Replaceable tool edge rotary cutting tool and insert

A technology for indexing inserts and cutting tools, applied in the direction of manufacturing tools, milling cutting inserts, milling cutters, etc., can solve the problems of pulling the cutting edge, high frequency chatter, easy to produce chipping, etc., to improve the strength of the cutting edge and prevent chipping. Knives, effects that suppress high-frequency chattering or bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

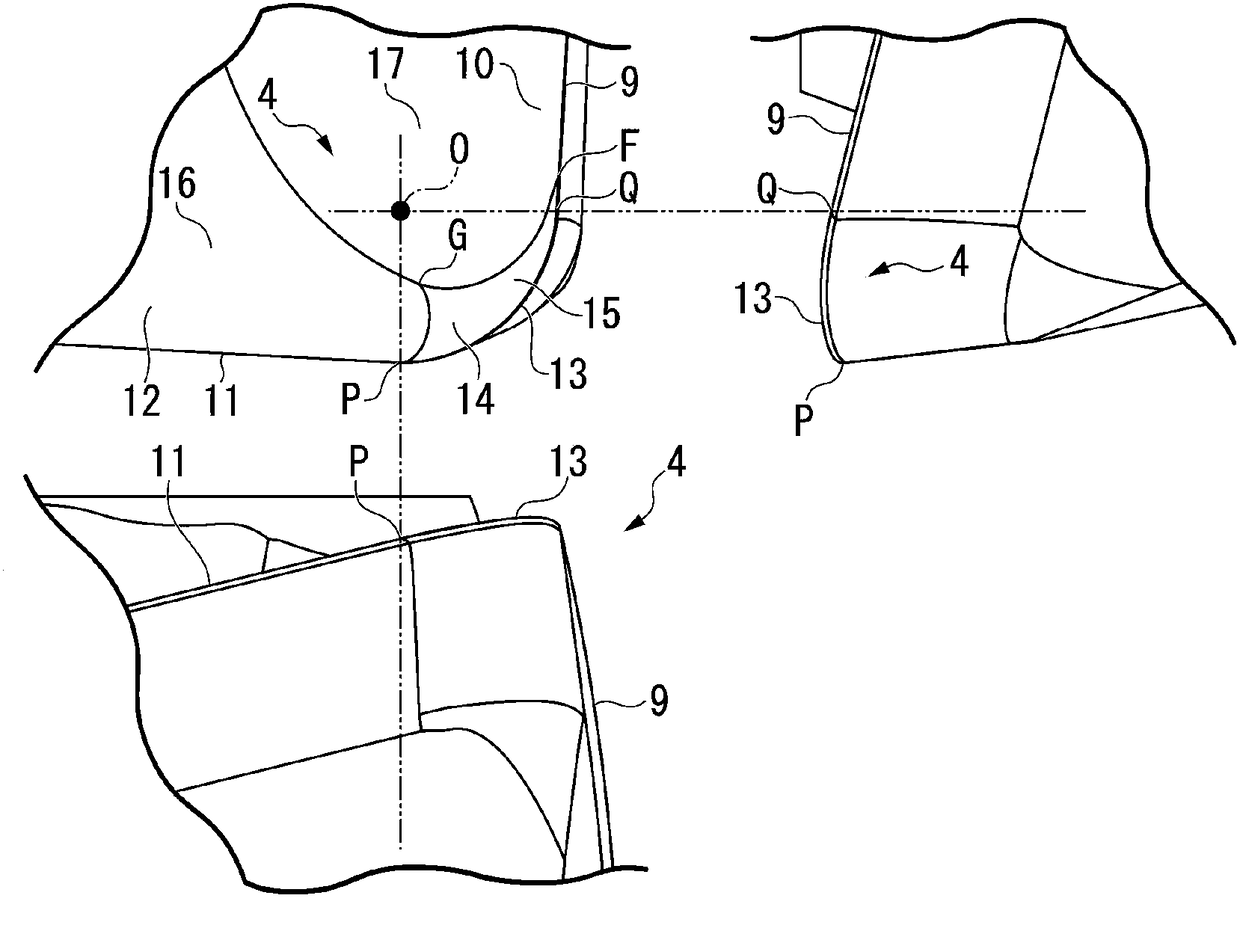

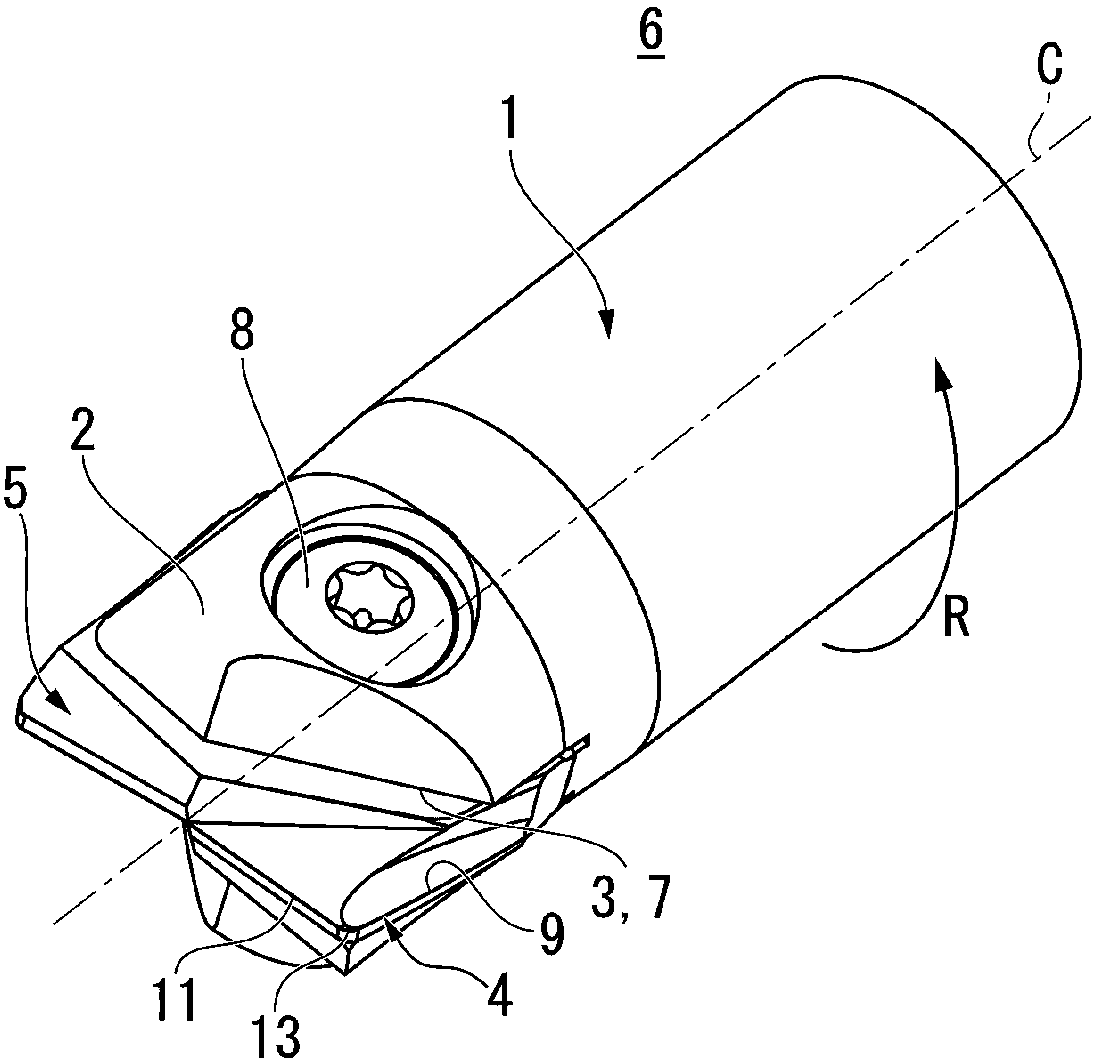

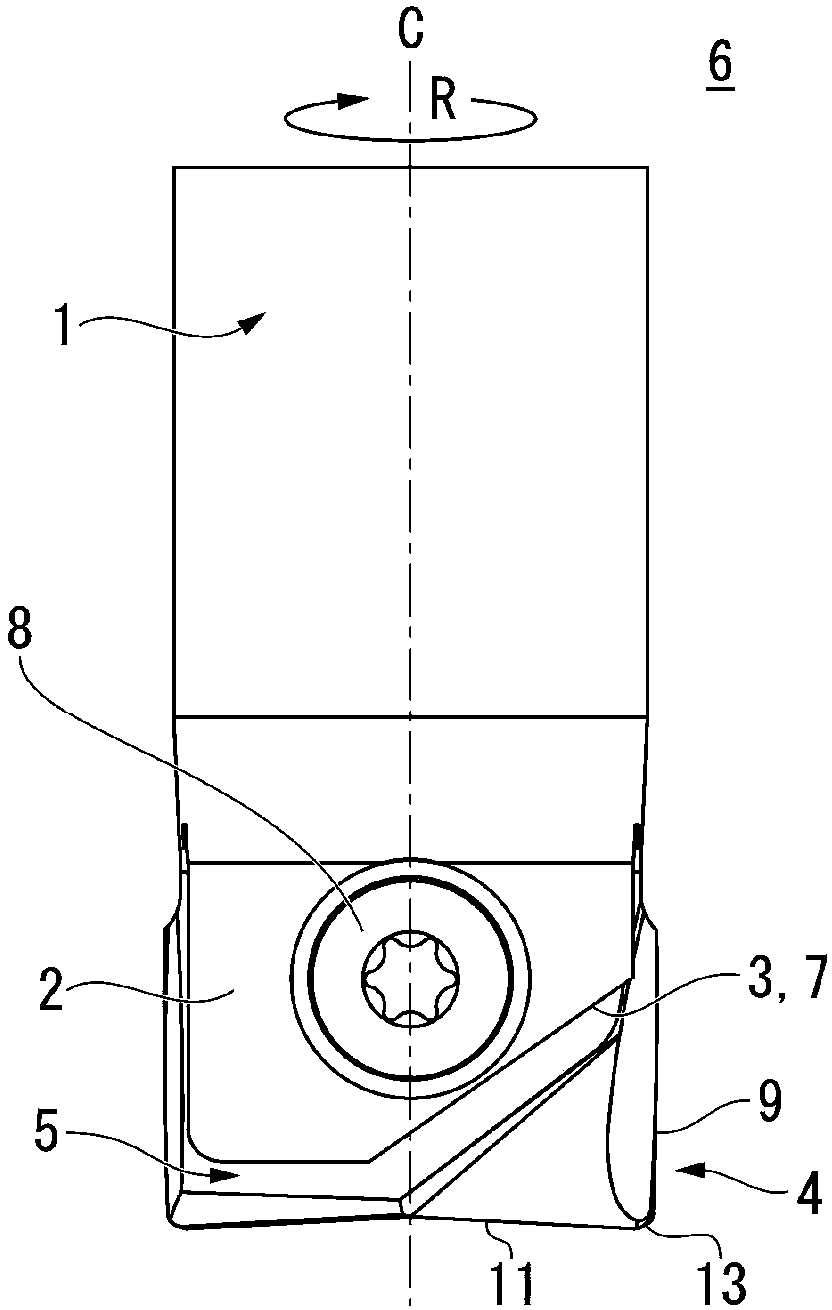

[0088] Next, an indexable insert type rotary cutting tool according to an embodiment of the present invention will be described with reference to the drawings. The indexable insert type rotary cutting tool in this embodiment is an indexable insert type arcuate end mill 6 . The indexable insert type arc head end mill 6 is especially suitable for front cutting (plane machining) and side rough machining of workpieces under the cutting conditions of long tool overhang (L / D is 4 or more). . In addition, the above-mentioned L value is the length in the direction of the rotation center axis C of the tool, and the above-mentioned D value is the diameter of the rotation track of the cutting edge of the tool.

[0089] [General structure of indexable insert type arc head end mill]

[0090] Such as Figure 1 to Figure 4 As shown, the indexable-insert-type arc-end end mill 6 includes: a tool body 1 having a substantially cylindrical shape; On the mounting seat 3, and the insert 5 has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com