UV coating decorative plate and preparation method thereof

A decorative board and coating technology, applied in the field of UV coating decorative board and its preparation, can solve the problems of failing to reflect the individual requirements of modern people, affecting visual effects, monotonous colors, etc., to achieve different and personalized colors. Prominent, high surface gloss, good plump effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

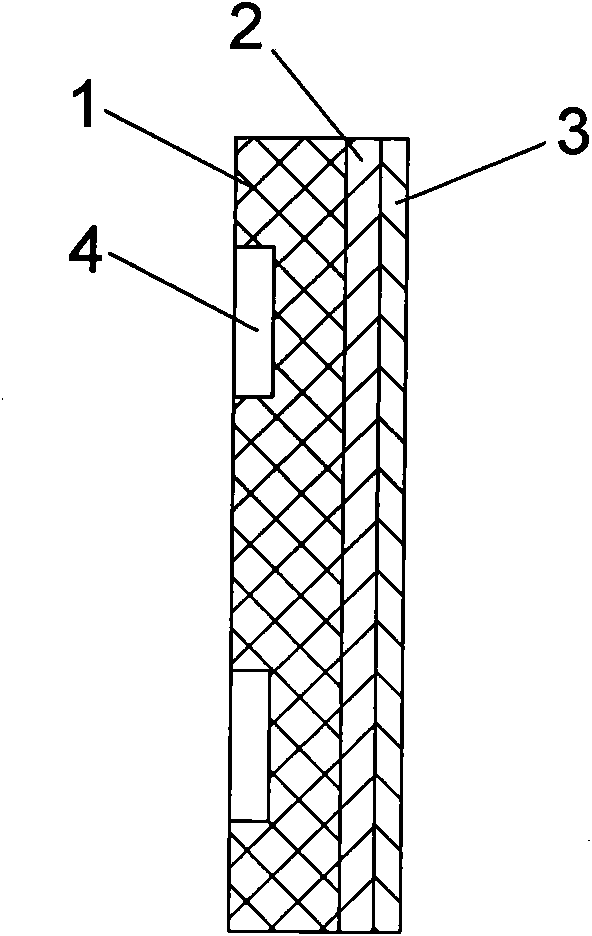

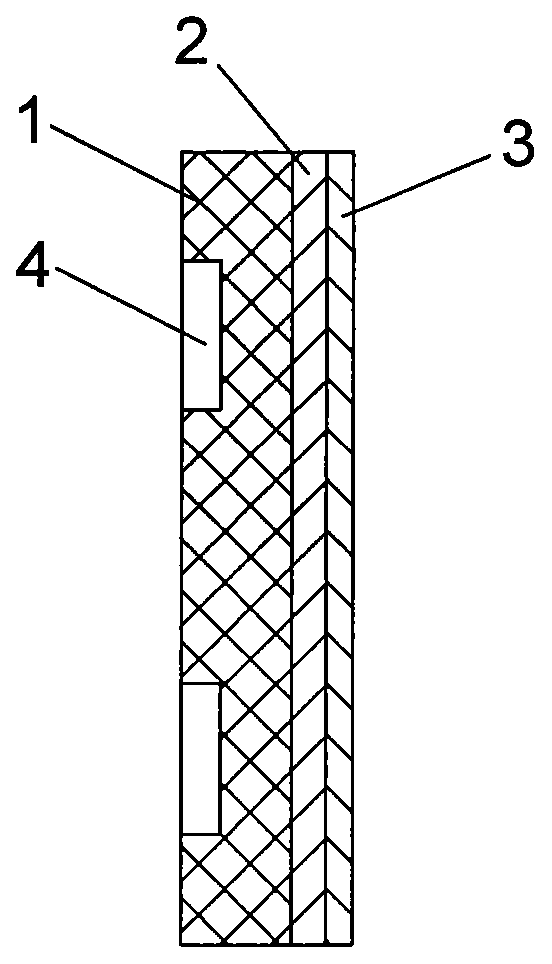

[0024] Such as figure 1 As shown, a UV-coated decorative board includes a base layer 1, and the base layer 1 can be ceramics, or glass, or a metal plate, or a medium-fiber board, or a density board, or a particle board, or a chemical board, or other composites board, wherein, the density board can be a melamine board, or a PVC board, or a PV board, or a density board commonly known in the industry; veneer, or printed paper, or pattern paper, the decorative layer 2 is a veneer containing veneer, leather, or PVC, or PET, or PE, or ABS, or HAPS, or PP, or other materials, the decorative The surface of the layer 2 is provided with a UV coating layer 3, and the base layer 1 is also opened or preset with a relevant groove or an installation connection block 4; , or hand-painted on the surface of the decorative layer 2 .

[0025] A method for preparing the above-mentioned UV coating decorative plate, comprising the following steps:

[0026] Step 1, pasting and curing, pasting a de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com