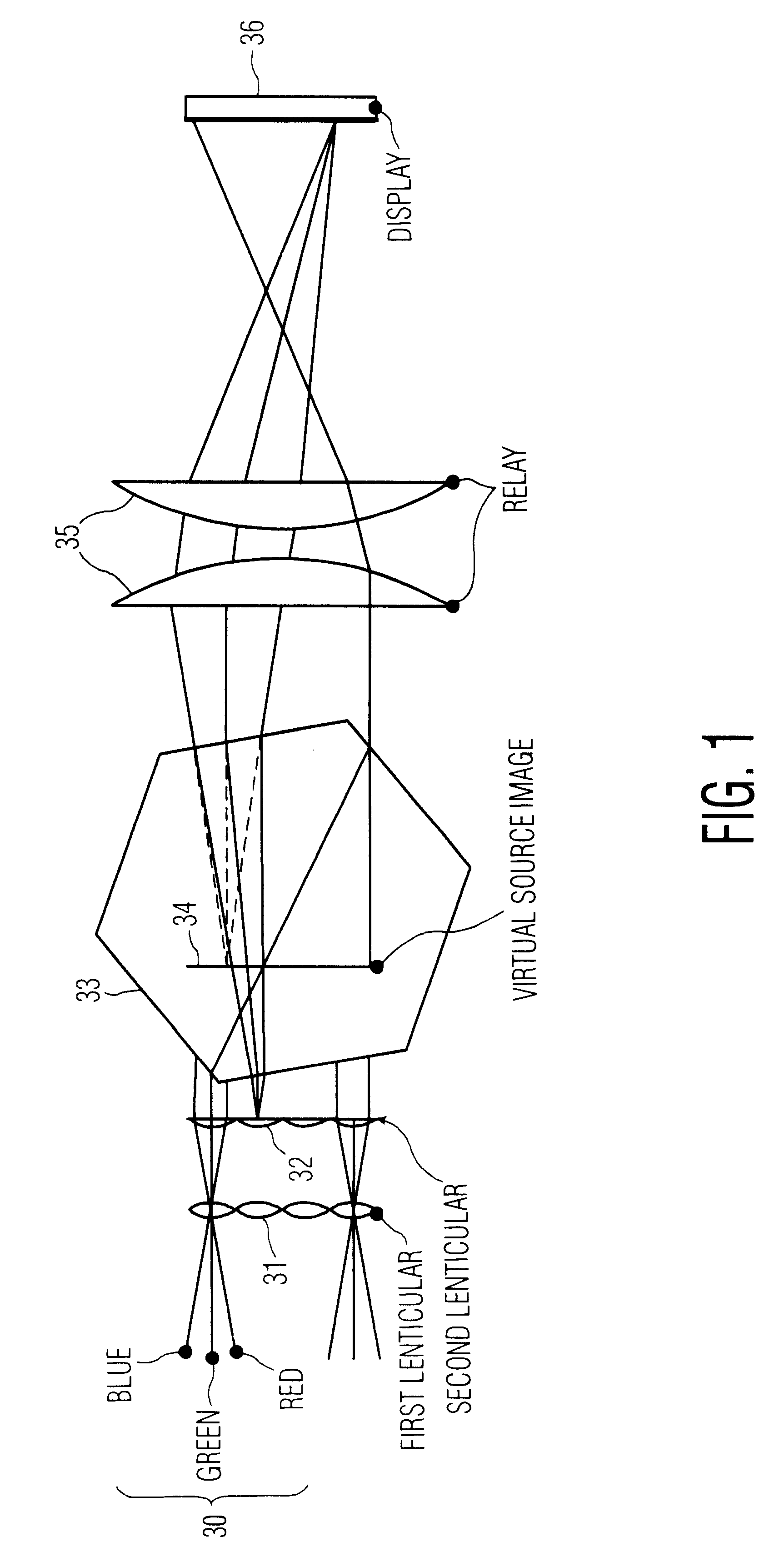

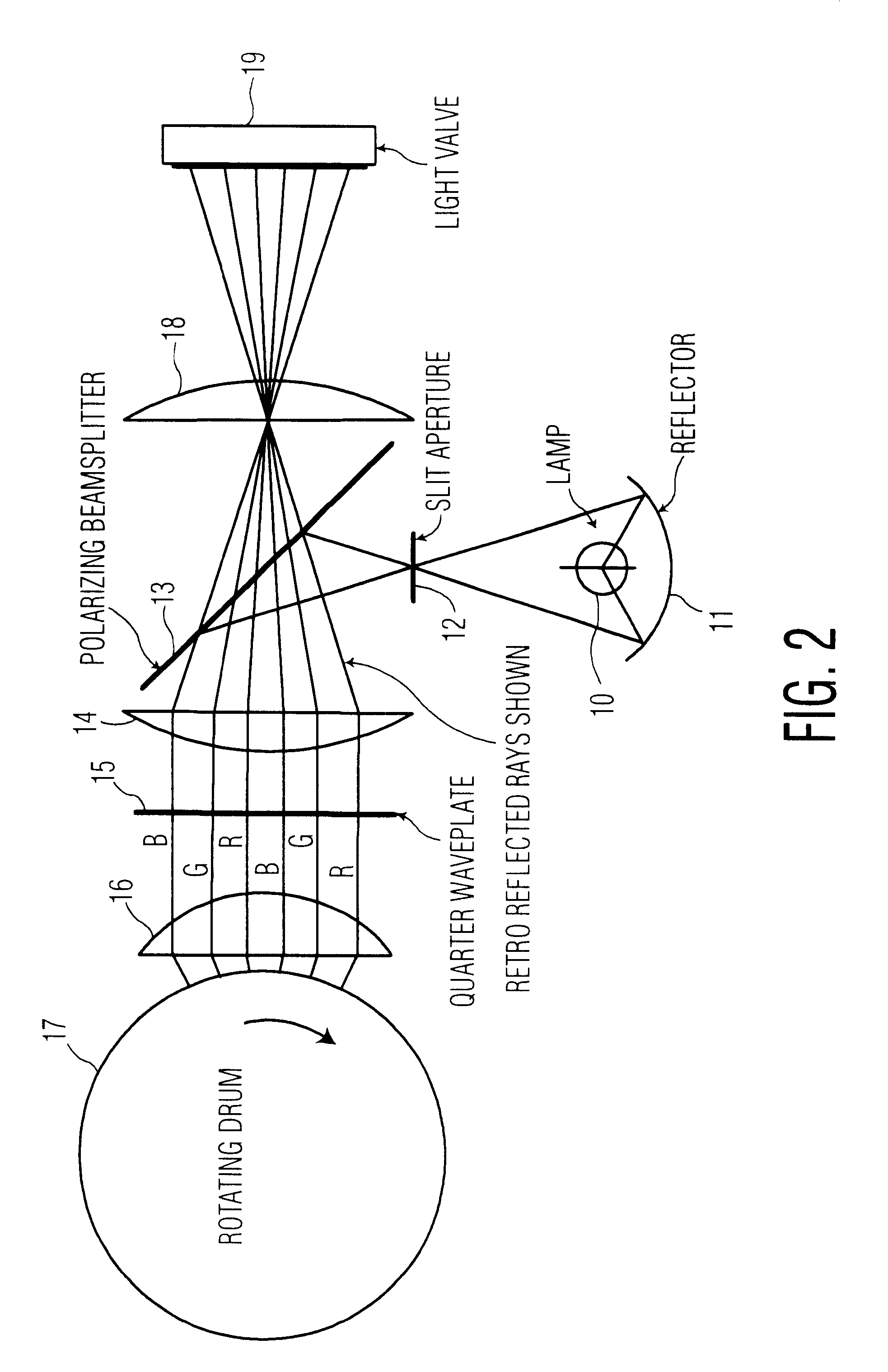

Scrolling multi-stripe color illumination system

InactiveUS6540362B1Different colorsProjectorsPicture reproducers using projection devicesGraphicsPrism

Single panel scrolling color projection systems using three (red, blue and green) scrolling color stripes have been demonstrated to be adequate for television images. However, computer graphics displays are more prone to color artifacts. The invention increases the number of scrolling color stripes in order to suppress these artifacts. One implementation is to break up the three color stripes into multiple bands using a lenticular lens array, and then to collimate the multiple stripes with a second lens array. The collimated stripes are scrolled using the rotating prism of the prior systems.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV +1

Expandable children garment with an improved adjustable feature

An adjustable garment includes an article of clothing and a plurality of unique adjustment features. The unique adjustment features includes a plurality of spaced apart pocket members and elastic band members disposed along sleeves, inseams and interior front and back portions of a shirt body portion, pants inseams, interior front and back pants leg portions, waist section of pants, interior portions of foot or bootie portions and associated extended body portions on one-piece garments. The spaced apart pocket members include a lower closed end and an upper open end with a fastener adjacent thereto. The elastic band having a first end cooperating with the lower closed end and a second end extending partially out of the open end with a plurality of fastener holes thereon. Adjustment of the garment is achieved by pulling the second end to connect a desired fastener hole with the pocket member fastener.

Owner:BAILEY TERESA +2

Manufacture method for flame-retardant heat-insulation acrylic sheet

The invention relates to a manufacture method for a flame-retardant heat-insulation acrylic sheet. The flame-retardant heat-insulation acrylic sheet provided by the invention is manufactured from the following raw materials in a proportion by weight: 100 g of organic glass prepolymer, 60-80 g of wastes generated from a heat power plant, 0-5 g of a coloring pigment, 20-30 g of a flame retardant and 0.4-0.6 g of an antifoaming agent through mixing and pouring polymerization. The flame-retardant heat-insulation acrylic sheet provided by the invention has a heat-insulation temperature difference of 15-25 DEG C and a burning scale of FH-3-15 mm / min, and has the characteristics of diverse colors, high surface hardness and glossiness, light weight, easiness in shaping processing and good flame-retardant and heat-insulation effects; and the manufacture method provided by the invention can increase the utilization rate of wastes, reduce environmental pollution and lower production cost, and the flame-retardant heat-insulation acrylic sheet provided by the invention can be widely applied in building and house decoration industries.

Owner:SHAANXI UNIV OF TECH

Color effect yarn and process for the manufacture thereof

A multicolored effect yarn for use in carpeting includes a core yarn which exhibits substantially zero twist and is formed of a multiplicity of BCF singles yarns, at least one of which has a different color from another, and which are entangled at first and second frequencies of entanglement points and different degrees of entanglements, and a wrapper yarn helically wrapped around the core yarn and has a lower denier than any of the singles yarns.

Owner:UNIVERSAL FIBERS INC

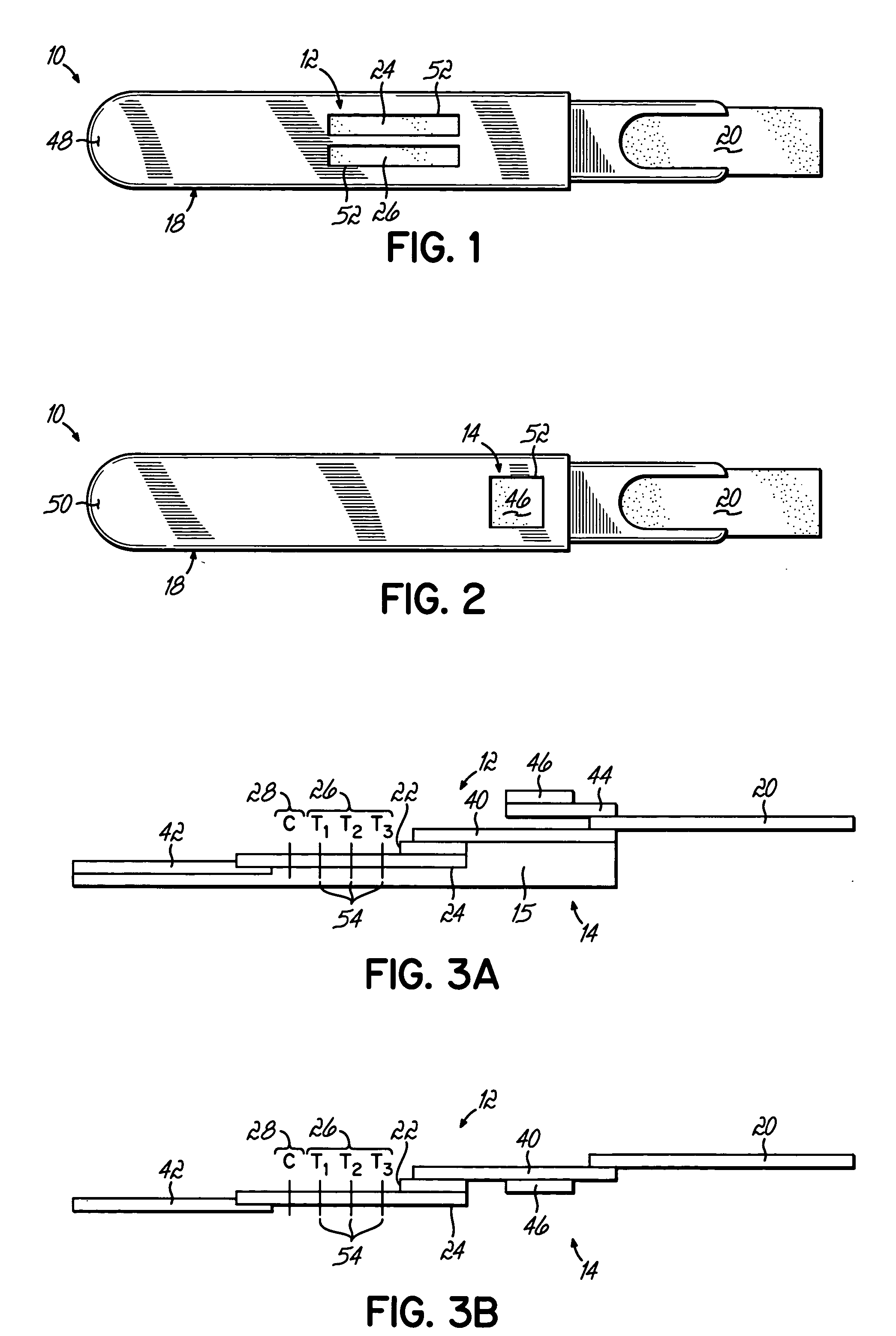

Combination assay for alcohol and drugs of abuse

A test apparatus that allows testing for the presence of both drugs of abuse and alcohol within a single device. In general, the apparatus of the present invention includes a lateral flow immunoassay screening for various drugs of abuse and a reactive pad including an enzyme as a test for alcohol. The two types of tests are contained within the same housing and these tests are performed using the same sample source from a subject being tested.

Owner:BRANAN MEDICAL

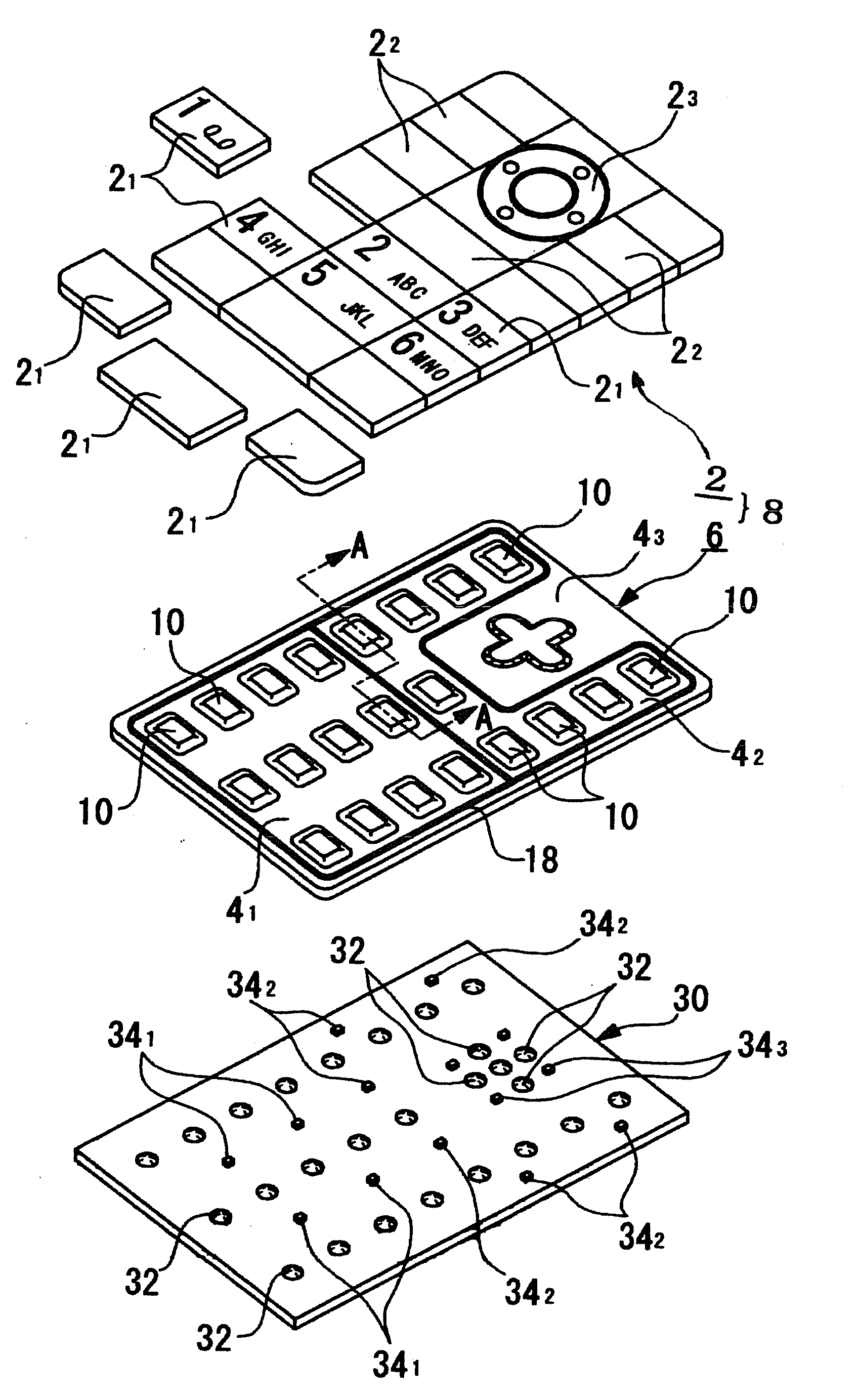

Key sheet, key unit having thereof, and method of manufacturing keysheet

InactiveUS20090322568A1Different colorsLegendsElectronic switchingBoundary regionBiomedical engineering

Owner:SUNARROW CO LTD

Aqueous ink for ball point pens

The present invention relates to an aqueous ink for ball point pens comprising a coloring pigment, a water-soluble organic solvent, water and a polysaccharide, wherein pigment particles of said coloring pigment gather and form a spotted agglomerate phase. The present invention also relates to an aqueous ink with a coloring pigment and a metallic powder pigment comprising a water-soluble organic solvent, water and a polysaccharide, wherein pigment particles of both the coloring pigment and the metallic powder pigment gather to the same pigment phase and form a complex agglomerate phase.

Owner:SAKURA COLOR PRODUCTS CORPORATION

Fabric capable of color changing

InactiveCN103126149AReasonable preparationSimple structural designLayered productsFibre treatmentSurface layerEngineering

The invention discloses a fabric capable of color changing. The fabric capable of the color changing is composed of a surface layer and a base layer, wherein the surface layer is made of fabric materials which are capable of color changing, good in abrasion resistance and good in air breathing performance, the fabric materials of the surface layer are composed of color changing fibers, polyamide fibers and bamboo fibers, the base layer is made of fabric materials which are soft, warm keeping, and air breathing, the fabric materials of the base layer is composed of polyester fibers, imported long staple cotton and acrylics, and the fabric materials of the surface layer and the fabric materials of the base layer are prepared through a double-side machine woven process. According to the fabric capable of color changing, the raw materials of the fabric capable of color changing are in reasonable proportion, the design of the structure is simple, different colors can be shown along with the temperature change of outer environment, and the fabric capable of color changing is suitable for making fashion color changing clothes or military disguise clothes.

Owner:KUSN ZHOUSHI TOWN JISHENG CLOTHING FACTORY

Aesthetics resin composition with fantasy colors and preparation method thereof

The invention provides an aesthetics resin composition with fantasy colors and a preparation method of the aesthetics resin composition. The aesthetics resin composition comprises the following components in parts by weight: 100 parts of a thermoplastic resin, 0.1-5.0 parts of irregular hollow glass beads, 0.1-3.0 parts of a lubricant and 0.1-1.0 part of an antioxidant. The preparation method comprises the following steps of: mixing the components in a high-speed mixer, subsequently feeding the components into a double-screw extruder, melting and compounding under conveying, shearing and blending, further drawing out, stripping, cooling and cutting into grains so as to obtain the aesthetics resin composition. Different from the glass prepared in the conventional mode of adding pearlescent pigment, the aesthetics resin prepared from irregular glass beads has strong fantasy color effects, is attractive and fashion and simple in preparation process, the environment-friendly spraying-free solving scheme is realized, and the aesthetics resin composition can be widely applied to fields having high requirements on appearances, such as automobiles, electronic appliances, consumer electronics, electronics and home furnishing.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

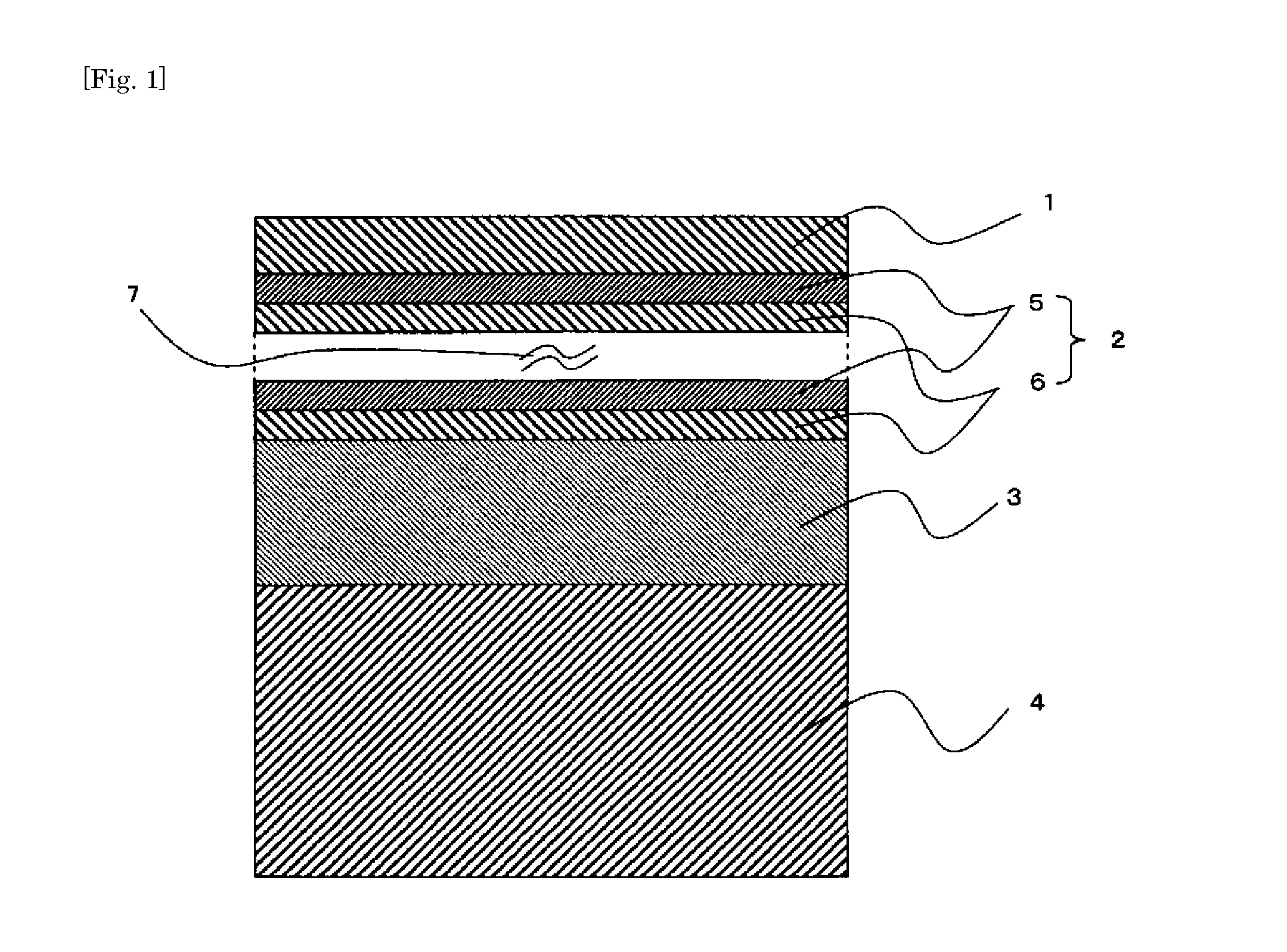

Decorative part

ActiveUS20100227156A1Reduce brightnessDifferent colorsVacuum evaporation coatingSputtering coatingAlloyOxygen

[Subject] In a decorative part having a pink Au alloy hard coating film, the sophisticated pink aesthetic appearance thereof can be maintained for long time use by making the decorative part that flaws or peelings are hardly visible even if flaws are caused in the coating film or the coating film is peeled off.[Means for Solving Subject] The decorative part comprises a hardening layer having a pink Au alloy coating film on the surface whereinthe hardening layer is obtainable by laminating a base layer, a primary layer and a finishing layer from the side of a substrate,the base layer comprises a metal layer comprising one metal or two or more metals selected from Hf, Ti and Zr and, superimposed thereon, a compound layer comprising the same metal constituting the metal layer and further comprising nitrogen, carbon or oxygen,the primary layer has a laminating structure such that an Au alloy layer, and a compound layer comprising one metal or two or more metals selected from Hf, Ti and Zr and further comprising nitrogen, carbon or oxygen are laminated one after the other, andthe finishing layer comprises an Au alloy layer.

Owner:CITIZEN WATCH CO LTD

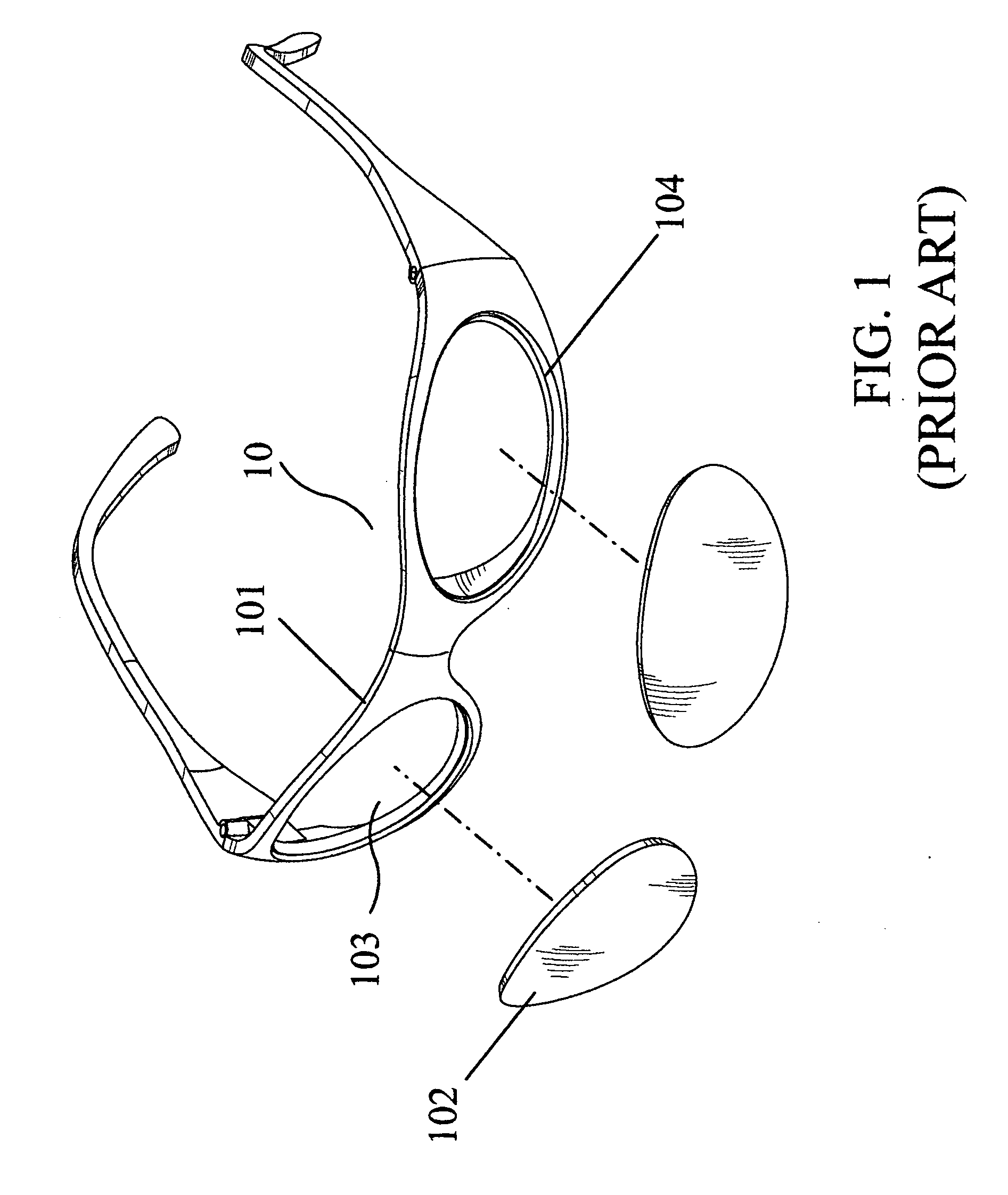

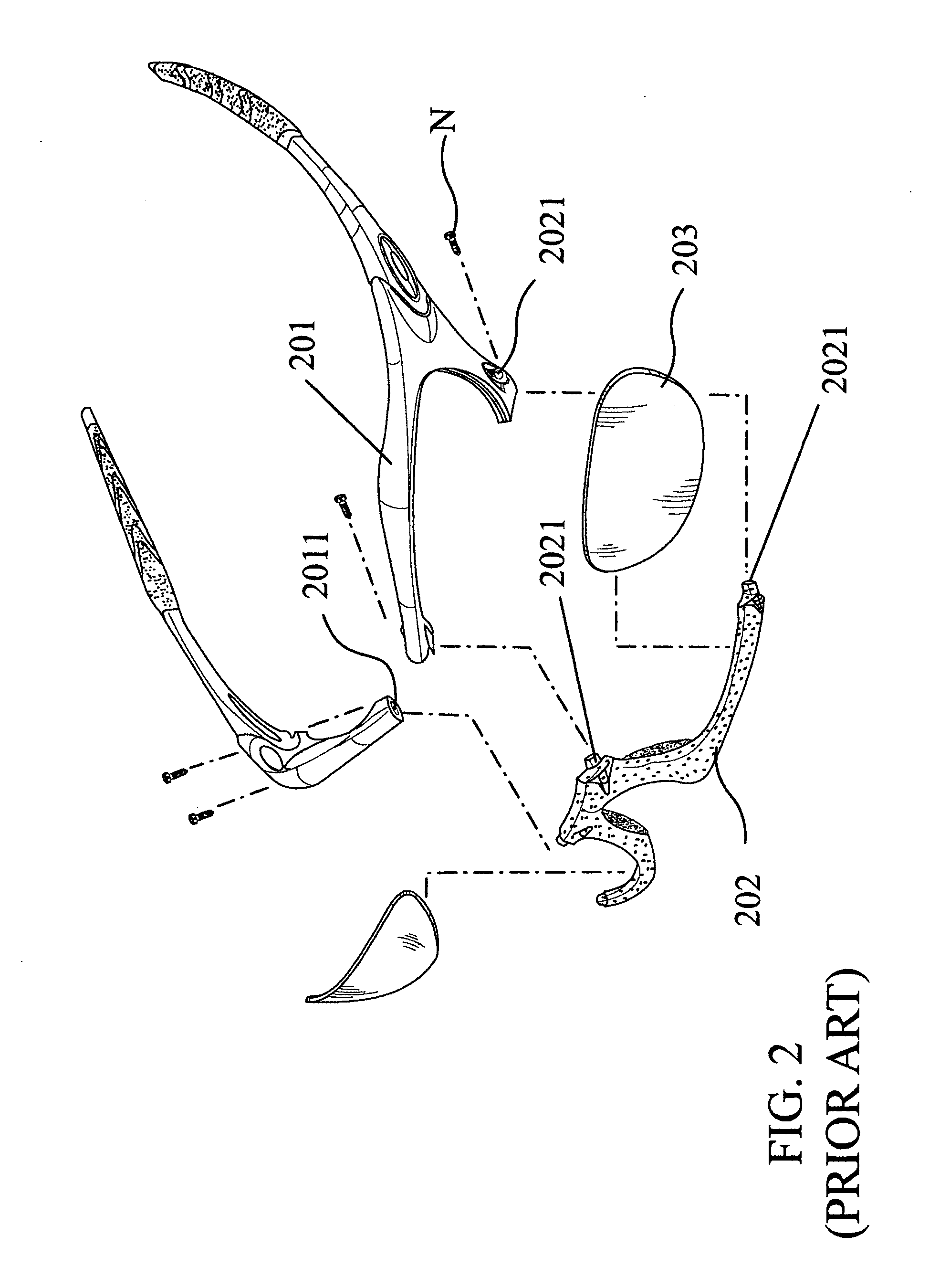

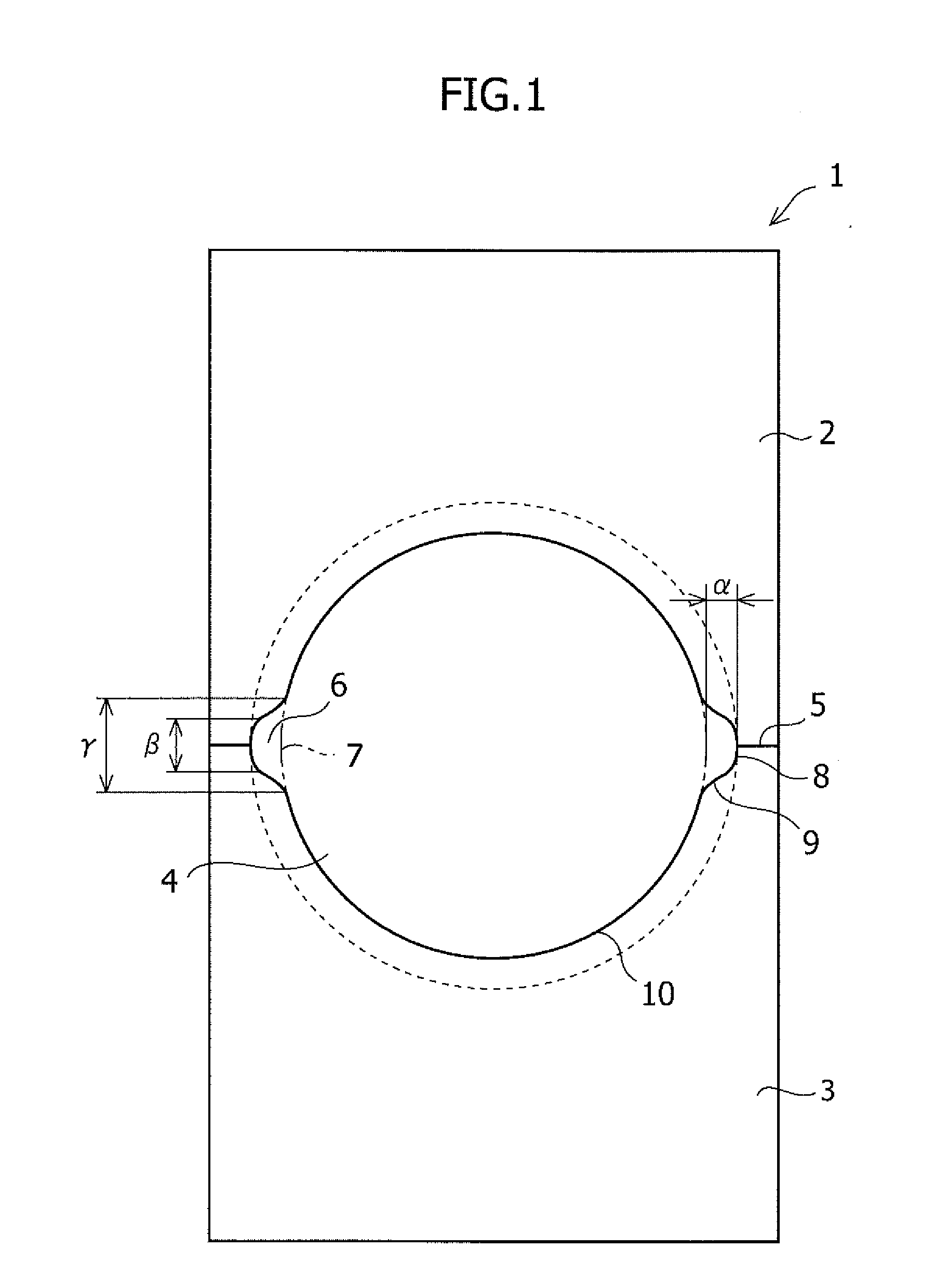

Eyeglass assembly and coupling system

InactiveUS20050151925A1Drawback can be obviatedEasily and promptly assembled and disassembledSpectales/gogglesNon-optical partsCoupling systemEngineering

An eyeglass assembly and coupling system is assembled by an upper half frame, a lower half frame, a pair of lenses and a pair of temples. The characteristic lies in that the upper half frame is provided with an upper hollow in the bridge portion, a flanged portion is formed at each side of the upper hollow, an elongated groove is provided at one side of each flanged portion, and each flat end of the upper half frame is provided with a screw hole. The lower half frame is provided with a flanged block at the bridge portion, a lower hollow is formed at each side of the flanged block, an elongated groove is provided at one side of each lower hollow, and each flat end of the lower half frame is provided with a screw hole.

Owner:HIGH RAINBOW ENT

UV-LED glass ink and preparation method and use method thereof

The invention discloses a UV-LED glass ink and a preparation method thereof. The glass ink is prepared by the steps: taking polyester acrylate, difunctional polyurethane acrylate and hexafunctional polyurethane acrylate as main raw materials, adding an active monomer, a filling agent, a photoinitiator, an auxiliary agent and silicon dioxide, and evenly mixing the raw materials and grinding to prepare the glass ink. The glass ink has the characteristics of fast curing speed and high curing efficiency. By adjustment of the composition of the filling agent, the glass ink with different appearanceeffects can be prepared. The invention also provides a use method for the UV-LED glass ink; 250-300 mesh screen printing is adopted, the thickness of an ink layer is controlled to 10-30 [mu]m, and photo-curing is carried out for 40-60 s after printing is completed. The glass ink has short curing time and good curing effect, cannot make glass products yellowed, and does not cause damage to operator bodies due to too strong light illumination in the curing process.

Owner:FOSHAN CITY GREEND CHEM

Method for producing luminous organic glass embedded handicraft

The invention discloses a method for producing a luminous organic glass embedded handicraft. The method comprises the following steps of: adding an initiator into a methyl methacrylate monomer, and heating and reacting to obtain prepolymerization slurry; adding luminous powder, an antisettling agent and a defoaming agent into 1 / 3 to 2 / 3 of prepolymerization slurry, and casting the mixture into a mould for polymerization until slurry in the mould is in a solidification state; sequentially embedding an insert and casting the residual prepolymerization slurry, and polymerizing at the temperatures which are sequentially varied from high to low and are in gradient distribution; and finally, polymerizing at the temperature of 100 and 120 DEG C, demoulding, grinding, and polishing to obtain the luminous organic glass embedded handicraft. The luminous organic glass embedded handicraft produced by the method has the advantages that: one-time polymerization production time can be controlled to be between 4 and 6 hours; a luminous bottom layer has different colors and uniform luminescence; no bubble exists in an intermediate layer of the insert, and original appearances of various animal and plant specimens, pebbles, photos and billboards are maintained; and an upper transparent layer is high in transparency.

Owner:SHAANXI UNIV OF TECH

Golf ball and method for manufacturing the same

A method for manufacturing a golf ball includes the steps of forming the golf ball by using a mold, which mold includes at least two body parts, and is configured so that a cavity is formed within the mold by the joining of the at least two body parts, and in at least one of the body parts, a groove for forming a projecting land part which is ground after the formation of the golf ball is provided in a cavity wall surface near the entire circumference of a parting line formed by the joining; and performing treatment in which the golf ball formed by using the mold is treated so that the color of the entire land part of the golf ball is different from the color of dimples.

Owner:BRIDGESTONE SPORTS

Granulated ceramic and production technology thereof

The invention discloses granulated ceramic and a production technology thereof. The granulated ceramic is characterized by comprising the following formula compositions in percentage by weight: 30%-75% of SiO2, 1%-20% of CaO, 0-17% of MgO, 1%-21% of Al2O, 1%-7% of Na2O+K2O, 0%-6% of B2O3, 0%-10% of BaO, 0%-7% of ZnO, 0%-5% of Sb2O3, 0%-2% of Cl, 0%-10% of F, 0%-10% of P2O5 and 0-10% of ZrO2, and a coloring material is added as required. The production technology comprises the following steps: firstly, laying a layer of blocky (flaky) glass blocks made of special compositions, or crude glass granules with mesh of more than 2 on a ceramic blank or a die, sintering and polishing. The prepared granulated ceramic bricks or glass ceramic crystals are strong in three-dimensional layering of color, and glittering and translucent.

Owner:冯翠兰

UV coating decorative plate and preparation method thereof

InactiveCN102069673AHigh surface glossImprove plumpnessSpecial ornamental structuresLaminationEngineeringHigh surface

The invention discloses an ultraviolet (UV) coating decorative plate, which comprises a base layer, wherein the surface of the base layer is glued and cured with a decorative layer; the surface of the decorative layer is provided with a UV coating layer; and the base layer is also provided with related grooves or installation connecting blocks. The UV coating decorative plate has the advantages of high surface gloss, good plump effect, pattern diversity, different colors, outstanding individuation and environmental friendliness. In addition, the invention also discloses a convenient and simple method for manufacturing the UV coating decorative plate.

Owner:李德华 +1

Dyeing technology of ramie strips and manufacturing method of spinning

ActiveCN102277755AImprove spin performanceDifferent characteristicsDyeing processYarnPolymer scienceAqueous solution

The invention discloses a dyeing technology of ramie strips. The technology comprises the following steps: 1, pretreating: boiling the ramie strips for 8-12min, wherein a boiling agent is an aqueous solution containing 1-3g / L of a penetrating agent, and a bath ratio is 1:4-10; and 2, dyeing: dyeing the boiled ramie strips in a reactive dye, wherein the bath ratio is 1:4-10. The invention also discloses a making method of ramie spinning. The dyed ramie strips of the invention allows the performance of a ramie fiber to be improved, so the broken of the ramie fiber is not easy to occur when folding and drawing the fiber, and the hardening of the ramie fiber is also not easy to occur, thereby phenomena of adverse drawing, needle breaking and lacking and the like caused by post-operation carding do not occur, and a purpose of smooth spinning is reached.

Owner:HUNAN HUASHENG ZHUZHOU CEDAR

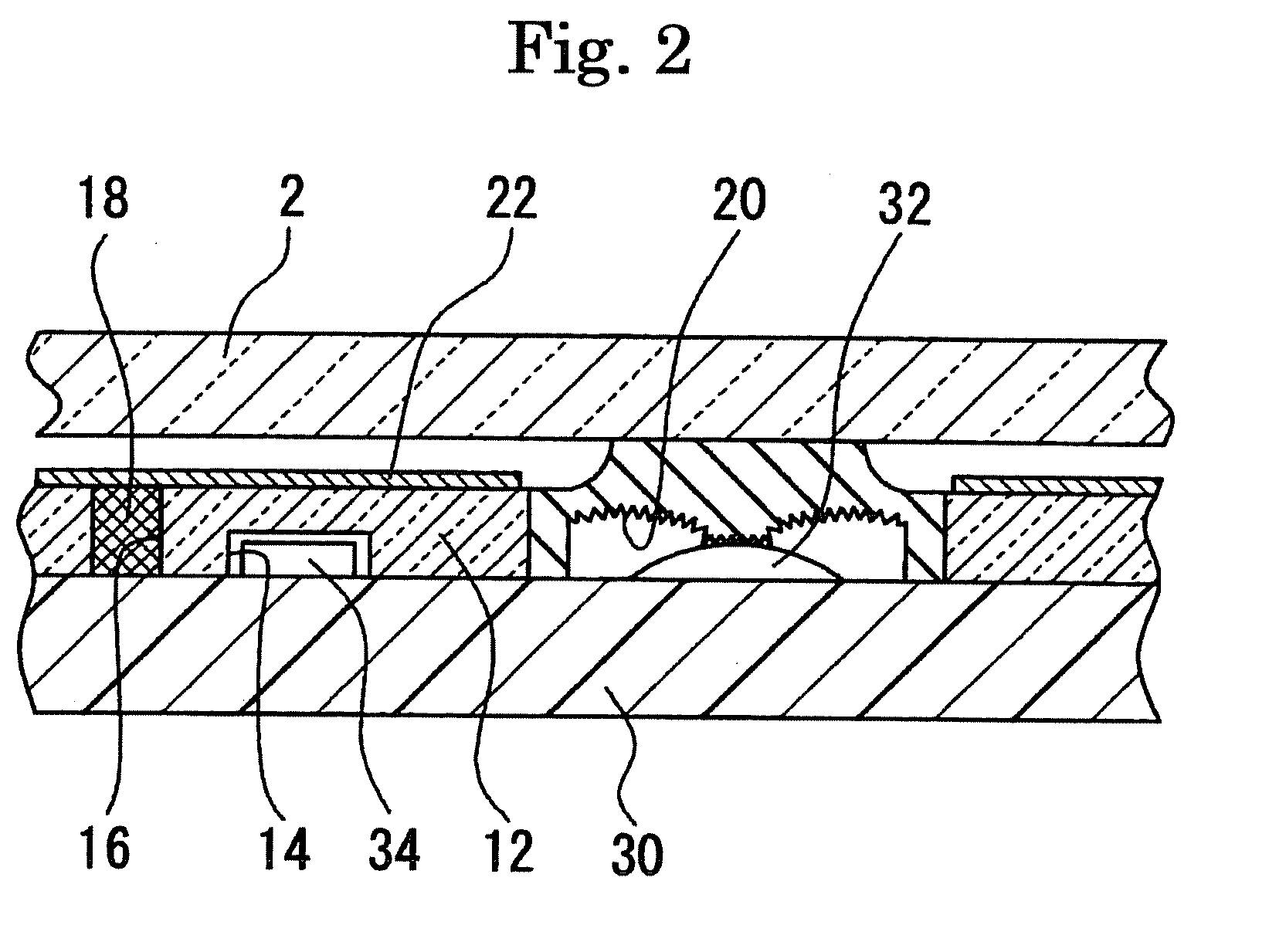

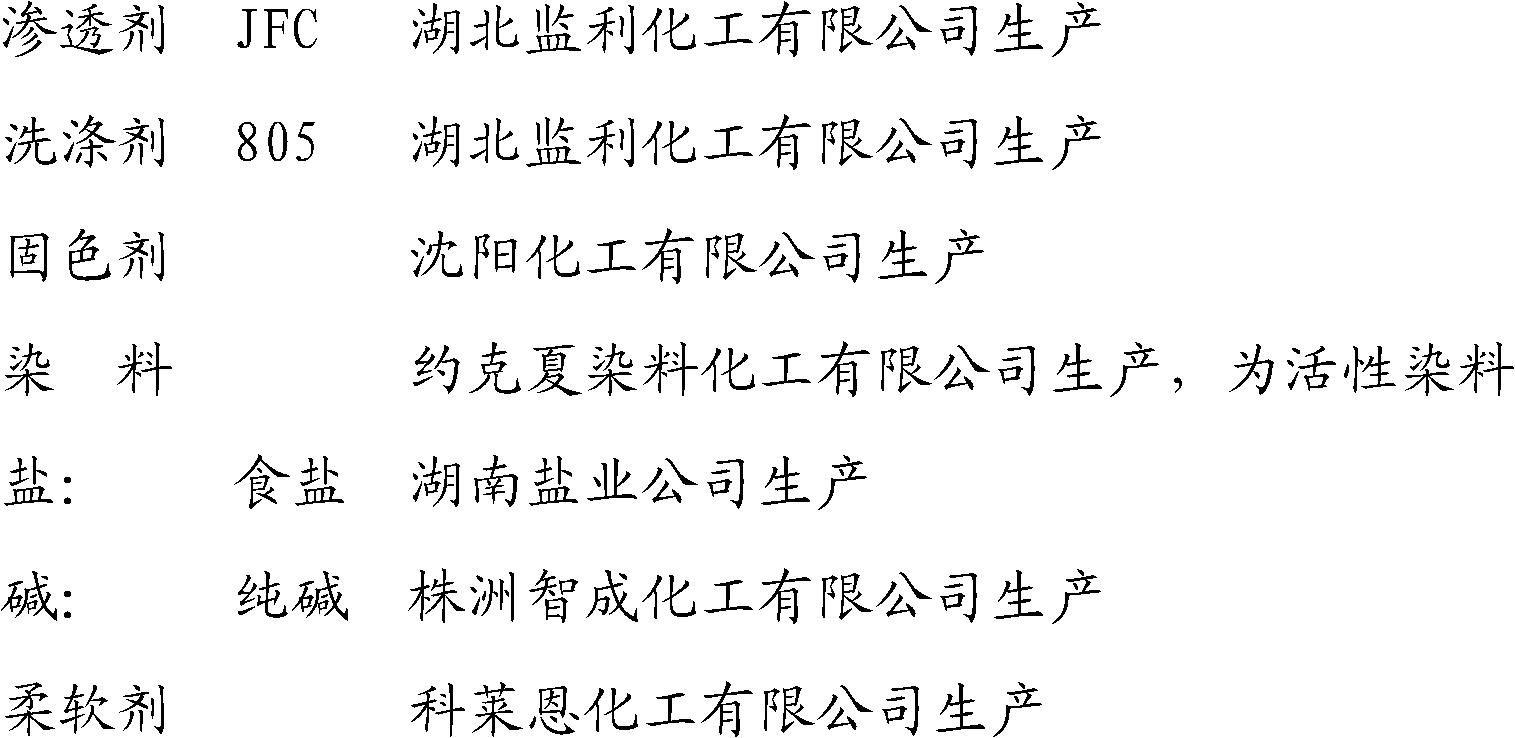

Method of making a porous tio2 photonic film

ActiveUS20110214998A1Improve their various applicationDifferent colorsElectrolysis componentsSurface reaction electrolytic coatingElectric fieldSine wave

A porous titanium dioxide film having photonic properties is made by etching a titanium substrate in an electrolyte solution in the presence of an electric field. The electrolyte solution can be an organic electrolyte solution. Etching involves providing an electrolyte solution in contact with a pair of electrodes and passing an electric current through the electrolyte solution. The titanium substrate can be one of the pair of electrodes. The current has a wave profile selected from a group consisting of a periodic square profile, a sine wave, a linear profile, or a quintic profile, and is provided either parallel of perpendicular to a plane of the substrate.

Owner:CITY UNIVERSITY OF HONG KONG

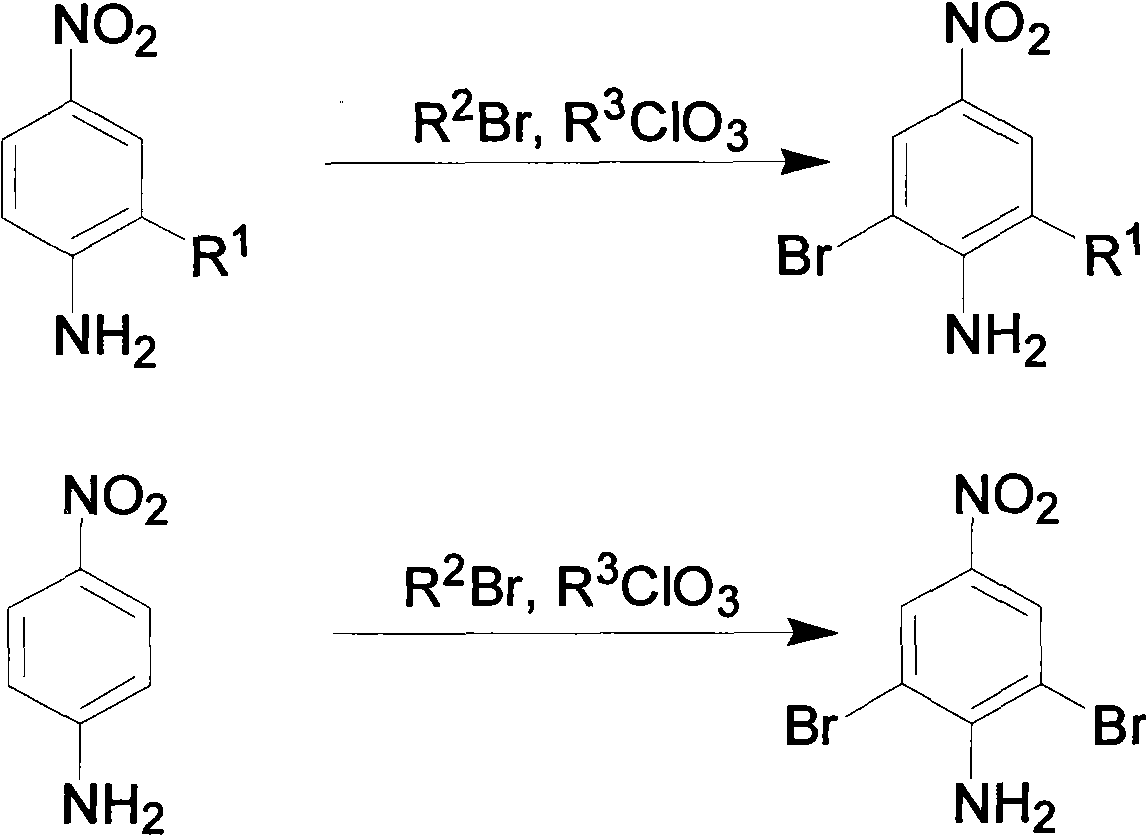

Preparation method of bromo-nitroaniline dye stuff intermediate

ActiveCN101838174AHigh strengthHigh fastnessCarboxylic acid nitrile preparationOrganic compound preparationWastewaterHydrogen bromide

The invention discloses a preparation method of a bromo-nitroaniline dye stuff intermediate, which comprises the following steps of: adding inorganic acid aqueous solution into bromide aqueous solution; stirring the mixture; adding a nitroaniline compound into the mixture; raising the temperature of the mixture to be between 35 and 55 DEG C; pulping and stirring the mixture; dropping chlorate aqueous solution into the mixture, wherein the dropping time is more than 2 hours; stirring the mixture, and raising the temperature of the mixture to between 65 and 75 DEG C; filtering the mixture after reaction; washing a filter cake until the pH value is 5 to 8; and drying the filter cake to obtain the bromo-nitroaniline dye stuff intermediate. The product obtained by adopting the method has high quality and yield, the production cost is greatly reduced, the process is simple, and simultaneously, the pollution, caused by waste gases containing hydrogen bromide and waste water containing bromide salts, to the environment is greatly cut down.

Owner:浙江长征化工有限公司

Multifunctional biodegradable composite material and preparation method of same

The invention discloses a multifunctional biodegradable composite material and a preparation method of same. The composite material includes a biodegradable material substrate and a natural biomass additive dispersed therein. The preparation method includes preparation of the natural biomass additive and preparation of the multifunctional biodegradable composite material. The method is not depended on mineral resources, such as petroleum, natural gas and the like, so that the composite material is energy-saving and environment-friendly and has simple preparation process and low cost. According to different performances of different biodegradable material substrates, a series of the multifunctional biodegradable composite materials are applied to different fields, such as product packaging, biomedicine, water area environment, agriculture mulching films, stationery and sporting goods, mechanical appliances and the like. The composite material has excellent mechanical performances, can reach 4-5 level in color fastness to rubbing, can reach 90-99% in antibacterial ratio, and can reach 0-1 level in mildew-proofing capability.

Owner:SHAANXI UNIV OF SCI & TECH

Anti-dazzle fire-resistance polycarbonate and preparation method thereof

The invention relates to anti-dazzle fire-resistance polycarbonate and a preparation method thereof, which belong to the field of fire-resistance polycarbonate. The anti-dazzle fire-resistance polycarbonate comprises the following ingredients: 10 to 95 parts of polycarbonate, 10 to 85 parts of high-viscosity high-melt-point large-grain-diameter polycarbonate grains, 1 to 20 parts of fire-resistance agents, 0.1 to 8 parts of ultraviolet absorbents, 0.1 to 6 parts of antioxidizers and 0.1 to 5 parts of demolding agents. The high-viscosity high-melt-point large-grain-diameter polycarbonate grains consist of the following ingredients: 100 parts of polycarbonate, 0.1 to 5 parts of cross linking agents and 0.1 to 0.3 part of antioxidizers. The anti-dazzle fire-resistance polycarbonate of the invention has the advantages of light transmission, non-transparency, nebulous and unique patterns, naturalness and non-repeated effect of ice glass, has the effects of dazzle elimination and fire resistance, and has good heat resistance performance, ultraviolet resistance, excellent mechanical property, repeated dismounting and installation, and freely carrying and transportation.

Owner:广州金园聚合物挤出成型科技有限公司

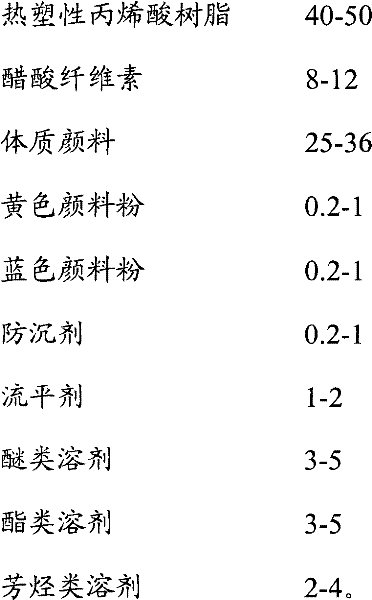

Colorful paint

ActiveCN102241932ADifferent colorsLiquid surface applicatorsMulticolor effect coatingsAromatic solventAcrylic resin

The invention discloses a colorful paint used for motorcycles. The colorful paint is composed of a primer and a finishing paint, wherein the primer is composed of the following components in parts by weight: 40-50 parts of thermoplastic acrylic resin, 8-12 parts of cellulose acetate, 25-36 parts of inert pigment, 0.2-1 part of yellow pigment powder, 0.2-1 part of blue pigment powder, 0.2-1 part of anti-settling agent, 1-2 parts of leveling agent, 3-5 parts of ether solvent, 3-5 parts of ester solvent and 2-4 parts of aromatic solvent; and the finishing paint is composed of the following components in parts by weight: 75-85 parts of thermoplastic acrylic resin, 3-5 parts of weathering-resistant pearl powder, 1-2 parts of acrylic leveling agent, 0.5-1.5 parts of defoamer, 2-4 parts of anti-settling agent, 2-4 parts of ether solvent, 4-6 parts of ester solvent and 1-3 parts of aromatic solvent. The colorful paint prepared by the invention has different color changes under light source irradiation, and is very glittering, beautiful and more stylish when being observed from different view points.

Owner:ANHUI YADEA LOCOMOTIVE CO LTD

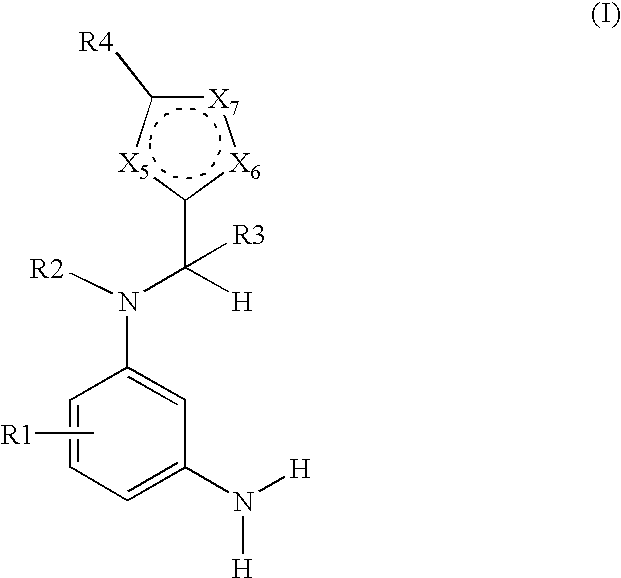

N-heteroarylmethyl-m-phenylenediamine derivatives-containing dyes for keratin fibers and novel n-heteroarylmethyl-m-phenylenediamine derivatives

InactiveUS6997961B2Good water solubilityImproved color stabilityCosmetic preparationsHair cosmeticsFiberKeratin

Owner:WELLA INT OPERATIONS SWITZERLAND SARL

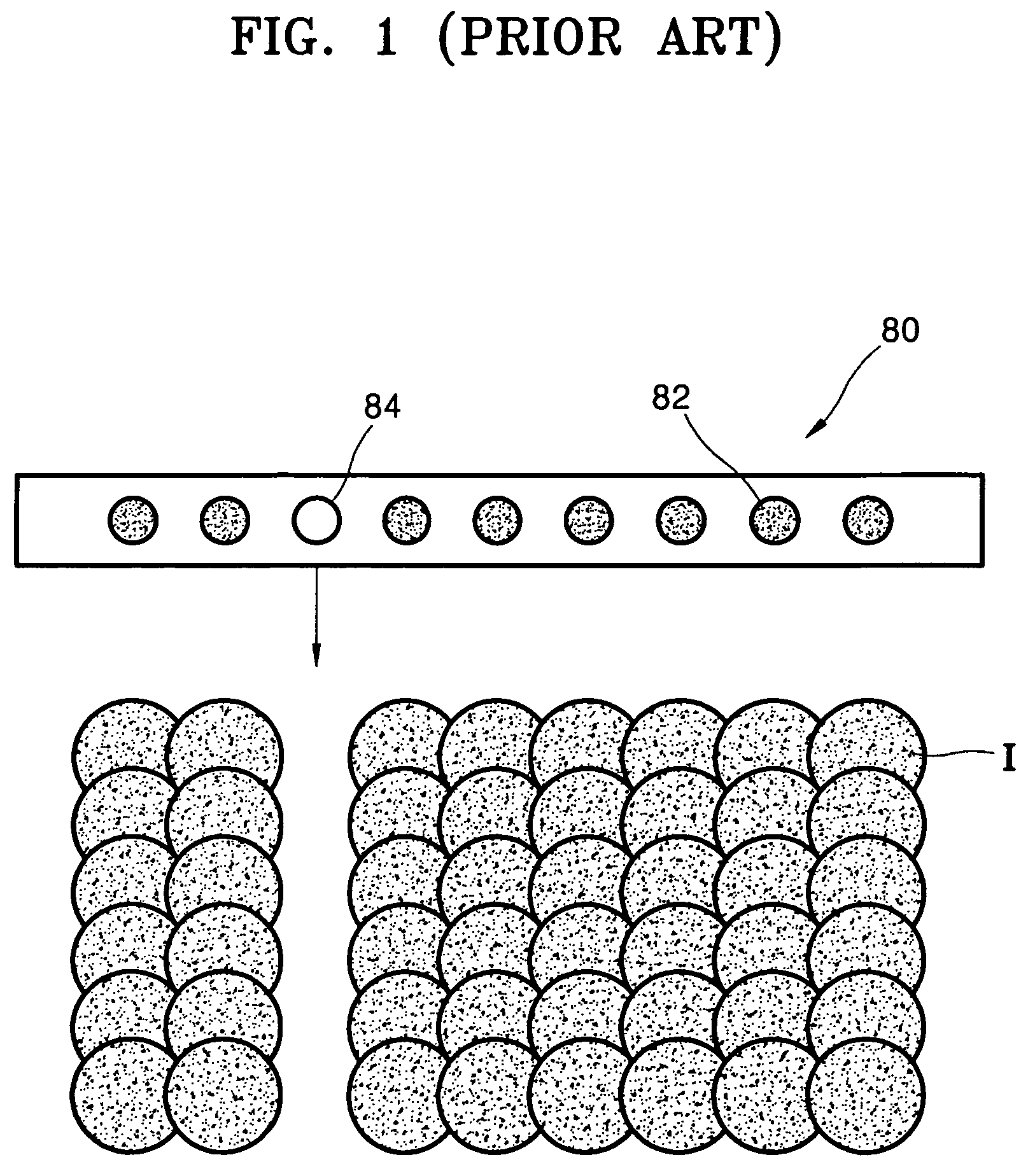

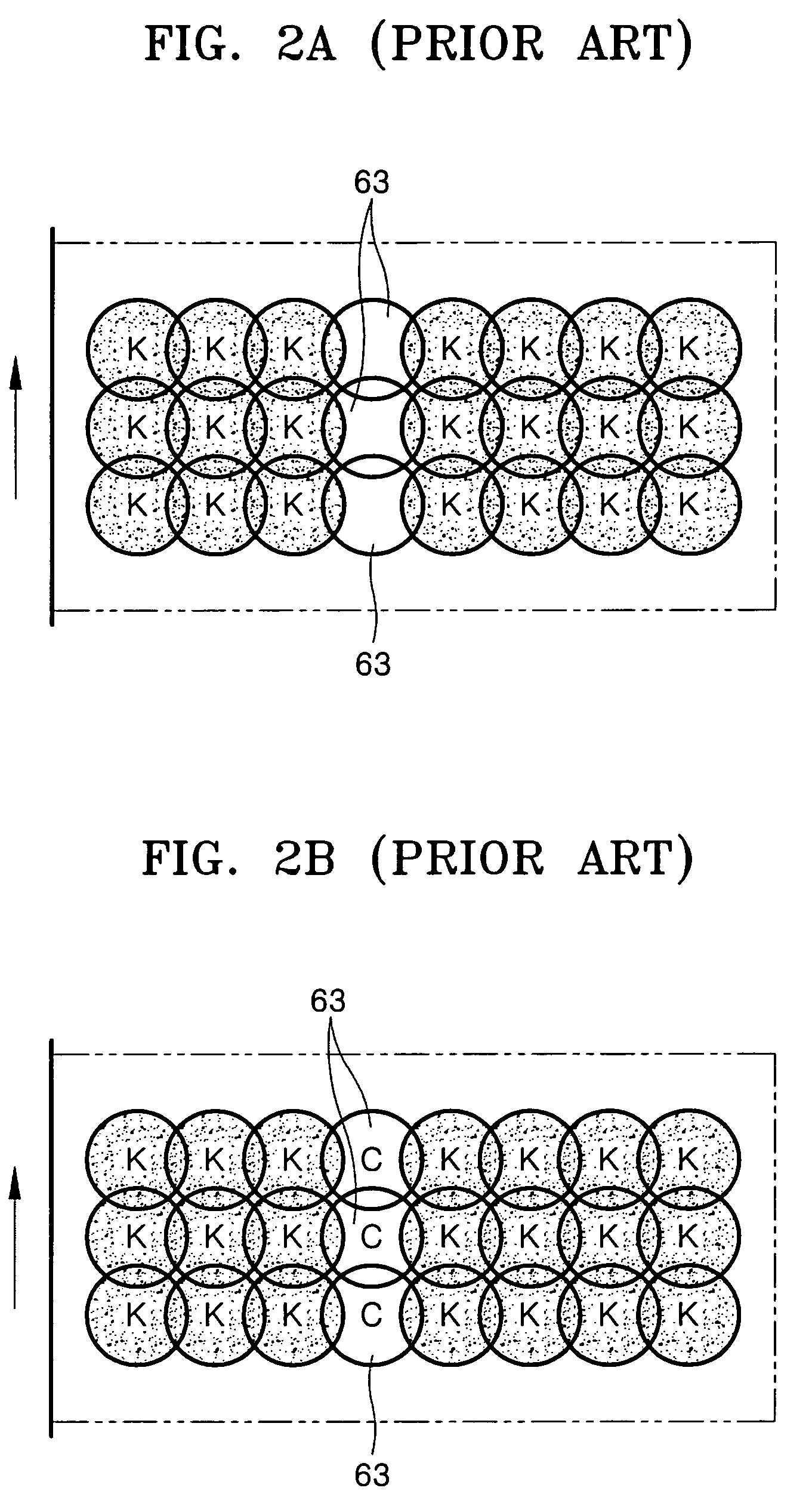

Method and apparatus for compensating for defective nozzle in inkjet image forming apparatus

InactiveUS7533953B2Improve printing qualityMinimize impactOther printing apparatusEngineeringWhite line

Owner:HEWLETT PACKARD DEV CO LP

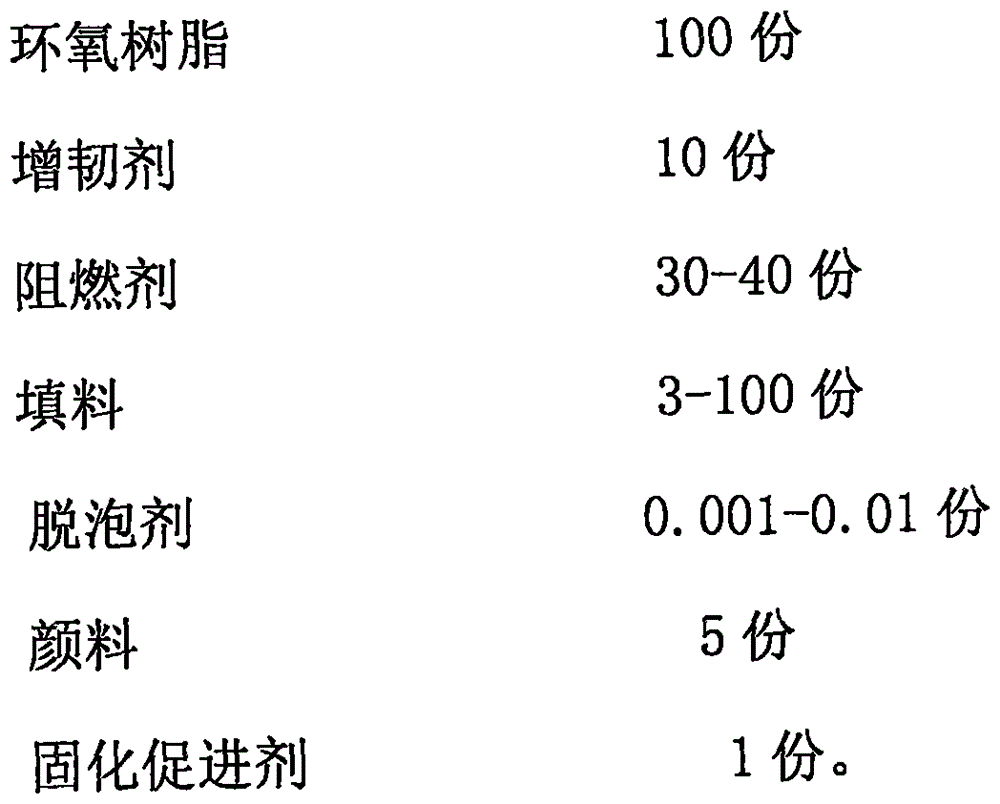

Thermosetting non-photocureable 3D printing material and printing method thereof

InactiveCN105907043AHigh strengthFlat surfaceAdditive manufacturing apparatusSurface layerThin layer

The invention relates to a thermosetting non-photocureable 3D printing material and a printing method thereof. The 3D printing material is a thermosetting resin, and is composed of a component A and a component B. The component A consists of epoxy resin, a toughening agent, a flame retardant, filler, a defoaming agent and a pigment, and the component B consists of a curing agent, a defoaming agent and other components. The method includes: firstly subjecting the component A to thin layer printing, subjecting the component B to spray deposition to the surface layer of the component A, and performing fast curing; repeating the component A thin layer printing, conducting spray deposition on the component B to the surface layer of the component A until a model is completely printed; and then carrying out medium temperature post-curing so as to obtain a print model with high strength, smooth surface and good toughness.

Owner:余若冰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com