Five-axis corner characteristic efficient machining tool path generation method

A corner and tool path technology, used in instruments, digital control, control/regulation systems, etc., can solve problems such as large changes in cutting allowance, complex programming, and chattering of machining systems, optimize cutting conditions, and reduce tool wear. , to avoid the effect of the knife letting the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0060] Material species of processing workpieces: aluminum alloy;

[0061] Machine tool performance: five coordinate high-speed gantry machine, spindle maximum speed 24000R / min, use speed 9000R / min;

[0062] Tool cutting performance: 2 teeth 2, diameter is 10mm;

[0063] Maximum equivalent cut: 3mm;

example 2

[0065] Material species of processing workpieces: aluminum alloy;

[0066] Machine tool performance: five coordinate high-speed gantry machine, spindle maximum speed 24000R / min, use speed 20000R / min;

[0067] Tool cutting performance: The number of teeth is 2, a diameter is 16mm;

[0068] Maximum equivalent cut: 5mm;

example 3

[0070] Material Type of Processing Workpapers: Titanium Alloy;

[0071] Machine tool performance: five coordinate high-speed gantry machine, spindle maximum speed 6000R / min, use 2400R / min;

[0072] Tool cutting performance: number of teeth is 4, diameter is 10mm;

[0073] Maximum equivalent cut: 1mm.

[0074] This embodiment is implemented using the data of the above example 1.

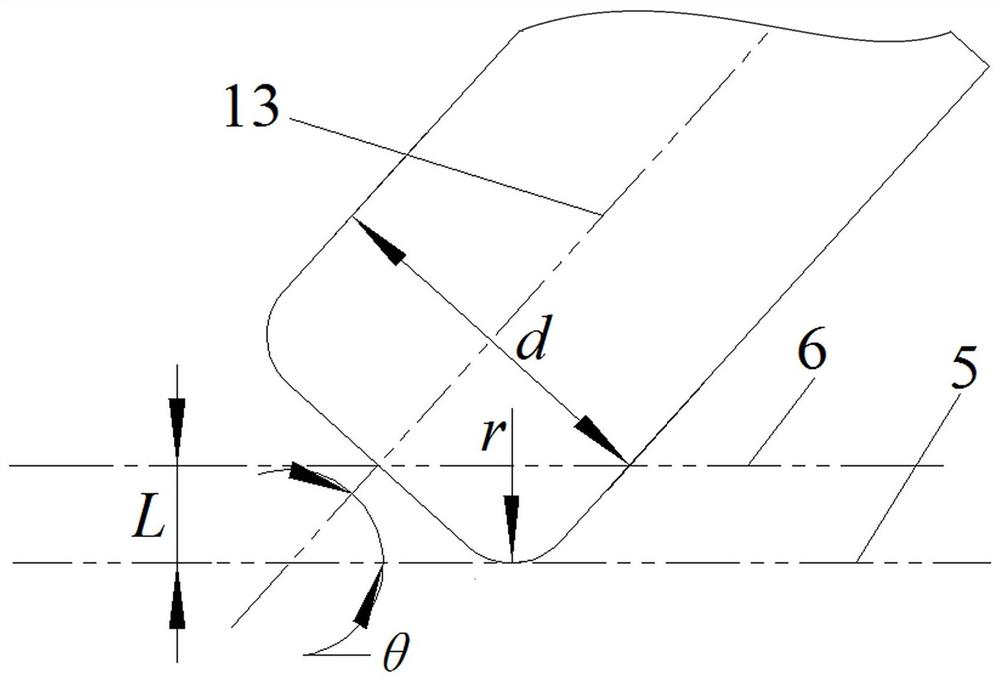

[0075] S4, set the tool diameter and bottom angle radius, calculate the deviation value of each layer of the five-axis corner to each layer of the five-axis angle, and create an equivalent bottom surface 6; specifically, such as figure 2 As shown, the offset value between the equivalent bottom surface 6 and the cut bottom surface 5 of each layer , In which the tool diameter D = 10mm, the bottom angle radius r = 3mm, the angle of the cutter shaft 13 and the cut bottom surface 5 θ = 75.22 °, calculate L = 0.427mm.

[0076] S5, intersecting point 8 with the equivalent bottom surface 6 of the corner surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com