Tool for whirlwind milling of square shaft

A whirling milling and cutting tool technology, which is applied in the direction of milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problems of increasing the instability of processing dimensions, poor rigidity of the process system, and the inability to use the follower tool holder, etc., so as to improve the processing accuracy and Surface quality, extended tool life, avoiding back-off effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

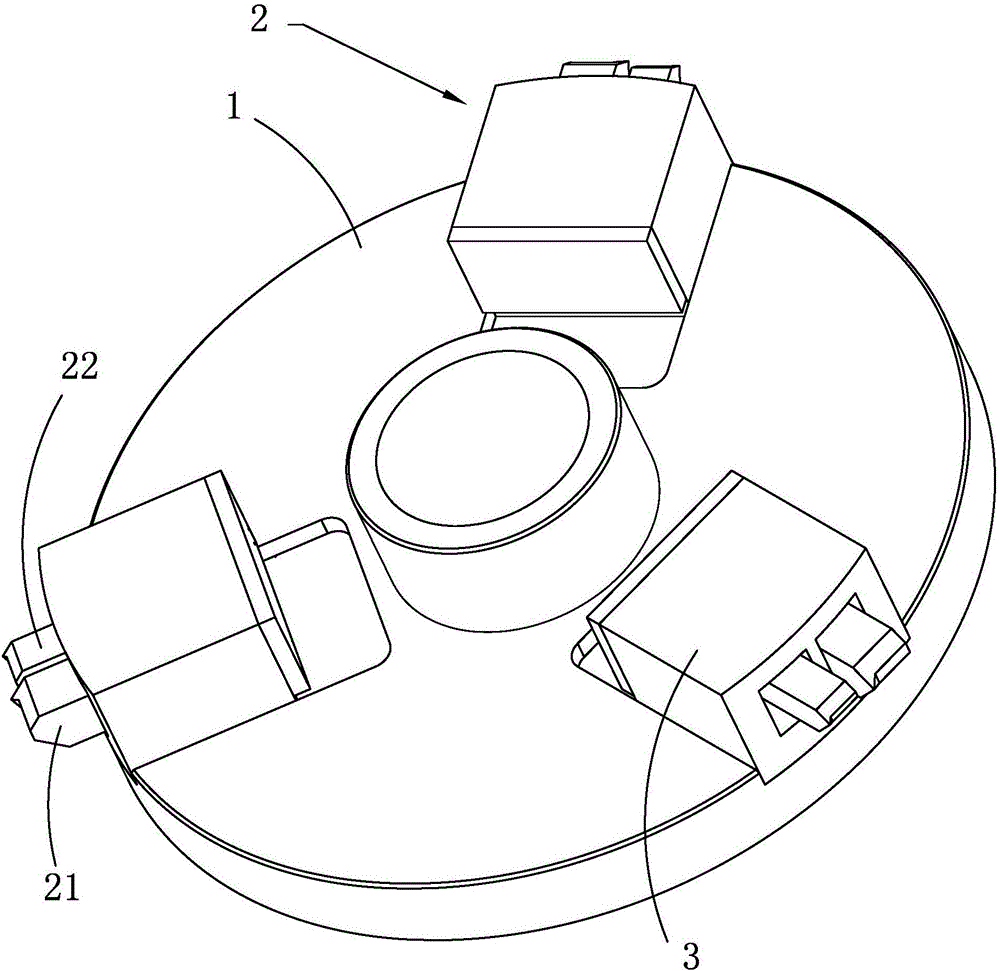

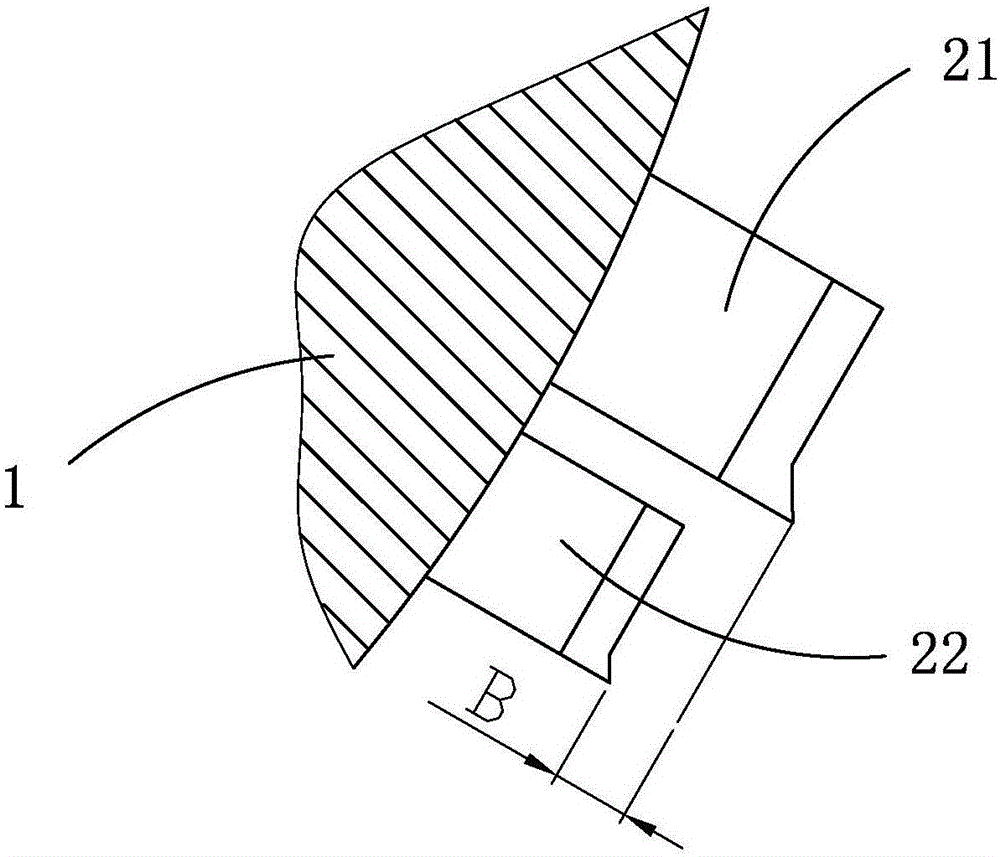

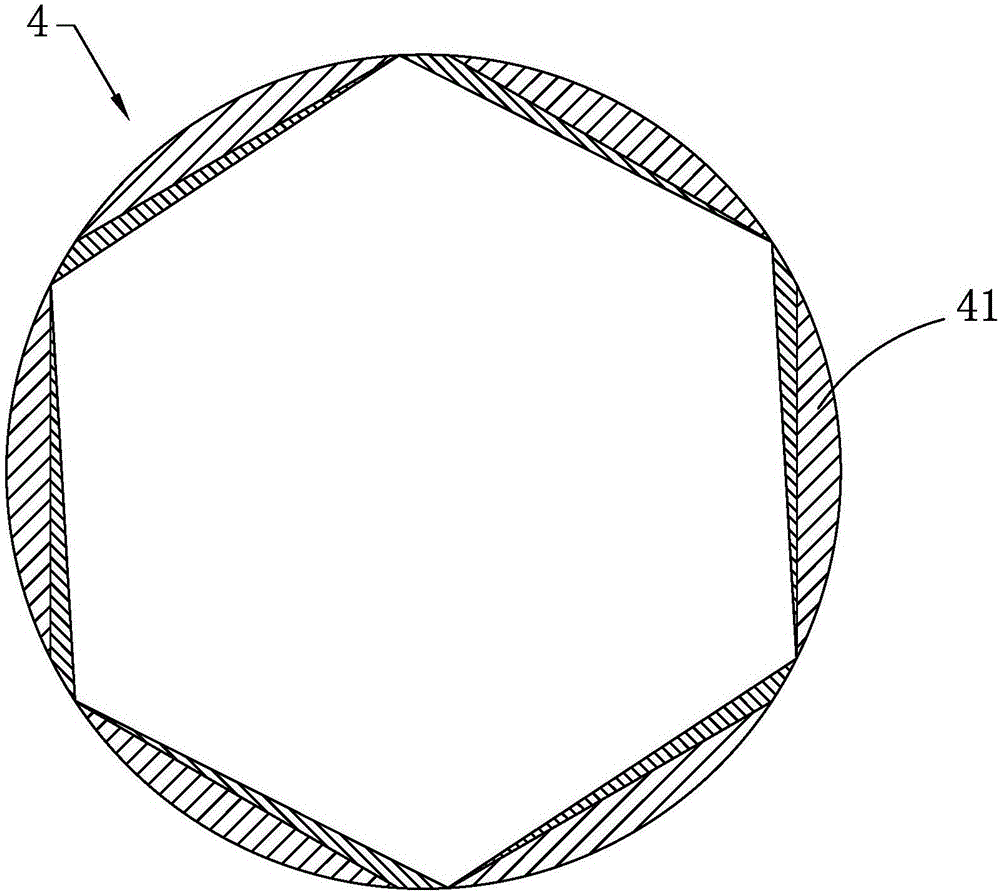

[0030] Example: A tool for whirling a square shaft, such as figure 1 As shown, it includes a disk body 1, which is arranged on the disk body, and a pair of cutting knives 2 are respectively installed at the positions of equal parts of the circumference. The cutting knives are radially distributed with the center of the disk body as the center. The part is located outside the disc body. Each pair of said cutting blades has two cutter bodies arranged side by side, which are respectively a roughing blade 21 and a finishing blade 22. edge distance.

[0031] The cutting knife pair on each part of the disc body has two cutting knives, one for rough machining and one for finish machining. There is no need for repositioning, avoiding errors caused by repositioning and affecting machining errors. At the same time, the tool holder can always be used, which not only improves the machining accuracy, but also improves the machining efficiency. Since each processing surface has been pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com