Curved surface formed tool

A technology of curved surface forming and tool handle, which is applied to the accessories of tool holders, tools for lathes, turning equipment, etc., can solve the problems of low precision, complicated procedures, low efficiency, etc., and improve processing efficiency and lubrication effect Good, the effect of improving the precision of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

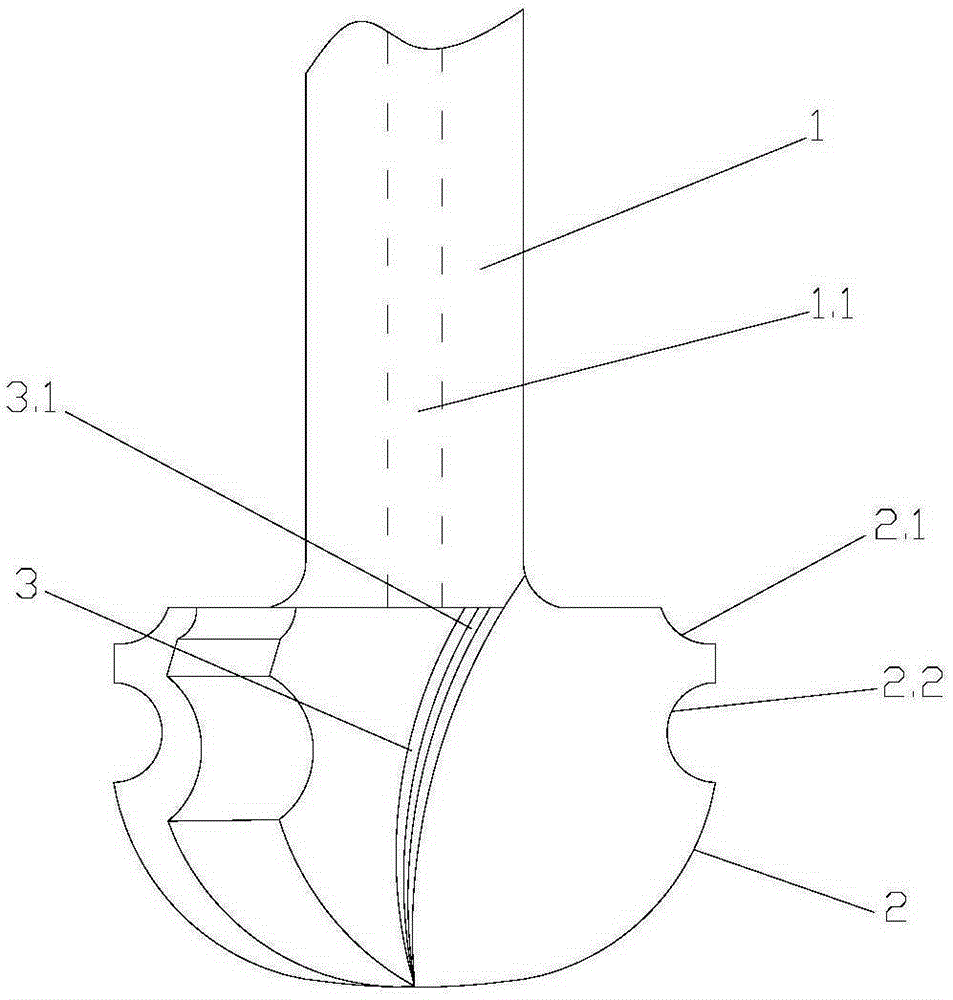

[0015] Embodiment 1: as figure 1 The curved surface forming knife shown includes a handle 1 and a cutting portion at the front end of the handle 1. The cutting portion is spherical, and the transition between the handle 1 and the cutting portion is in an arc structure to ensure the connection strength. The cutting portion is equipped with multiple Three evenly distributed helical cutting edges 2, between adjacent cutting edges 2 are spiral chip relief grooves, the three cutting edges 2 gather at the front end of the cutting part to form a tool tip, so that the tool can perform axial cutting, cutting edge 2 The thickness of the corresponding blade body increases from front to rear, and the blade body corresponding to the cutting edge 2 is a bevel that matches the helical direction of the chip edge 2, which facilitates the cutting process of the cutting edge 2, and the bevel promotes the cutting edge 2 to have a certain toughness , good strength, to avoid chipping, the cutting e...

Embodiment 2

[0016] Embodiment 2: refer to figure 1 The curved surface forming knife shown includes a handle 1 and a cutting portion at the front end of the handle 1. The cutting portion is spherical, and the transition between the handle 1 and the cutting portion is in an arc structure to ensure the connection strength. The cutting portion is equipped with multiple Four evenly distributed helical cutting edges 2, between adjacent cutting edges 2 are spiral chip relief grooves, the four cutting edges 2 gather at the front end of the cutting part to form a tool tip, so that the tool can perform axial cutting, cutting edge 2 The thickness of the corresponding blade body increases from front to rear, and the blade body corresponding to the cutting edge 2 is a bevel that matches the helical direction of the chip edge 2, which facilitates the cutting process of the cutting edge 2, and the bevel promotes the cutting edge 2 to have a certain toughness , good strength, to avoid chipping, the cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com