Matching die cutting and half-and-half rotating pasting processing method for conductive adhesive

A processing method and technology of conductive adhesive, applied in metal processing and other directions, can solve the problems of no competitive advantage in product price and no change in material cost, and achieve the effect of preventing chipping, improving utilization rate and ensuring normal production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

[0021] The conductive adhesive pairing die-cutting half-transfer processing method of the present invention comprises the following steps:

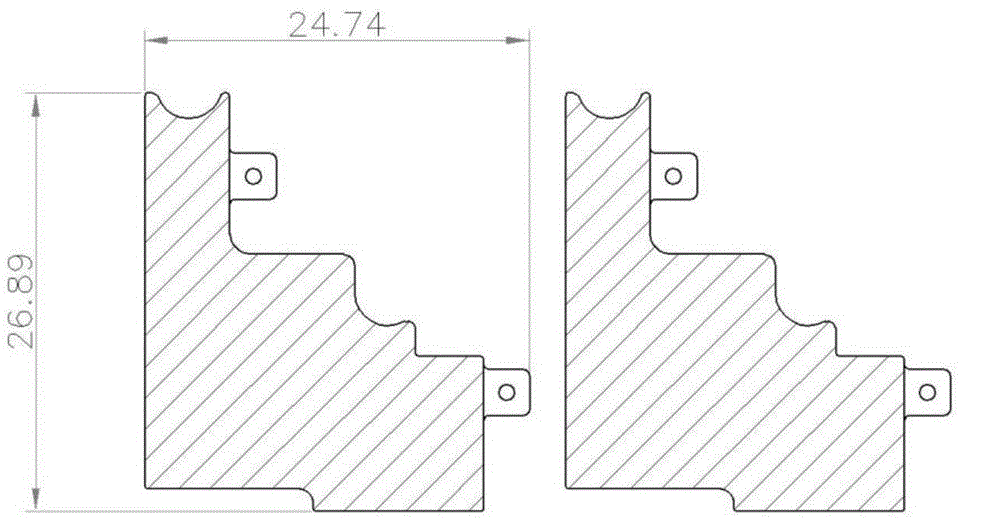

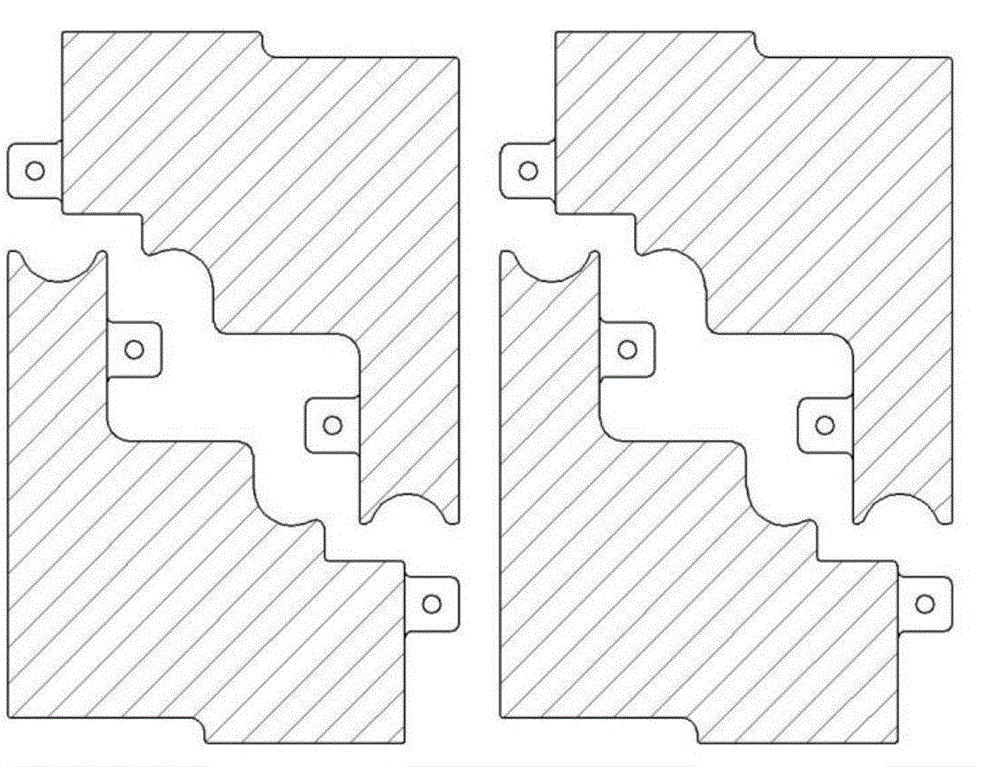

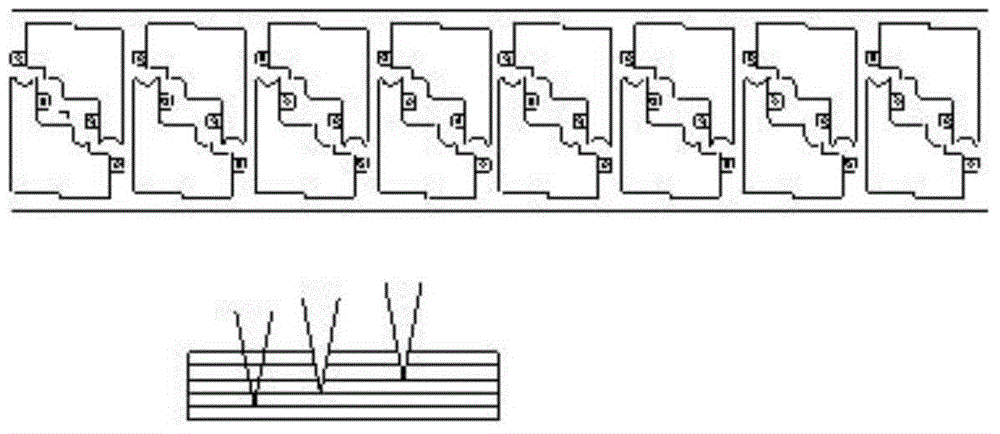

[0022] (1) Typesetting design: In order to improve the utilization rate of conductive adhesive and reduce the cost of materials, firstly, it is necessary to temporarily change the typesetting on the customer's established typesetting, and secondly, determine the cutting width of conductive adhesive. Ideally, the whole raw material of conductive adhesive can be Slitting into small rolls of material without ends. Such as figure 1 , according to customer typesetting, the area of conductive adhesive required for a single PCS product is = (26.89+5)*(24.74+2) = 852.74, such as figure 2 , according to the new typesetting, the area of conductive adhesive required for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com