Butterfly valve for water storage tank

A water storage tank and butterfly valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of reducing the service life of the butterfly valve, easy to damage the valve core, easy to cause cavitation, etc., to stabilize the water flow in the pipe and improve the filtration efficiency. , the effect of reducing cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

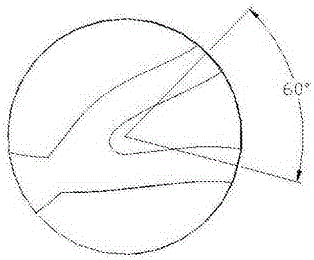

[0030] like figure 1 As shown, the present invention has a valve body 4, an electromagnetic controller 1 is installed on the valve body 4, an electromagnet 2 is built in the electromagnetic controller 1, and a butterfly plate 12 with a permanent magnet 7 is installed in the inner cavity of the valve body 4. Drive the rotation of butterfly plate 12;

[0031] Upper bonnet 14 and lower bonnet 11 are respectively fixed on the upper and lower ends of valve body 4 by bolt 3, as Figure 5-6 As shown, the permanent magnet 7 is fixed in the middle of one end face of the butterfly plate 12, and the upper and lower parts of the end face of the butterfly plate 12 where the permanent magnet 7 is located are respectively fixed with a coaxial upper bushing 6 and a lower bushing 8, so that the butterfly plate 12 and the upper The valve stem 5 and the lower valve stem 9 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com