Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Avoid the knife" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

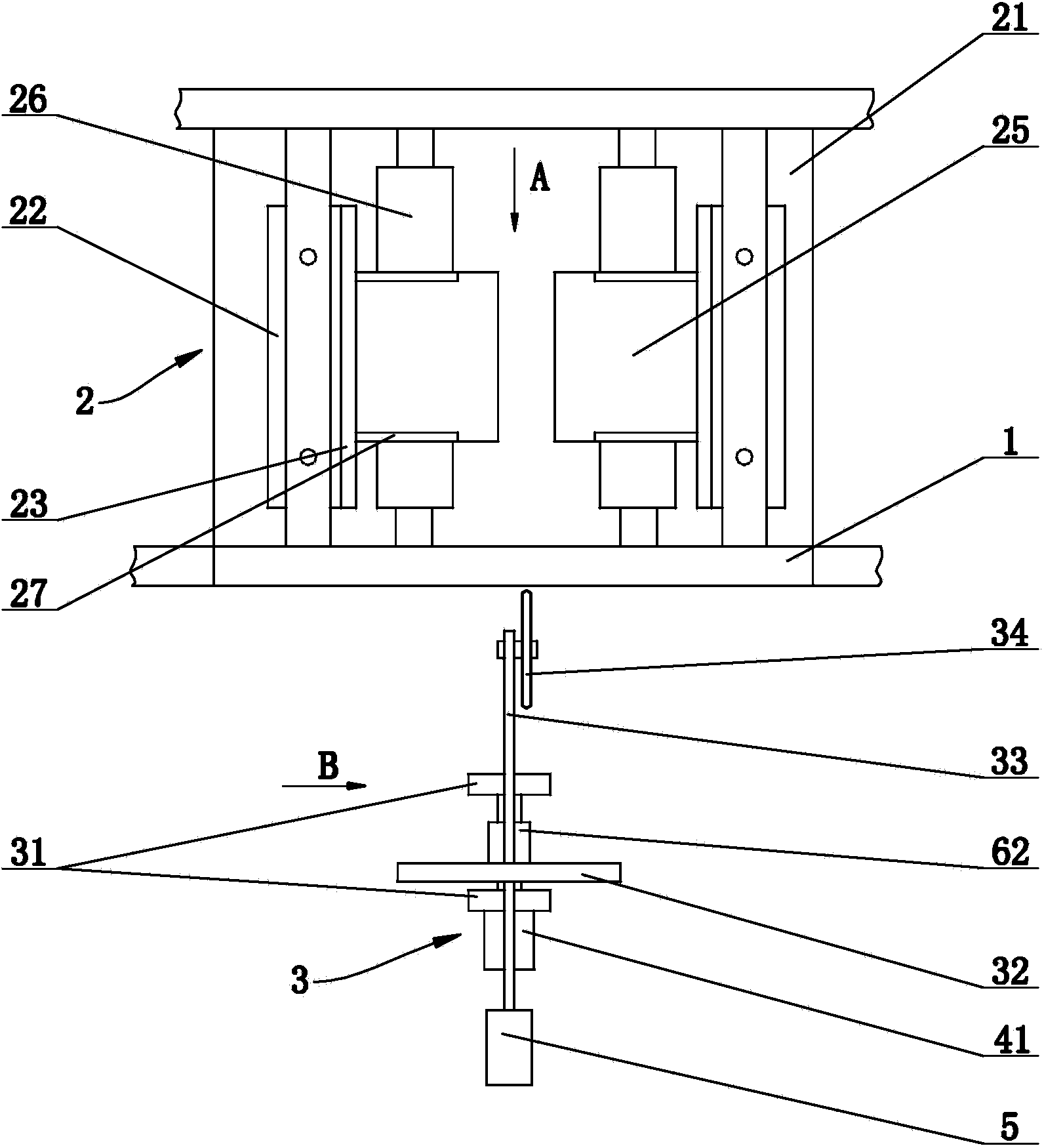

Synchronous spraying device for large machine

InactiveCN105772293ARealize simultaneous sprayingEnsure consistencySpraying apparatusArthrobotrysMechanical engineering

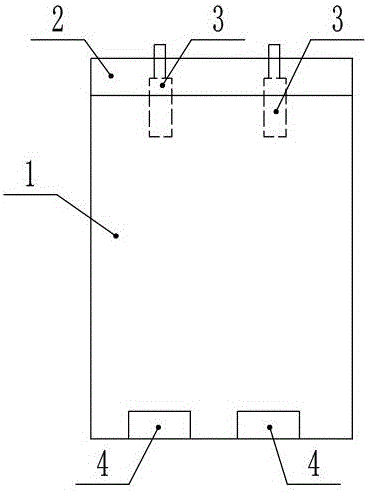

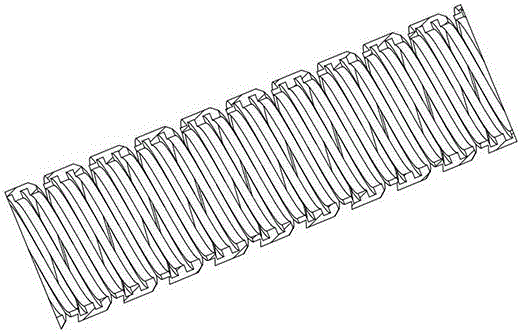

The invention provides a synchronous spraying device for a large machine. The synchronous spraying device comprises a plurality of movable bases (1), wherein a six-axis joint robot is installed on each movable base (1), and a spray gun is installed at the tail end of each six-axis joint robot; a steel plate (2) is arranged at the front end of each movable base (1), a piston cylinder (3) is further horizontally arranged at the front end of each movable base (1), the outer end of a piston rod of each piston cylinder (3) is level with the outer side of the corresponding steel plate (2) while retracting, and an electrically-controlled magnetic attraction device (4) is arranged at the rear end of each movable base (1); and the movable bases (1) attract the electrically-controlled magnetic attraction devices (4) through the steel plates (2) and are sequentially connected in series to form an integrated movable platform. According to the synchronous spraying device provided by the invention, the integrated movable platform formed by sequentially connecting the plurality of movable bases (1) in series is provided, and synchronous spraying of all the six-axis joint robots can be realized; and moreover, the problem of interference is avoided, and the consistency of the spraying quality of parts of the large machine can be ensured.

Owner:李富平

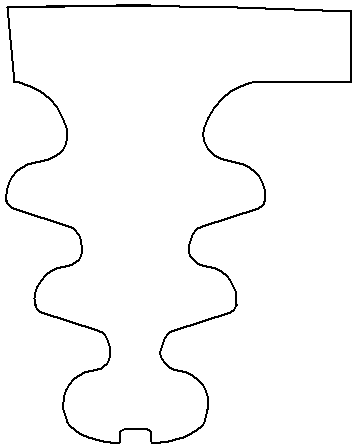

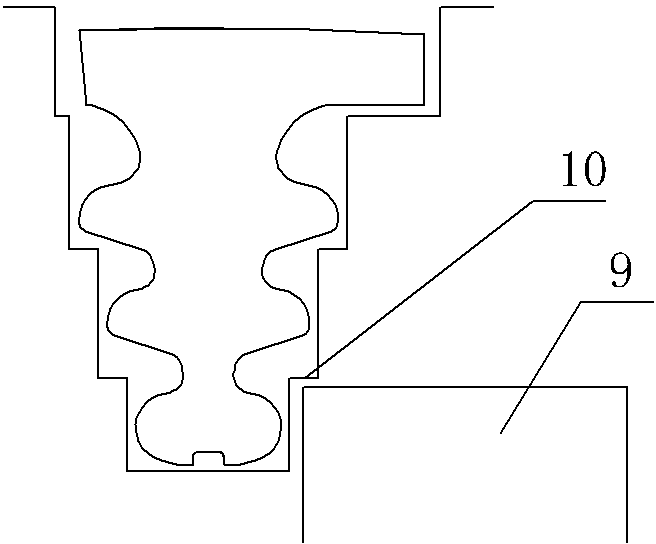

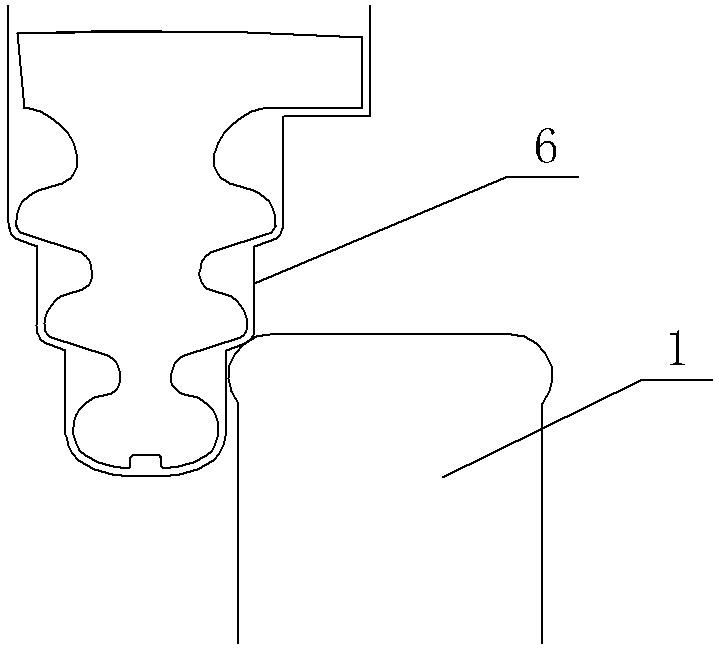

Machining device and method for double-layer casing of aero-engine

InactiveCN110774002ALoading and unloadingReasonable arrangementAircraft componentsOther manufacturing equipments/toolsAviationMechanical engineering

The invention discloses a machining device and method for a double-layer casing of an aero-engine. The device comprises an end surface gland, a shell, an inner sleeve, movable tensioning blocks, an air bag, a supporting rod, supporting arm nuts, supporting arms, a connecting seat, a ball head guiding rod, an inner hole fixing claw, an outer stand column, a transverse top head and a pressing plate.A turning and milling compound machining method is adopted, when an inner hole and an end surface are turned, the mode that an outer supporting is matched with the air bag for tensioning is adopted,and when an outer boss is milled, the mode that an inner supporting is matched with the air bag for tensioning is adopted; and according to the machining device, the high-quality and high-efficiency machining of the similar thin-wall double-layer casing can be achieved, and it is ensured that the circular degree of the casing meets the requirement.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

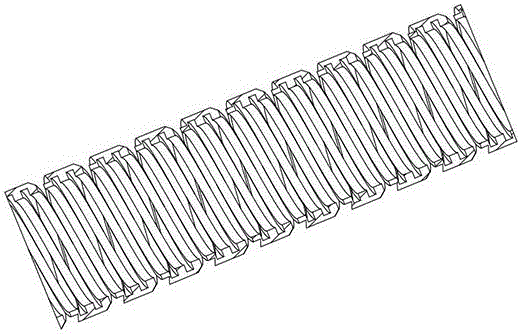

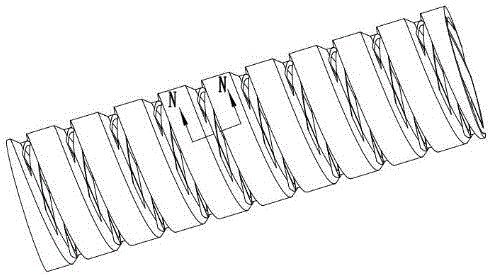

Rough mill processing method of fir tree blade root

ActiveCN103100742AExtended service lifeReduce cutting powerMilling equipment detailsNumerical controlMilling cutter

The invention provides a rough mill processing method of a fir tree blade root, and solves the problem that the existing rough mill processing method has low processing efficiency and high cost. The rough mill processing method comprises the following steps of: (1) establishing a processing coordinate system of a four-axis horizontal type numerical control milling machine, and processing a driving auxiliary surface; (2) calculating a processing path along contour of the blade root fir tree and the contour of a midbody, and milling a blade root processing step surface by using a bull nose circular knife end mill; (3) calculating the processing path of a deep groove in milling the contour of the fir tree, and processing the deep groove of the fir tree blade root on the basis of the blade root processing step surface by adopting a circular knife disc milling cutter; and (4) calculating a layered processing track of a forming tooth-type knife, and processing the teeth patterns of the fir tree blade root by using the forming tooth-type knife.

Owner:WUXI TURBINE BLADE

Butterfly valve for water storage tank

InactiveCN105715808APrevent leakagePlay a diversion decompressionOperating means/releasing devices for valvesValve members for absorbing fluid energyCavitationWater storage tank

The invention discloses a butterfly valve of a water storage tank. An electromagnetic controller is mounted on a valve body, a butterfly plate with a permanent magnet is mounted in an inner cavity of the valve body; upper valve covers are respectively fixed to the upper end of the valve body, lower valve covers are respectively fixed to the lower end of the valve body, and the permanent magnet is fixed to the middle part of one end surface of the butterfly plate; an upper shaft sleeve and a lower shaft sleeve are coaxial, the upper shaft sleeve is fixed to the upper part of the end surface, on which the permanent magnet is positioned, of the butterfly plate, and the lower shaft sleeve is fixed to the lower part of the end surface, on which the permanent magnet is positioned, of the butterfly plate; the upper shaft sleeve is in matching connection with the upper valve covers through an upper valve rod, and the lower shaft sleeve is in matching connection with the lower valve covers through a lower valve rod; an inlet flow channel and two outlet flow channels are arranged on the other end surface of the butterfly plate; an inlet filter pipe is also connected to the inlet flow channel. According to the butterfly valve disclosed by the invention, the situation of leakage between the valve rods and fillings is avoided, besides, a gaseous cavitation preventing flow channel is processed on the surface of the butterfly plate, and one side of the butterfly plate is a spherical protrusion. The butterfly valve has the effects of shunting decompressing, reducing gaseous cavitation, preventing vibration and reducing noise, and the service life of the butterfly valve is prolonged. On the other hand, the inlet filter pipe has the effects of filtering water flows, and preventing valve cores from being destroyed.

Owner:陈杰

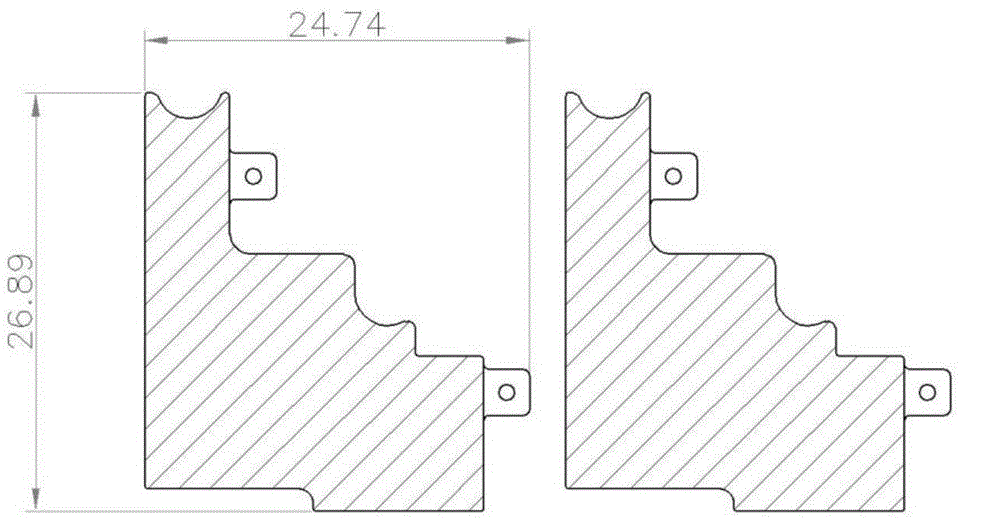

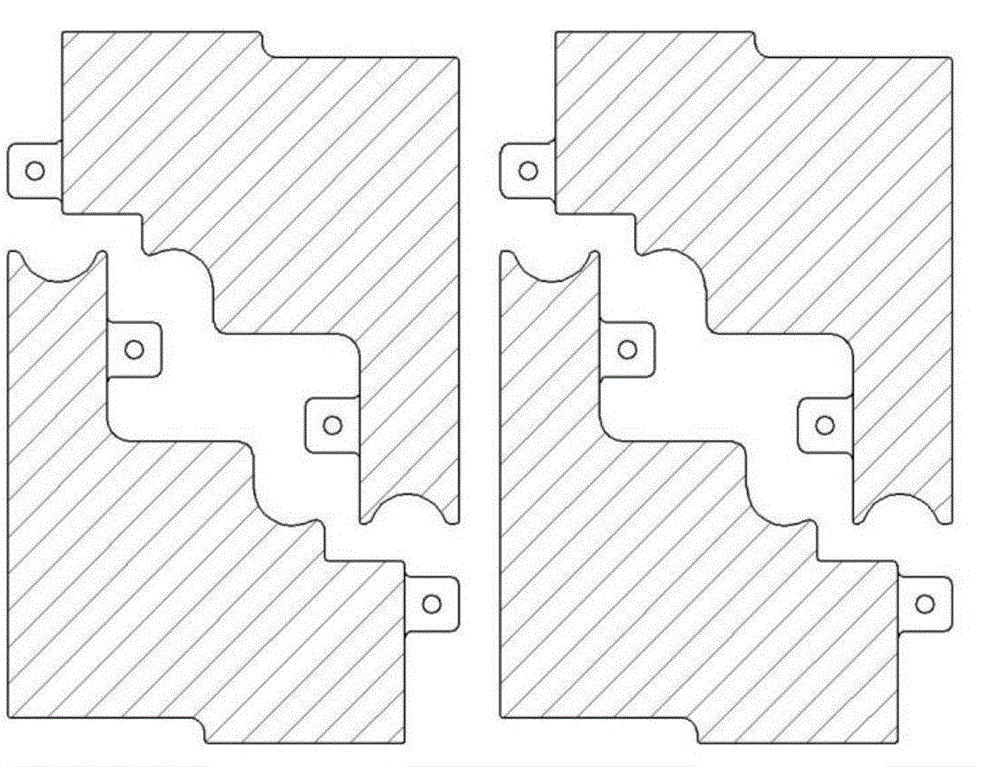

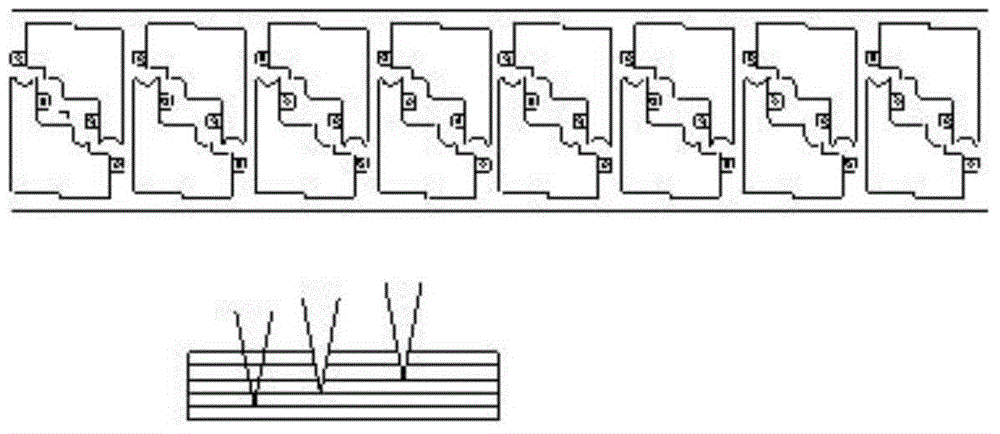

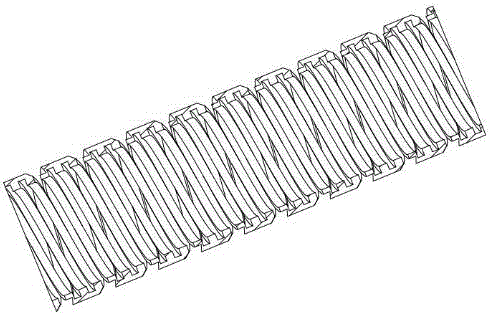

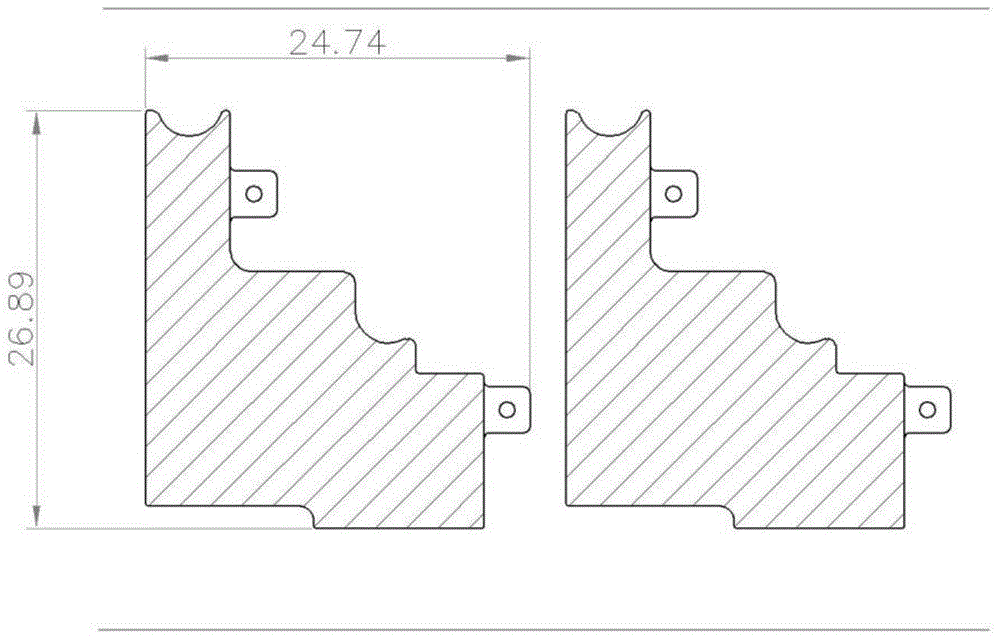

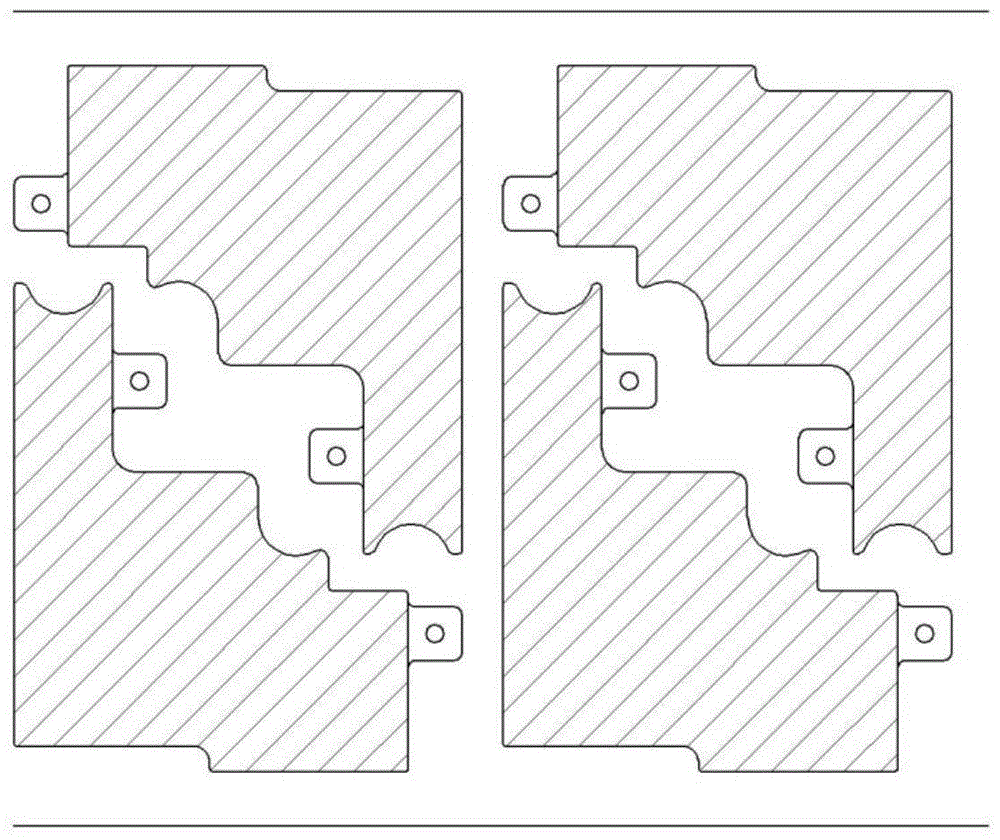

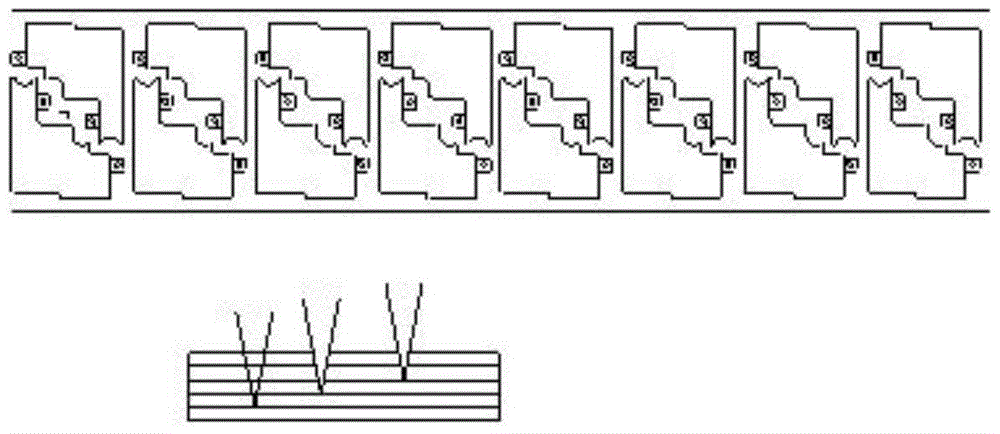

Matching die cutting and half-and-half rotating pasting processing method for conductive adhesive

The invention relates to a matching die cutting and half-and-half rotating pasting processing method for conductive adhesive. The matching die cutting and half-and-half rotating pasting processing method for the conductive adhesive includes the following steps of 1, typesetting and designing; 2, die cutting mode designing; 3, waste scheme designing; 4, product rotating pasting. After die cutting is performed on a single product, the half-and-half rotating pasting technology is adopted. The half-and-half rotating pasting technology comprises the steps that a row of products are pasted in a rotating mode, after material strips are cut, and the other half products are reposted; two strips of box sealing tape with the width of 5 mm are needed in product rotating pasting, a single PCS product is firstly fixed, dislocation or amount missing are prevented, then face paper on the conducting adhesive is removed, the original two rows of side-by-side products which are designed through the up-down and front-back rope winding are changed into products by rotating pasting in sequence and material strap cutting in sequence, therefore, the typesetting of a client is restored, and products the customer needed are manufactured. The matching die cutting and half-and-half rotating pasting processing method for the conductive adhesive improves the use efficiency of conducting resin materials, the waste materials in the manufacturing process are eliminated, the blade collapse is prevented, the normal production is guaranteed, and the production efficiency is improved; the conducting resin product rotating pasting is achieved, and the product typesetting is restored.

Owner:W B ROYMAX TECH SHENZHEN

One-way valve

ActiveCN105650293ASimplify complex structuresNot easy to damageCheck valvesEqualizing valvesCheck valveEngineering

The invention discloses a one-way valve. The one-way valve comprises a valve rod, a valve body, a gate plate, a valve cover, a hand wheel and a check valve core assembly, wherein a water inlet and a water outlet are formed in the valve body, the check valve core assembly is arranged in a cavity body of the water inlet to form a check valve, at least one threading hole is formed in the valve cover, a threading hole is formed in the valve body, and a filter pipe is further connected to the outer end of the water inlet. According to the one-way valve, a gate valve and the check valve are integrated, so that the one-way valve has dual functions of two valves, and an original complex combined structure is simplified; the threading holes are formed in the valve cover and the valve body, and the valve cover and the valve body are stringed by threads, so that water is effectively prevented from being stolen by users; and furthermore, the one-way valve further has a filter function, so that the damage of the valve core is effectively prevented.

Owner:东营市东凯园区运营管理有限公司

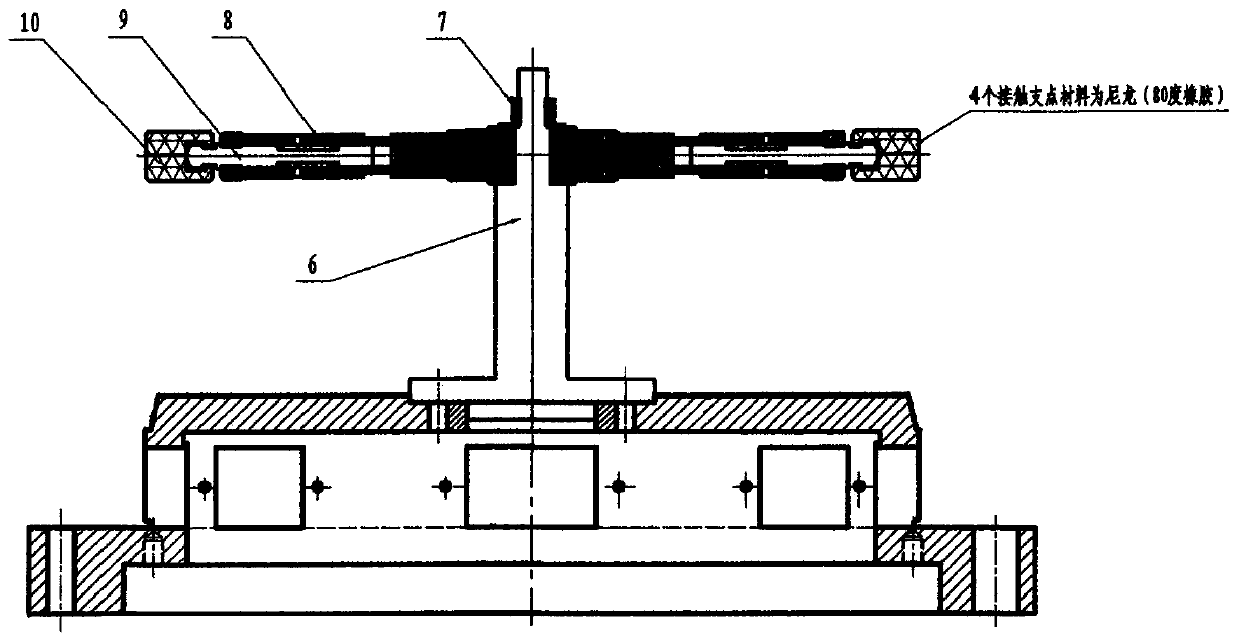

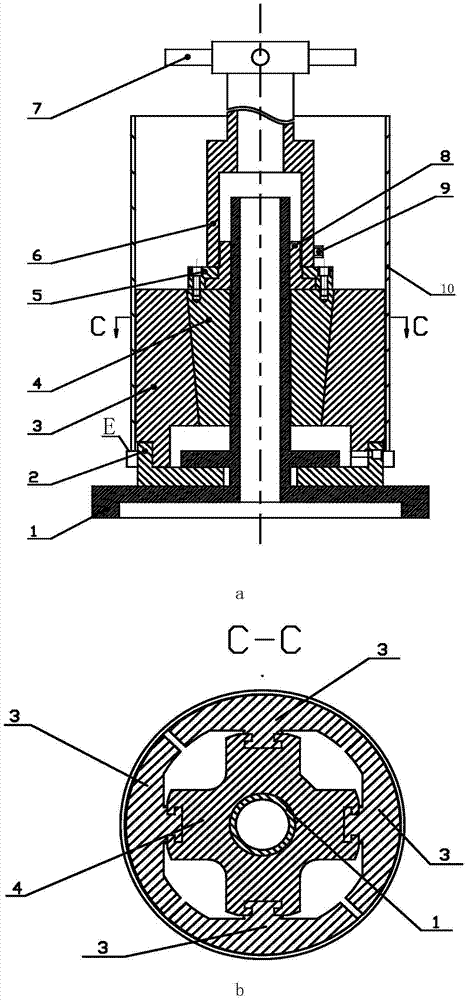

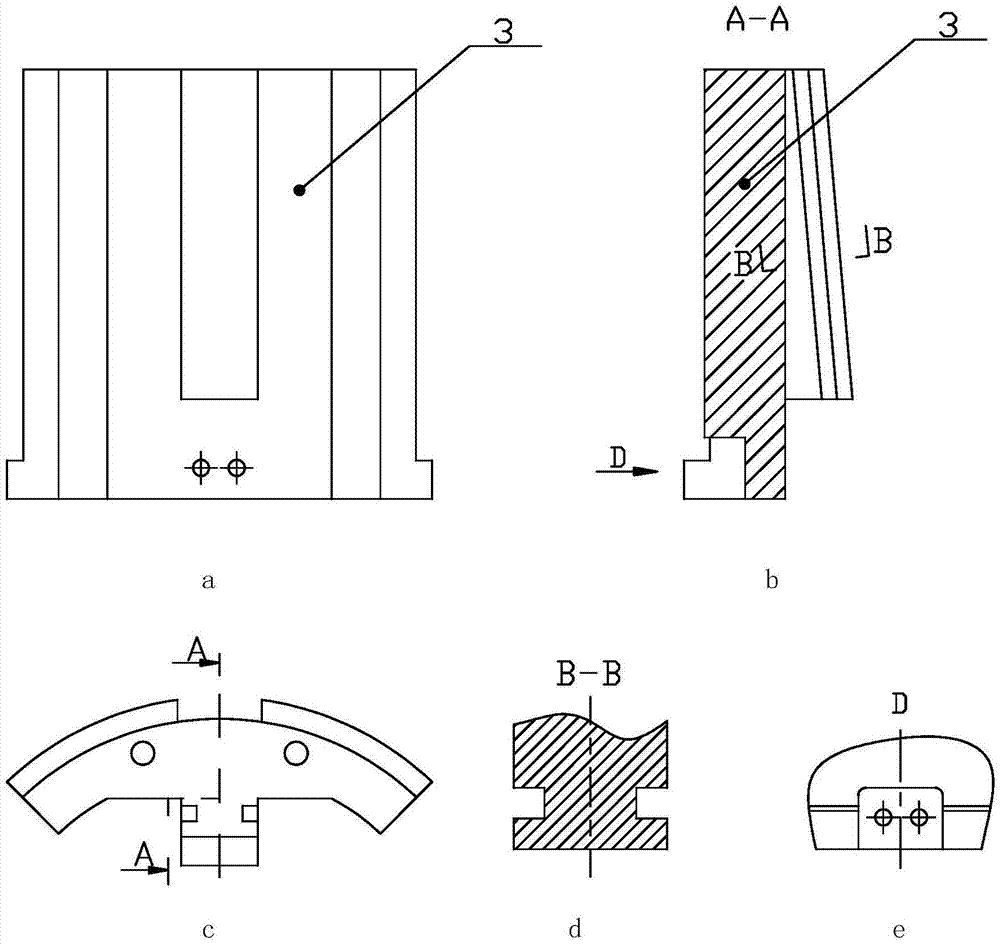

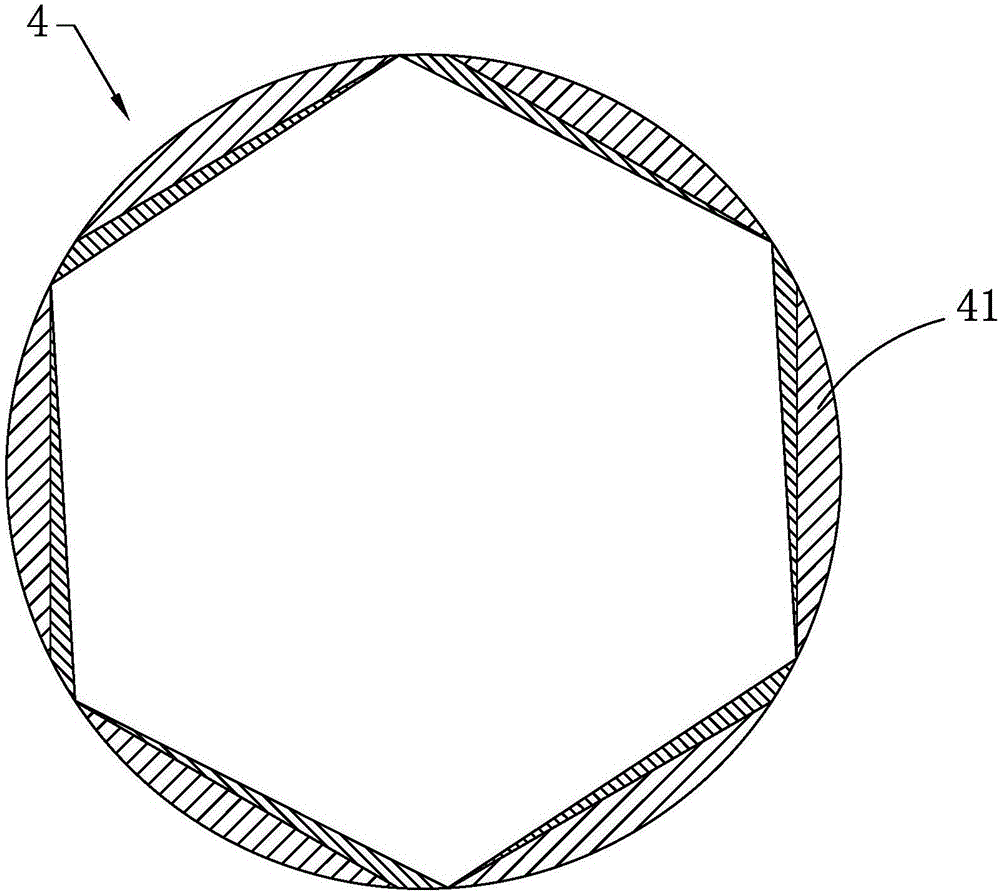

Milling inner profile expanding tool of thin-wall variable-wall-thickness cylinder

The invention relates to a milling inner profile expanding tool of a thin-wall variable-wall-thickness cylinder. Limiting blocks are arranged at the lower end of a mandrel in a sleeving manner and embedded between the upper surface of a base of the mandrel and an annular baffle of the mandrel, and an inner conical block is arranged on the mandrel in a sleeving manner. Outer arc blocks are arranged on the inner conical block in a sleeving manner, and the lower end faces of the outer arc blocks are arranged on the upper surfaces of the limiting blocks. A large outer hexagonal nut is arranged on the mandrel in a sleeving manner and attached to the upper end face of the inner conical block. A conduction disc is located on the upper surface of a locating disc at the lower end of the large outer hexagonal nut, and fixedly connected with the inner conical block through a screw. A sleeve is located above the mandrel, and an inner hexagon at the lower end of the sleeve and the large outer hexagonal nut match. The milling inner profile expanding tool is arranged in the spinning cylinder, and correction, rounding and clamping of the spinning cylinder can be achieved; the milling inner profile expanding tool has the beneficial effects that matching precision is high, tool errors are small, and product stress is even in the use process; the rigidity and machining precision of the cylinder are effectively improved; and the technical problems in thin-wall cylinder milling are solved.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

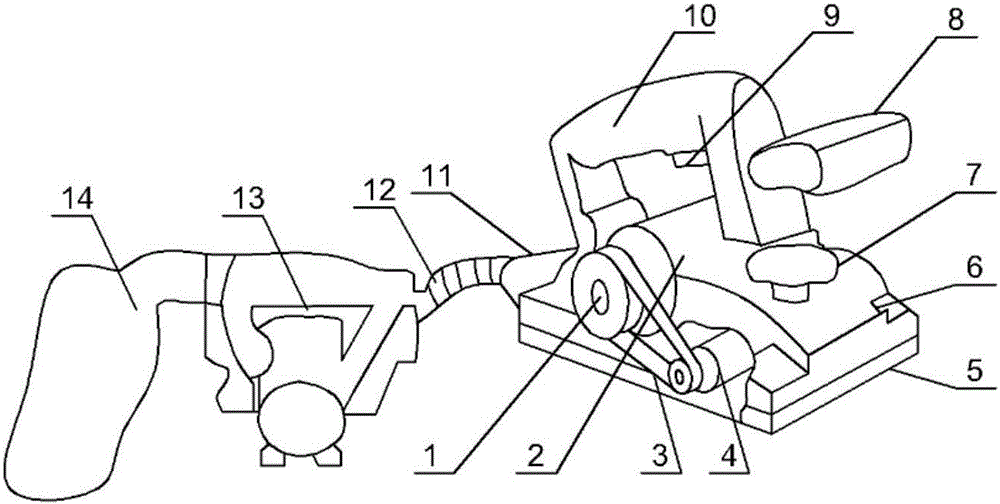

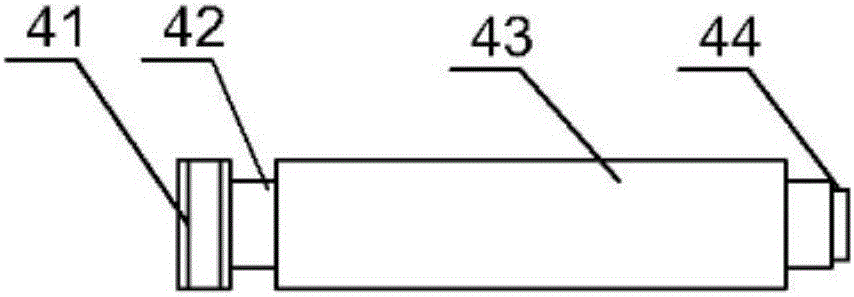

Electric wall outerskin remover with steel wire roller

InactiveCN106836837AProtection securityReduce manufacturing costBuilding repairsTransmission beltElectric machinery

The invention provides an electric wall outerskin remover with a steel wire roller. The electric wall outerskin remover comprises a belt pulley, a drive motor, a transmission belt, a steel wire roller, a bottom plate, a shell, an adjusting knob, a secondary handle, a switch, a grab handle, a blanking hopper, a dust inlet pipe, a dust collector and a dust collecting bag, wherein the belt pulley is fixed at the end part of the drive motor; the drive motor is arranged in the shell; the steel wire roller is connected with the belt pulley through the transmission belt; the bottom plate is arranged at the lower part of the shell; the adjusting knob is connected with the steel wire rope; and the secondary handle is arranged at the end part of the grab handle. Through arrangement of the steel wire roller, the adjusting knob and the transmission belt, the problem of knife collapse is effectively solved, the problems that a rigid cutter body is great in damage to a wall and easily generates a crack and peels off a wall body are solved; the problem that the outerskin on the uneven wall surface is difficult to remove is solved; the security of the drive motor is effectively protected; adjustment of the planning depth of the wall according to the actual requirements is facilitated; and market popularization and application are facilitated.

Owner:GUIZHOU UNIV

Valve with filtering function

InactiveCN105782478AEasy to realize automatic controlEasy to achieve damageSlide valveFiltration separationAutomatic controlFiltration

The invention discloses a valve with a filtering function. The valve comprises a shell, and a water quantity control mechanism positioned in the shell; the water quantity control mechanism includes a valve stator, and a valve rotor capable of rotating on the valve stator relative to the valve stator; the valve stator has at least one liquid flowing-in port; the valve rotor has stoppers for opening the liquid flowing-in ports in part phase when rotating on the valve stator; in other phases, the stoppers shield the liquid flowing-in ports; two liquid flowing-in ports of the valve stator are provided, and are symmetrically distributed on two sides of the center of the valve stator; two stoppers on the valve rotor are provided, and the positions thereof on the valve rotor are corresponding to the liquid flowing-in ports of the valve stator; and the liquid flowing-in ports of the valve stator are connected with filter pipes. The valve has the advantages of simple structure, long service life, excellent tightness, capability of realizing filtration and easy realization of automatic control.

Owner:潘豪杰

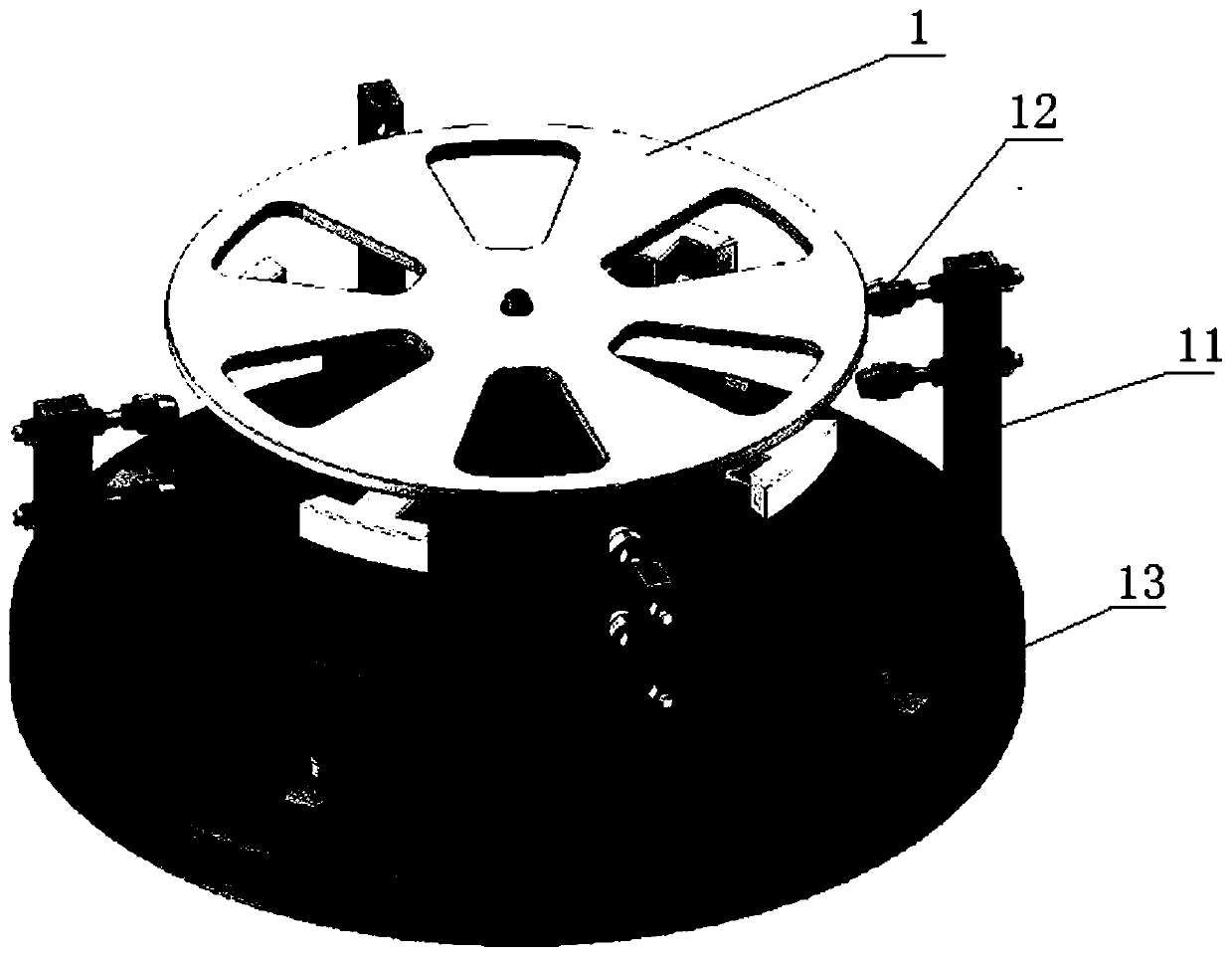

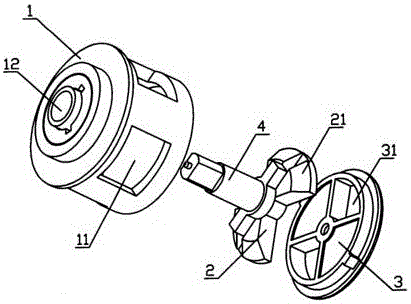

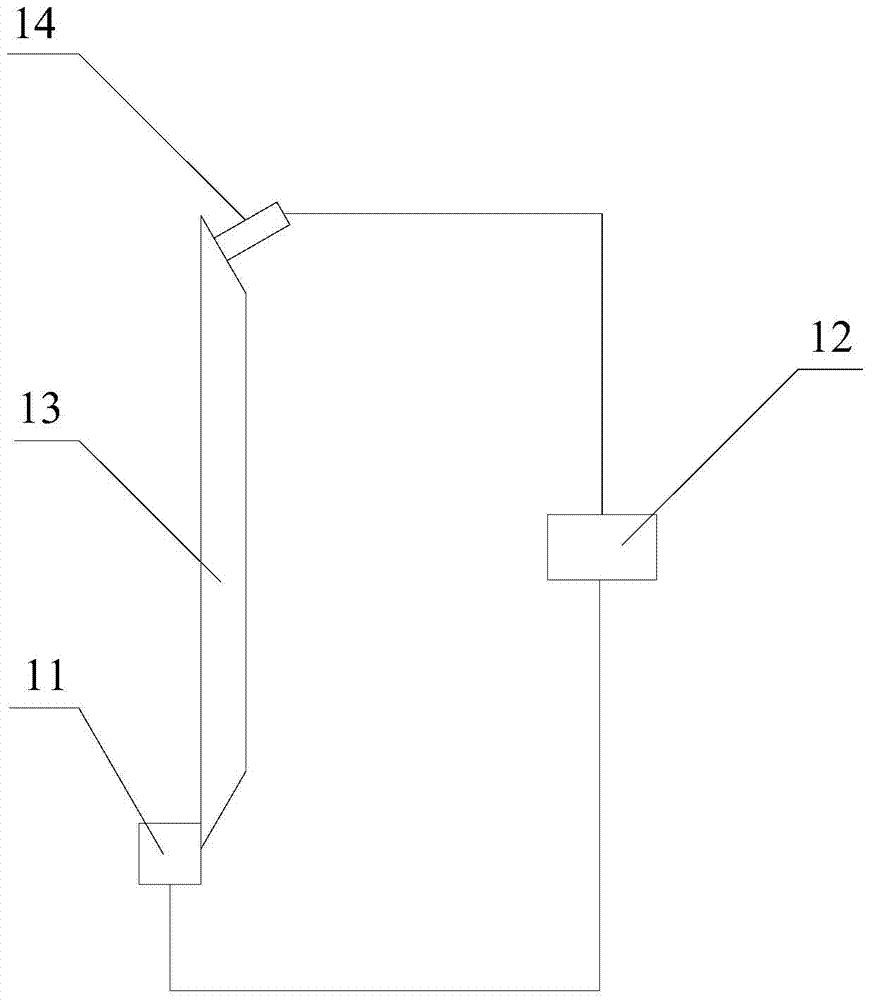

Heavy type part spraying device

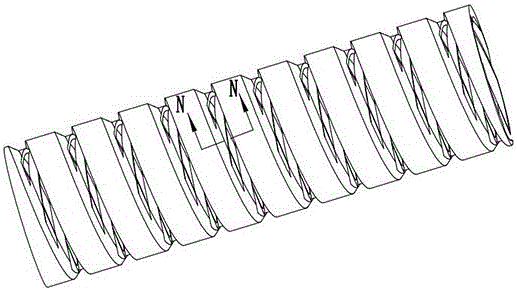

InactiveCN105772297AAvoid UndersprayAvoid the situationSpraying apparatusControl systemTurbine blade

The invention provides a heavy type part spraying device. The heavy type part spraying device comprises a six-axis joint robot and a spraying gun (1), a pressure adjusting device is arranged on the spraying gun (1) and comprises a shell installed on the spraying gun (1), turbine blades (3) installed in the shell and capable of rotating relative to the shell and a motor connected with the turbine blades (3), and a paint channel used for conveying paint is arranged inside the spraying gun (1); the lower portions of the turbine blades (3) are located in the paint channel inside the spraying gun (1); a control system connected with the six-axis joint robot and used for controlling motion of the six-axis joint robot is connected to the motor; and a mixing device is connected to an inlet of the paint channel of the spraying gun (1). By means of the heavy type part spraying device, the rotating speed of the variable frequency motor (2) can be set according to the height of the tail end of the six-axis joint robot at present, the aim of adjusting the pressure of the paint in the spraying gun (1) according to the height is achieved, and the conditions of insufficient spraying and excessive spraying are avoided.

Owner:李富平

Processing method of shock tunnel high Mach number throat channel inner profile

The invention relates to a processing method of a shock tunnel high Mach number throat channel inner profile. Theprocessing method is characterized by comprising the steps that step 1, an inner hole is drilled, wherein the diameter of the inner hole is smaller than that of a throat hole, and the inner hole is used as a turning bottom hole; step 2,rough turning is carried out, excess materials arequickly removed, and preparation is made for finish turning; step 3, finish turning is carried out, an area far away from the throat hole and with larger diameter of the profile is subjected tofinish turning to the required final size; an area,close to the throat hole,with smaller profile diameter is subjected tofinish turning to leave a machining allowance of about 0.15 mm; and step 4, reaming iscarried out, a forming reamer isused for processinga throat channelto the final profile requirement.The processing method processes the inner profile near the throat hole by using the forming reamer,the seriousreamer back-off problem in the turning process is avoided, the processing precision is improved, the high-precision processing problem of the inner profile of a shock tunnel high Mach number throat channel is solved, and the flow field quality is improved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

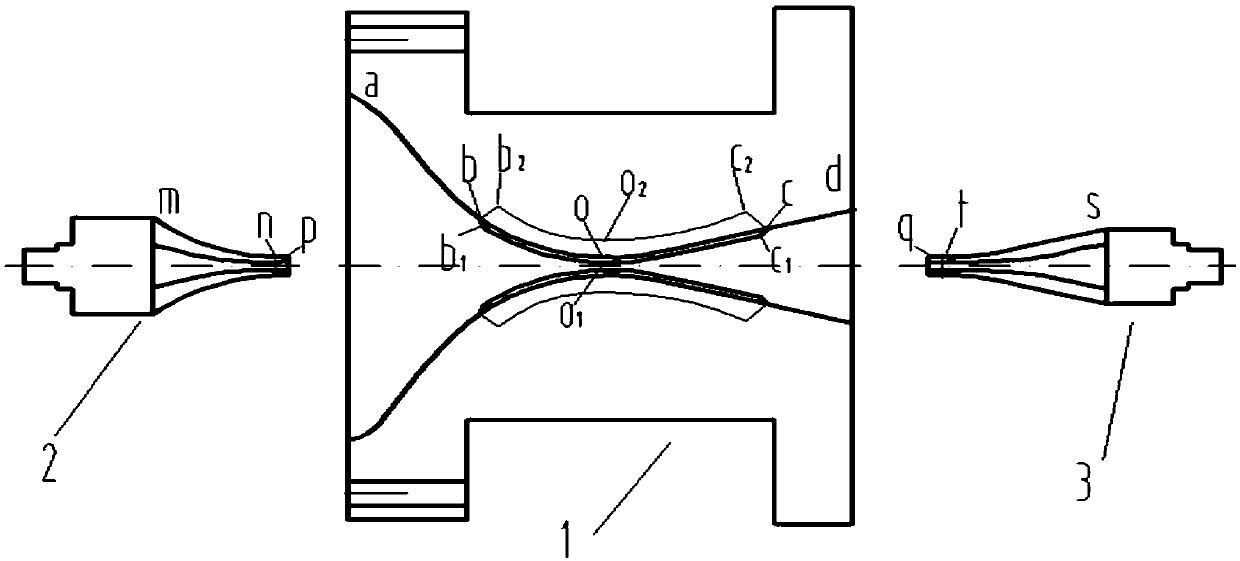

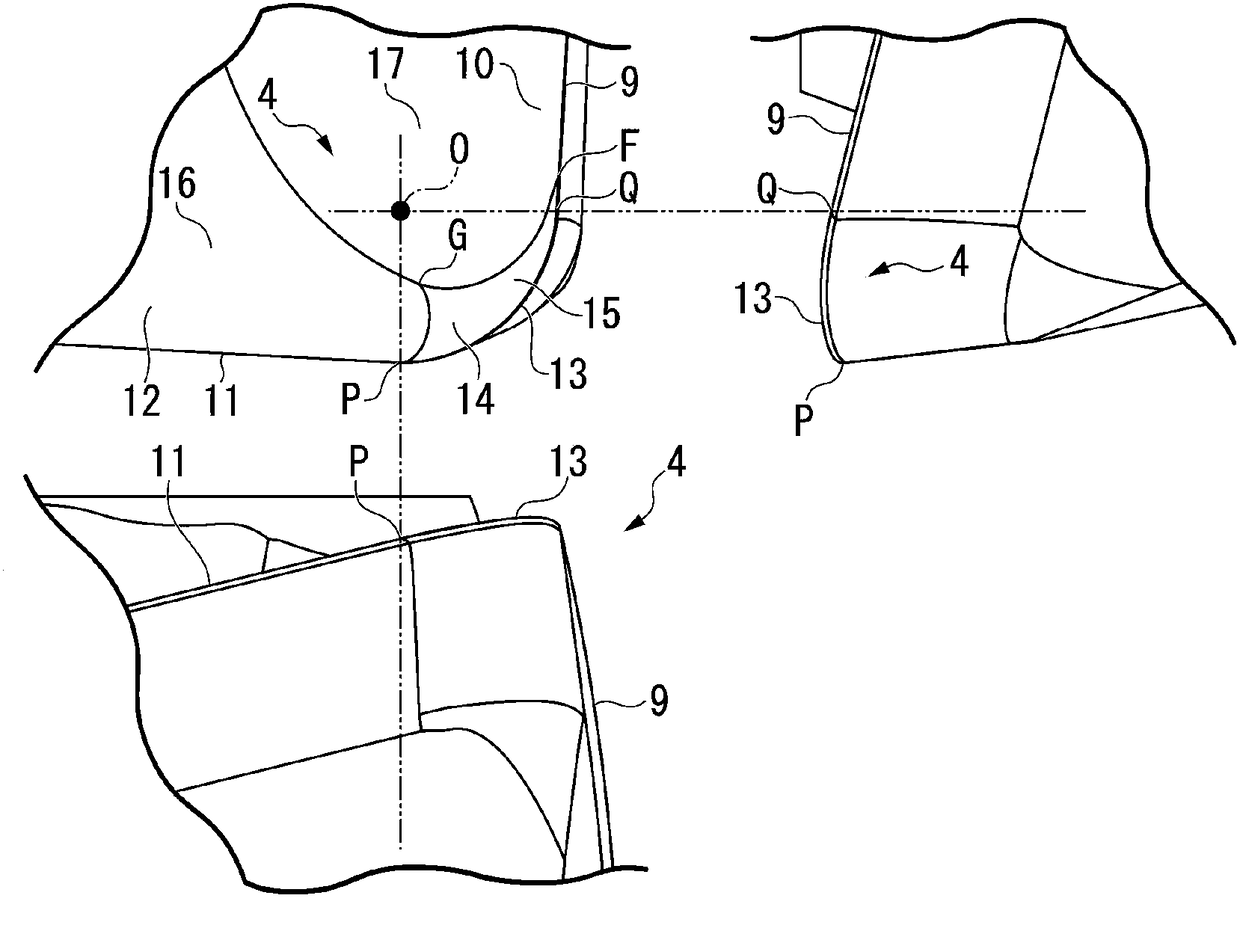

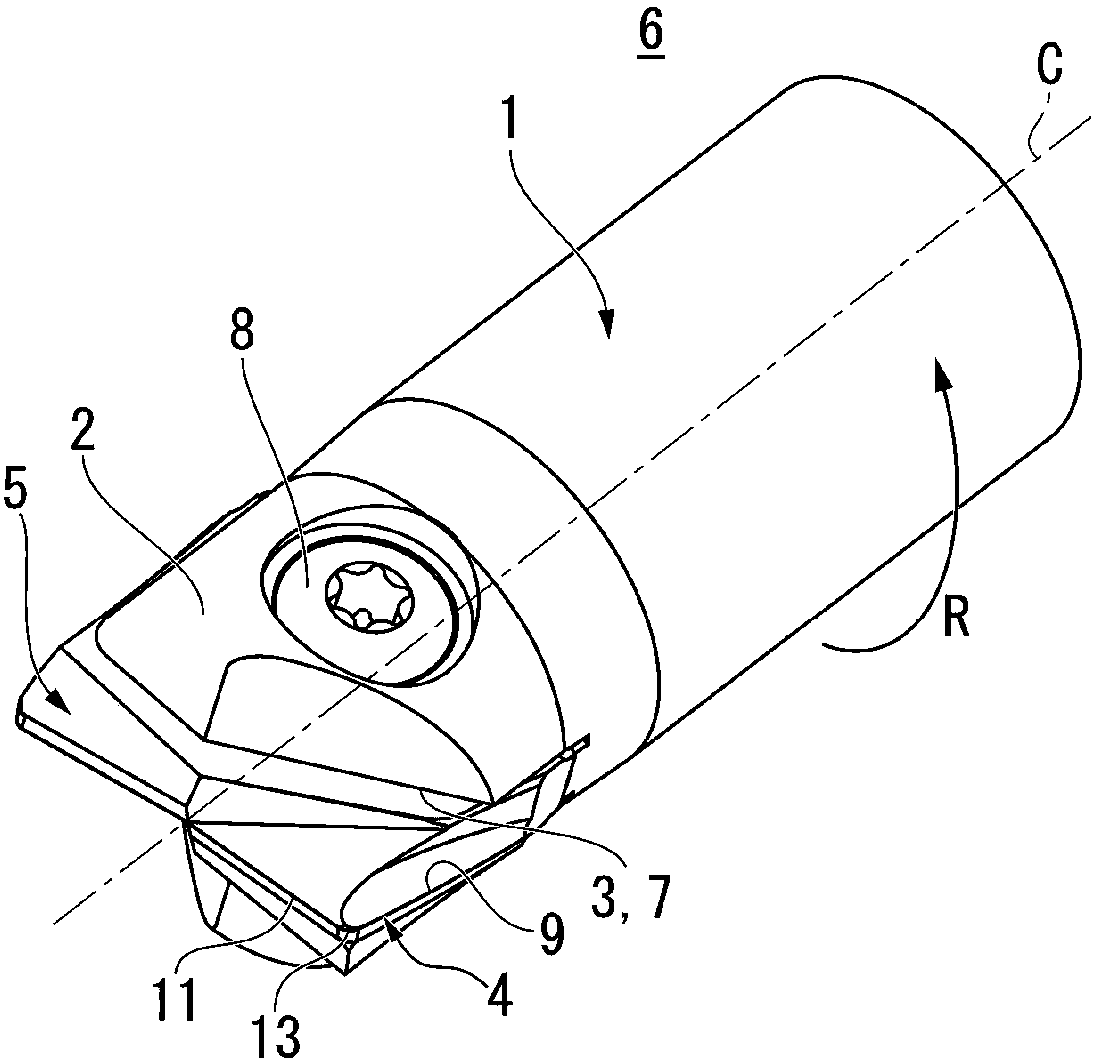

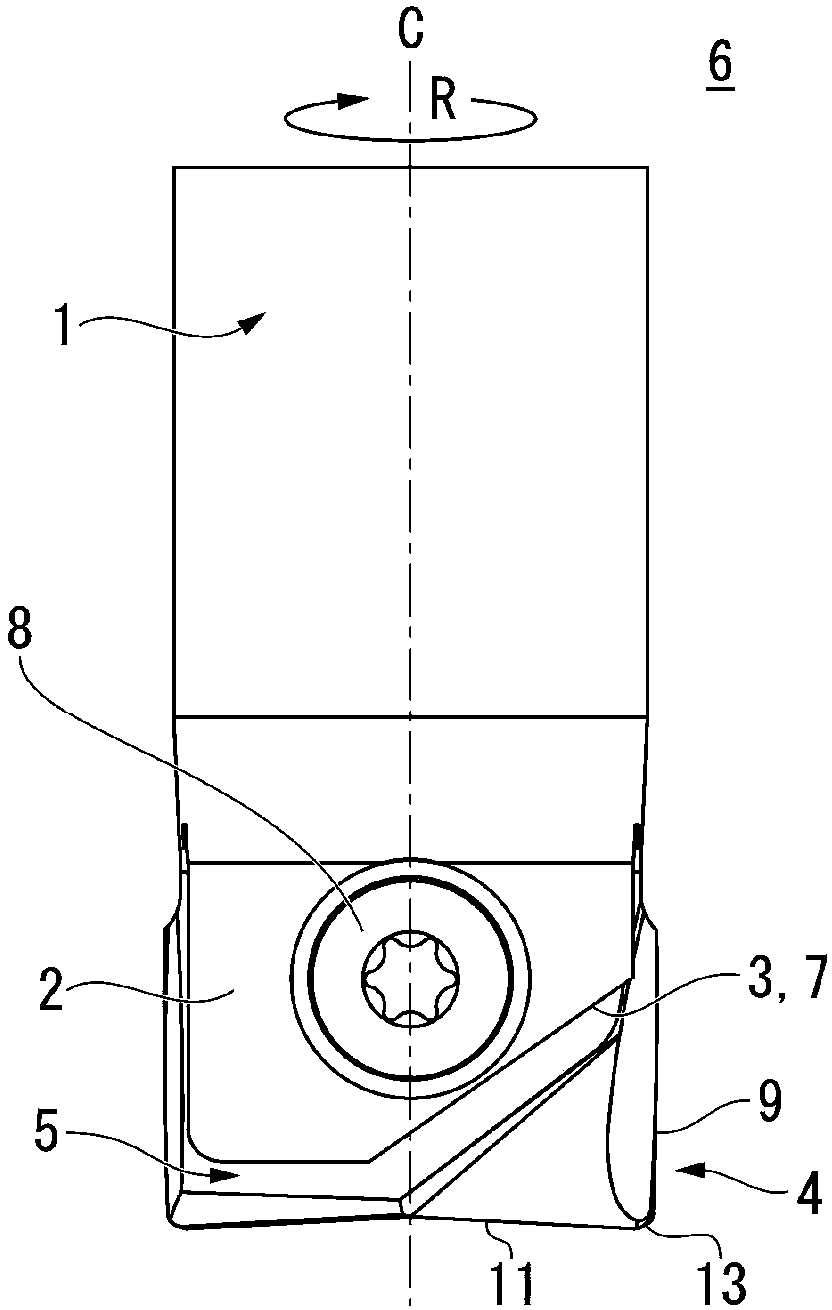

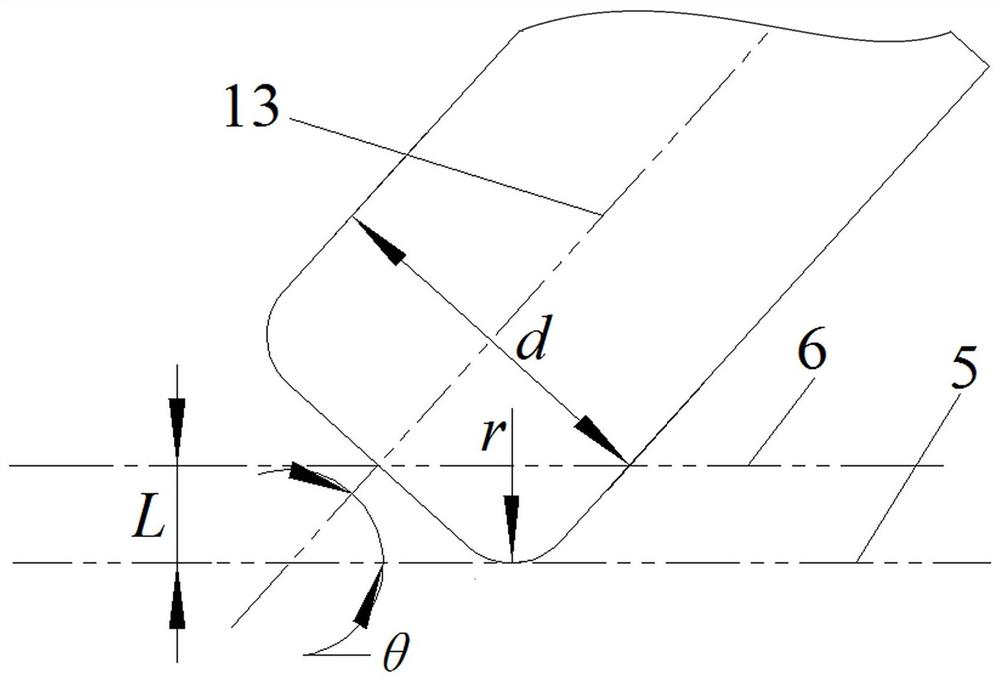

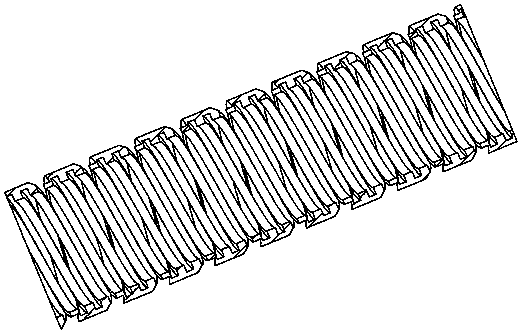

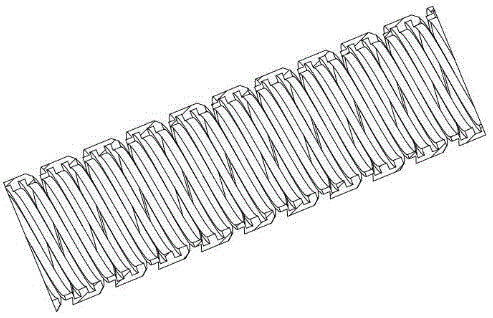

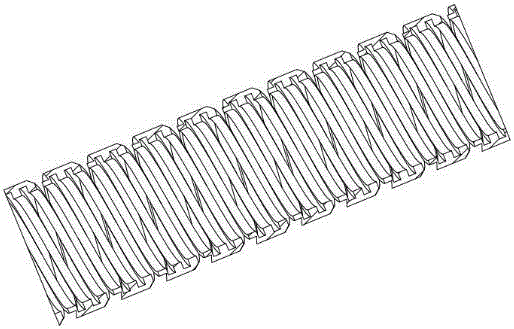

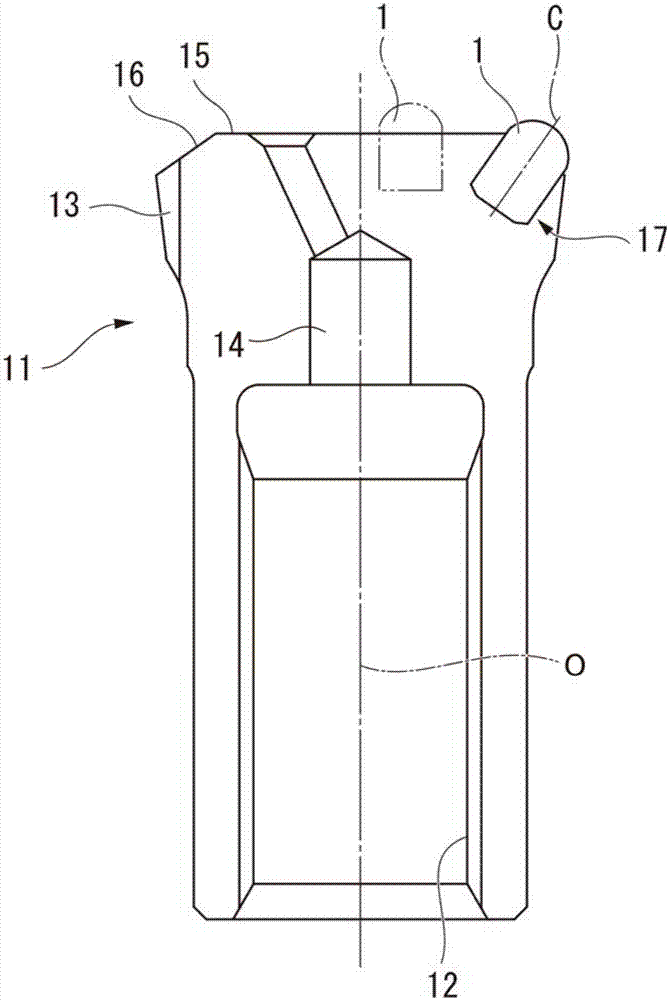

Replaceable tool edge rotary cutting tool and insert

ActiveCN108290233AHigh strengthHigh precisionTransportation and packagingMilling cuttersRadiation angleRake angle

In a virtual plane (VS): the angle at which the cutting face (14) of a corner-rounded cutting edge (13) is inclined with respect to a reference plane (Pr) is defined as the radial direction rake angle(Delta), the angle at which a virtual line (VL) projected on the reference plane (Pr) is inclined with respect to the rotation center axis is defined as the radiation angle (Theta), and the point atwhich the virtual line (VL) with a radiation angle (Theta) of 5 degrees intersects the corner-rounded cutting edge (13) is defined as the reference point (RP); the twist angle of an outer circumferential cutting edge (9) has a positive value; the axial direction rake angle (Ar1) of the corner-rounded cutting edge (13) at a boundary point (Q) has a positive value; the axial direction rake angle (Ar2) of the corner-rounded cutting edge (13) at the reference point (RP) has a negative value; of the entire edge length of the corner-rounded cutting edge (13), the radial direction rake angle (Delta)at least in the region between the boundary point (Q) and the reference point (RP) has a negative value; and the radial direction rake angle (Delta) is smaller at the reference point (RP) than at theboundary point (Q).

Owner:HITACHI TOOL ENG LTD

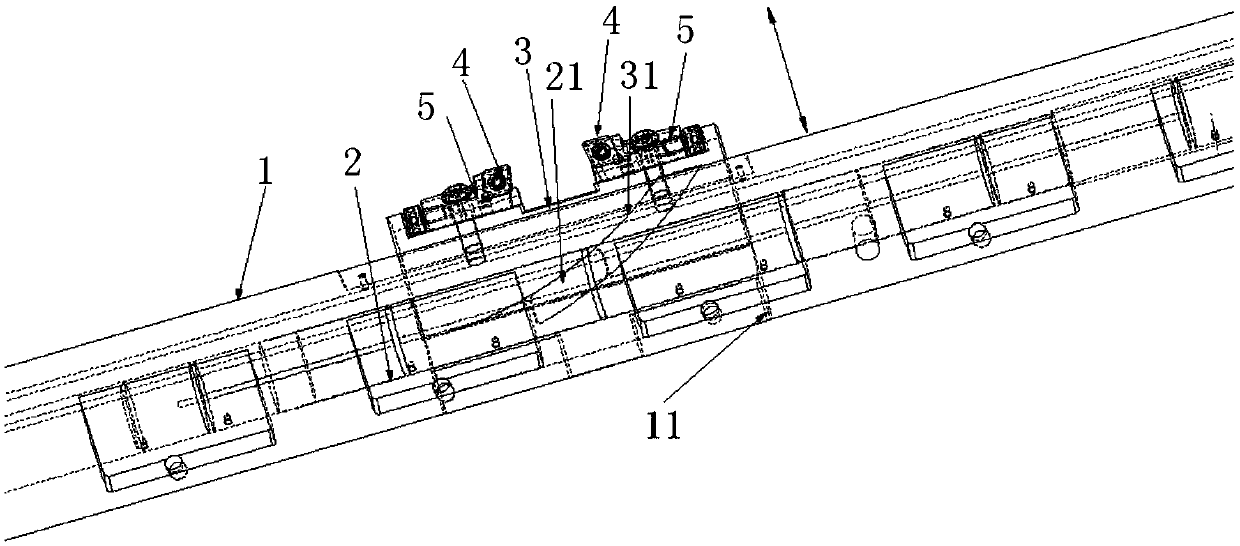

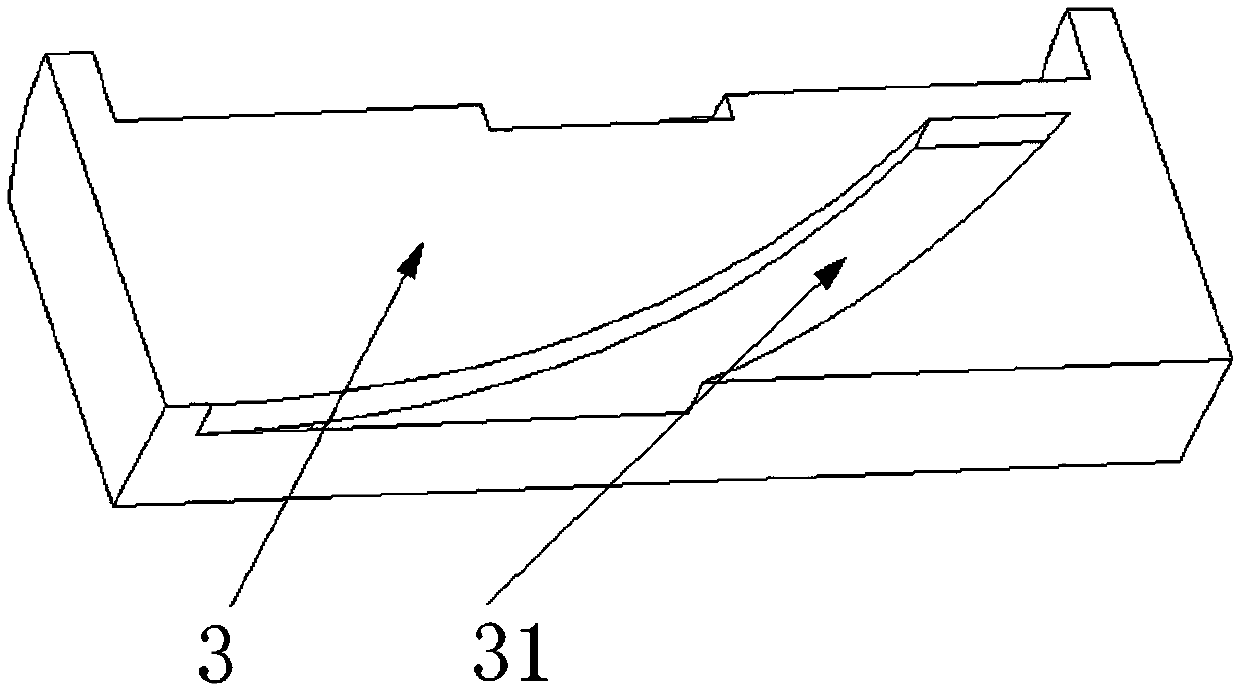

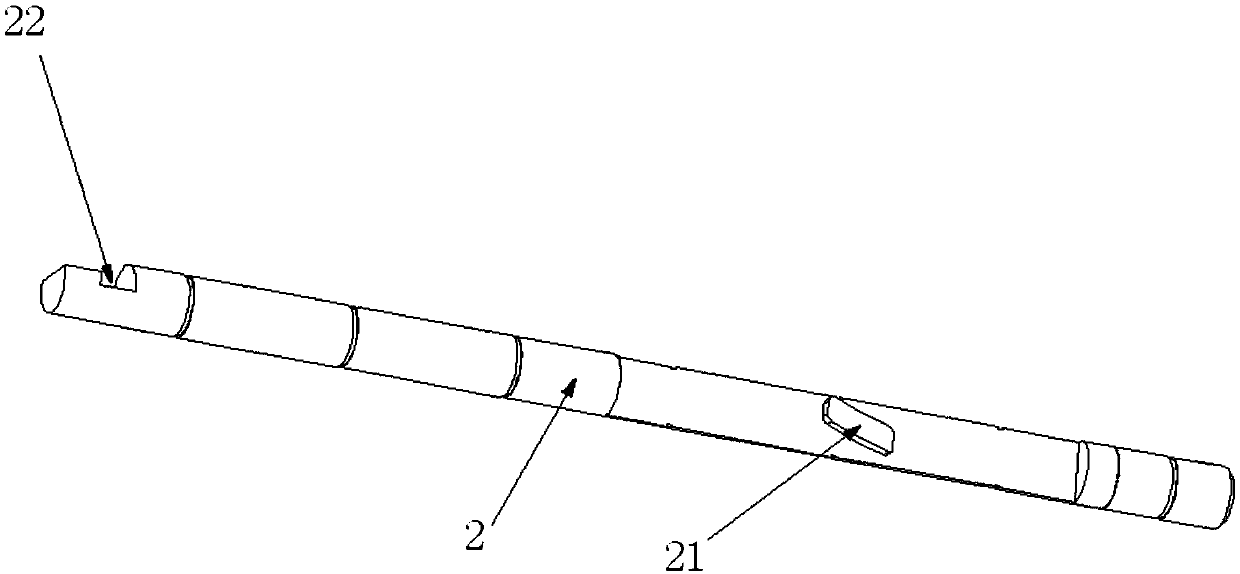

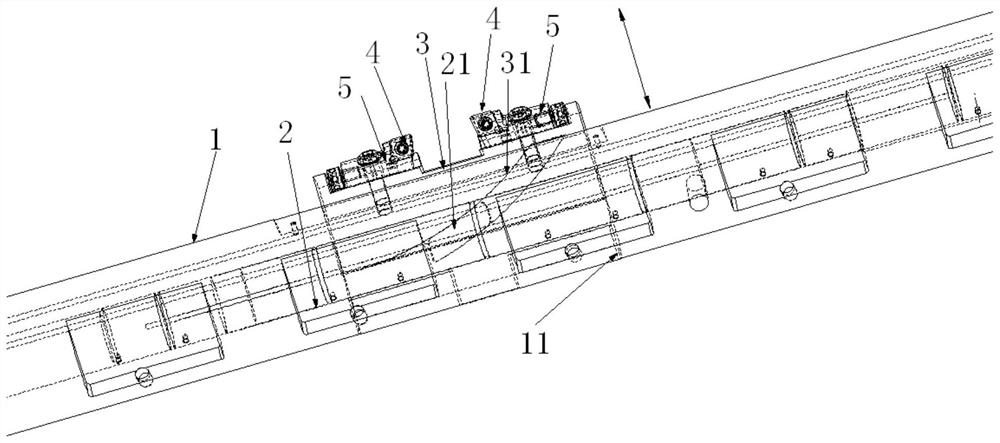

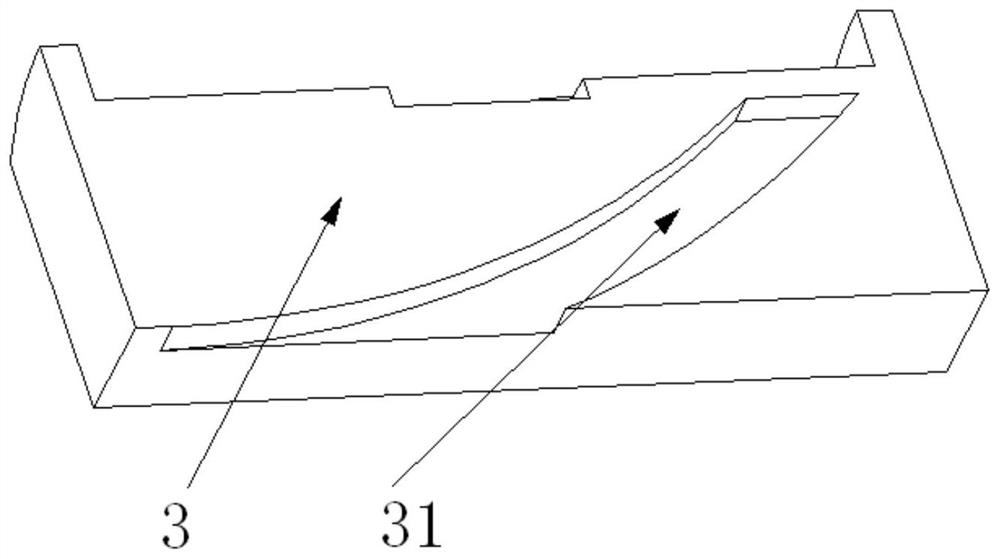

Linear boring tool capable of achieving variable feeding cutting

The invention discloses a linear boring tool capable of achieving variable feeding cutting. A linear boring tool outer tool body, a linear boring tool inner pull rod and a turning displacement block are included. The linear boring tool inner pull rod is sleeved with the linear boring tool outer tool body. The circumferential face of the linear boring tool outer tool body is provided with a matching groove in which the turning displacement block is inserted. The turning displacement block is provided with an arc groove. The linear boring tool inner pull rod is provided with a boss capable of sliding in the arc groove and driving the turning displacement block to move in the radial direction of the linear boring tool outer tool body. The part, protruding out of the matching groove, of the turning displacement block is provided with two symmetrically-arranged turning blades. The circle center of the arc groove and the turning blades are located on the same side. During bent shaft hole third thrust face turning through the linear boring tool, turning feeding becomes high from low and conforms to the specific curvature change, tool breakage at the cutting-in moment during turning is prevented, the performance of the turning blades is improved, the service life of the turning blades is prolonged, and the surface quality of the third thrust face turned by the linear boring tool is improved.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Cutting equipment and knife-damaging-resistant device thereof

InactiveCN103496005AAvoid the knifeImprove work efficiencyMetal working apparatusElectricityPower flow

The invention discloses cutting equipment and a knife-damaging-resistant device thereof. The knife-damaging-resistant device comprises an electricity conducting part, a power supply, a current sensing device and a hint device. The electricity conducting part is arranged below materials to be cut. After a knife cuts off the materials, a part exposed from the inner portion of the materials is in contact with the electricity conducting part. When the materials are not cut by the knife, the knife and the electricity conducting part are isolated by the materials. One electrode of the power supply is connected with the knife in a conducting mode. The other electrode of the power supply is connected with the electricity conducting part in a conducting mode. The current sensing device is used for sensing whether currents exist in a closed loop formed by the power supply, the electricity conducting part and the knife. The hint device is in communication connection with the current sensing device. When the current sensing device does not sense currents, the hint device gives out hint information. According to the cutting equipment and the knife-damaging-resistant device thereof, knife damaging problems can be effectively avoided, and compared with the fact that in the prior art, a photoelectricity sensing device is used as a knife-damaging-resistant device, working efficiency can be effectively improved.

Owner:SHANDONG JINYU INDUSTRIAL CO LTD

Letter bending machine

ActiveCN104014872AImprove securityAvoid the knifePositioning apparatusMaintainance and safety accessoriesLinear motionEngineering

The invention discloses a letter bending machine, and belongs to the technical field of stereoscopic luminous letter machining equipment. The letter bending machine comprises a rack, and a plate clamping device is arranged on the rack; a cutting device is arranged below the plate clamping device and comprises an installation base, a rotating disc is installed on the installation base in a rotating mode, a cutter bar is arranged on the rotating disc in a sliding mode, a cutter head is arranged on the cutter bar, and a linear driving device making the cutter bar move linearly is arranged between the rotating disc and the cutter bar; a stopping block used for limiting the rotating position of the cutter bar is arranged on the rack, and a limiting block corresponding to the stopping block in position is installed at one end, close to the cutter head, of the cutter bar. According to the letter bending machine, once electric control fails, the limiting block on the cutter bar will impact the stopping block to prevent the cutter bar from continuing rotation, and it is effectively avoided that cutter tipping happens on the cutter head rotating at high speed because the cutter bar does not rotate in place; safety performance of using the letter bending machine is improved through mechanical limiting.

Owner:WEIFANG HANDUN CNC EQUIP

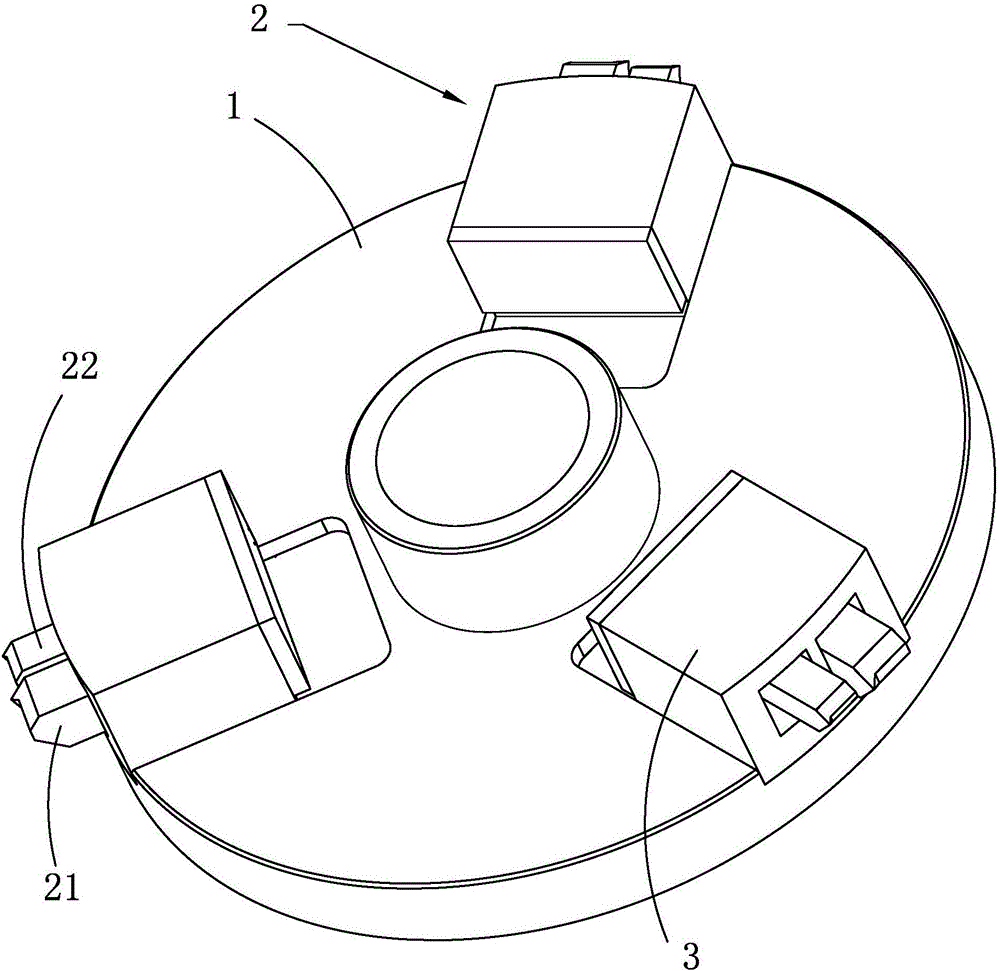

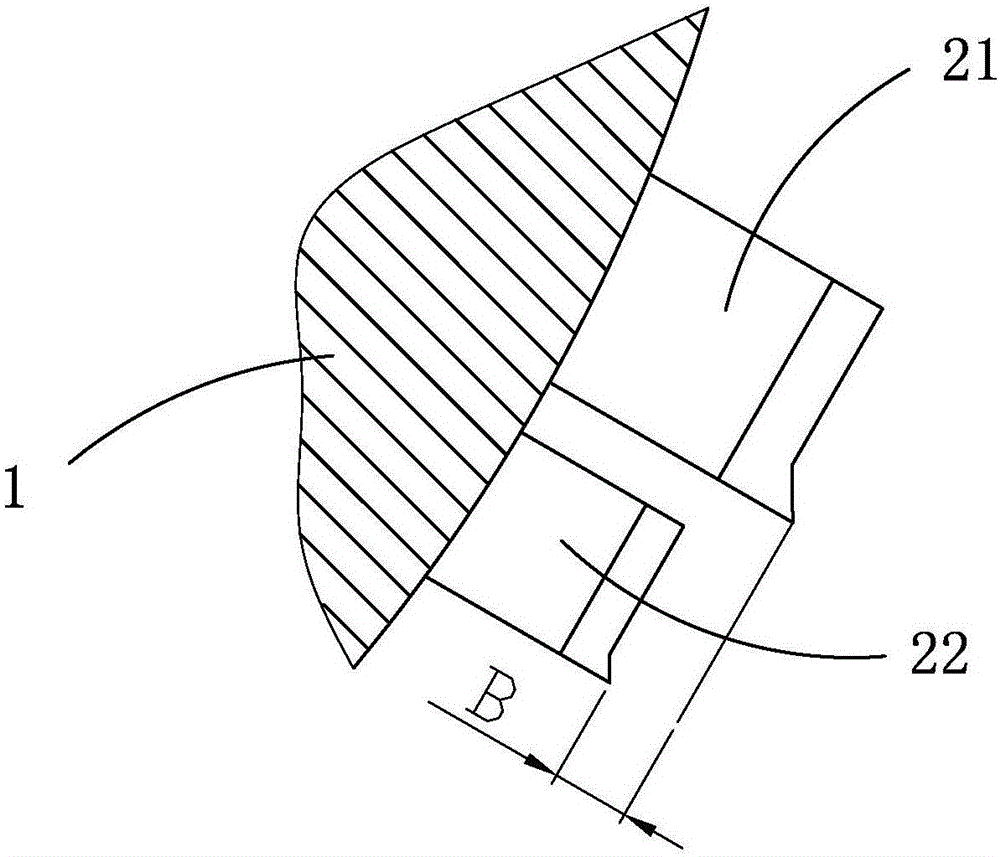

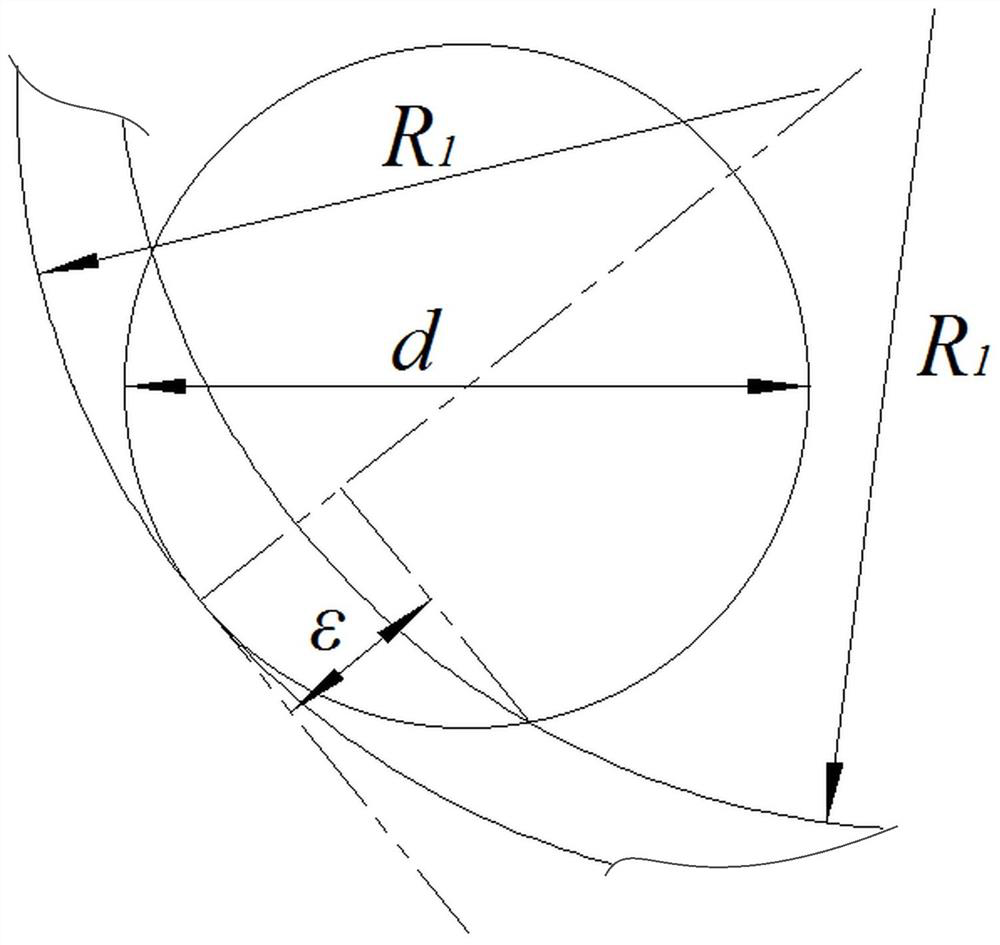

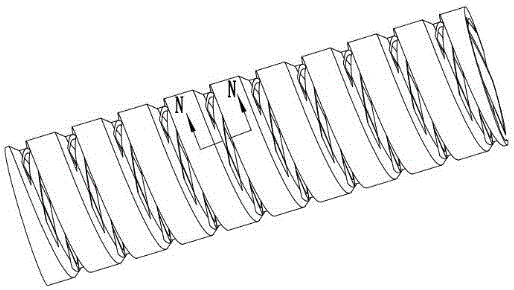

Tool for whirlwind milling of square shaft

InactiveCN106513806ADoes not affect normal useGuaranteed rigidityMilling cuttersEngineeringWhirlwind

The invention relates to a tool for whirlwind milling of a square shaft. By adoption of the tool for whirlwind milling of the square shaft, the problem of two-round successive milling including a round of rough machining and a subsequent round of finish machining in the prior art is solved. According to the technical scheme, the tool for whirlwind milling of the square shaft comprises a disc body; cutting tools are arranged on the disc body, each circumferential equipartition point is provided with one cutting tool, and the cutting tools are distributed in a radial shape with the center of the disc body as the center; and the blade portion of each cutting tool is located outside the disc body. The tool for whirlwind milling of the square shaft is characterized in that each cutting tool is provided with two tool bodies, namely the rough machining tool body and the finish machining tool body, which are arranged side by side, and the distance from the blade portion of each rough machining tool body to the edge of the disc body is smaller than the distance from the blade portion of the corresponding finish machining tool body to the edge of the disc body. The tool for whirlwind milling of the square shaft has the effects that since the rough machining tool body and the finish machining tool body of each cutting tool are arranged in the front-back direction, rough machining and finishing machining are conducted continuously, using of follow rests is not affected, and workpieces can be supported by the follow rests; and the rigidity of a system can be maintained, and the machining precision can be ensured easily.

Owner:SHIMGE PUMP IND GRP CO LTD

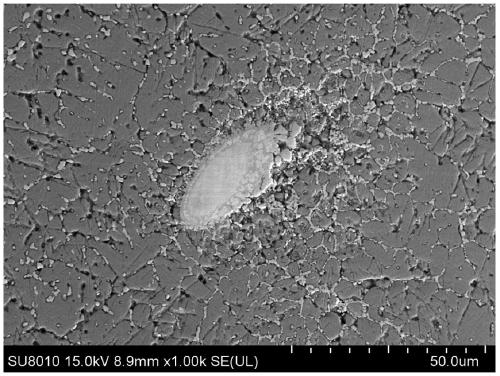

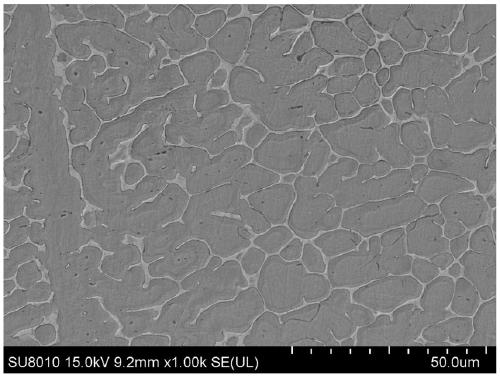

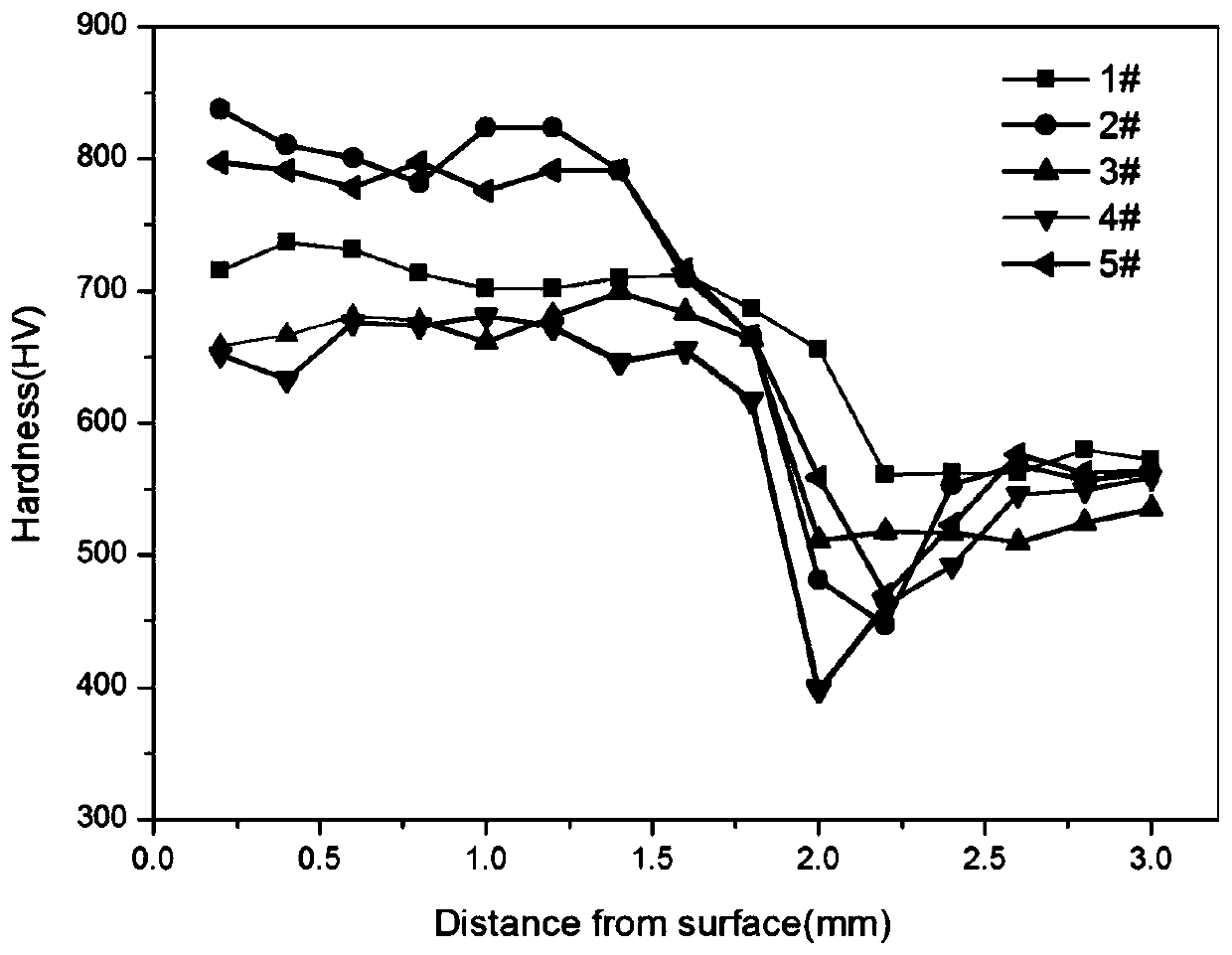

Fe-based alloy powder for hot-extrusion die laser cladding and application of Fe-based alloy powder

InactiveCN111188037AGood surface morphologyHigh hardnessMetallic material coating processesAlloyMachinability

The invention belongs to the technical field of laser cladding, and particularly relates to Fe-based alloy powder for hot-extrusion die laser cladding and application of the Fe-based alloy powder. TheFe-based alloy powder comprises following components including, by mass percent, 0.3%-0.5% of C, 0.8%-1.0% of Si, 0.2%-0.4% of Mn, 4%-6% of Cr, 1%-1.5% of Mo, 0.8%-1.1% of V, 5%-20% of WC, 0.5%-2% ofY2O3, and the balance Fe, and the sum of mass percents of all the components is 100%. Y2O3 and WC are added at the same time, WC particles can be melted and become small to enter a cladding layer structure, a new strengthening phase is generated, the integral hardness of the cladding layer is uniform, the cutting performance is improved, tool breakage is avoided, the surface of the prepared cladding layer is good in feature, performance is stable and hardness is high at the high temperature, the service life of a die can be prolonged, and cost is low.

Owner:SHIJIAZHUANG TIEDAO UNIV +1

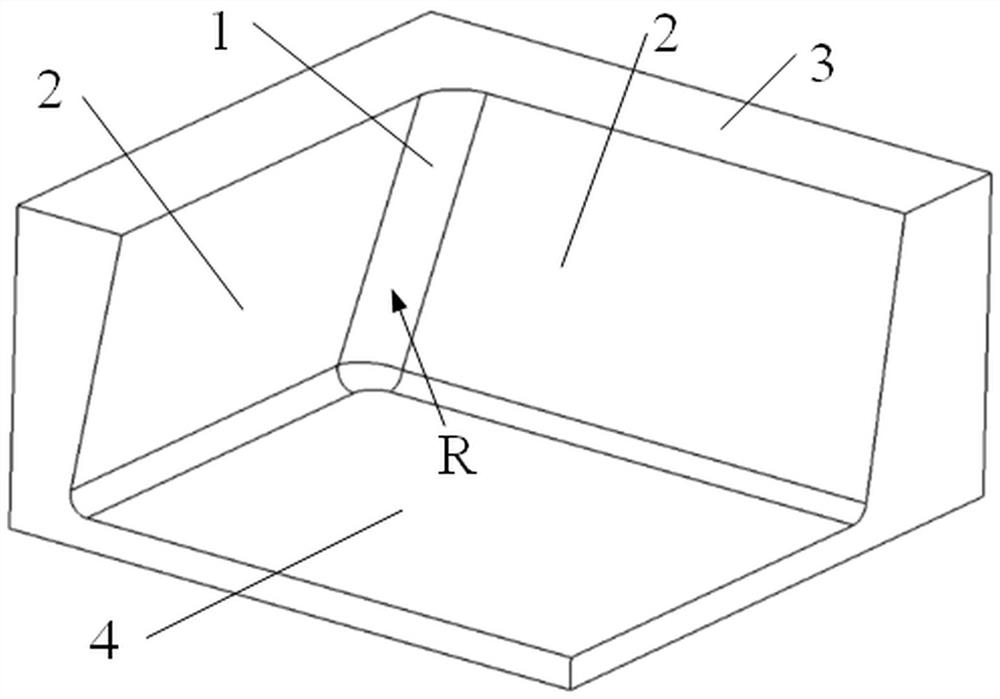

Five-axis corner characteristic efficient machining tool path generation method

ActiveCN114217570AImprove processing efficiencyImprove processing qualityNumerical controlNumerical controlStructural engineering

The invention relates to the field of numerical control machining of parts, in particular to a five-axis corner characteristic efficient machining tool path generation method. The cutting state optimization of five-axis corner machining is realized by controlling the cutter shaft vector and the equivalent cutting width of the cutter during five-axis corner machining. Firstly, a cutter axis vector is calculated according to the corner side face, and then the tool path driving geometry of the five-axis corner is obtained according to tool geometric parameters, the corner depth and the axial cutting depth; the maximum equivalent cutting width of a current tool is determined according to the machining tool performance and the machining tool information, and a machining tool path with the five-axis corner characteristic in the groove cavity is generated through a cyclic machining strategy. The five-axis corner machining tool path can be suitable for machining of various five-axis corners with the side faces being planes or equivalent planes, and the machining quality of the corners can be effectively improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Automobile spraying device capable of realizing uniform spraying

The invention provides an automobile spraying device capable of realizing uniform spraying. The automobile spraying device capable of realizing uniform spraying comprises a six-axis joint robot and a spray gun (1) installed at the tail end of the six-axis joint robot, wherein a vibration generator is installed on the spray gun (1), and comprises a motor installed on the spray gun (1) and an eccentric block (3) installed at the tail end of an output shaft of the motor; the spray gun (1) is further connected with a mixing device, and the mixing device comprises a main box body as well as a pressure pump, a paint tank and a water tank which are installed on the main box body; the main box body is provided with an inlet I connected with the paint tank and an inlet II connected with the water tank, and further provided with an output port connected with the spray gun (1) through the pressure pump; and a filter tube immersing into the water tank and with a sealed outer end is installed in the inlet II, so that a water flow is filtered through the filter tube while entering the inlet II. The automobile spraying device provided by the invention has the advantage of uniform coating.

Owner:李富平

Curved surface formed tool

The invention belongs to the technical field of cutting tools, and particularly relates to a curved surface formed tool. The curved surface formed tool comprises a tool holder and a cutting part at the front end of the tool holder, the cutting part is shaped like a sphere and is provided with multiple screw-type cutting edges which are evenly distributed, screw flutes are formed between the adjacent cutting edges, the multiple cutting edges are collected at the front end of the cutting part, the corresponding edge thicknesses of the cutting edges are gradually increased from front to back, the portion, at the rear end of the cutting part, of each cutting edge is provided with a first forming cutting edge which is of an inward arc-shaped sunk structure, each cutting edge is further provided with a second forming cutting edge which is shaped like an inward semicircle, the rear portion of each cutting edge is provided with an arc-shaped groove which is right opposite to another cutting edge, each arc-shaped groove is internally provided with an arc-shaped nozzle, each arc-shaped nozzle is communicated with a cutting fluid pore passage formed in the axis of the tool holder, the special type curved surface can be formed in one time, the precision is high, and the efficiency is high.

Owner:CHANGZHOU HAILI TOOL

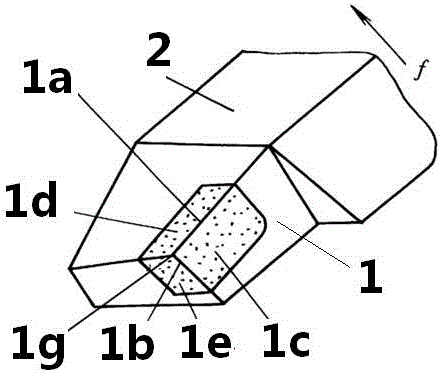

Gradually-cutting inner hole cutter and machining method

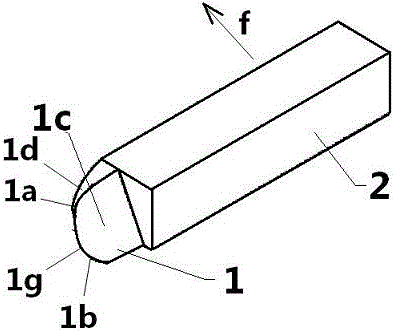

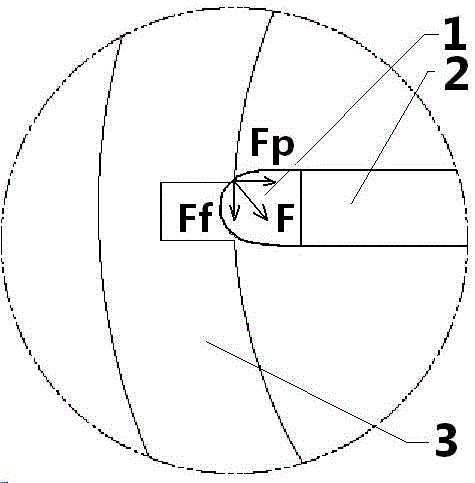

PendingCN106541157AReduce shockReduce momentary displacementCutting insertsTurning toolsTool bitPull force

The invention discloses a gradually-cutting inner hole cutter and a machining method. The gradually-cutting inner hole cutter comprises a cutter head and a cutter bar. The cutter head comprises a main cutting edge, an auxiliary cutting edge, a front cutter face, a main rear face and an auxiliary rear face. The main cutting edge and the auxiliary cutting edge are each a section of arc line; the intersection of the main cutting edge and the auxiliary cutting edge is a section of arc line for smooth connection, and inflection points are absent at the intersection between the main cutting edge and the auxiliary cutting edge; and an included angle which is an acute angle is formed between the front cutter face 1c and the direction of main cutting force. The gradually-cutting inner hole cutter and the machining method have the advantages that impact on a traditional cutter due to interrupted cutting is reduced; impact on the traditional cutter due to gaps of a transmission mechanism of a machine tool is reduced, pushing force of the traditional cutter due to impact cutting is changed to pulling force caused by gradually cutting, and cutter back-off during cutting of a traditional turning tool is avoided; and instantaneous displacement of the cutter bar due to cutting impact is reduced, cutting tends to be stable, phenomena of breaking edges and blade jamming are avoided, damage to the traditional cutter due to impact cutting is reduced, the machining accuracy is greatly improved, and rejected products caused by the phenomena of breaking edges, blade jamming and the like are avoided.

Owner:TIANHE FUAO AUTO SAFETY SYST CHANGCHUN

A linear boring tool capable of variable feed cutting

The invention discloses a linear boring tool capable of achieving variable feeding cutting. A linear boring tool outer tool body, a linear boring tool inner pull rod and a turning displacement block are included. The linear boring tool inner pull rod is sleeved with the linear boring tool outer tool body. The circumferential face of the linear boring tool outer tool body is provided with a matching groove in which the turning displacement block is inserted. The turning displacement block is provided with an arc groove. The linear boring tool inner pull rod is provided with a boss capable of sliding in the arc groove and driving the turning displacement block to move in the radial direction of the linear boring tool outer tool body. The part, protruding out of the matching groove, of the turning displacement block is provided with two symmetrically-arranged turning blades. The circle center of the arc groove and the turning blades are located on the same side. During bent shaft hole third thrust face turning through the linear boring tool, turning feeding becomes high from low and conforms to the specific curvature change, tool breakage at the cutting-in moment during turning is prevented, the performance of the turning blades is improved, the service life of the turning blades is prolonged, and the surface quality of the third thrust face turned by the linear boring tool is improved.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

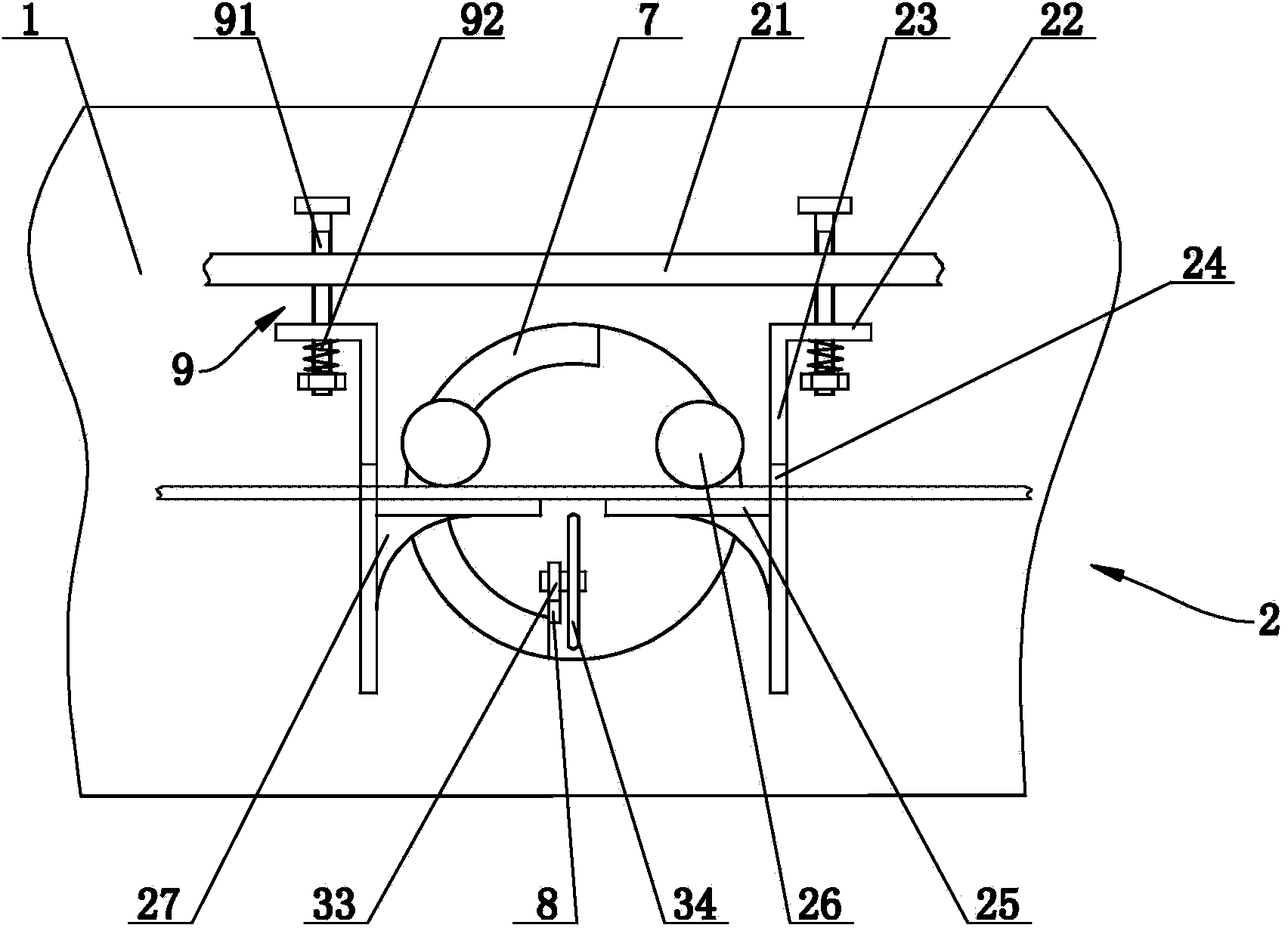

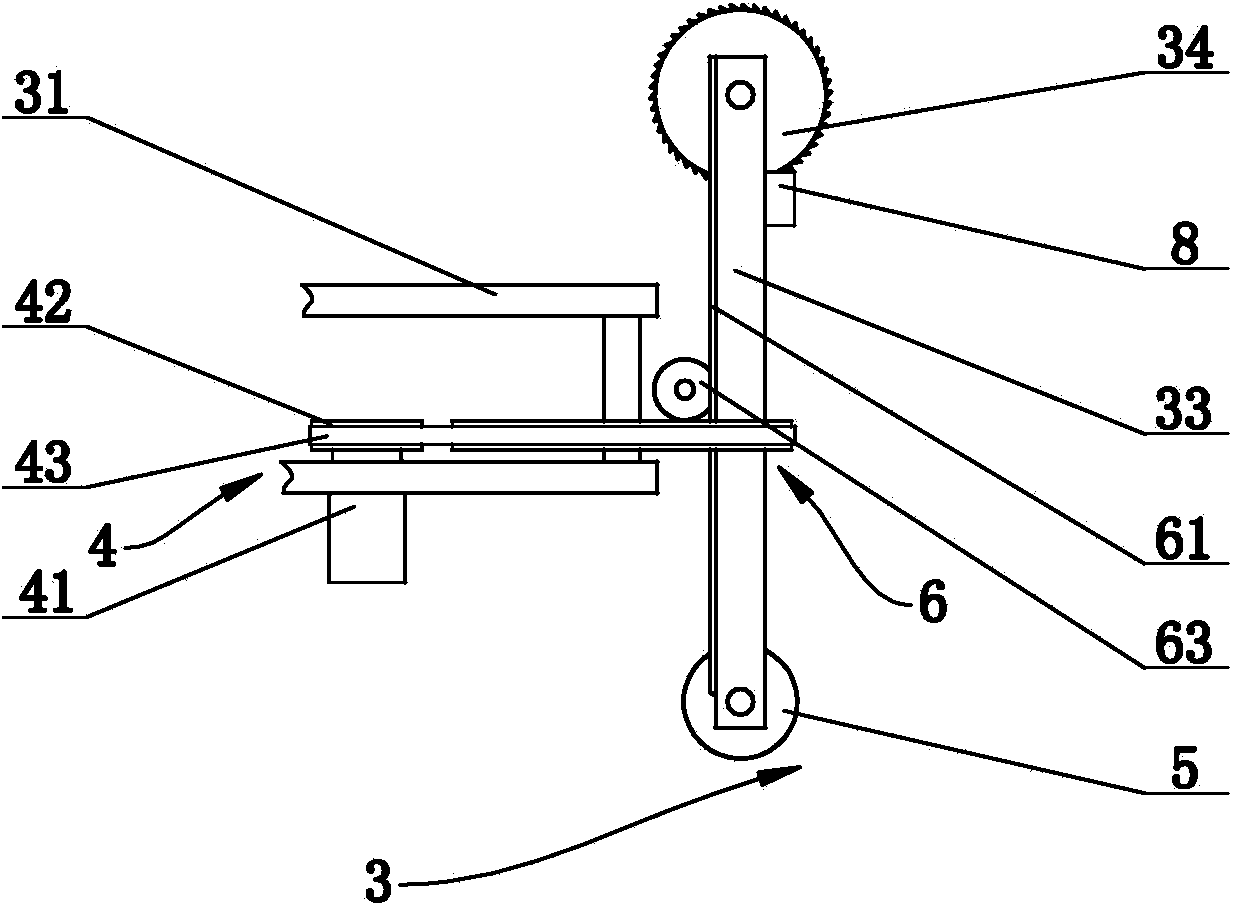

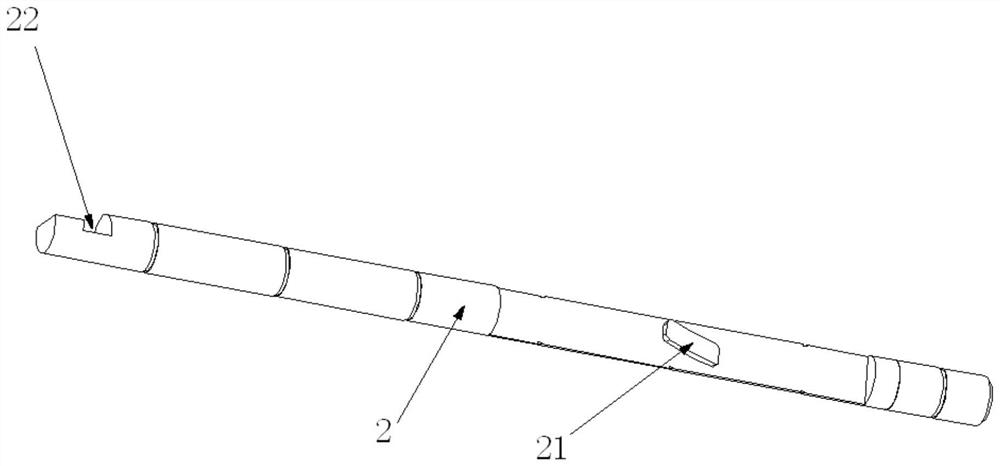

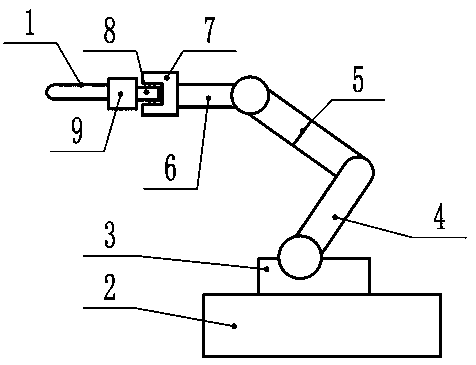

An obstacle avoidance spraying robot

ActiveCN105798887BIncrease freedomConvenient obstacle avoidance path planningProgramme-controlled manipulatorSpraying apparatusEngineeringObstacle avoidance

The invention provides an obstacle avoidance spraying robot. The obstacle avoidance spraying robot comprises a base (2), a waist portion (3), a big arm (4), a middle arm (5), a small arm (6), a wrist portion (7), a hand portion (8) and a tail end (9). The rotating axis, relative to the small arm (6), of the wrist portion (7), the rotating axis, relative to the wrist portion (7), of the hand portion (8) and the rotating axis, relative to the hand portion (8), of the tail end (9) are pairwise orthogonal and intersect with one another at one point. The upper end of the middle arm (5) can also rotate relative to the lower end of the middle arm (5). A spray gun (1) is mounted at the tail end (9). The obstacle avoidance spraying robot can bypass obstacles horizontally arranged and obstacles vertically arranged, has the obstacle avoidance function and meanwhile can avoid blocking of the spray gun (1) effectively.

Owner:杜弗尼工程机械(苏州)有限公司

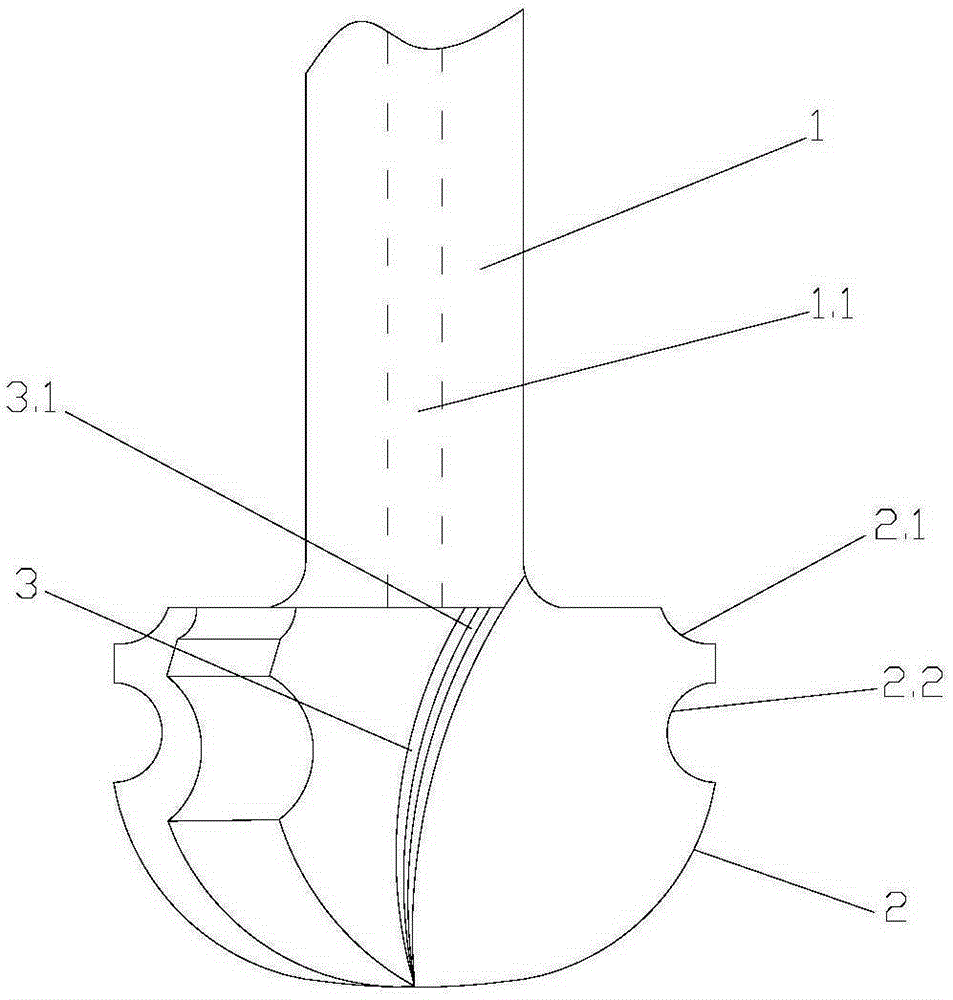

Diverter valve for roof water tank of building

InactiveCN105650309ATo achieve the purpose of self-cleaningRealize the filtering functionValve arrangementsFiltration separationLeaking waterEngineering

The invention provides a diverter valve for a roof water tank of a building. The diverter valve consists of a shell (1), a diverter shaft (2) and a pipeline (3), wherein the pipeline (3) penetrates through the shell (1); the diverter shaft (2) is arranged in the shell (1) and can move in a reciprocating manner; one end of the diverter shaft (2) is opposite to the side wall of the pipeline (3); a diverter channel (4) is formed in the diverter shaft (2); an inlet of the diverter channel (4) is formed in the side face of the diverter shaft (2); the diverter shaft (2) can completely cut off the pipeline (3) when penetrating through the pipeline (3), and the pipeline (3) is communicated with the diverter channel (4); an inlet of the pipeline (3) is further connected with a filtering pipe and a connection port with an inner diameter greater than the outer diameter of the filtering pipe; and the filtering pipe is provided with a pipe body with a blocked outer end. The diverter valve has the positive effects that when the pressure of the water tank is extremely high and a downstream pipeline leaks water, the diverter shaft penetrates through the pipeline to completely cut off the pipeline and make the pipeline communicated with the diverter channel; and furthermore, the inlet of the pipeline is further connected with the filtering pipe, thus realizing a filtering function of a diverter water path.

Owner:陈杰

Deep hole forming tool

InactiveCN104475830AReduce contact areaAvoid breakingTransportation and packagingTrepanning drillsEngineeringDeep hole

The invention relates to the technical fields of cutting tools, particularly to a deep hole forming tool. The deep hole forming tool comprises a tool shank and a cutting module at the front end of the tool shank, wherein the cutting module is composed of a third cutting unit connected with the tool shank, a second cutting unit at the front end of the third cutting unit, and a first cutting unit at the front end of the second cutting unit; the third cutting unit and the second cutting unit are in a ball shape and are connected through a transitional smooth curved surface; the first cutting unit is composed of a taper unit connected with the second cutting unit, and a ball unit at the front end of the taper unit, and the small-diameter end of the taper unit is smoothly connected with the second cutting unit; the cutting module is provided with at least three screw cutting edges uniformly distributed in the circumferential direction of the cutting module, and the screw cutting edges are correspondingly provided with screw flutes and converge in the center of the front end of the first cutting unit. According to the deep hole forming tool, during a cutting process, the contact area between the cutting module and hole walls can be small, so that the possibility of tool tipping due to radial movement can be greatly reduced.

Owner:常州华尔澜工具有限公司

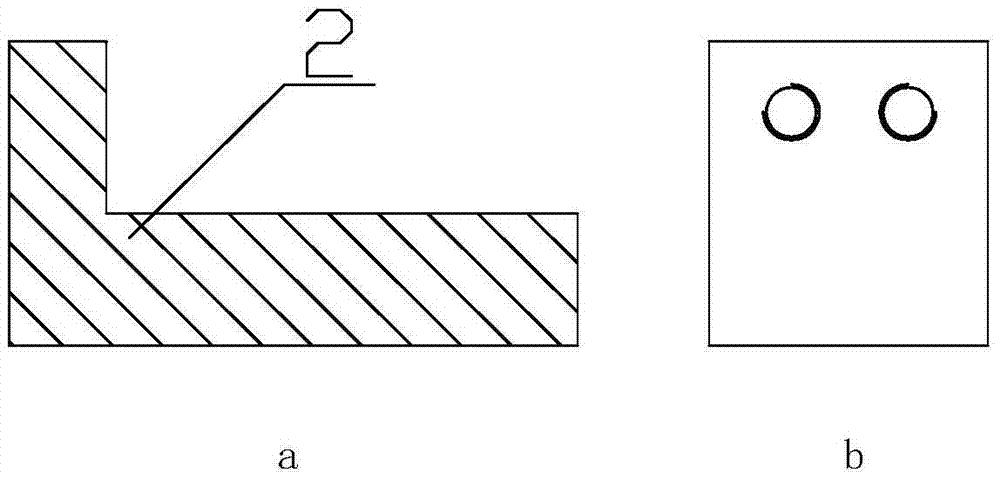

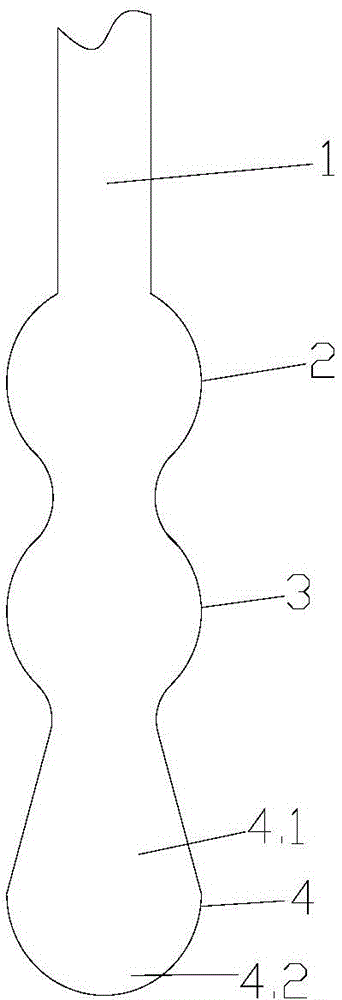

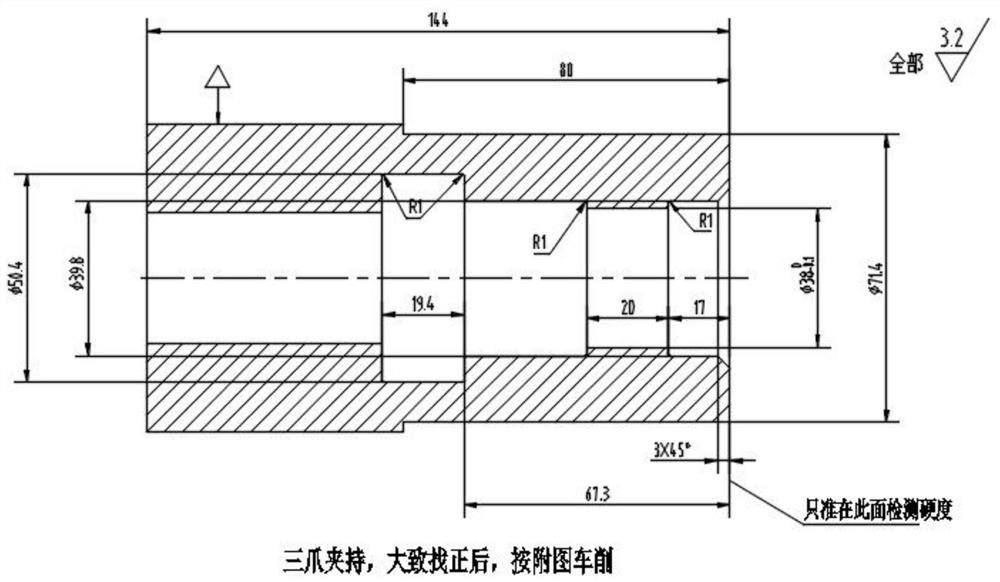

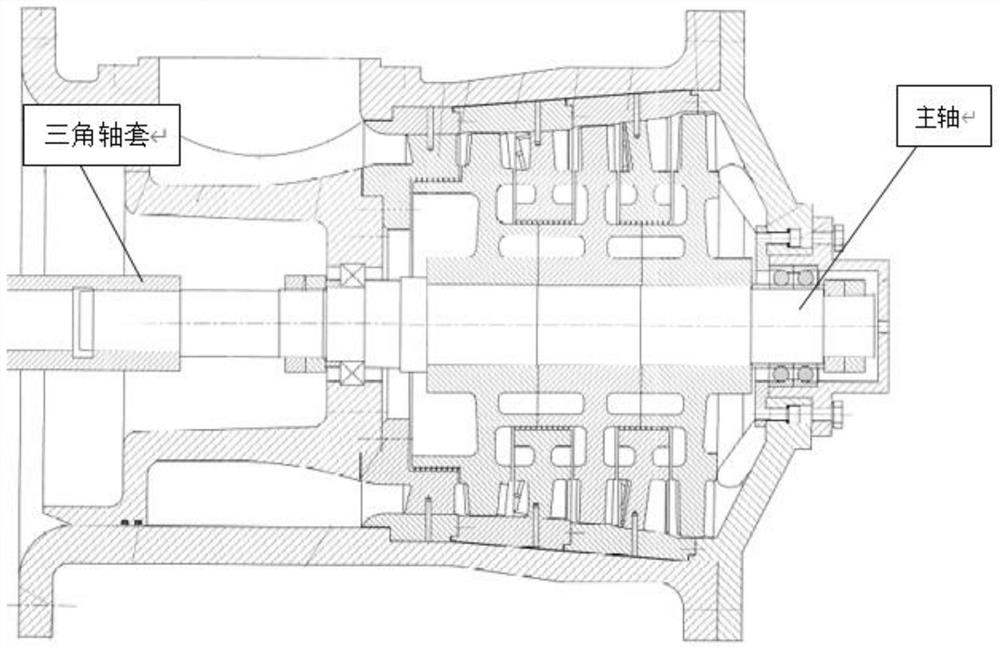

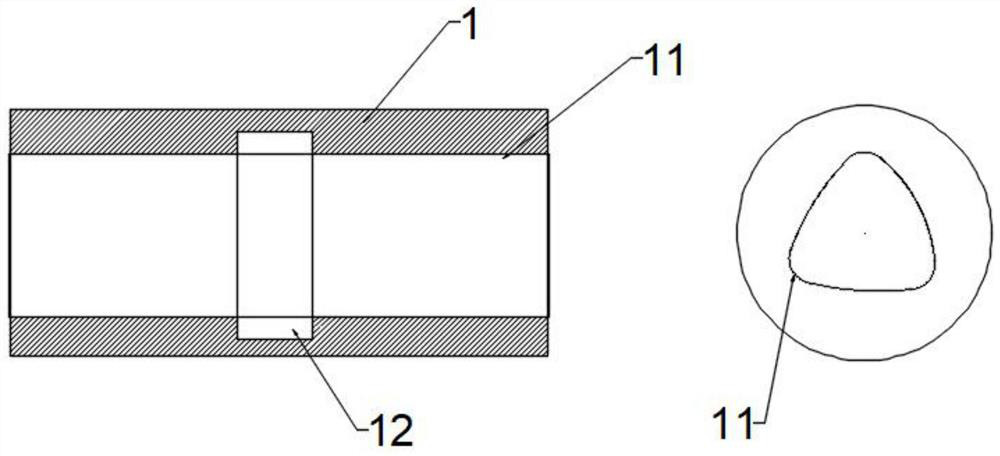

Triangular shaft sleeve machining method

PendingCN113814667AAvoid unqualifiedHigh strengthCouplings for rigid shaftsElectric dischargeWire cutting

The invention relates to the field of machine tool machining, in particular to a triangular shaft sleeve machining method. The method comprises the steps that a test bar is obtained and detected; an inner circular hole of the test bar is machined; heat treatment is conducted on the machined test bar; semi-finish turning is conducted on a large outer circle and the inner circular hole; the test bar is clamped by adopting a first tool, and finish machining is conducted on the outer circle and two end surfaces of the test bar; and the test bar is clamped by adopting a second tool, and a special-shaped hole is cut through low-speed wire cutting. Before manufacturing, the quality of the test bar is detected, then the inner circular hole is machined to remove redundant allowance, then heat treatment is conducted to improve strength and reduce deformation, then semi-finish turning and finish machining are conducted to guarantee the machining quality, low-speed wire cutting and electric discharge machining are adopted, parts are not contacted, and the machining quality can be better controlled by means of the precision of equipment.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

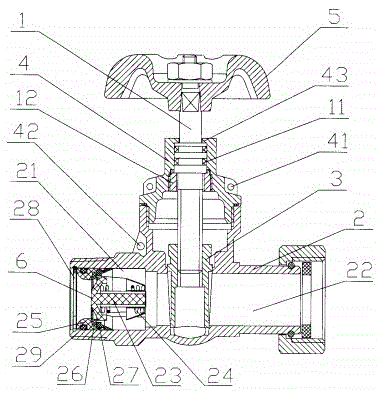

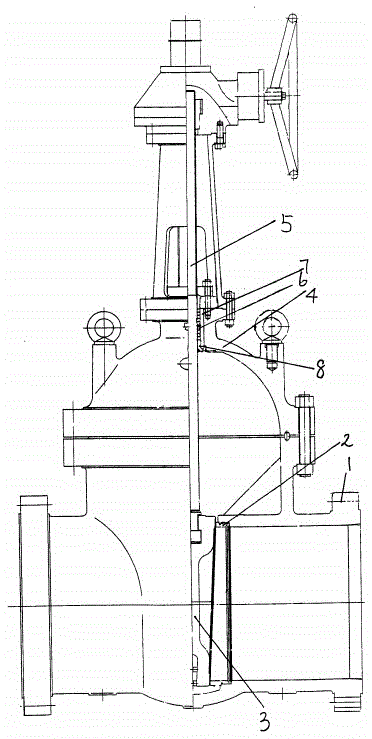

Wedge gate valve

InactiveCN105673874AEasy to replaceImprove sealingSlide valveFiltration separationEngineeringGate valve

The invention discloses a wedge gate valve. The wedge gate valve comprises a valve body, a valve base, a wedge gate plate, a valve cover and a valve rod. The stuffing box part of the valve cover is welded to the valve cover through a lining, and an upper sealing base is connected to the lining through threads. The wedge gate valve is reasonable in structure, and the upper sealing base is convenient to replace and good in sealing performance; furthermore, the wedge gate valve has the filtering function, and a valve element is not damaged easily.

Owner:项敬来

Conductive adhesive matching die-cutting half-and-half transfer processing method

InactiveCN104786285BAchieve repostAchieve restorationMetal working apparatusConductive pasteEngineering

Owner:W B ROYMAX TECH SHENZHEN

Diversion valve

InactiveCN105697814ASimple structureEasy to operateMultiple way valvesValve housingsEngineeringFerrule

The invention discloses a diversion valve which comprises a valve body (3); the valve body (3) is provided with a three-way inner cavity comprising an upper inner cavity, a left inner cavity and a right inner cavity; a turnover plate (1) positioned between the left inner cavity and the right inner cavity and positioned under the upper inner cavity is arranged in the inner cavity, the lower end of the turnover plate (1) is hinged to the bottom wall of the valve body (3) through a turnover plate shaft (2), and a ferrule I (4) and a ferrule II (5) are respectively arranged on the two sides of the upper end of the turnover plate (1); a hole I (7) and a hole II (8) for allowing a glass rope to thread through are respectively formed in the two sides of the valve body (3); the ferrule I (4) is connected with the glass rope in the hole I (7); the ferrule II (5) is connected with the glass rope in the hole II (8); the upper inner cavity is connected with an inlet; the inlet is connected with a filtering pipe and a connecting port of which the internal diameter is larger than the external diameter of the filtering pipe. The diversion valve disclosed by the invention is simple in structure, convenient to operate and low in cost and has a filtering function, and the valve body is not easy to damage.

Owner:张作玮

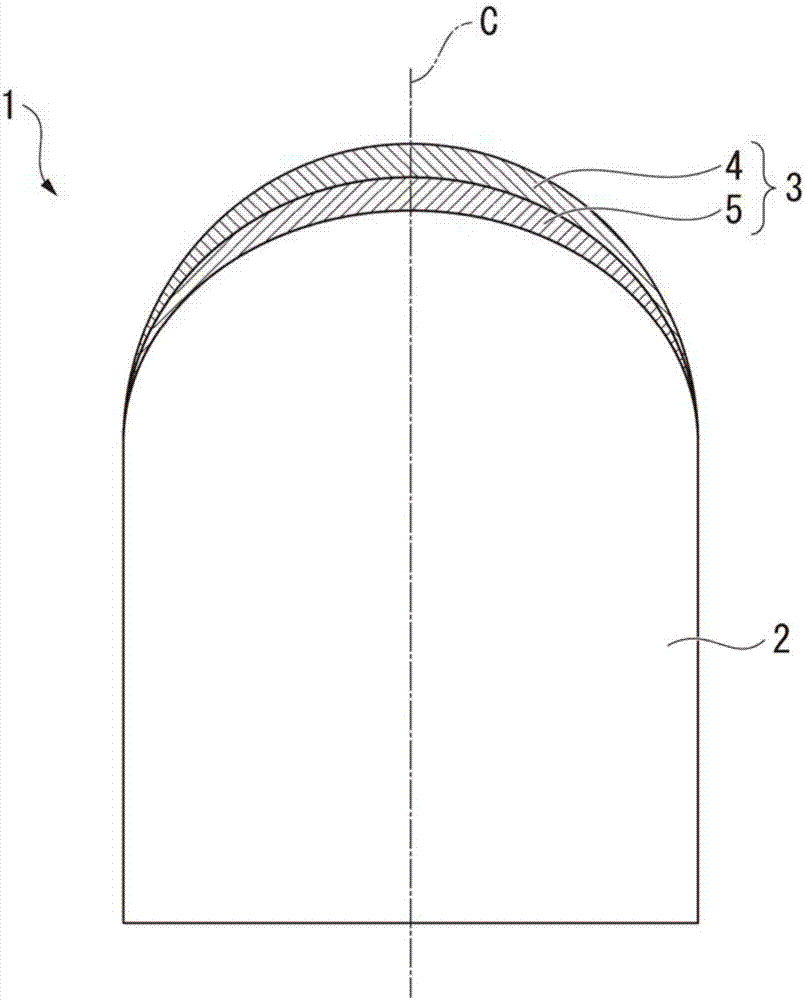

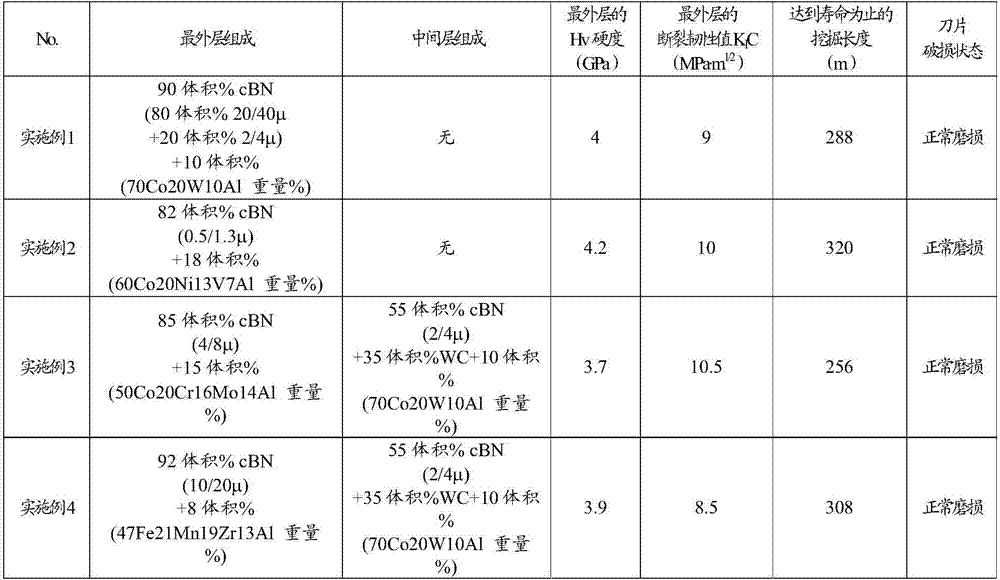

Drill tip and drill bit

A drill tip that is attached to the distal end of a drill bit and that performs drilling, the drill tip having a tip main body (1) provided with a proximal-end part embedded in a bit body of the drill bit and a distal-end part that tapers toward the distal-end side and protrudes from the surface of the drill bit. The surface of at least the distal-end part of the tip main body (1) is formed from a polycrystalline cubic boron nitride sintered compact (4) containing 70 to 95 vol% of cubic boron nitride sintered by a catalyst metal that contains Al and at least one of Co, Ni, Mn, and Fe.

Owner:MITSUBISHI MATERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com