Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Conductive stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

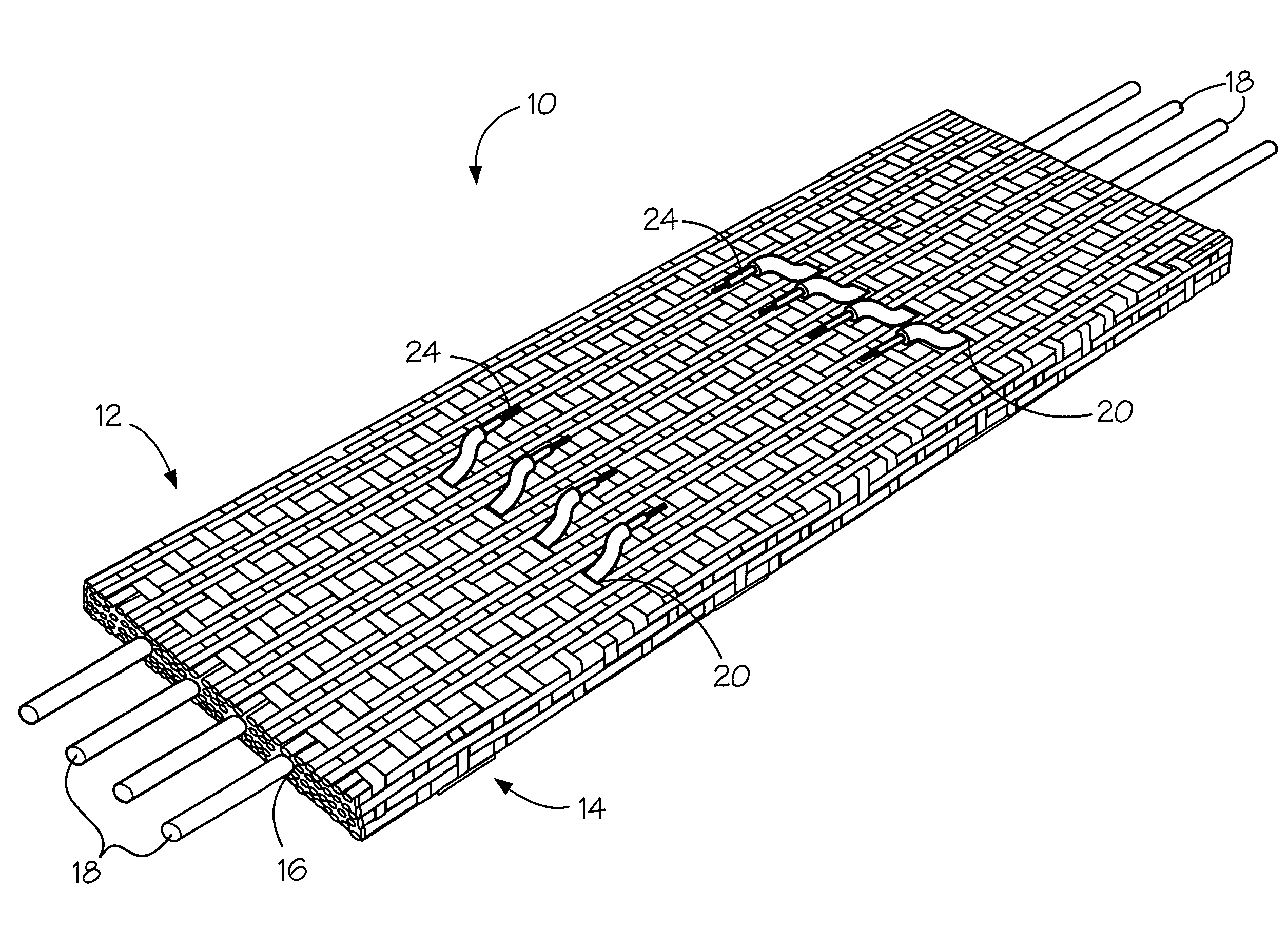

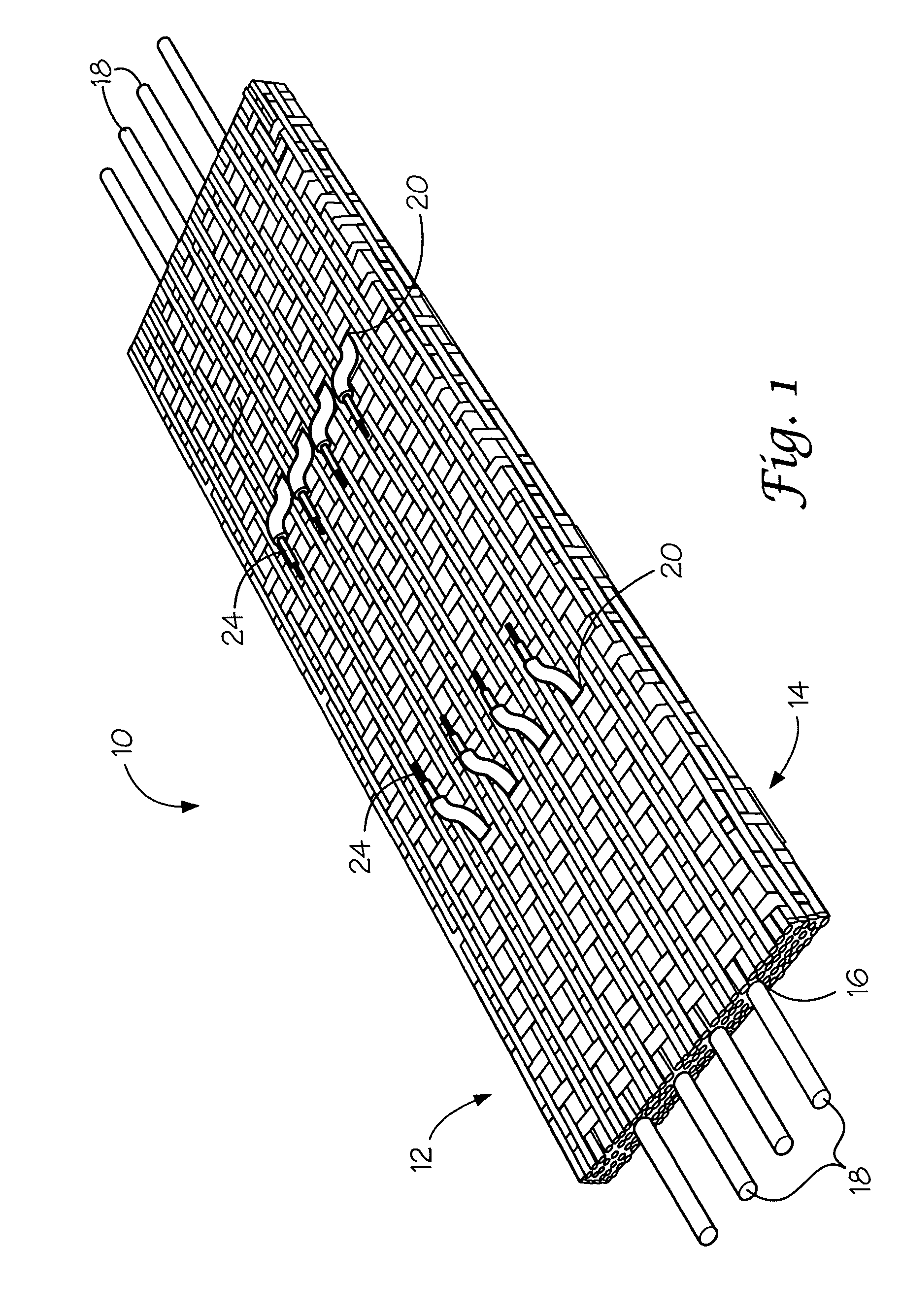

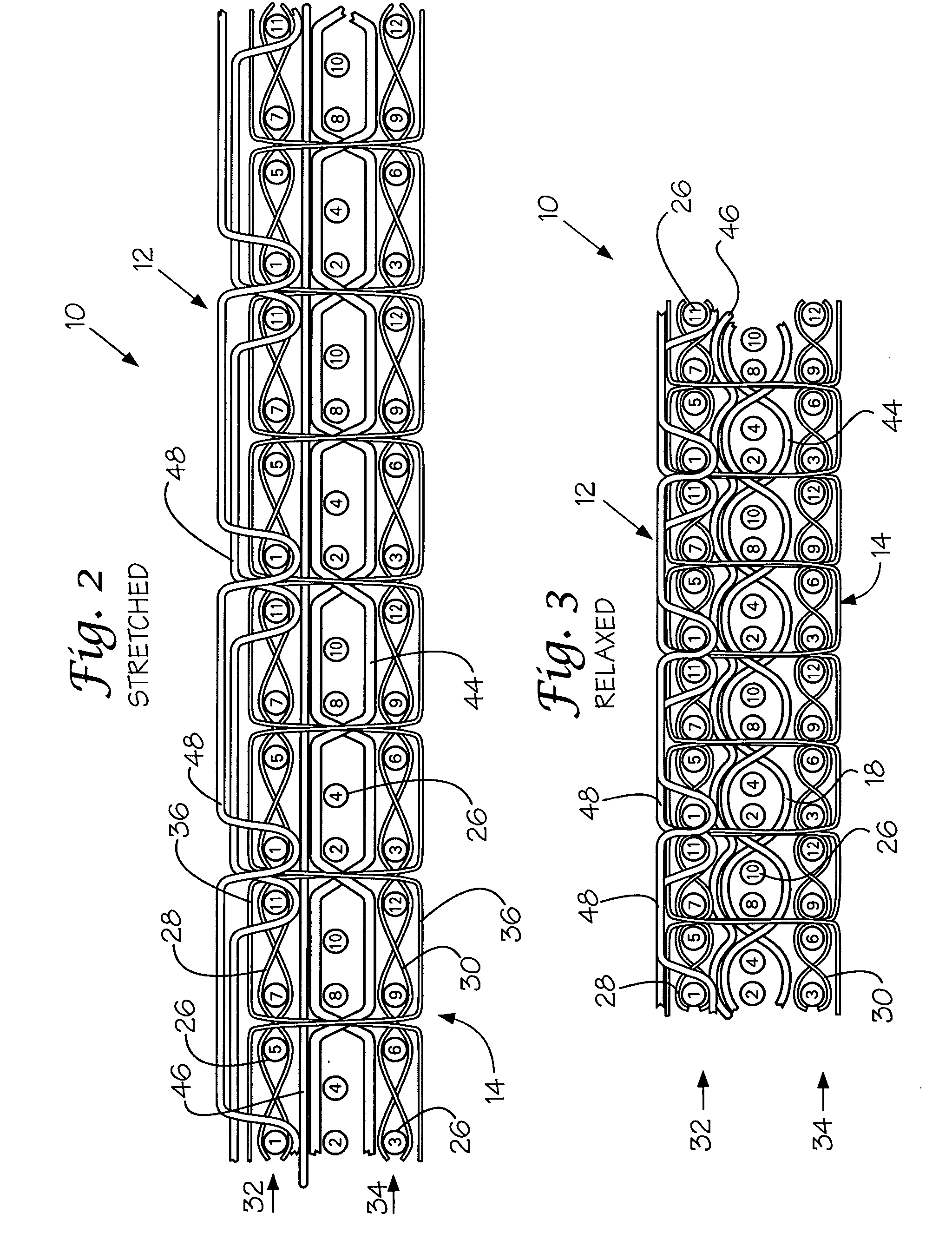

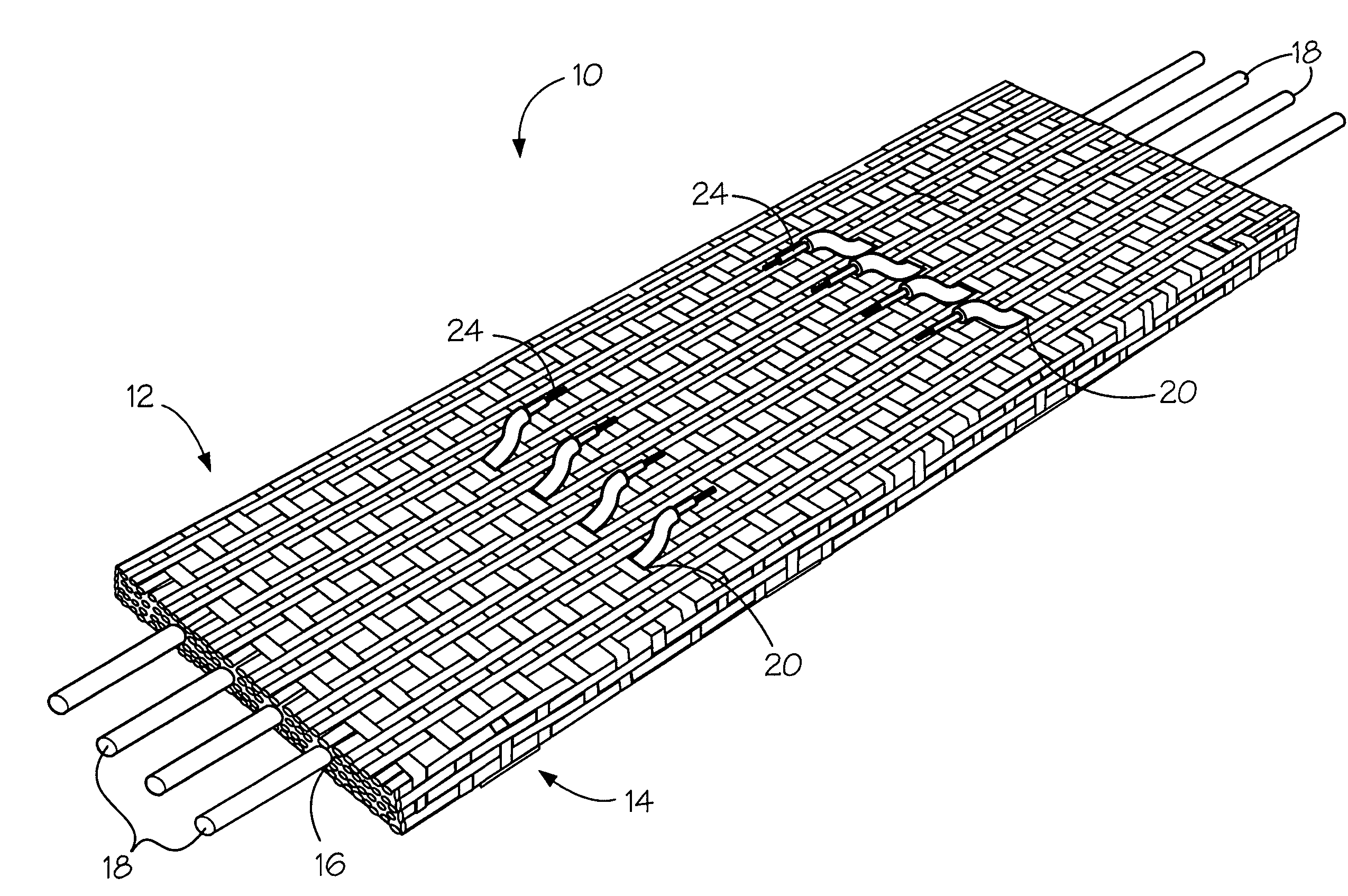

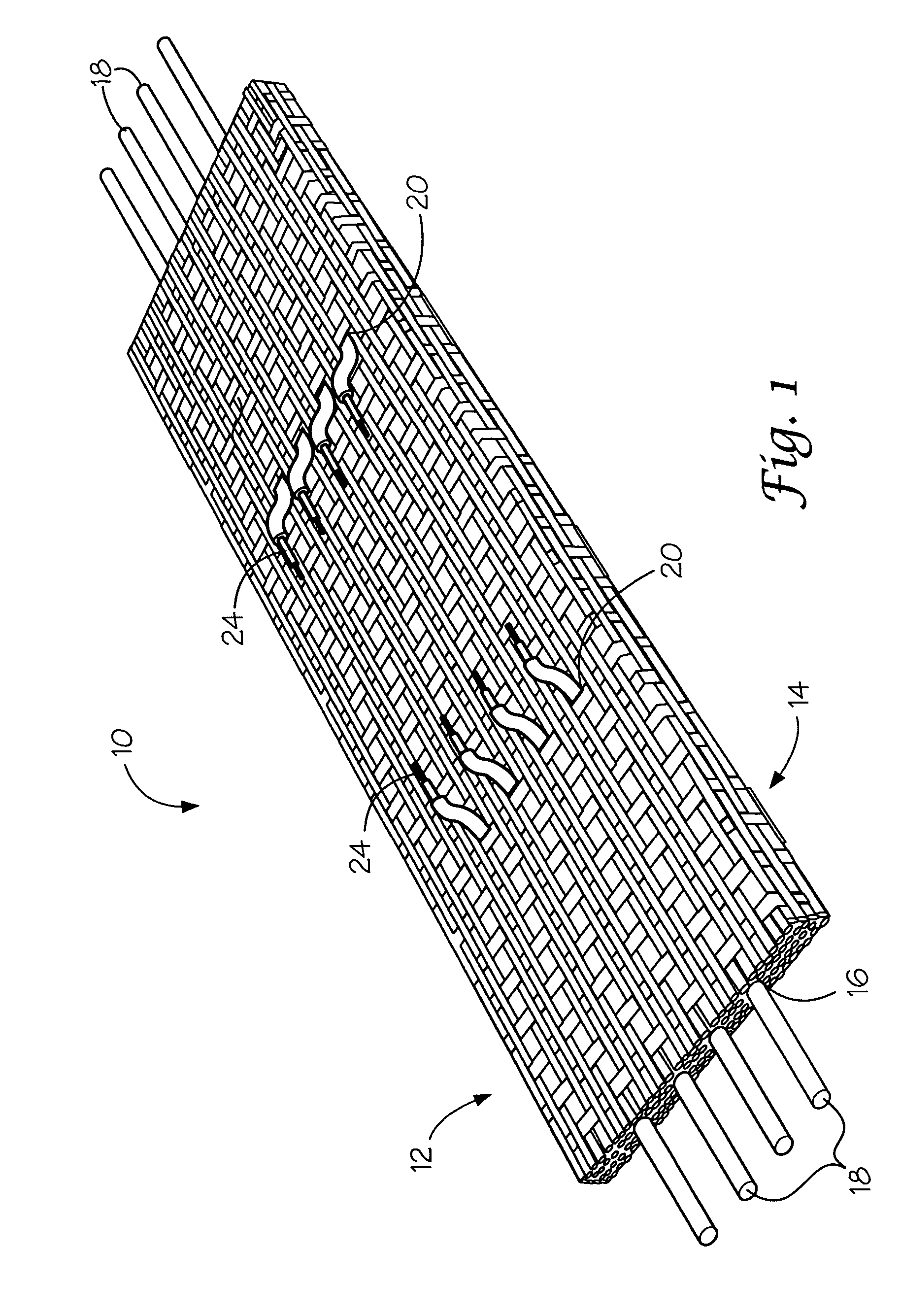

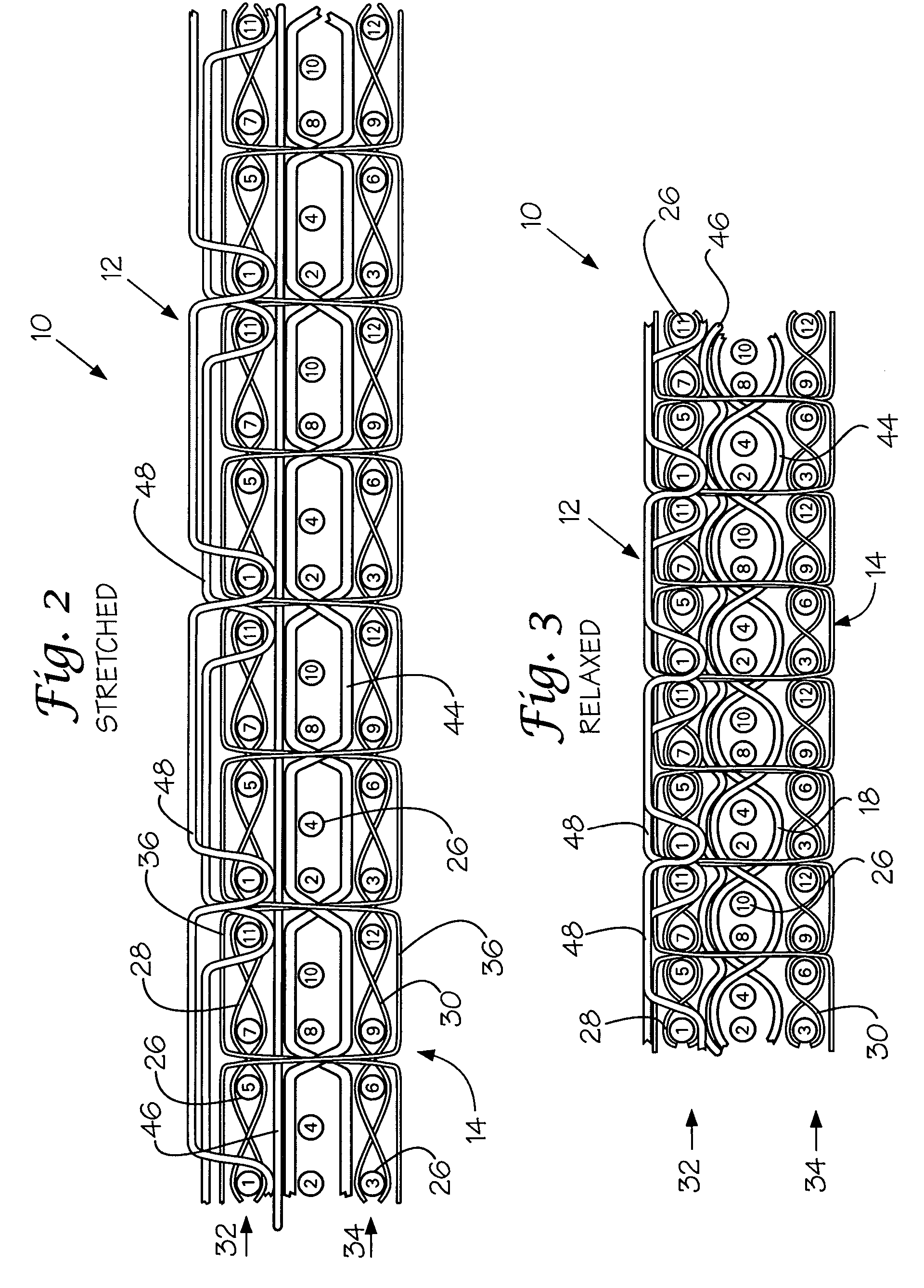

Elastic fabric with sinusoidally disposed wires

ActiveUS20060124193A1Reducing fabric lengthConductive stabilityCircuit bendability/stretchabilityGarmentsYarnEngineering

A fabric for use with a system for monitoring prescribed body functions comprising an elastic fabric, adapted to be carried by a torso, which is stretchable in its longitudinal direction so as to expand and contract in response to body movement and size. The carrier includes at least one conductive and inelastic yarn arranged longitudinally of and located between upper and lower surfaces. The conductive yarn is arranged in sinusoidal configurations longitudinally of the fabric. The conductive yarn forms a breakout through one of the outer surfaces, at selected locations along the length of the fabric, forming opposed exposed ends above the surface. A monitoring unit, which includes a connector and a sensor, is secured with the one surface at the breakout with the connector being united with the exposed ends of the conductive yarn. The fabric acts to maintain the monitoring unit in a desired stationary position allowing the sensor to sense signals emitted from the torso and transmit these senses signals.

Owner:WOVEN ELECTRONICS

Elastic fabric with sinusoidally disposed wires

ActiveUS7191803B2Conductive stabilityShorten the lengthCircuit bendability/stretchabilityGarmentsEngineeringBody movement

A fabric for use with a system for monitoring prescribed body functions comprising an elastic fabric, adapted to be carried by a torso, which is stretchable in its longitudinal direction so as to expand and contract in response to body movement and size. The carrier includes at least one conductive and inelastic yarn arranged longitudinally of and located between upper and lower surfaces. The conductive yarn is arranged in sinusoidal configurations longitudinally of the fabric. The conductive yarn forms a breakout through one of the outer surfaces, at selected locations along the length of the fabric, forming opposed exposed ends above the surface. A monitoring unit, which includes a connector and a sensor, is secured with the one surface at the breakout with the connector being united with the exposed ends of the conductive yarn. The fabric acts to maintain the monitoring unit in a desired stationary position allowing the sensor to sense signals emitted from the torso and transmit these senses signals.

Owner:WOVEN ELECTRONICS

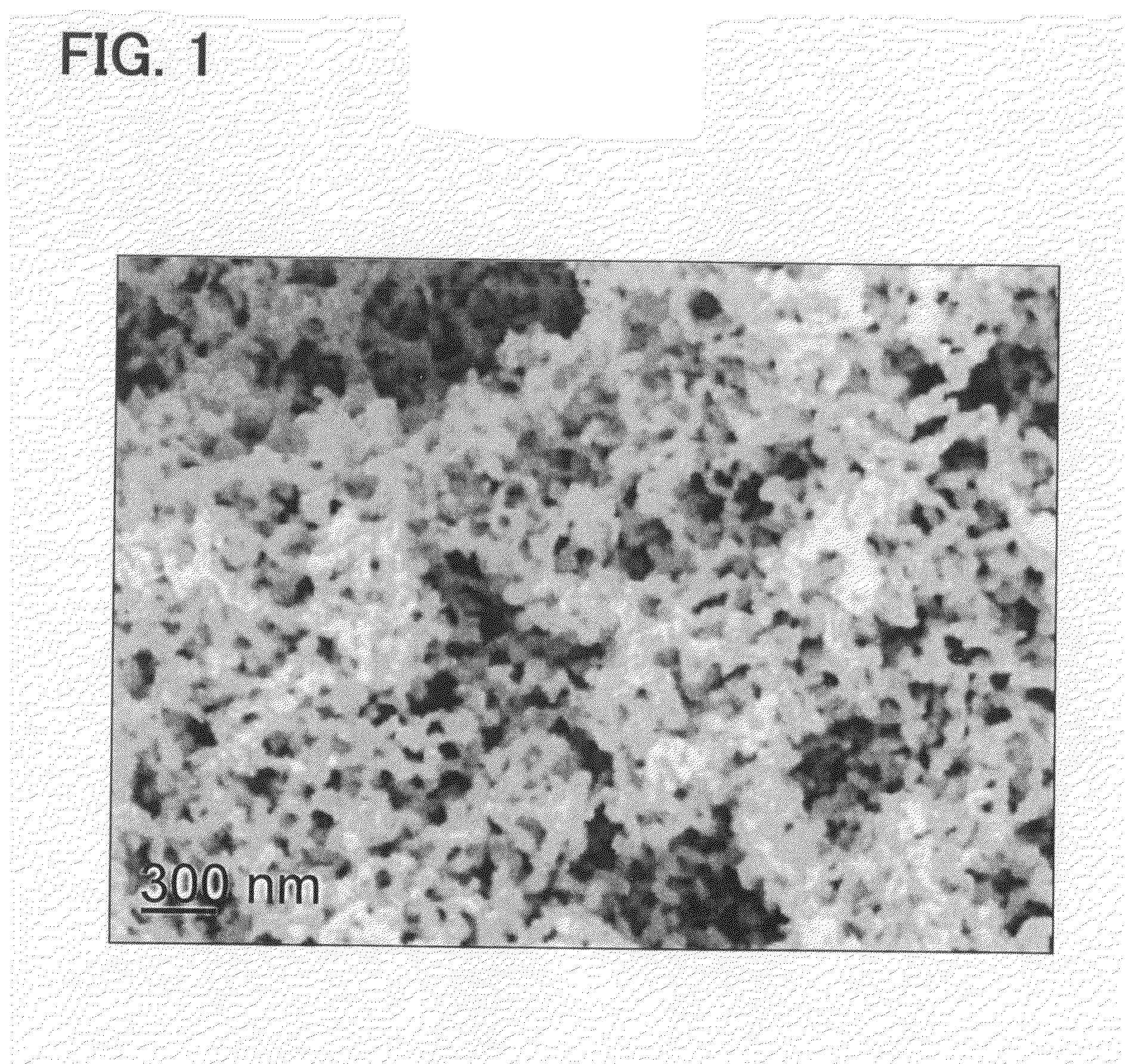

Negative electrode for nonaqueous electrolyte solution battery and nonaqueous electrolyte solution battery having the same

ActiveUS20100316907A1Stable electric conduction routeReduced characteristicsElectrode carriers/collectorsNanotechnologyLithiumCarbon composites

A negative electrode used for a nonaqueous electrolyte solution battery having nonaqueous electrolyte solution containing lithium ion includes a metal carbon composite material. The metal carbon composite material has a porous carbon material having cavities, and a metal material made of metal to reversibly store or emit lithium ion. The metal material is arranged on a surface of the porous carbon material including inner surfaces of the cavities. The porous carbon material has a mass of 1-65 mass % when the metal carbon composite material is defined to have a mass of 100 mass %.

Owner:SK ON CO LTD

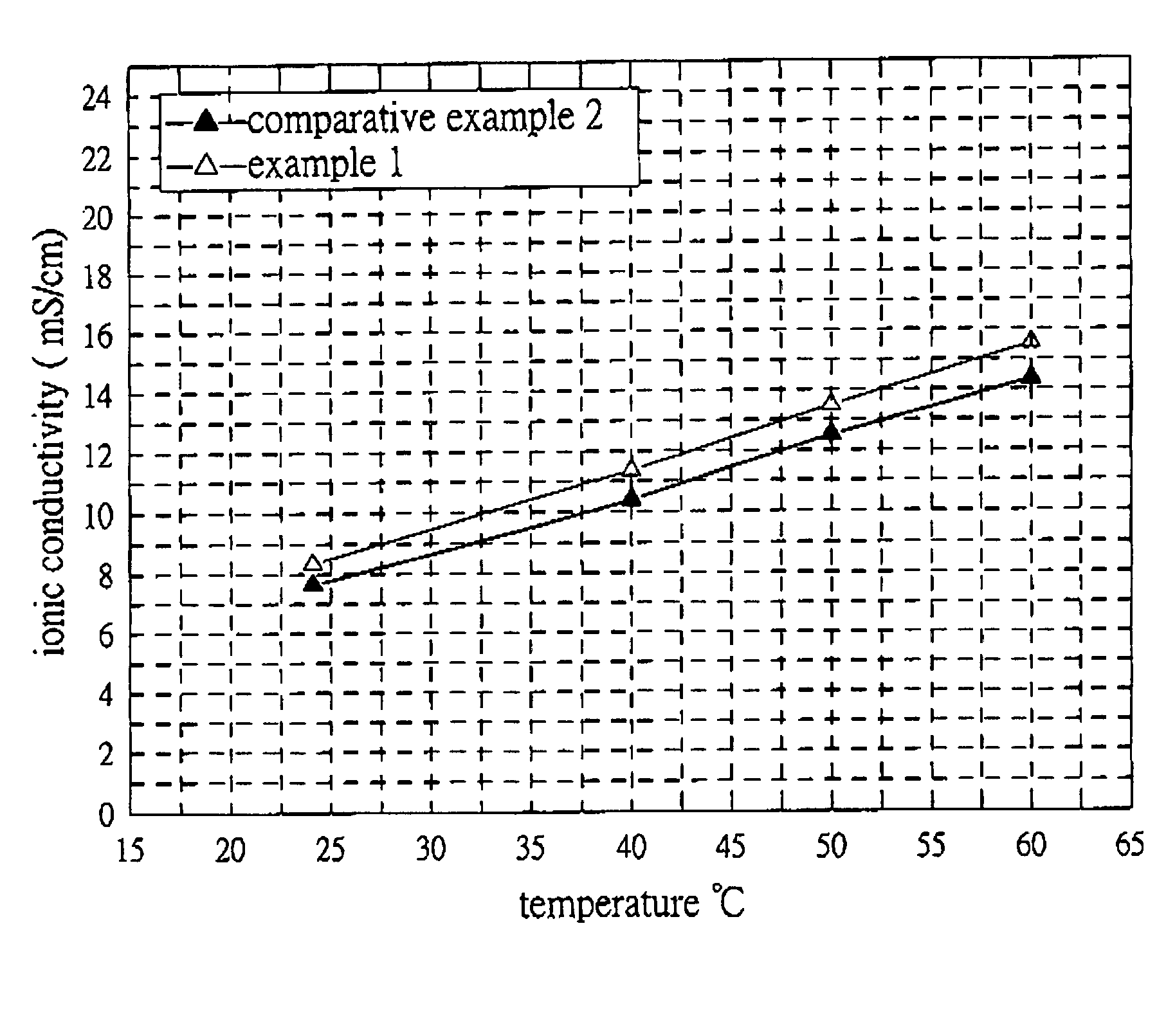

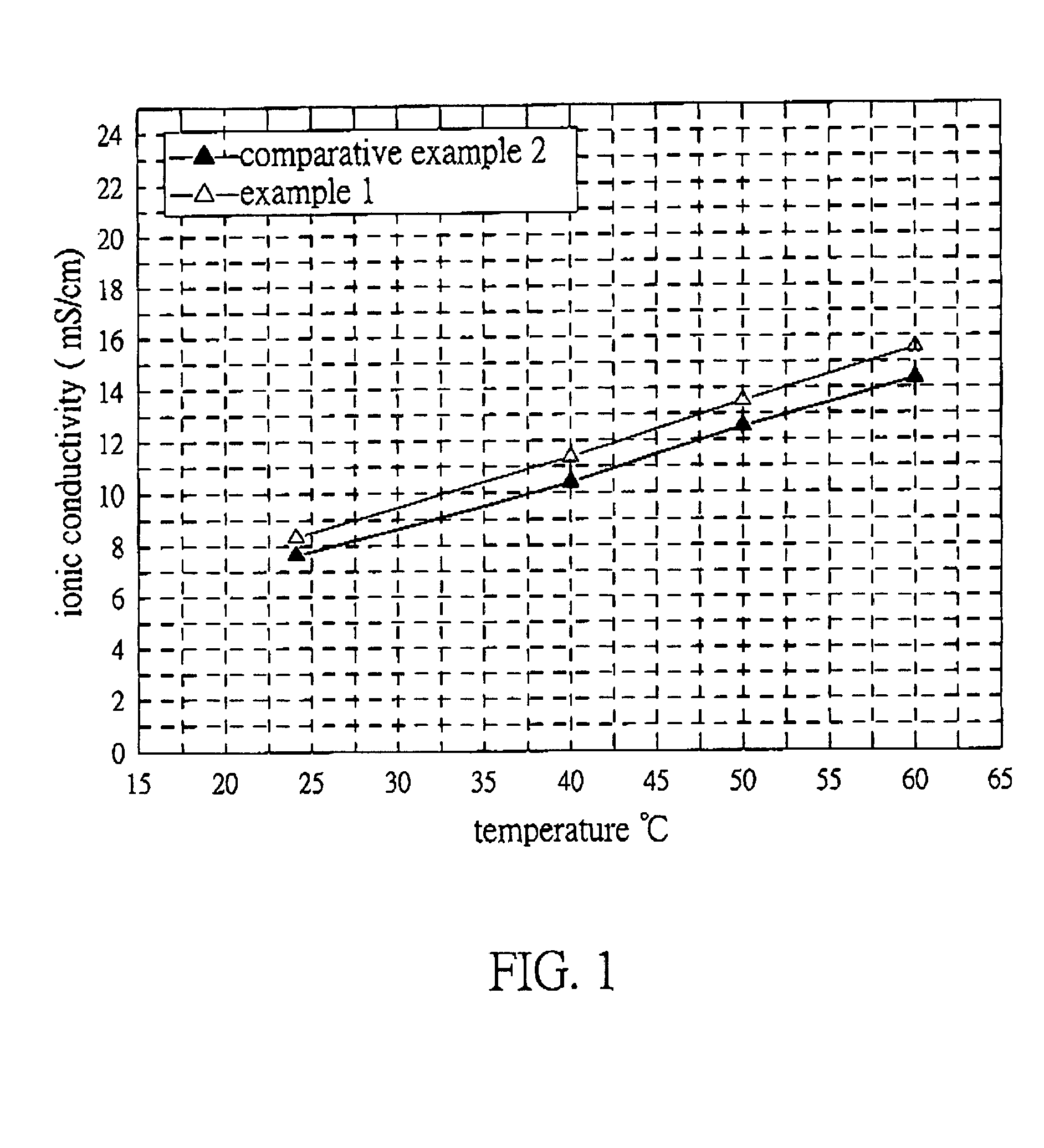

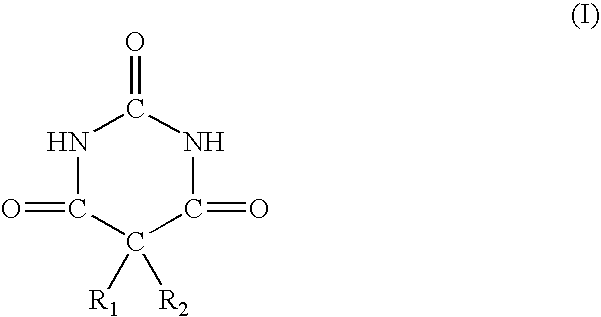

Flame retarding polymer electrolyte composition containing maleimides

ActiveUS20080176141A1Improve flame retardant performancePrevent leakageSolid electrolytesElectrolytic capacitorsLithiumDendrimer

A flame retarding polymer electrolyte composition containing maleimides includes a modified maleimide; a lithium salt; and at least one ionic solution in a ratio of at least 2 wt % relative to the total weight of the composition. By using the hyperbranched dendrimer-like structure of the modified maleimide as grafted skeleton for polymer electrolytes, the electrolyte composition can encapsulate an electrolytic solution continuously, thus preventing the exudation of the electrolytic solution and increasing the stability of lithium ionic conduction. Since the ionic solution is nonflammable, the safety of batteries are further enhanced when the polymer electrolyte composition is used as polymer electrolyte for a lithium secondary battery.

Owner:IND TECH RES INST

Electrode composite body, electrolyte, and redox capacitor

InactiveUS20070139862A1Conductive stabilityWide applicationHybrid capacitor electrolytesDouble layer capacitorsDopantConductive polymer

An electrode composite body including a conductive polymer film in which the doping and dedoping capacities of the conductive polymer are improved, an electrolyte, and a redox capacitor including those are provided. The object is achieved by the followings: (1) an electrode composite body including a conductive polymer and an electrode for redox capacitors; (2) an electrode composite including a conductive polymer film and an electrode body for redox capacitors; (3) an electrolyte for redox capacitors that contains an ionic liquid as an essential component; (4) a redox capacitor composed of an electrolyte containing an ionic liquid as an essential component and an electrode composite body for redox capacitors; and (5) a composite body in which the anionic component contained in the ionic liquid and is the same component as a part of the dopant of the conductive polymer.

Owner:KANEKA CORP

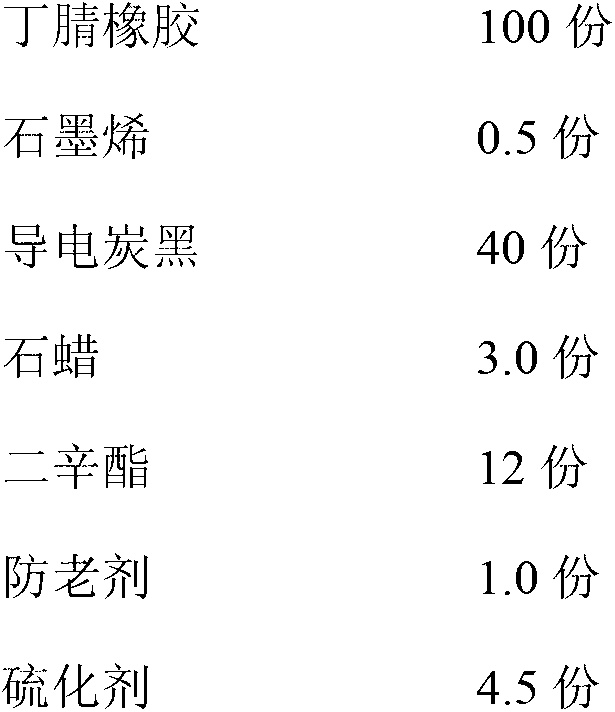

Strippable semiconductive shielding rubber for rubber insulation and preparation method thereof

ActiveCN103122085AHighly cleanAvoid performance biasPower cables with screens/conductive layersPlasticizerResidual carbon

The invention relates to a strippable semiconductive shielding rubber for rubber insulation and a preparation method thereof. The strippable semiconductive shielding rubber comprises the following components in parts by weight: 100 parts of nitrile-butadiene rubber, 0.5-8 parts of graphene, 10-40 parts of conductive carbon black, 7-15 parts of plasticizer, 1-2 parts of anti-aging agent and 2.5-4.5 parts of vulcanizing agent, wherein the nitrile-butadiene rubber is a solar one; the minimum surface-diameter ratio of the graphene is 1000; the plasticizer is one or a mixture of paraffin, dioctyl ester, stearic acid and the like; and the vulcanizing agent is a peroxide vulcanizing system. The preparation method comprises the following steps: plasticating the nitrile-butadiene rubber twice (10 minutes for each time), and standing at normal temperature for 12 hours; adding the graphene into the plasticated nitrile-butadiene rubber, evenly mixing, and adding 1 / 2 of the conductive carbon black or acetylene carbon black; 3 minutes later, adding the residual carbon black and the plasticizer, and compounding for 2 minutes; sequentially adding various assistants, finally adding the vulcanizing agent, compounding for 1 minute, and then discharging, wherein the compounding temperature is not higher than 120 DEG C; and after discharging, tabletting semiconductive shielding gum on a tabletting machine to prepare the semiconductive shielding rubber. The semiconductive shielding rubber provided by the invention is easy to process and strip and high in conductivity.

Owner:SHANGHAI LEVSON ENTERPRISE GRP

Touch panel, electronic device including same, and method for manufacturing touch panel

ActiveUS20170353181A1Reducing external light reflectivityReduce thicknessElectronic switchingPrinted circuit manufactureVisibilityEngineering

A touch panel is manufactured by a method that decreases undesirable reflections of external light while improving the visibility of emitted light. The touch panel includes a base layer including an active region responsive to an external touch to generate an electronic signal and a peripheral region adjacent to the active region, and a first conductive pattern disposed on the active region and a second conductive pattern disposed on the peripheral region, each of the first conductive pattern and the second conductive pattern including a conductive layer having an external light reflectivity and a darkening layer disposed over the conductive layer. External light reflectivity of each of the first and second conductive patterns is lower than that of the conductive layer.

Owner:SAMSUNG DISPLAY CO LTD

Silver-plated copper powder and preparation method thereof

InactiveCN102814496AImprove conductivityImprove antioxidant capacityLiquid/solution decomposition chemical coatingSilver plateAdhesive

The invention relates to silver-plated copper powder and a preparation method thereof; the powder comprises the following raw materials by the percentage of the raw materials in the total weight: 5 percent to 30 percent of silver, and the balance of copper. According to the invention, a method for replacing and reducing composite plating silver by copper powder is adopted, the prepared silver-plated copper powder has good coating performance, strong oxidation resistance and low volume resistivity, and can be widely applied to various electromagnetic shielding fillers, conductive adhesives and conducting coatings.

Owner:YANTAI DARBOND TECH

Non-aqueous electrolyte solution for lithium secondary battery and lithium secondary battery comprising the same

ActiveUS20170125845A1Improved life characteristicImprove high temperature safetyElectrolytesLi-accumulatorsPhysical chemistryLithium-ion battery

The present invention relates to an additive for a non-aqueous electrolyte solution including a compound represented by Formula 1 below, a non-aqueous electrolyte solution for a lithium secondary battery including the same, and a lithium secondary battery including the non-aqueous electrolyte solution.NC—(R)n—CN [Formula 1](in Formula 1,R is a cycloalkylene group having 3 to 6 carbon atoms in which at least one cyano group (—CN) is substituted or unsubstituted, a haloalkylene group having 2 to 5 carbon atoms in which at least one cyano group (—CN) is substituted or unsubstituted, or an alkylene group having 2 to 5 carbon atoms in which at least one cyano group (—CN) is substituted, and n is an integer of 1 to 5.)

Owner:LG ENERGY SOLUTION LTD

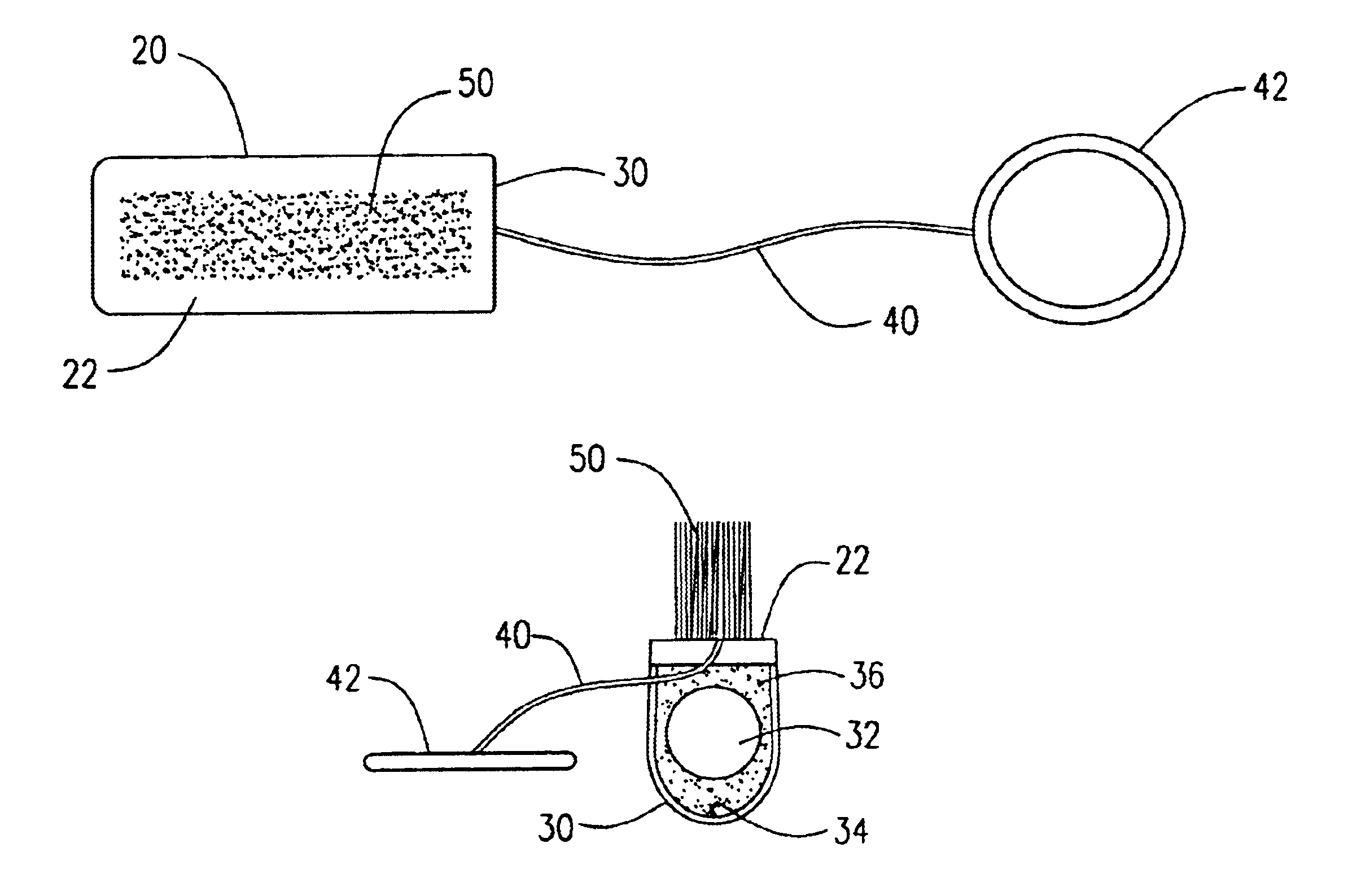

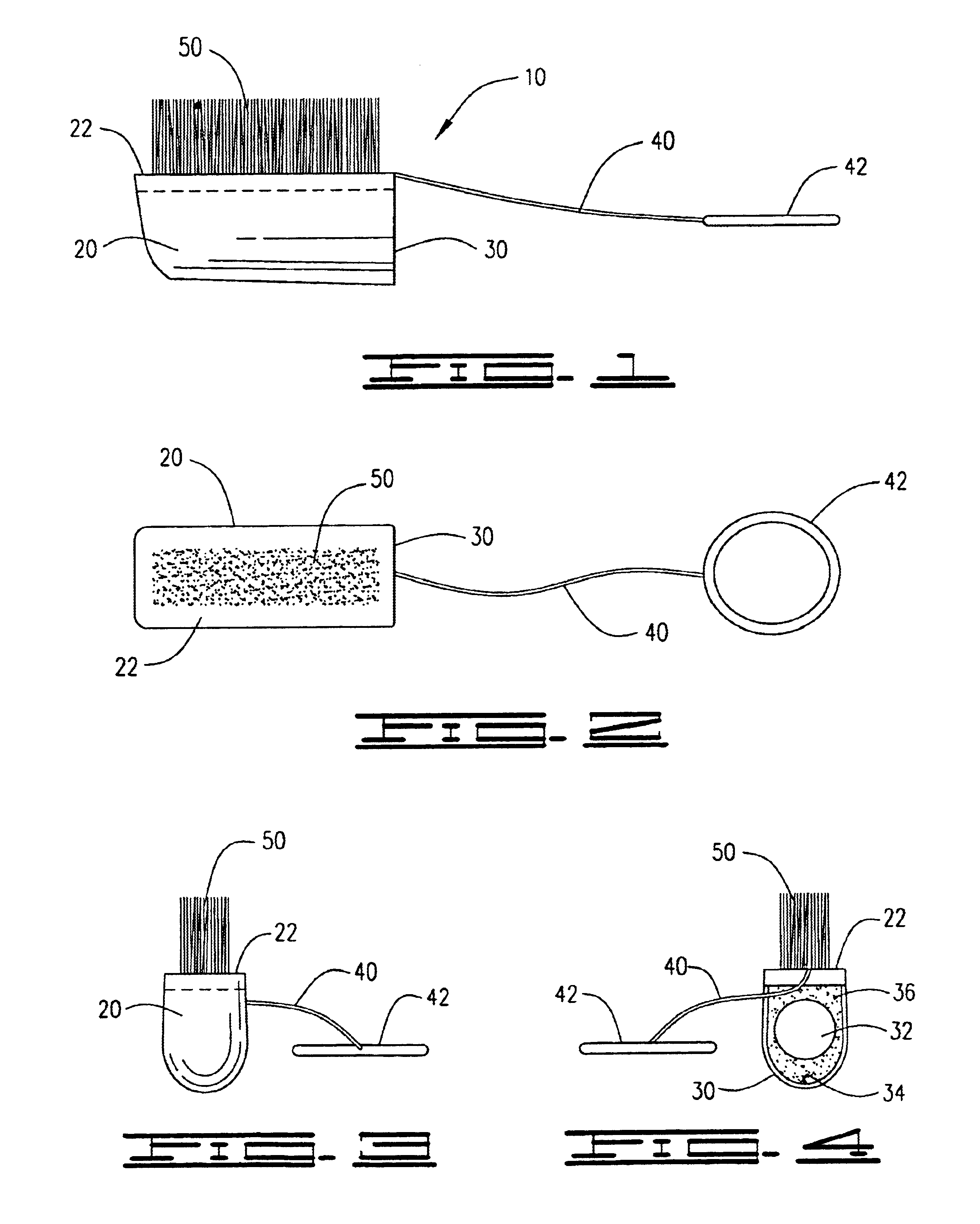

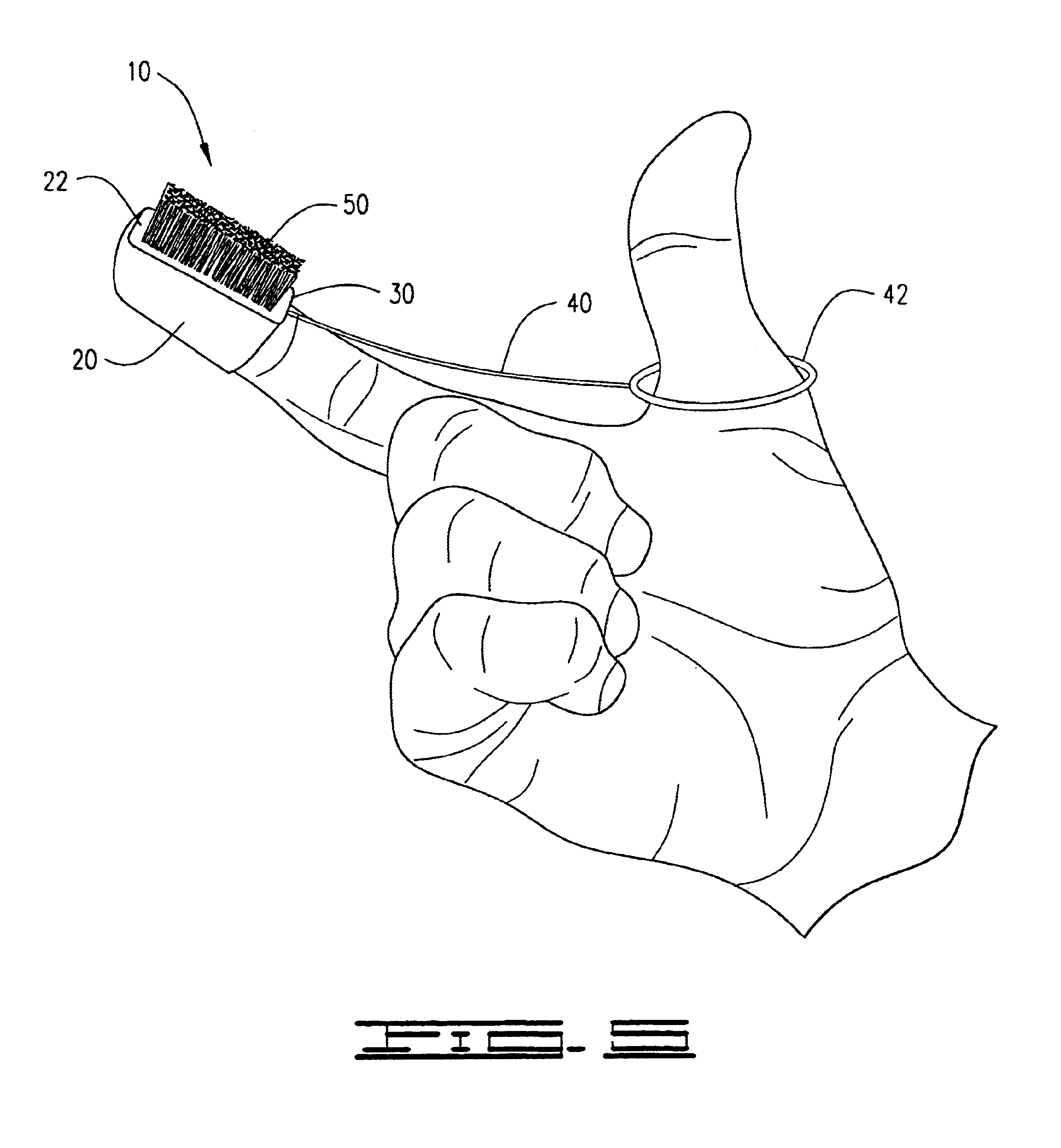

Safety fingertip toothbrush

InactiveUS6874194B1Stable instrument for oral hygieneConductive stabilityBoard cleaning devicesCarpet cleanersEngineeringThumb

The invention is a safety fingertip toothbrush for use by persons not desiring a full length toothbrush for space conservation reasons, but still desiring their regular oral hygiene practice using a toothbrush. The safety fingertip toothbrush is also a practical solution to safety hazards presented in penal institutions, where conventional toothbrushes with hard handles can pose a risk of being converted to lethal assault weapons. The safety fingertip toothbrush has no handle, but it includes a plurality of bristles embedded in a brush head, the brush head having a depression in one end to accept the fingertip of a finger and an elastic band connected to a thumb ring within which the thumb is placed, allowing for the user to brush their teeth and other mouth tissue using the fingers as the brush handle.

Owner:HARRIS GEROME C

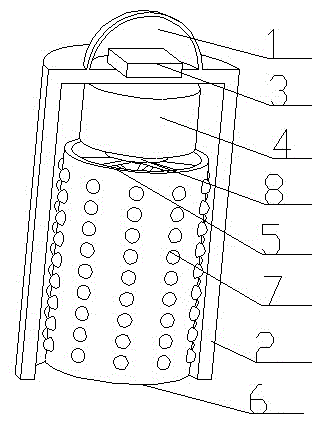

Remote control lift lamp

InactiveCN101050851APrecise dockingPromote repairTransmission systemsLighting support devicesRemote controlEngineering

A rising-and-falling lamp of remote control type is prepared for forming lifter by shell and forward-backward rotation motor as well as winding wheel set on shaft of said motor, hanging illumination lamp on steel wire rope wound on said winding wheel and forming remote control unit by signal receiver set in shell of lifter and power supply as well as hand signal emitter.

Owner:上海必金灯具有限公司

Nano-silver flexible conductive membrane and preparation method thereof

ActiveCN103992495AStable electrical conductivity on the surface of the filmLow resistivityConductive layers on insulating-supportsPretreated surfacesCellulosePolyethylene glycol

The invention relates to the technical field of conductive membranes, particularly to a nano-silver flexible conductive membrane and a preparation method thereof. The nano-silver flexible conductive membrane comprises a PET substrate layer, wherein corona treatment is performed on the surface of the PET substrate layer; a conductive coating layer which is arranged on the surface of the PET substrate layer comprises the following raw materials in percentage by weight: 50-75% of absolute ethyl alcohol, 2-5% of terpilenol, 1-3% of acetyl tributyl citrate, 2-8% of joint cement, 1-5% of polyethylene glycol 400, 2-3% of span 85, 1.5-3% of ethyl cellulose, 3-8% of silver powder of 20-40 nanometers, and 10-18% of silver powder of 150-450 nanometers. The nano-silver flexible conductive membrane, provided by the invention, has the characteristics of stable surface conductivity of the formed film, low resistivity, high light transmittance and strong adhesive force. The preparation process of the nano-silver flexible conductive membrane is simple and mature, coating equipment is simple, the operation is convenient, the cost is low, and the nano-silver flexible conductive membrane facilitates popularization and application.

Owner:杨佳雯

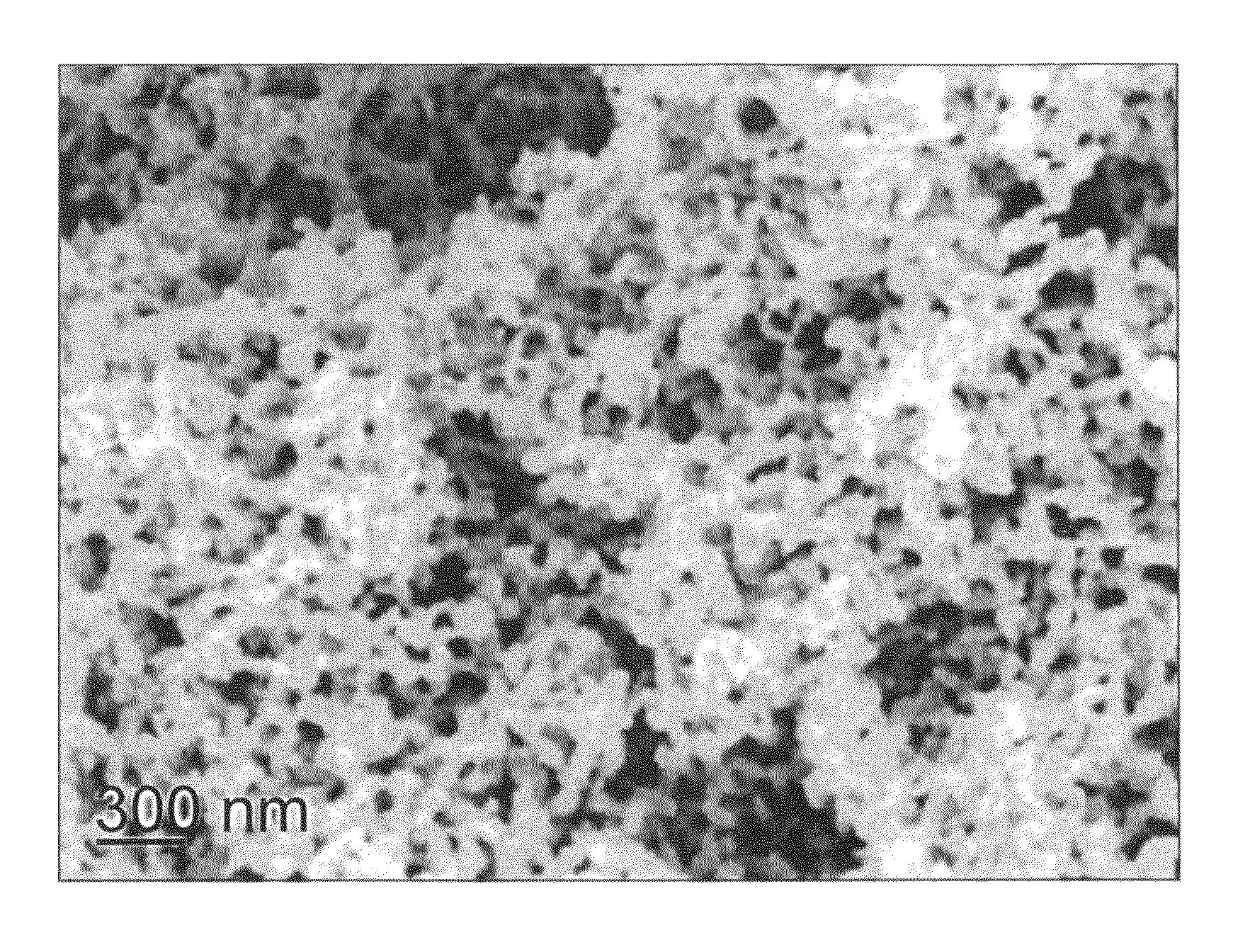

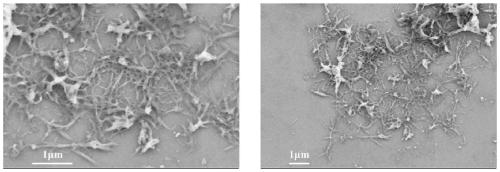

Negative electrode for nonaqueous electrolyte solution battery and nonaqueous electrolyte solution battery having the same

ActiveUS8778541B2Conductive stabilityReduce crackingElectrode carriers/collectorsActive material electrodesLithiumCarbon composites

A negative electrode used for a nonaqueous electrolyte solution battery having nonaqueous electrolyte solution containing lithium ion includes a metal carbon composite material. The metal carbon composite material has a porous carbon material having cavities, and a metal material made of metal to reversibly store or emit lithium ion. The metal material is arranged on a surface of the porous carbon material including inner surfaces of the cavities. The porous carbon material has a mass of 1-65 mass % when the metal carbon composite material is defined to have a mass of 100 mass %.

Owner:SK ON CO LTD

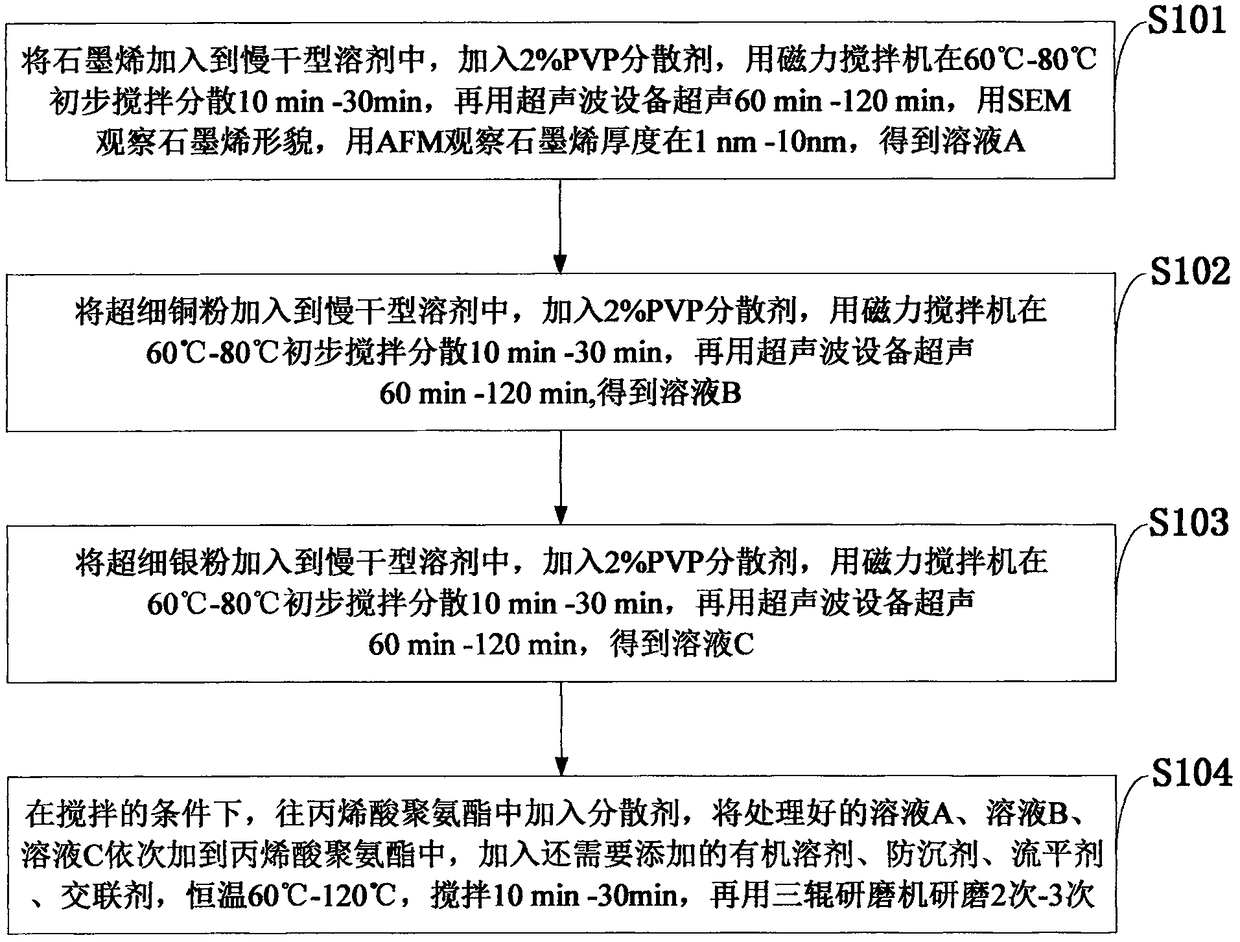

Graphene composite conductive coating as well as preparation method and application thereof

InactiveCN108129977APrevent oxidationLow costPolyurea/polyurethane coatingsElectrically-conductive paintsCross-linkUltra fine

The invention belongs to the technical field of conductive coatings, and discloses a graphene composite conductive coating as well as a preparation method and application thereof. The coating is composed of the following materials: 5-80% of resin, 0.1-5% of graphene, 2.5-20% of copper powder, 7.2-30% of silver powder, 0.55%-3.0% of a dispersant, 17-40% of an organic solvent, 0.3-1% of an anti-settling agent, 0.3-1% of a levelling agent and 0.1-1% of a cross-linking agent; and the preparation method comprises the following steps: adding the graphene into a slowly-drying solvent, adding the dispersant, performing stirring, and performing ultrasonication; adding the ultra-fine copper powder into a slowly-drying solvent, adding the dispersant, performing stirring, and performing ultrasonication; adding the ultra-fine silver powder into a slowly-drying solvent, adding the dispersant, performing stirring, and performing ultrasonication; and adding the dispersant into acrylate polyurethane, adding the treated solutions into the acrylate polyurethane in sequence, adding the organic solvent, the anti-settling agent, the levelling agent and the cross-linking agent, performing stirring, and performing grinding. The coating provided by the invention meets the requirements of conductive performance, avoids the single use of silver, reduces costs, and has a high price / performance ratio.

Owner:EVERPOWER SHENG TIE (XIAMEN) GRAPHENE TECH CO LTD

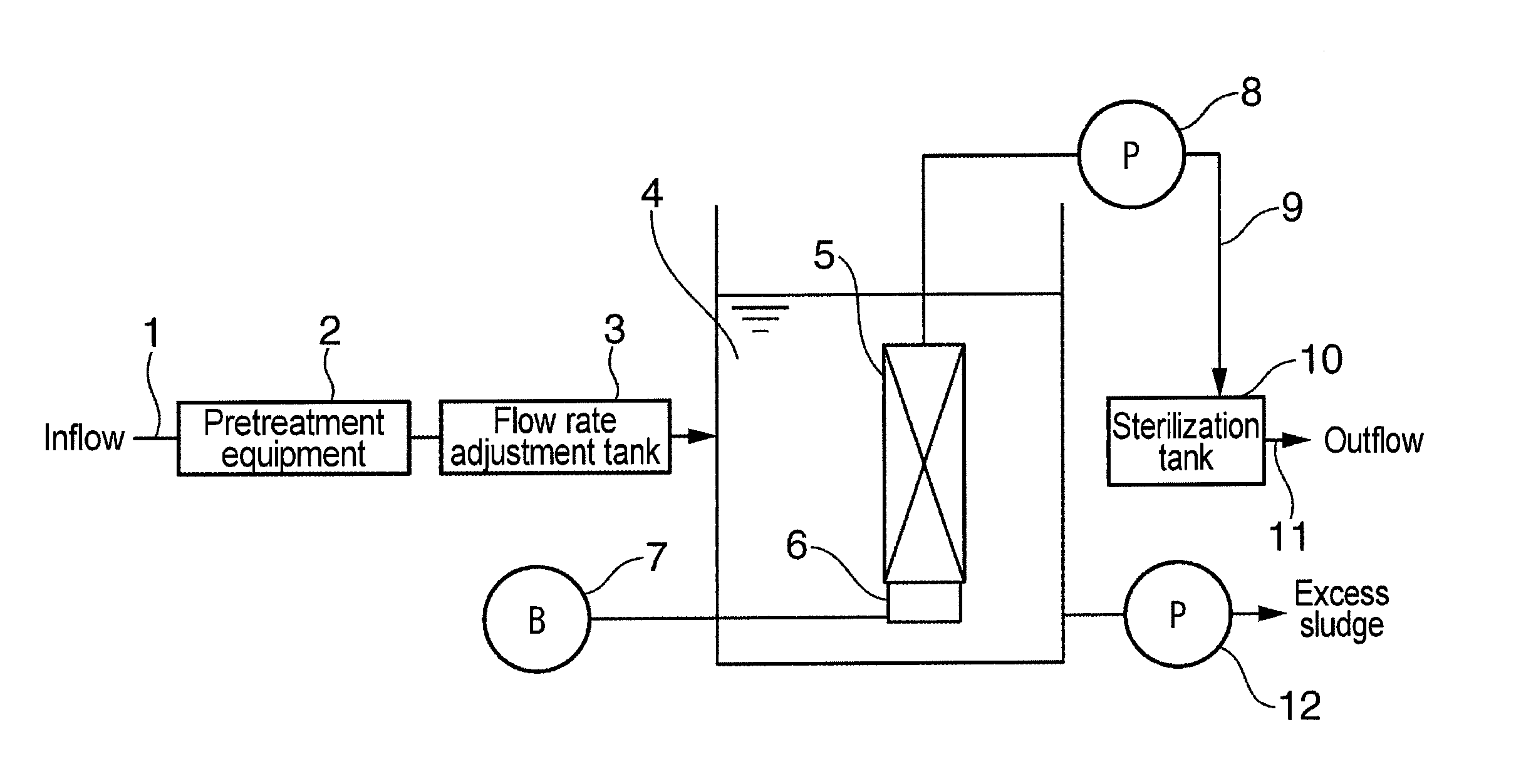

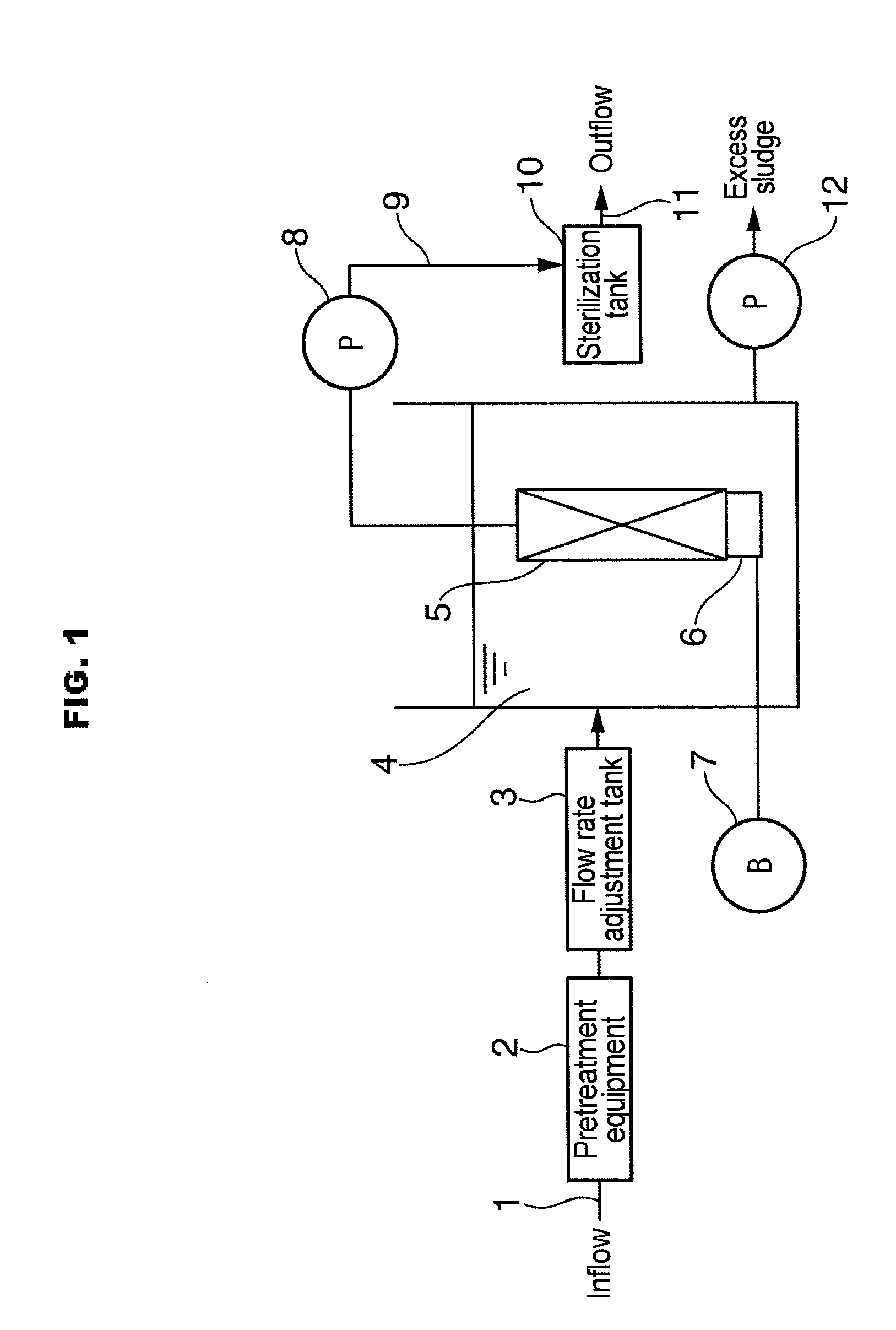

Additive used in a membrane-separation activated sludge process

InactiveUS20120160767A1Inexpensive and simple and easy methodProcess stabilityFungiSemi-permeable membranesActivated sludgeBiopolymer

In order to provide a means that can process organic wastewater via a membrane-separation activated sludge process that is stable over a long period of time, by reducing the quantity of biological polymers that can cause permeability problems, an additive is provided that is added to the activated sludge when treating organic wastewater via a membrane-separation activated sludge process. Said additive contains microorganisms that decompose polysaccharides.

Owner:ASAHI KASEI CHEM CORP +1

Film sheet feeding mechanism and thermal development recording apparatus having the same

InactiveUS20060071395A1Reduce sizeShort movement strokeArticle separationFilm (photographic)Arm moving

A film sheet feeding mechanism which can be reduced in size, and which can stably conduct a feeding operation, and a thermal development recording apparatus having such a mechanism are provided. A film sheet feeding mechanism that, from a tray on which plural film sheets are stacked, takes out one by one a uppermost film sheet, and that feeds the film sheet toward a downstream side in a direction of transporting the film sheet, includes: a feeding arm having film sucking unit for taking out the film sheet in the tray; arm moving unit for, while supporting the feeding arm, moving the feeding arm between a film taking out position of the tray and a film supplying position on the downstream side in the transportation direction; and a lifting and lowering amplification mechanism which is disposed in the feeding arm, and which lifts and lowers the film sucking unit.

Owner:FUJIFILM CORP +1

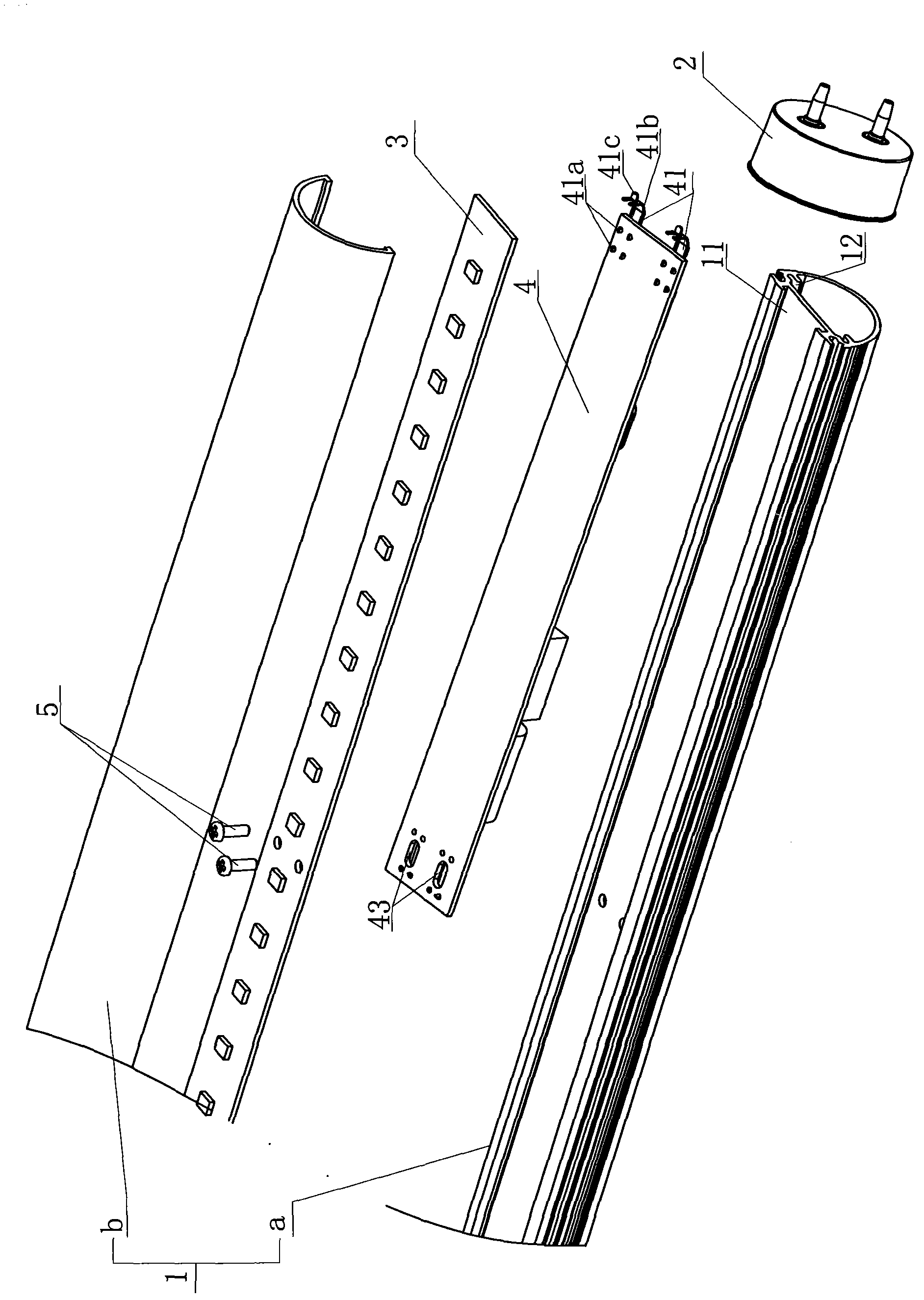

Automatically-produced light-emitting diode (LED) lamp tube

ActiveCN103216759ASimplifies wiring routingAchieve electrical connectionPoint-like light sourceElectric circuit arrangementsElectricityPower circuits

The invention provides an automatically-produced light-emitting diode (LED) lamp tube which comprises a lamp tube body, lamp bases at two ends of the lamp tube body, a luminous bead circuit board and a power circuit board. The luminous bead circuit board and the power circuit board are arranged in the lamp tube body. An upper plug-in groove and a lower plug-in groove are arranged in a substrate in an upper-lower layered mode in the axial direction. The luminous bead circuit board and the power circuit board are respectively arranged in the upper plug-in groove and the lower plug-in groove in an inserted and layered mode. Electrical input connecting pieces are arranged at one end of the power circuit board, and electrical output connecting pieces are arranged at the other end of the power circuit board. Electrode connecting pieces are arranged at the inner end of one lamp base and are connected with the electrical input connecting pieces in a plug-in mode. Conductive screws are arranged on the board surface of the luminous bead circuit board and are electrically connected with the electrical output connecting pieces. The automatically-produced LED lamp tube is simplified in connecting wire distribution, achieves technical effects of stable electricity conduction, and is suitable for automated production of LED ball lamps.

Owner:OUTRACE TECH

Additive for non-aqueous electrolyte, non-aqueous electrolyte comprising the same, and lithium secondary battery comprising the same

ActiveUS20170125847A1Improved cycle life characteristic and high-temperature storage safetyInhibitory responseLi-accumulatorsOrganic electrolytesMetalNon aqueous electrolytes

The present invention relates to an additive for a non-aqueous electrolyte solution, which has an excellent effect of adsorbing metal ions dissolved from a positive electrode, a non-aqueous electrolyte solution for a lithium secondary battery including the same, and a lithium secondary battery including the non-aqueous electrolyte solution.

Owner:LG ENERGY SOLUTION LTD

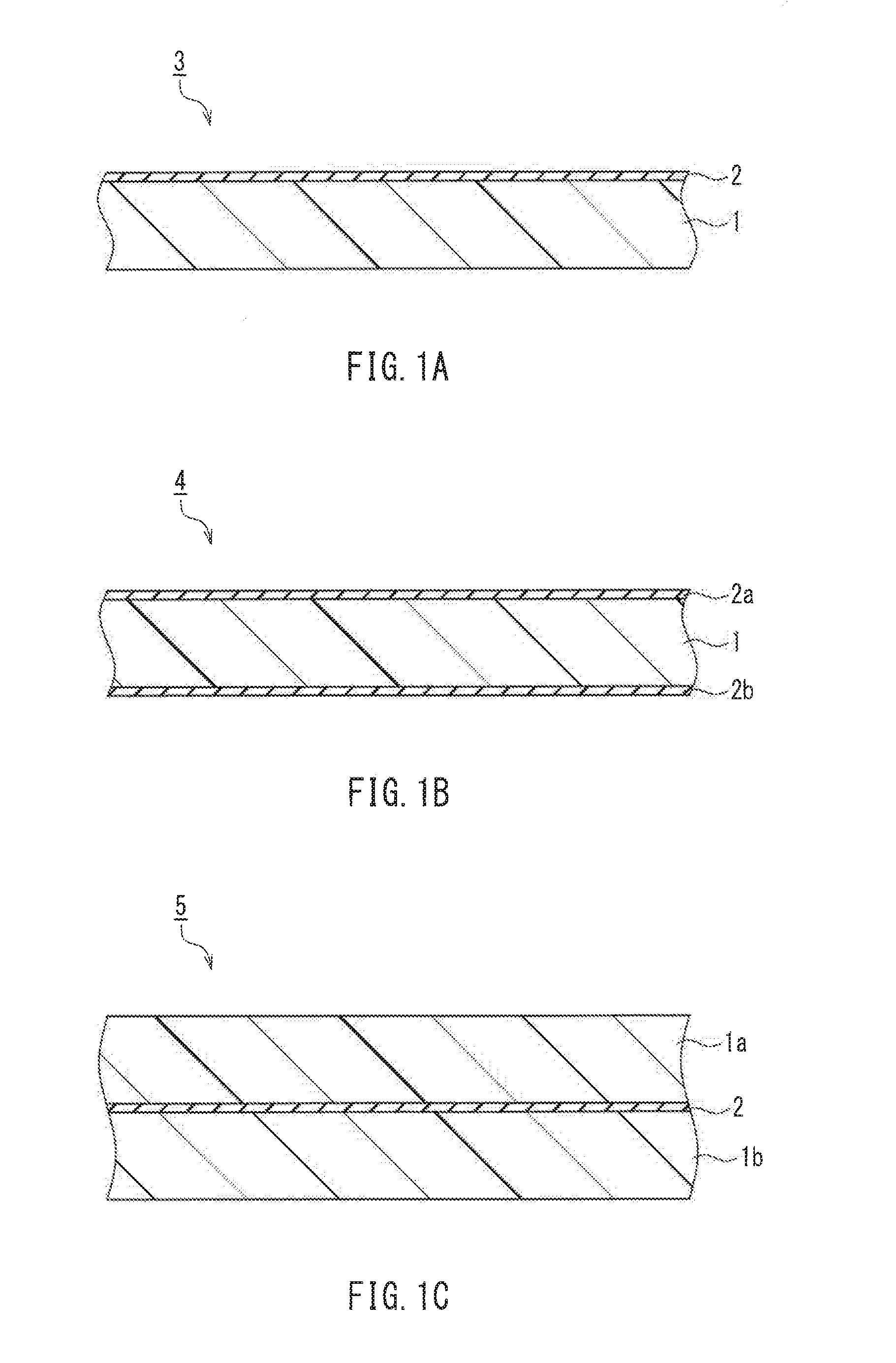

Heat-storage, thermally conductive sheet

InactiveUS20170043553A1Improve thermal conductivityImprove diffusivitySemiconductor/solid-state device detailsSynthetic resin layered productsInorganic particleInorganic particles

A heat storage and conduction sheet (3, 4, 5) of the present invention includes: a heat storage sheet (1, 1a, 1b) including a matrix resin and heat storage inorganic particles; and a heat diffusing material (2, 2a, 2b) that is united with the heat storage sheet. The heat storage inorganic particles are composed of a material that undergoes an electronic phase transition and has a latent heat of 1 J / cc or more for the electronic phase transition. The amount of the heat storage inorganic particles is 10 to 2000 parts by mass with respect to 100 parts by mass of the matrix resin. The heat storage sheet has a heat conductivity of 0.3 W / m·K or more. The heat diffusing material has a heat conductivity in a planar direction of 20 to 2000 W / m·K. Thus, the present invention provides a physically stable heat storage and conduction sheet having high heat storage properties and high heat conduction properties, and excellent heat diffusion properties in a planar direction.

Owner:FUJI POLYMER INDUSTRIES CO LTD

Electrically Conductive Composites with Resin and Vgcf, Production Process, and Use Thereof

InactiveUS20080075953A1Less deteriorationConductive stabilityNon-conductive material with dispersed conductive materialGlass/slag layered productsMolten stateCarbon fibers

Conductive composites with resin, produced by mixing a vapor grown carbon fiber having a fiber diameter of 2 to 500 nm with a matrix resin in a molten state while suppressing breakage of the fiber 20% or less, exhibit conductivity higher than that of a conventional conductive composites with resin through incorporation of vapor grown carbon fiber in an amount equivalent to a conventional amount, or exhibit conductivity equal to or higher than that of a conventional conductive composites with resin through incorporation of vapor grown carbon fiber in an amount smaller than a conventional amount. In the case where the melt-mixing of the fiber with resin is performed using a co-rotating twin-screw extruder, the vapor grown carbon fiber is preferably fed to the extruder by way of side feeding. In the case where the melt-mixing is performed using a pressure kneader, resin is sufficiently melted in the kneader in advance, and vapor grown carbon fiber is fed to the molten resin.

Owner:SHOWA DENKO KK

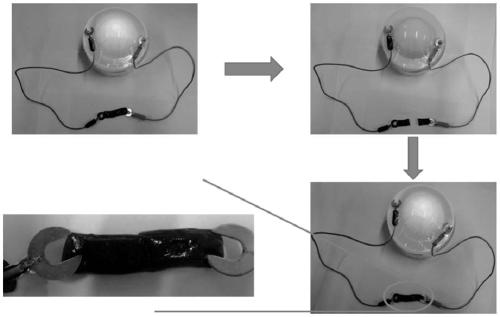

Method for preparing cellulose nanocrystal gel bionic skin sensing material with electric-conducting and self-healing functions

The invention provides a method for preparing a cellulose nanocrystal gel bionic skin sensing material with electric-conducting and self-healing functions. The method comprises the following steps: adding a conductive polymer monomer to a cellulose nanocrystal (CNC) suspension mixed with an acid, adding and dissolving an appropriate amount of different valence metal salts, carrying out in-situ oxidative polymerization to generate conductive CNC, then adding an appropriate amount of a boron compound and an appropriate amount of polyvinyl alcohol (PVA), and preparing the cellulose nanocrystal gel bionic skin sensing material with electric-conducting and self-healing functions under high temperature conditions. The cellulose nanocrystal gel bionic skin sensing material combines the high strength and biocompatibility of the CNC with the electrical conductivity, self-healing performance and other excellent performances of the conductive polymer, has excellent stretchability and plasticity,and has broad application prospects in fields of bionic robots, bio-sensing, flexible bionic skin sensors and supercapacitors.

Owner:ZHEJIANG SCI-TECH UNIV

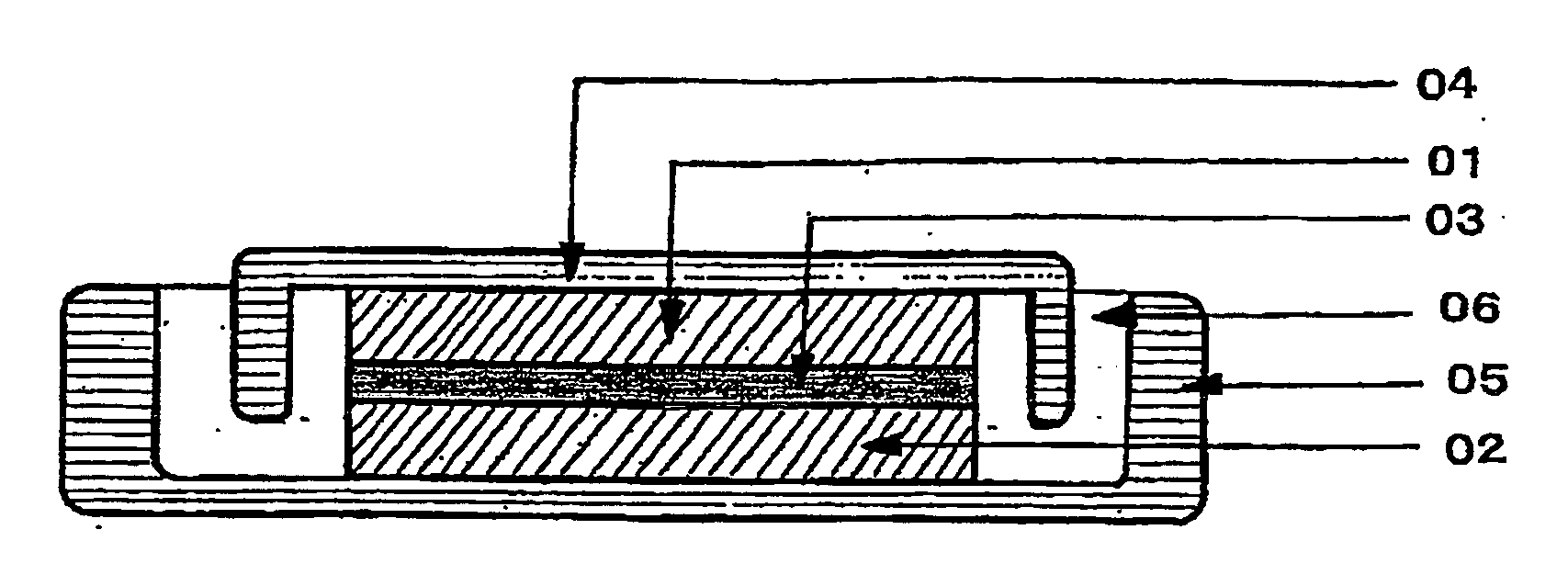

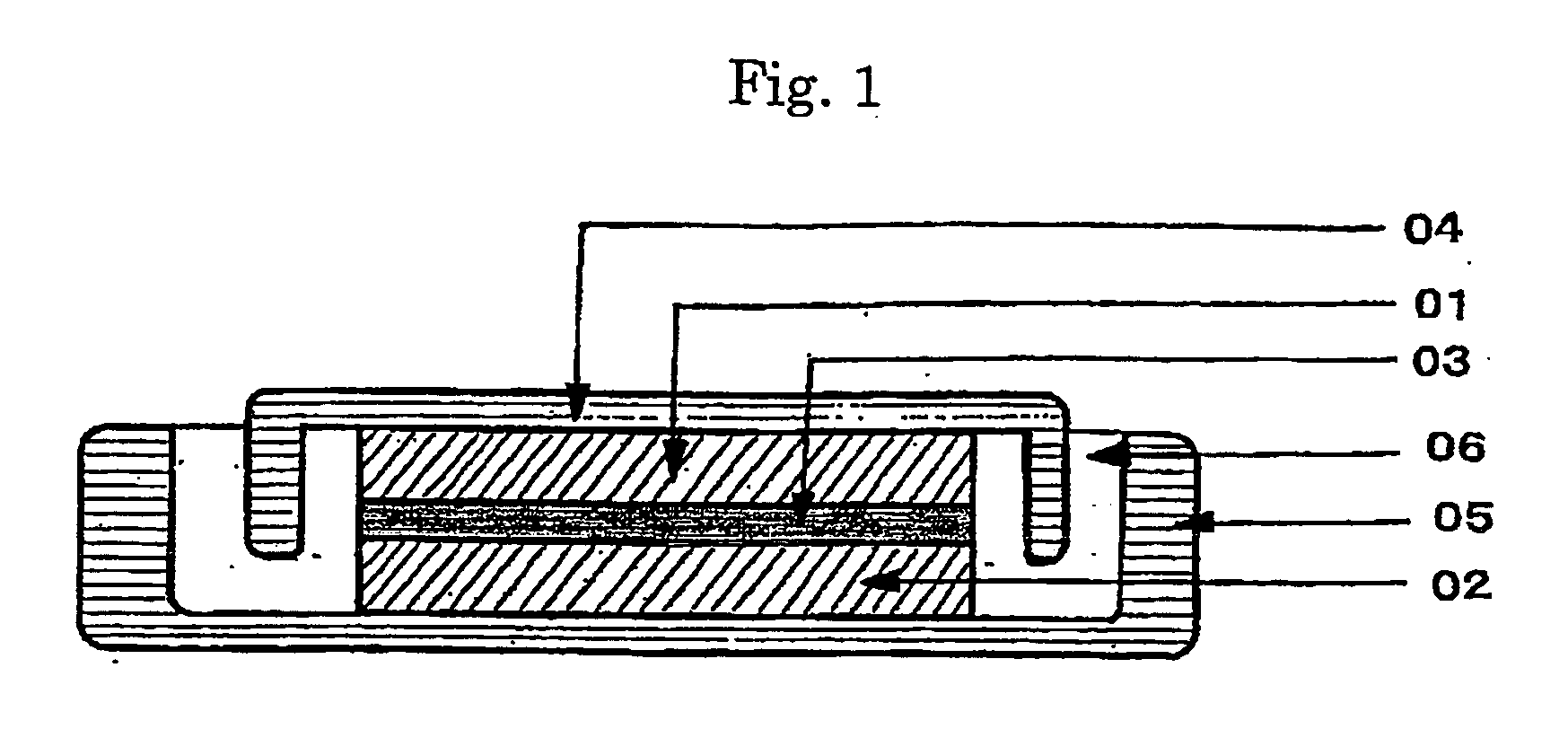

Antenna coil device

ActiveUS9407009B2Conductive stabilityLoop antennas with ferromagnetic coreLogperiodic antennasEngineeringExternal circuit

An antenna coil device including: a connector unit mounted with a connector of an external circuit detachably by being plugged-in; and a base unit provided with an antenna body including a coil, in which the connector unit and the base unit are constituted by separate members and are used by being combined integrally each other, wherein for the connector unit and the base unit, there are formed a connector fitting portion and a base fitting portion which are formed with a concave and a convex in a direction intersecting with respect to the plug-in direction of the connector unit, and by fitting the connector fitting portion and the base fitting portion, the connector unit and the base unit are combined in a state in which the antenna body is positioned with respect to the connector unit.

Owner:SUMIDA CORP

Flame retarding polymer electrolyte composition containing maleimides

ActiveUS7875204B2Improve flame retardant performancePrevent leakageSolid electrolytesElectrolytic capacitorsDendrimerPolymer electrolytes

Owner:IND TECH RES INST

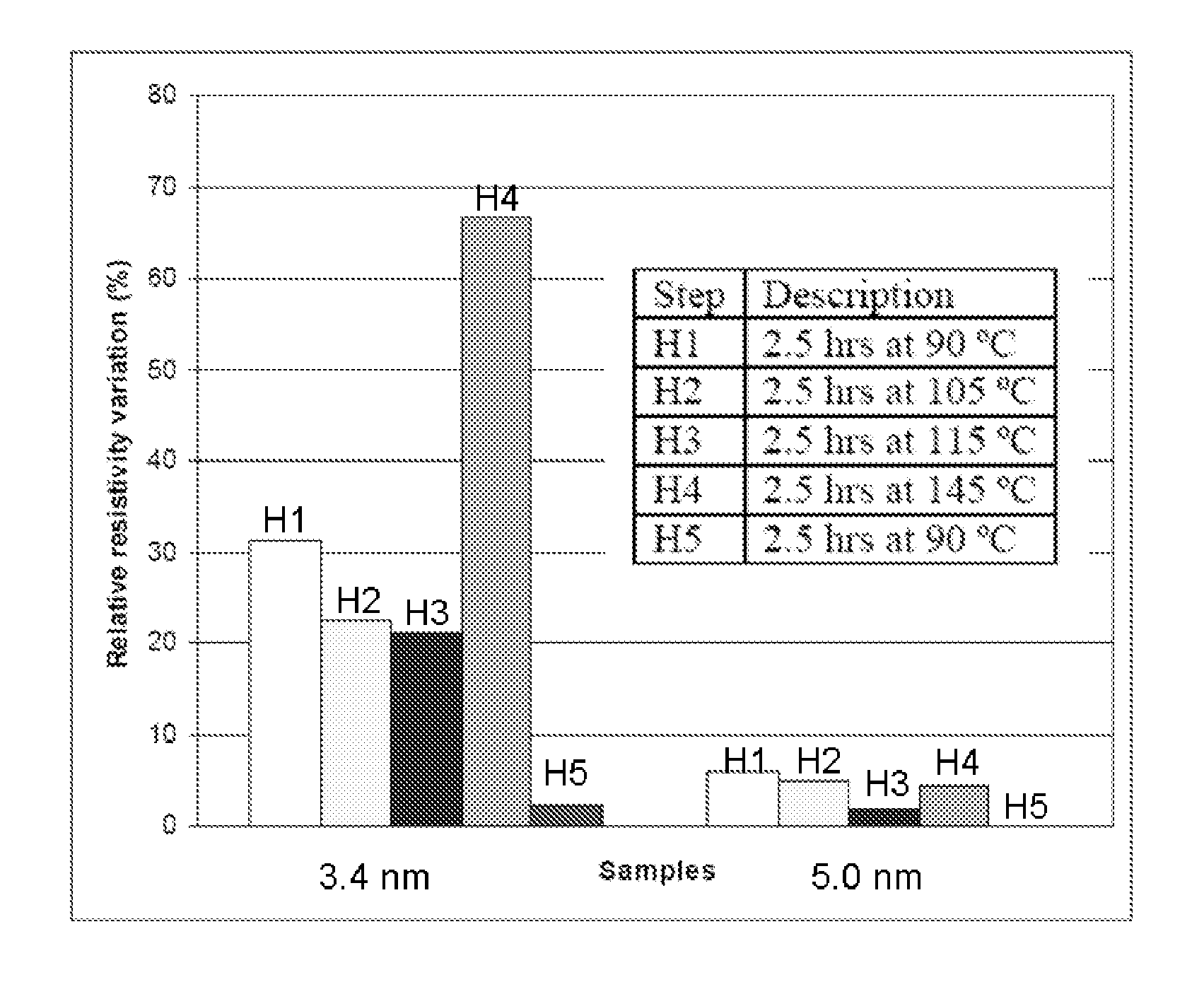

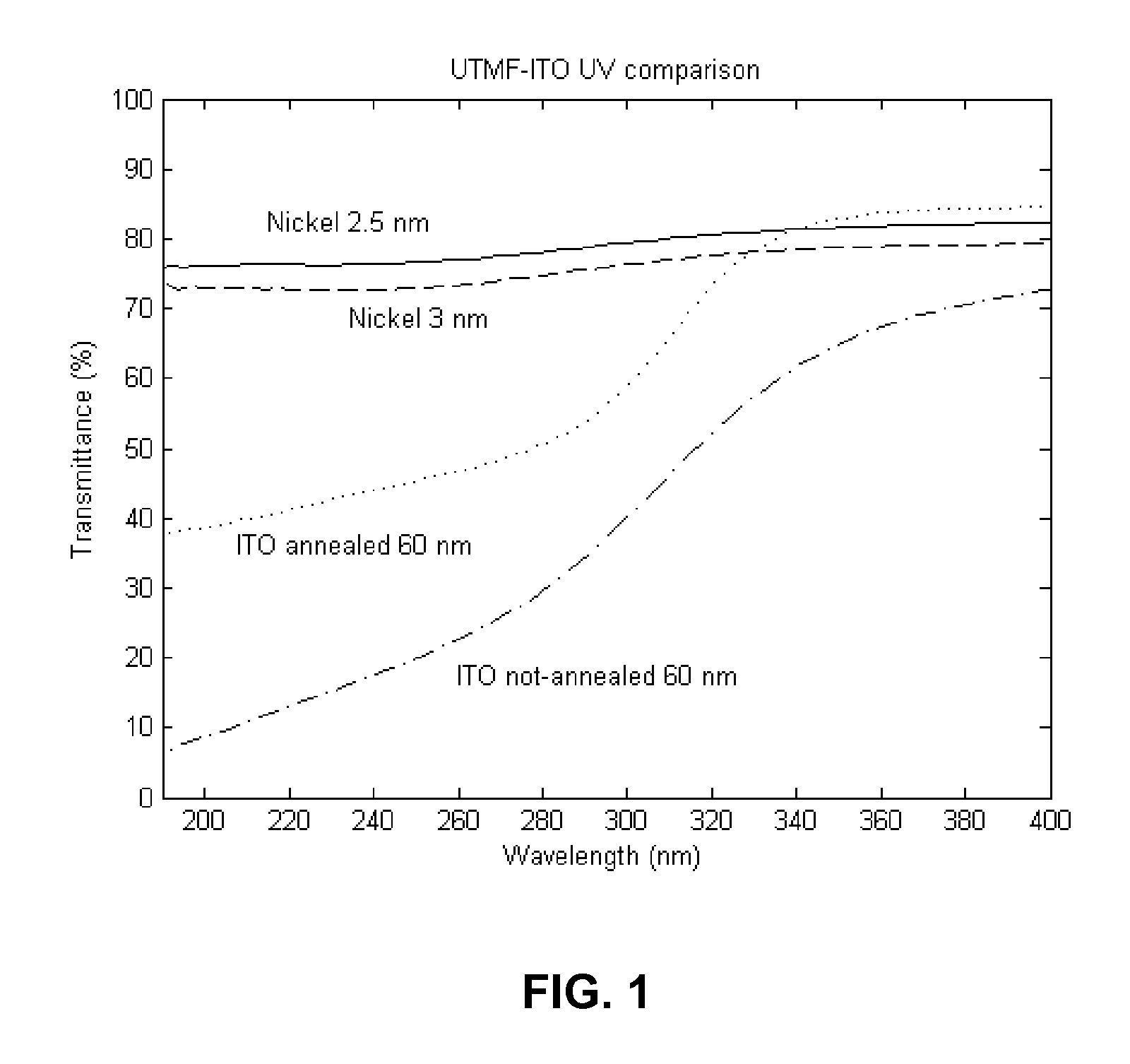

Method to prepare a stable transparent electrode

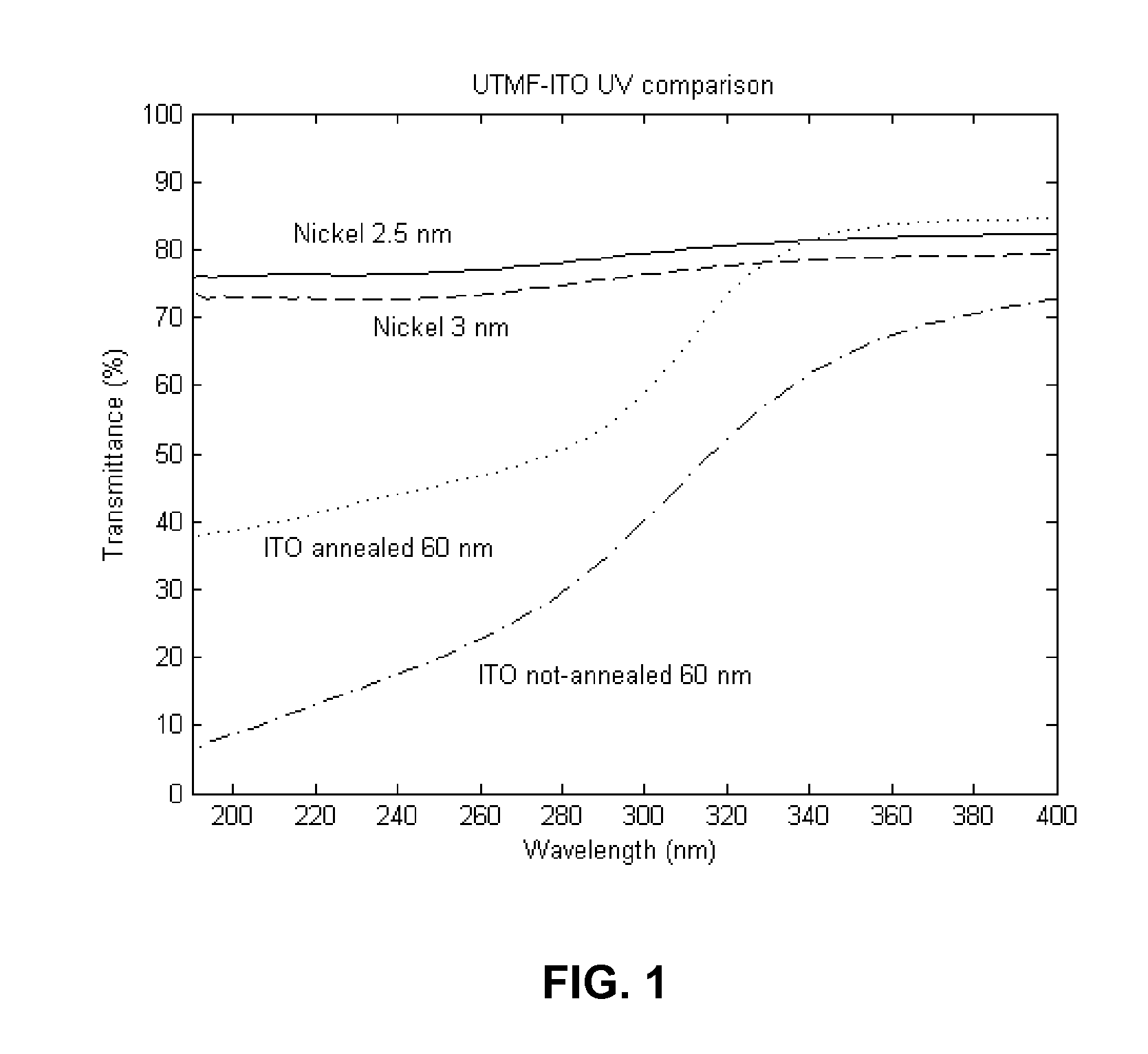

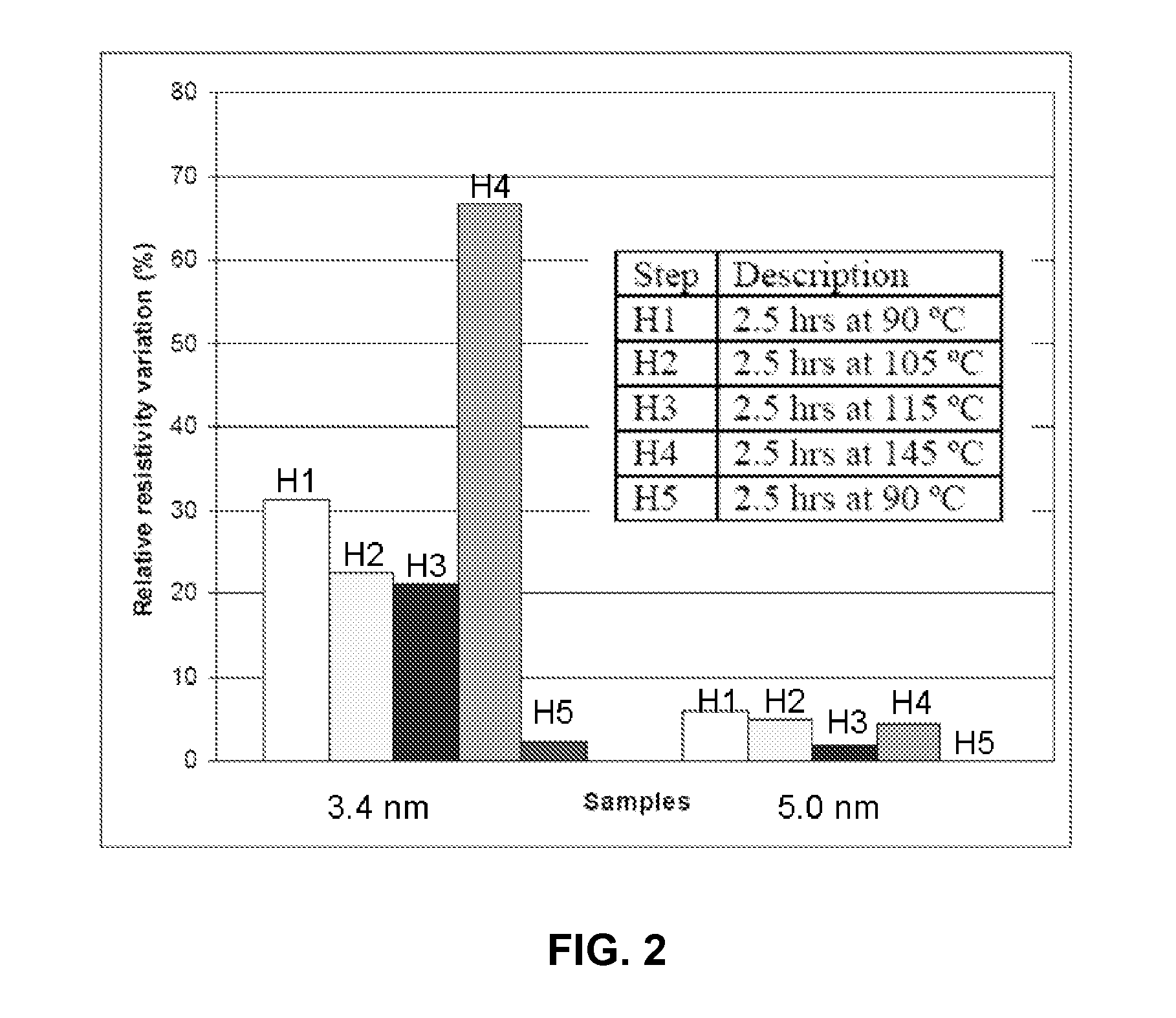

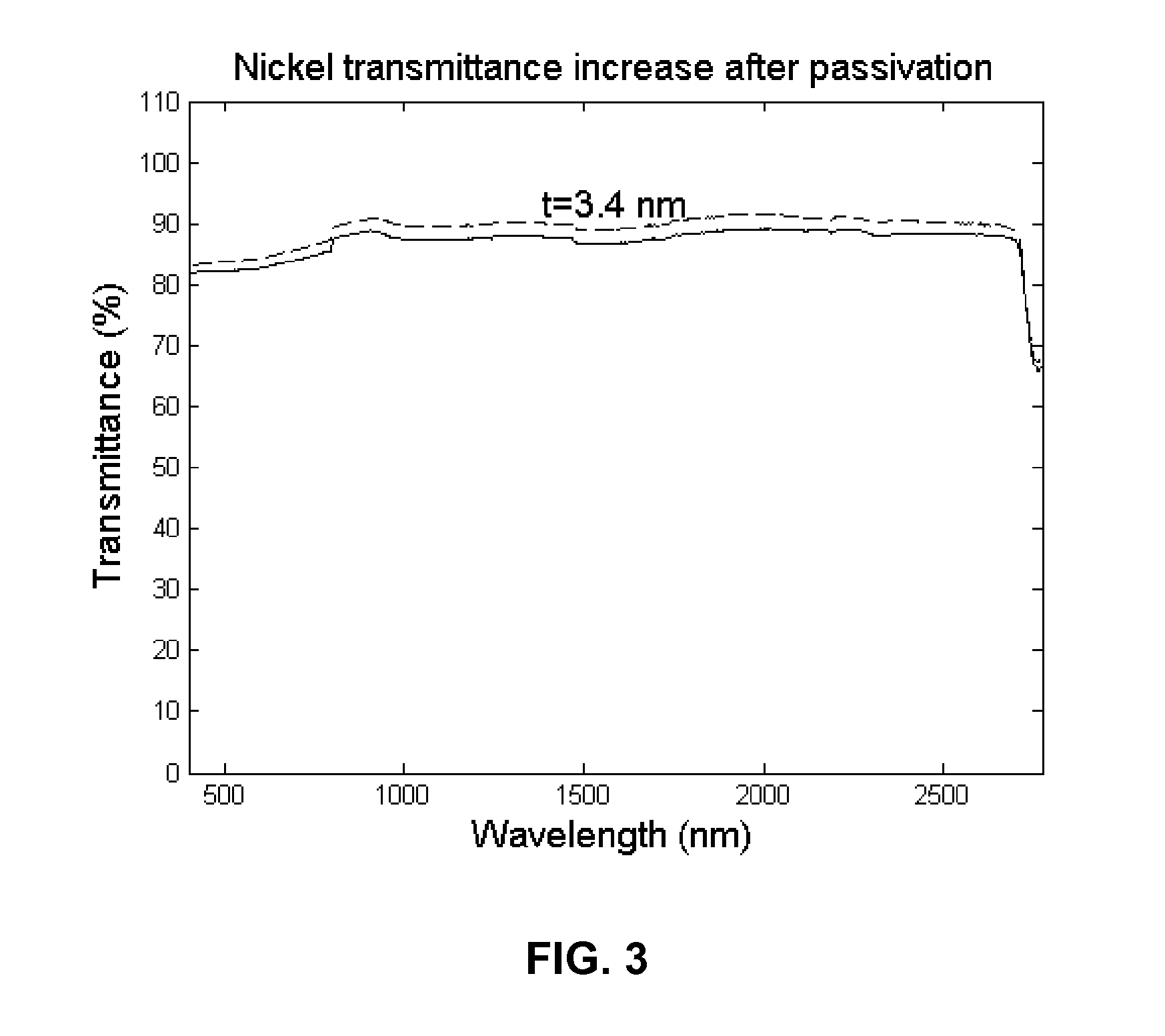

ActiveUS20110114226A1Low costConductive stabilityElectroluminescent light sourcesSolid state diffusion coatingTitaniumProtective oxide

The present application discloses a method for producing a stable ultra thin metal film that comprises the following steps: a) deposition, on a substrate, of an ultra thin metal film, such as an ultra thin film of nickel, chromium, aluminium, or titanium; b) thermal treatment of the ultra thin metal film, optionally in combination with an O2 treatment; and c) obtaining a protective oxide layer on top of the ultra thin metal film.

Owner:FUNDACIO INST DE CIENCIES FOT NIQUES +1

Graphene conducting material and preparation method thereof

The invention discloses a graphene conducting material. The graphene conducting material is prepared from the following raw materials in parts by weight: 30 to 41 parts of graphene oxide, 20 to 30 parts of a conducting dispersion solution, 35 to 40 parts of aniline, 1 to 2 parts of ammonium persulfate, 0.4 to 1 part of melamine, 0.1 to 0.2 part of tert-butyl p-diphenol, 4 to 5 parts of diphenyl silanediol and 2 to 3 parts of calcium propionate. According to the graphene conducting material disclosed by the invention, various conducting substances, such as polyaniline, acetylene carbon black and graphene, are added; all the raw materials are blended and the graphene conducting material has very strong cooperatively enhanced conductivity; after the raw materials are treated by a method disclosed by the invention, the effects of stable finished products and efficient electric conduction are realized.

Owner:温州市赢创新材料技术有限公司

Ionic conductor, method of manufacturing the same, and electrochemical device

InactiveUS20060204813A1Conductive stabilityImprove performanceMaterial nanotechnologySolid electrolytesElectrical conductorProton

An ionic conductor insoluble to water and fuel, and capable of stably allowing ions such as protons to conduct therethrough, a method of manufacturing the same, and an electrochemical device. The ionic conductor having a derivative in which an ion-dissociative group is bound to a carbonaceous substance composed of at least one species selected from the group consisting of fullerene molecule, cluster mainly composed of carbon, and structure of linear or tubular carbon; and a polymer of a substance having a basic group. A method of manufacturing an ionic conductor having a step of dissolving the above-described derivative; and a polymer of the substance having the basic group; into a solvent to thereby prepare a homogeneous solution; and a step of removing the solvent. An electrochemical device having a negative electrode, a positive electrode, and an ionic conductor held therebetween, wherein the ionic conductor is composed of the ionic conductor of the present invention described in the above.

Owner:SONY CORP

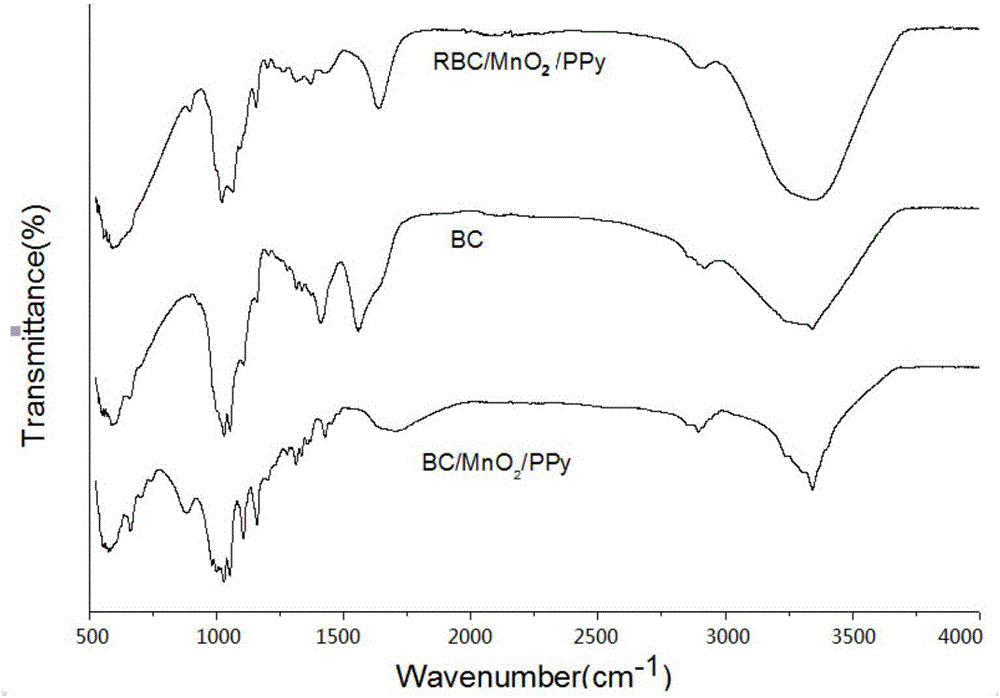

Bacterial cellulose/manganese dioxide/polypyrrole composite film and preparation method thereof

InactiveCN105778497ALarge specific surface areaConductive stabilityManganese oxides/hydroxidesComposite filmPolypyrrole

The invention discloses a bacterial cellulose / manganese dioxide / polypyrrole composite film and a preparation method thereof. The composite film is prepared by soaking bacterial cellulose in alkali, performing impurity removal and pretreatment, adding potassium permanganate and pyrrole, performing oxidization and reduction to obtain manganese dioxide and polypyrrole, and finally performing suction filtration. According to the bacterial cellulose / manganese dioxide / polypyrrole composite film, polypyrrole which is high in air stability, can be easily prepared into a film in an electrochemical way and is low in poison is utilized, and manganese dioxide which shows high capacitive property in neutral aqueous electrolyte under a wider potential window, and high-strength material bacterial cellulose are compounded, so that the method is simple and feasible. Polypyrrol is loaded on bacterial cellulose, so that the conductivity of the film is improved; meanwhile, manganese dioxide has high capacitive property, so that the electrical property of the composite film is further improved. The bacterial cellulose / manganese dioxide / polypyrrole composite film can be applied to the fields of lithium ion battery cathode materials, supercapacitors, electronic devices and biological sensor wrapping materials.

Owner:NANJING UNIV OF SCI & TECH

Method to prepare a stable transparent electrode

ActiveUS8623153B2Low costConductive stabilityElectroluminescent light sourcesSolid state diffusion coatingTitaniumProtective oxide

The present application discloses a method for producing a stable ultra thin metal film that comprises the following steps: a) deposition, on a substrate, of an ultra thin metal film, such as an ultra thin film of nickel, chromium, aluminum, or titanium; b) thermal treatment of the ultra thin metal film, optionally in combination with an O2 treatment; and c) obtaining a protective oxide layer on top of the ultra thin metal film.

Owner:FUNDACIO INST DE CIENCIES FOT NIQUES +1

Method for manufacturing high-voltage solid-electrolyte aluminum electrolytic capacitor

ActiveUS20180025846A1Process stabilityGood batch consistencySolid electrolytic capacitorsElectrolytic capacitor manufactureSolid state electrolyteChemical treatment

A method for manufacturing high-voltage solid electrolyte aluminum-electrolytic capacitor: (1) welding a capacitor core onto an iron bar, applying a voltage for chemical treatment, and then, washing and drying; (2) impregnating the core in dispersion A for 1˜30 minutes; (3) removing the core from dispersion A, creating vacuum and impregnating the core in dispersion A for 1˜10 minutes; (4) keeping the core in dispersion A, breaking the vacuum and performing pressurization, and keeping pressurized state for 1˜10 minutes; (5) keeping the core in the dispersion A, performing depressurization to atmospheric pressure, and keeping atmospheric pressure for 1˜10 minutes; (6) taking the core out, placing in a 65˜100° C. temperature of and drying it for 20˜60 minutes, and then placing in a 135˜165° C. temperature of and drying for 20˜60 minutes; (7) repeating (3) to (6) at least once; and (8) putting the core in an aluminum cover and sealing it, and performing aging treatment.

Owner:ZHAOQING BERYL ELECTRONICS TECH

Rotary LED lamp

InactiveCN104154480AConvenient lightingImprove cooling efficiencyPoint-like light sourceElectric circuit arrangementsEngineeringLED lamp

The invention discloses a rotary LED lamp. The rotary LED lamp comprises a lamp holder, a shell, a power source, a motor, a heat dissipation device, a circuit board, LEDs and a connecting ring. The power source is arranged in the lamp holder. The shell is arranged below the lamp holder. The motor is coaxially arranged on the central axis of the lamp holder. The connecting ring is coaxially arranged at the upper end of the heat dissipation device. The heat dissipation device is connected to the lower end of the motor. The circuit board is designed on the heat dissipation device. The LEDs are attached to the circuit board. In this way, the rotary LED lamp has the advantages that the reliability is high, the structure is compact, the heat dissipation performance is good, electric conduction is stable, cost is low, and the service life is long. In addition, the rotary LED lamp has wide market prospect on the illumination market.

Owner:JIANGSU DALEN ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com