Fe-based alloy powder for hot-extrusion die laser cladding and application of Fe-based alloy powder

A technology of hot extrusion die and laser cladding, which is applied in the coating process and coating of metal materials, can solve the problems of differences in thermal expansion coefficient and elastic modulus, formation of holes and cracks, etc., achieve uniform hardness and prolong service life , combined with good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

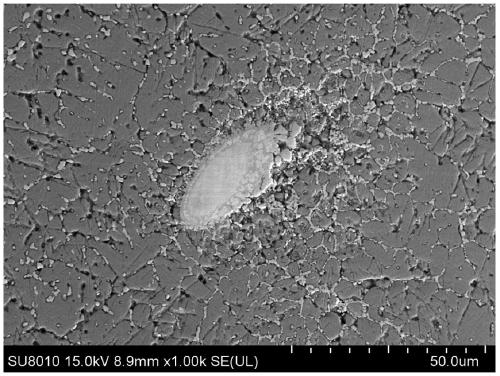

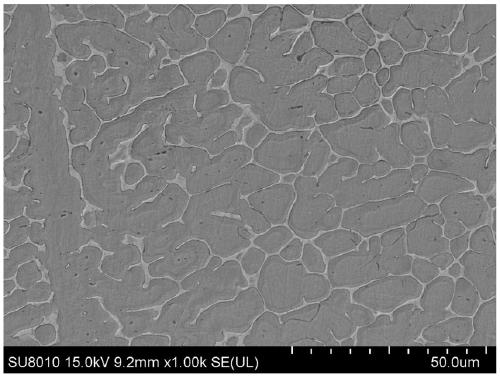

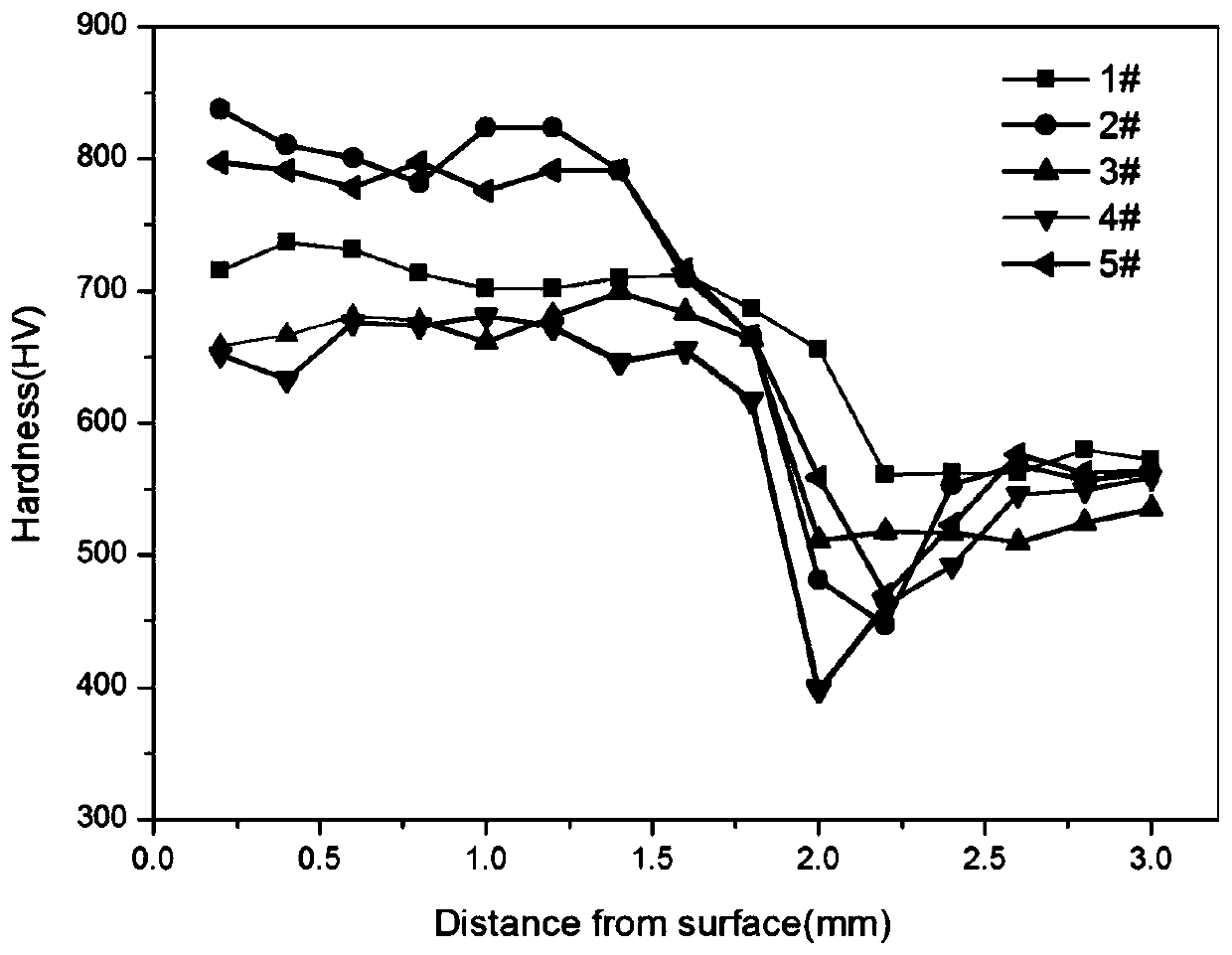

Image

Examples

Embodiment 1

[0032] In this embodiment, an Fe-based alloy powder used for laser cladding of hot extrusion dies includes the following components by mass percentage: C: 0.3%, Si: 0.8%, Mn: 0.2%, Cr: 4% , Mo: 1%, V: 0.8%, WC: 5%; Y 2 o 3 : 0.5%, Fe: 87.4%.

[0033] An application of Fe-based alloy powder for laser cladding of a hot extrusion die, specifically comprising the following steps:

[0034] (1) Pretreatment of the substrate: polish and clean the substrate, and use a hand grinding wheel to grind the substrate until the surface is smooth, no coarse scratches, and the direction of the scratches is consistent, and then use alcohol to clean to remove surface oil and dirt. Oxidized layer, dried for later use.

[0035] (2) Put the weighed powder into a mechanical powder mixer, and mix it fully to obtain cladding powder. The parameter of mechanical powder mixing is 20r / min, mix for 14 hours, and put it in a vacuum drying oven to dry after mixing. 8h, set the temperature at 80°C.

[003...

Embodiment 2

[0038] In this embodiment, an Fe-based alloy powder used for laser cladding of hot extrusion dies includes the following components by mass percentage: C: 0.5%, Si: 1.0%, Mn: 0.4%, Cr: 6% , Mo: 1.5%, V: 1.1%, WC: 20%; Y 2 o 3 : 2%, Fe: 67.5%.

[0039] An application of Fe-based alloy powder for laser cladding of a hot extrusion die, specifically comprising the following steps:

[0040] (1) Pretreatment of the substrate: polish and clean the substrate, and use a hand grinding wheel to grind the substrate until the surface is smooth, no coarse scratches, and the direction of the scratches is consistent, and then use alcohol to clean to remove surface oil and dirt. Oxidized layer, dried for later use.

[0041] (2) Put the weighed powder into a mechanical powder mixer and mix it fully to obtain a cladding powder. The parameter of the mechanical powder mix is 40r / min, mix for 8 hours, and put it in a vacuum drying oven to dry after mixing. 6h, set the temperature at 120°C.

...

Embodiment 3

[0044] In this embodiment, an Fe-based alloy powder used for laser cladding of hot extrusion dies includes the following components by mass percentage: C: 0.42%, Si: 0.86%, Mn: 0.35%, Cr: 4.5% , Mo: 1.3%, V: 1%, WC: 15%; Y 2 o 3 : 1.5%, Fe: 74.51%.

[0045] An application of Fe-based alloy powder for laser cladding of a hot extrusion die, specifically comprising the following steps:

[0046] (1) Pretreatment of the substrate: polish and clean the substrate, and use a hand grinding wheel to grind the substrate until the surface is smooth, no coarse scratches, and the direction of the scratches is consistent, and then use alcohol to clean to remove surface oil and dirt. Oxidized layer, dried for later use.

[0047] (2) Put the weighed powder into a mechanical powder mixer, and mix it fully to obtain cladding powder. The parameter of mechanical powder mixing is 35r / min, mix for 14 hours, and put it in a vacuum drying oven to dry after mixing. 10h, set the temperature at 120°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com