Processing method of shock tunnel high Mach number throat channel inner profile

A technology of high Mach number and shock wave wind tunnel, which is applied in the field of surface processing in the high Mach number throat of shock wave wind tunnel, which can solve the problems of high price, tool clearance, difficulty in guaranteeing machining accuracy and roughness, and reduce damage , Improving the machining accuracy and improving the quality of the flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

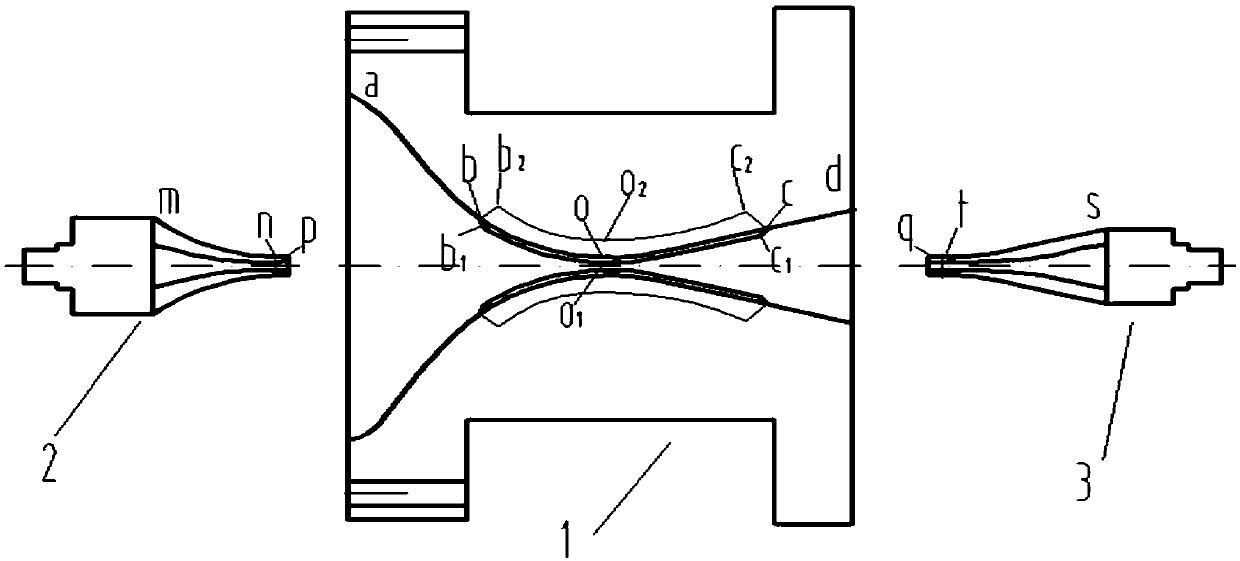

[0030] Such as figure 1 The inner profile of the throat section shown includes a contracted section ao, a throat o, and an expanded section od. Among them, the diameter of the profile is larger (for example, the diameter is greater than 50mm), and the easy-to-process parts are ab and cd, and the parts that are difficult to process For the bo and oc segments.

[0031] Set the first front section forming reamer, and the profile line mn of the blade is consistent with the profile line of the throat b2o2;

[0032] Set the first back section forming reamer, the profile line ts of the blade is consistent with the profile line of the throat o2c2 section;

[0033] A method for processing the inner profile of a high Mach number throat in a shock wave wind tunnel, the steps are as follows:

[0034] Step 1: Use a drilling machine to drill the inner hole, the diameter of which is smaller than the diameter of the throat hole, as the bottom hole for turning;

[0035] Step 2: The lathe uses a rough ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com