Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Accurate data measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Amplitude limiting device and method

InactiveCN102627231AHigh precisionImprove reliabilitySafety devices for lifting equipmentsCranesEngineeringControl theory

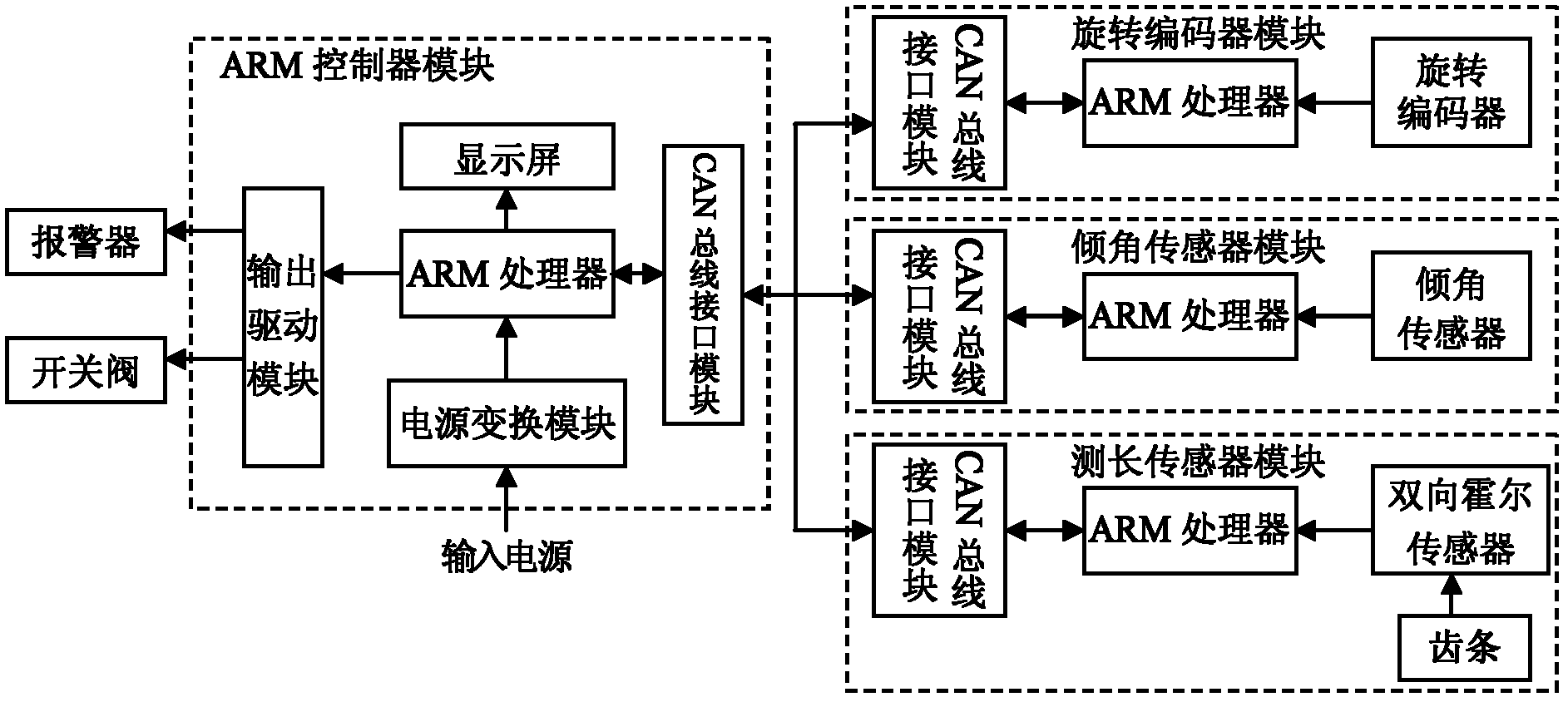

The invention discloses an amplitude limiting device and an amplitude limiting method. The amplitude limiting device is used for calculating and limiting the operating amplitude of a telescopic arm of a telescopic arm frame type construction machinery vehicle, and comprises an ARM (Advanced RISC Machine) controller module, a tilting angle sensor module, a length measurement sensor module and a rotary coder module, which are connected through a CAN (Controller Area Network) bus. The amplitude limiting method comprises the following steps: obtaining the pitching angle of the telescopic arm, the rotary position angle of the telescopic arm and the arm length of the telescopic arm; according to the structural form, the pitching angle and the arm length of the telescopic arm, calculating the operating amplitude of the telescopic arm; according to the rotary position angle, looking up a corresponding amplitude limiting critical value in a pre-stored amplitude limiting critical value corresponding table; and according to the comparison result of the operating amplitude and the amplitude limiting critical value, limiting or warning the operating amplitude of the telescopic arm to guarantee the working safety of the construction machinery vehicle and avoid the roll-over accident.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

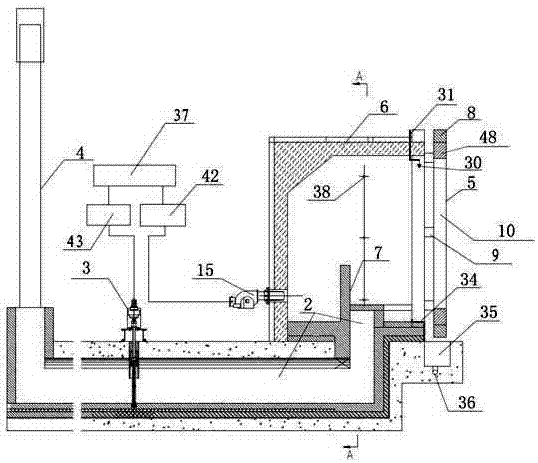

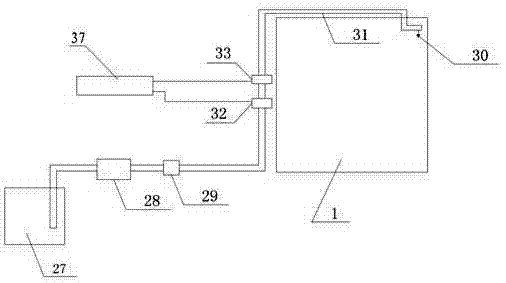

Oil reservoir water injection self-adaptive deep global regulation device and construction method

ActiveCN104727792ASimple structureReasonable designCleaning apparatusFluid removalInjection equipmentDissolution

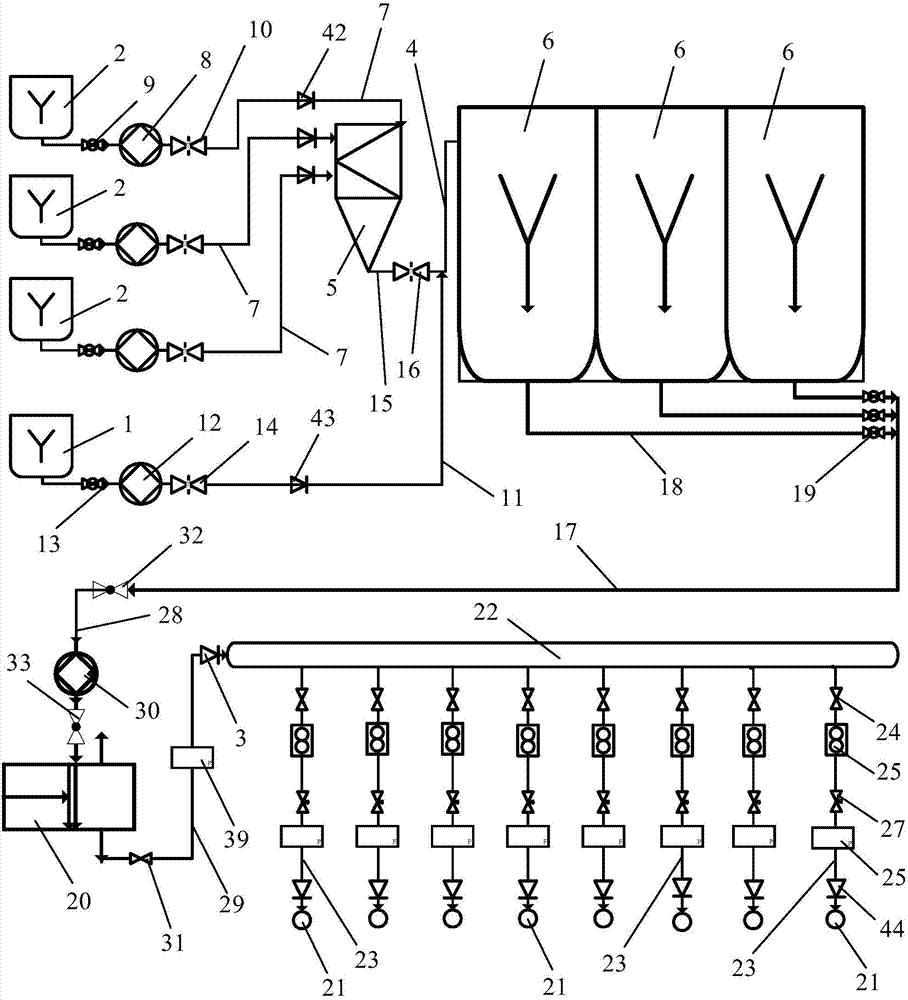

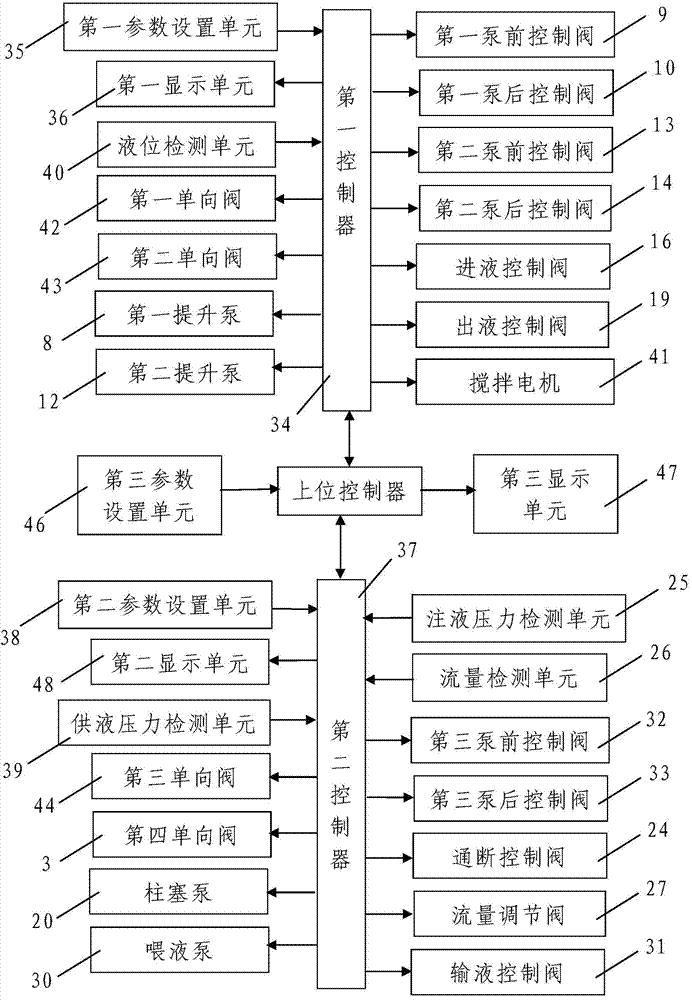

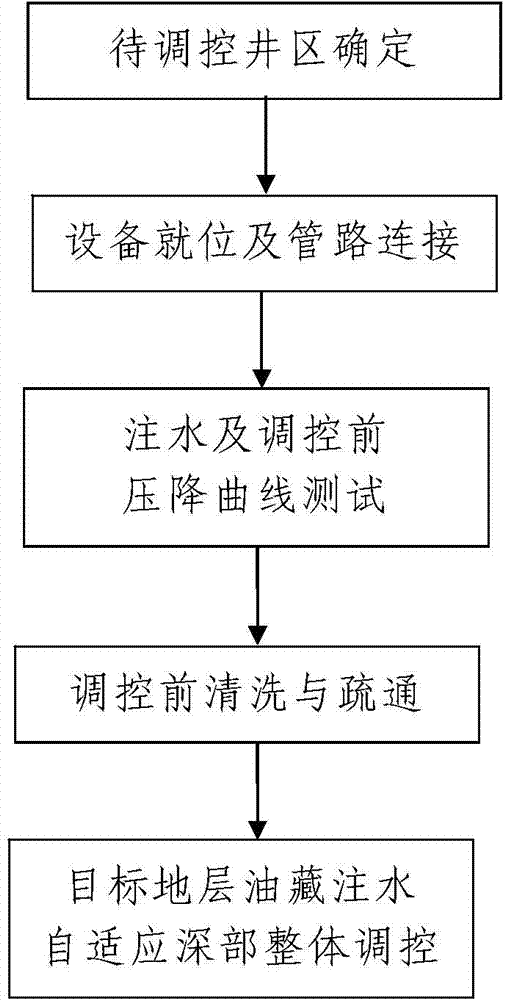

The invention discloses an oil reservoir water injection self-adaptive deep global regulation device and a construction method. The regulation device comprises agent dissolution and storage equipment and agent injection equipment which is connected with the agent dissolution and storage equipment through a connection pipeline. The agent dissolution and storage equipment comprises a cleaning and unchoking agent dissolution tank, a plurality of regulation agent dissolution tanks, an agent liquid mixer, an agent storage tank and a main liquid intake pipe. The agent injection equipment comprises a main liquid delivery pipe, a plunger pump installed on the main liquid delivery pipe, a liquid distributor connected with a liquid outlet of the main liquid delivery pipe, and a plurality of liquid injection pipes. The construction method includes the following steps that firstly, a well area to be regulated is determined; secondly, the equipment is placed in position and connected through the pipeline; thirdly, water is injected, and a pressure drop curve is tested before regulation; fourthly, cleaning and unchoking are conducted before regulation; fifthly, oil reservoir water injection self-adaptive deep global regulation is conducted on a target stratum. The oil reservoir water injection self-adaptive deep global regulation device is reasonable in design, convenient to install and lay, easy and convenient to operate, good in use effect and capable of effectively improving water displacing oil work efficiency and crude oil recovery efficiency.

Owner:西安始创能源科技有限公司 +1

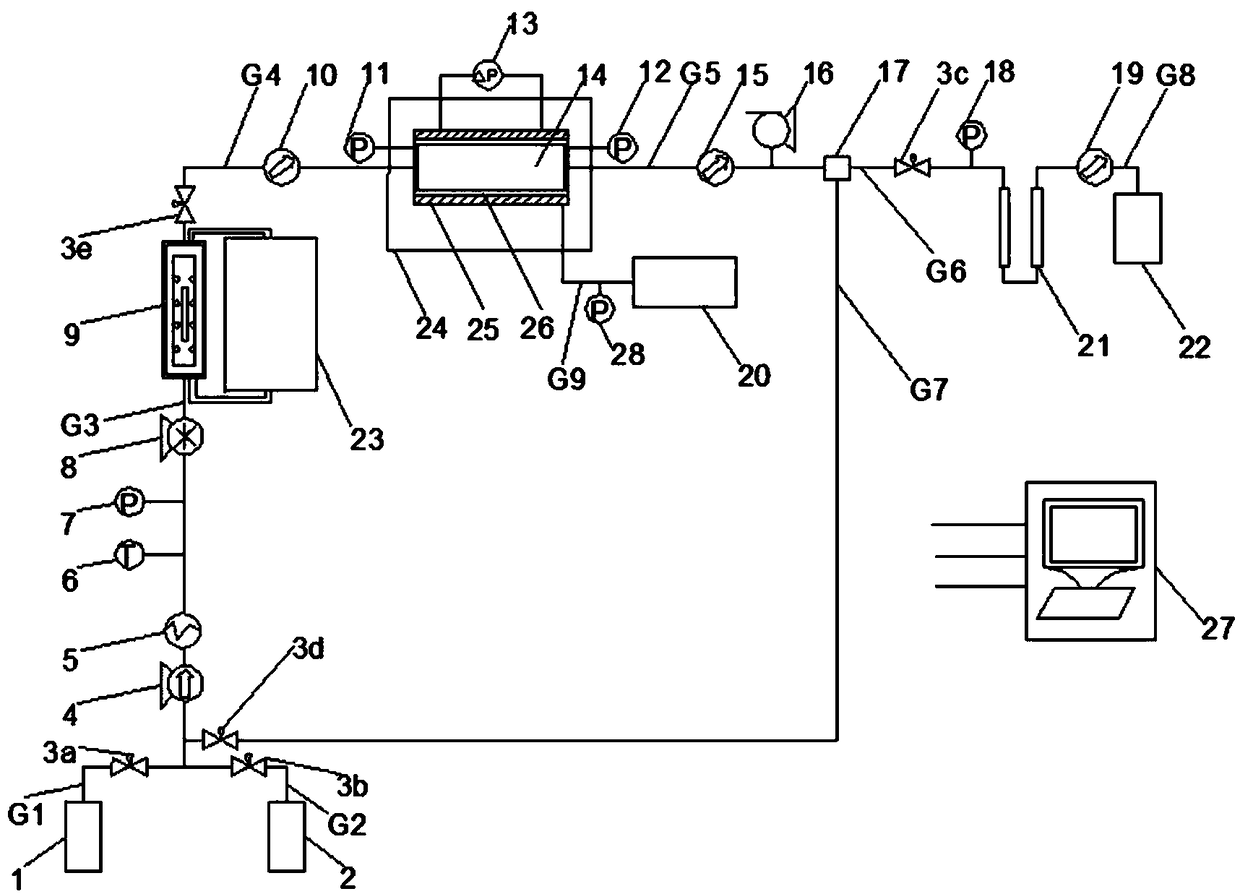

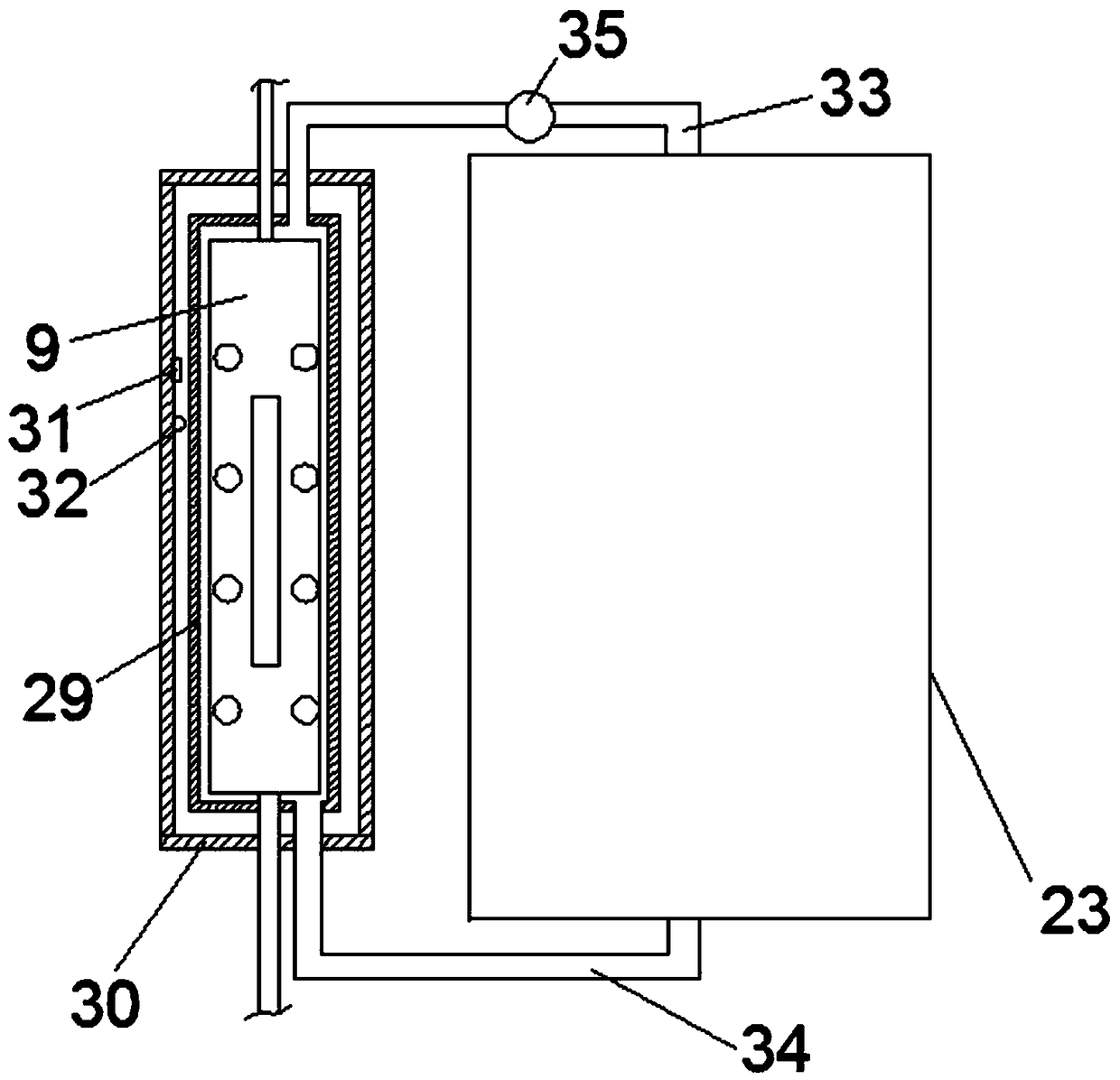

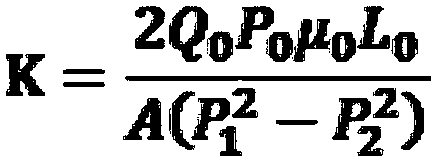

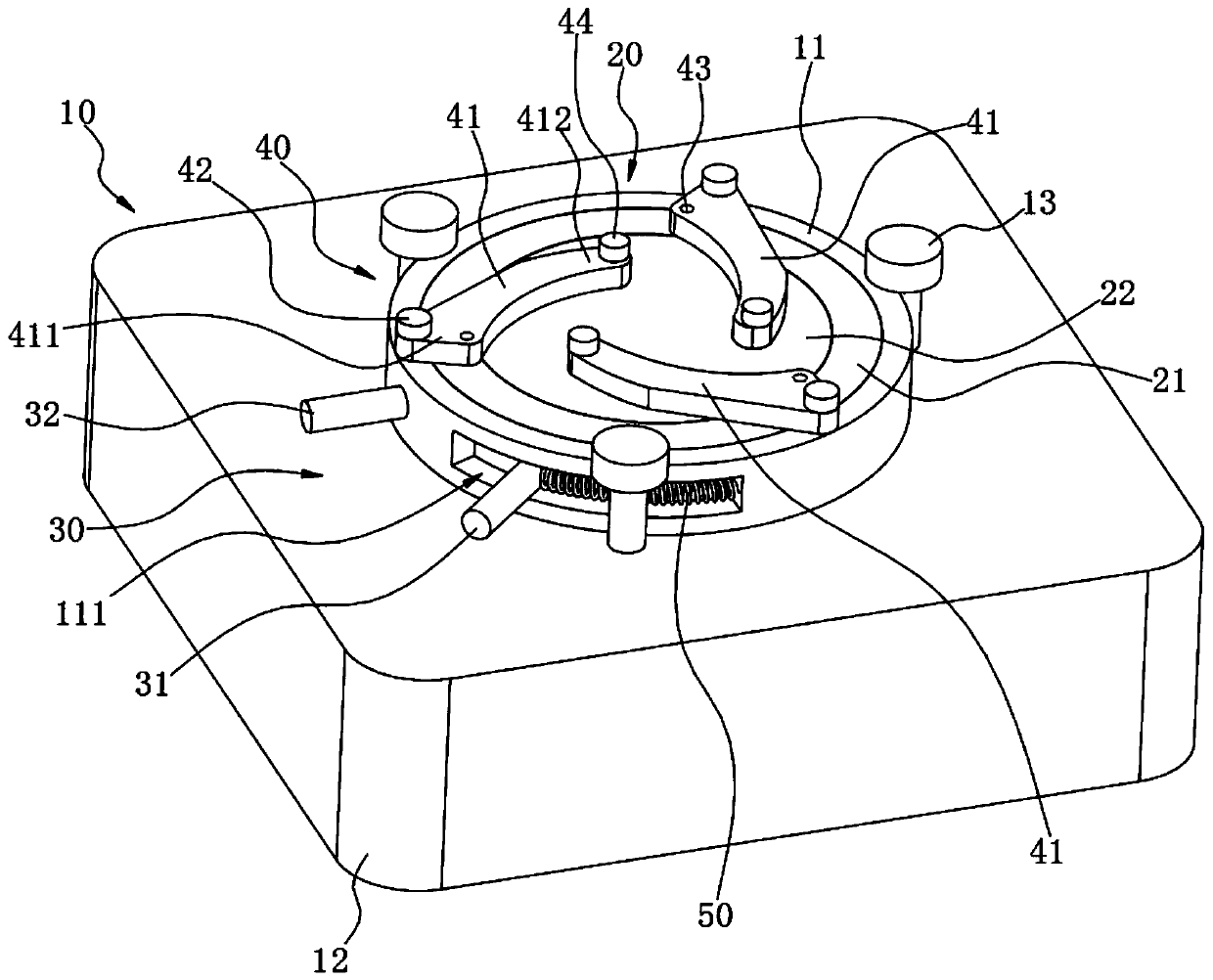

Supercritical carbon dioxide high-temperature and high-pressure PVT testing and methane displacement integrated experimental device and method

PendingCN109269962AHigh simulationEasy to observeSpecific gravity by measuring pressure differencesSpecific gravity using flow propertiesPressure differenceHigh pressure

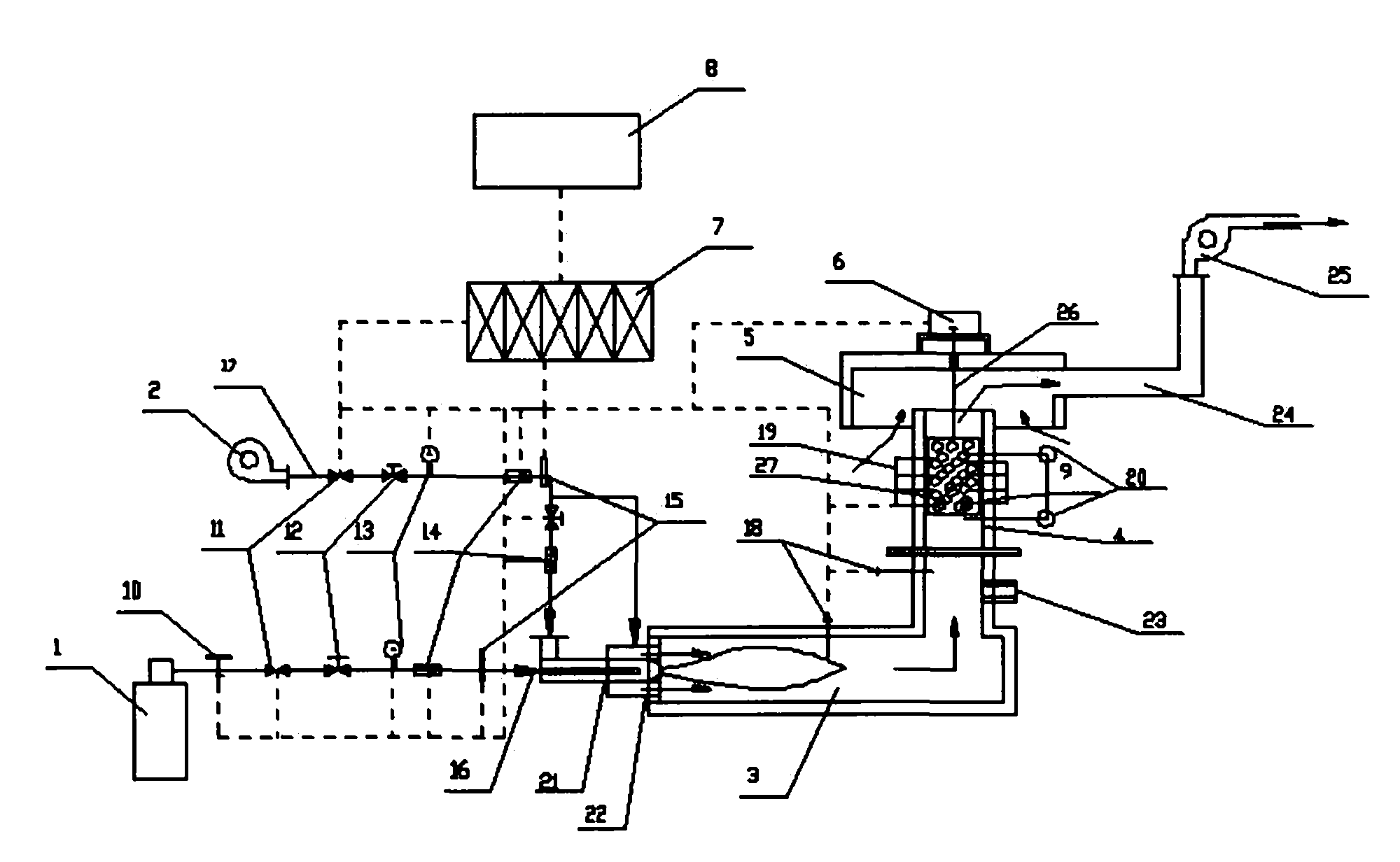

The invention relates to a supercritical carbon dioxide high-temperature and high-pressure PVT testing and methane displacement integrated experimental device and method. The device comprises a liquidcarbon dioxide storage tank, a liquid methane storage tank, a displacement pump, a core holding unit, a constant-temperature oil bath system, a PVT barrel, a ring pressure generation device, a pressure difference sensor, a flow sensor, a pressure sensor, a temperature sensor, a sodium hydroxide absorption storage tank and a gas storage tank, wherein the liquid carbon dioxide storage tank and theliquid methane storage tank are separately connected to an inlet of the PVT barrel via a first pipeline, a second pipeline and a third pipeline; an outlet of the PVT barrel is connected with an inletof the core holding unit through a fourth pipeline; a manifold tee is separately connected with the outlet of the core holding unit, the inlet of the sodium hydroxide storage tank and the third pipeline through a fifth pipeline, a sixth pipeline and a seventh pipeline; and the outlet of the sodium hydroxide storage tank is connected with the gas storage tank through an eighth pipeline. By the supercritical carbon dioxide high-temperature and high-pressure PVT testing and methane displacement integrated experimental device and method, the changing law of the phase state, viscosity and displacement efficiency of supercritical carbon dioxide at a high temperature and under high pressure along with the temperature and pressure can be researched.

Owner:ZHENGZHOU UNIV

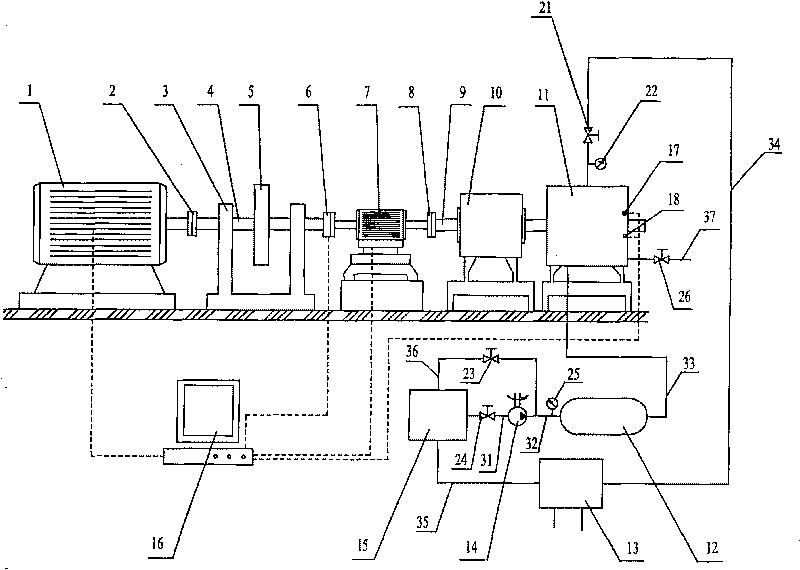

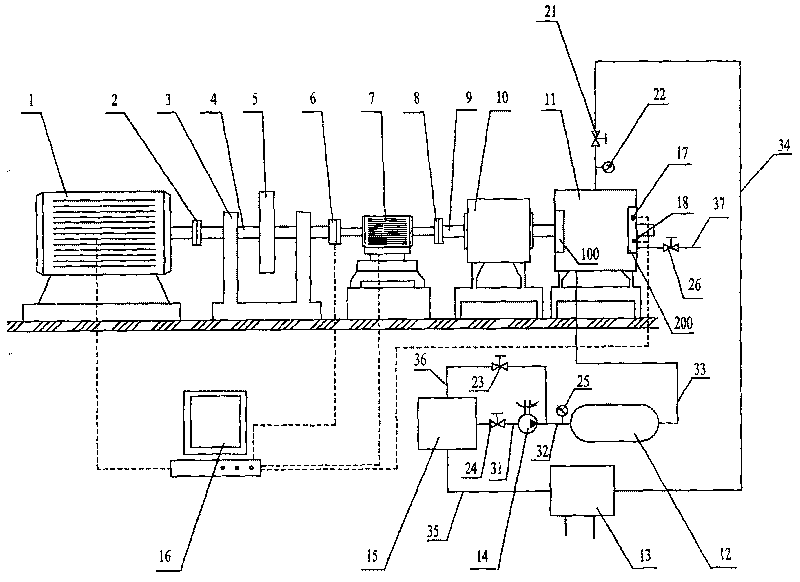

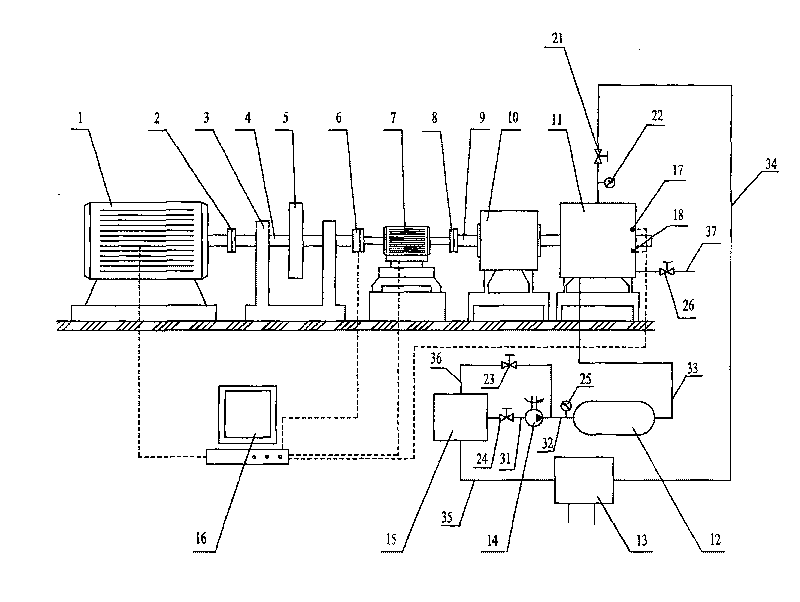

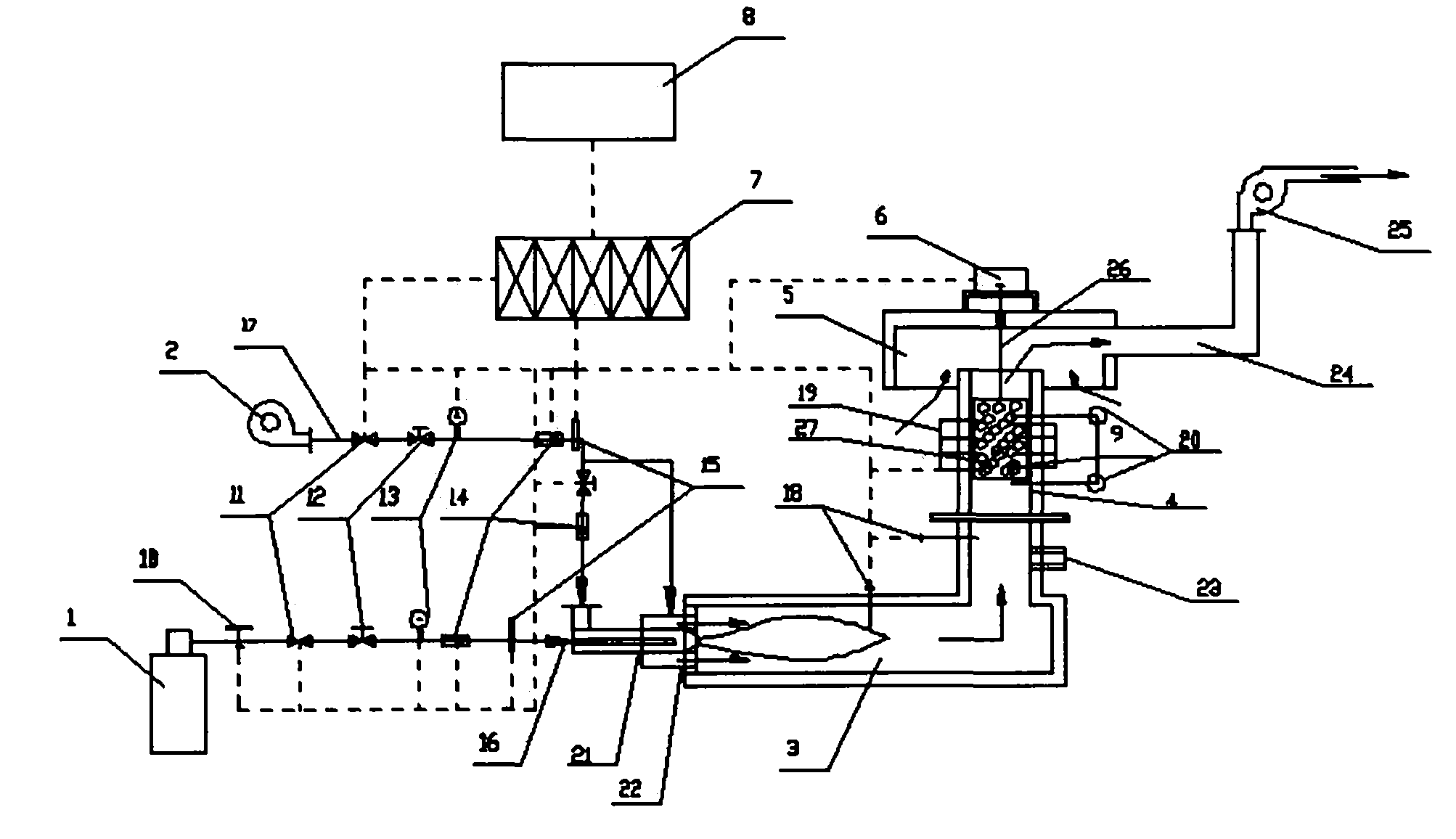

Experimental device and method for iron ore pellet roasting process

InactiveCN101575667AIncrease changeRealize continuous measurementProcess mechanismCombustion chamber

The invention relates to an experimental method and a device for an iron ore pellet roasting process, belonging to the field of iron manufacture production. In order to research the iron ore pellet roasting process in terms of heat transfer, mass transfer, a roasting process mechanism, and the like, the invention discloses the experimental method and the device, wherein the device comprises a gas tank, a draft blower, a combustion chamber, a roasting chamber, a smoke exhaust hood, an electronic balance, a PLC system, an industrial computer, a roasting cup, an electromagnetic disconnecting valve, an electrically operated valve, a manual control valve, a pressure gauge, a flow meter, a thermometer, a gas pipeline, an air pipeline, a combustion chamber high-temperature thermocouple, a roasting chamber high-temperature thermocouple, an annular pressure meter, a burner nozzle subassembly, a secondary air annular nozzle, a smoke gas collection hole, a smoke exhaust pipeline, an exhaust blower, a suspension fork, and the like. The device generates smoke gas with different flow speeds, different temperatures and different gases to roast a pellet material layer in a flow-through way, measures and collects relative data, especially the inner temperature distribution of the pellet material layer, and provides important experiment evidence for the theoretical research and the actual production of the pellet roasting mechanism.

Owner:UNIV OF SCI & TECH BEIJING

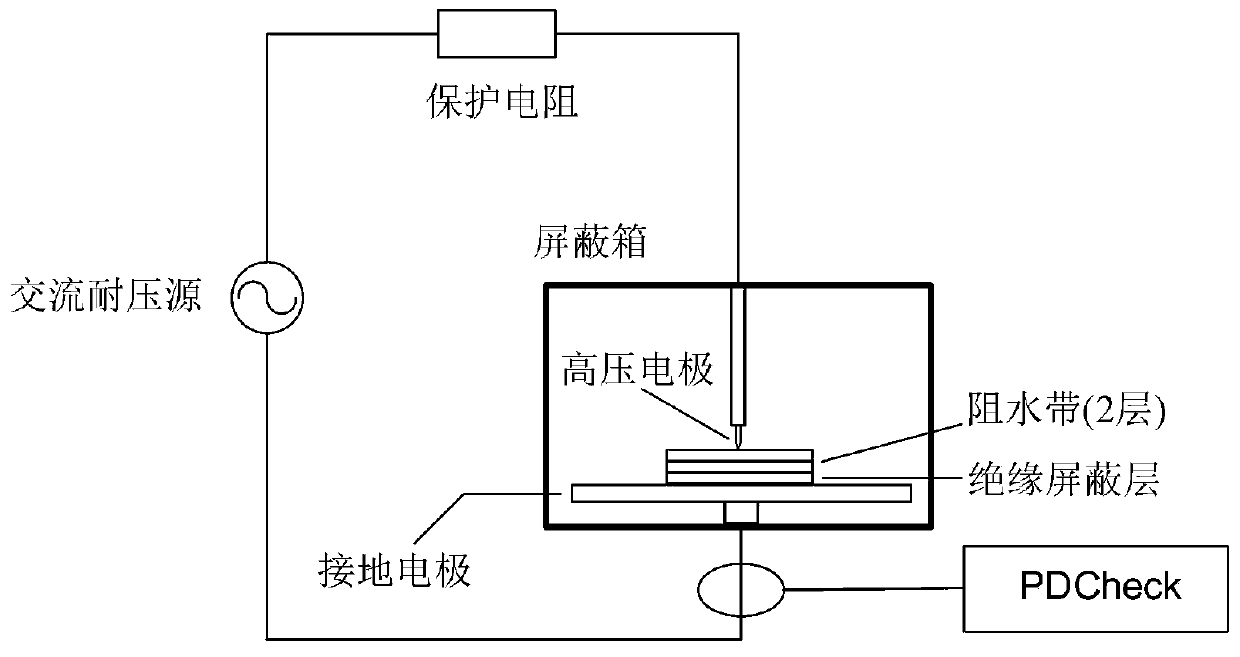

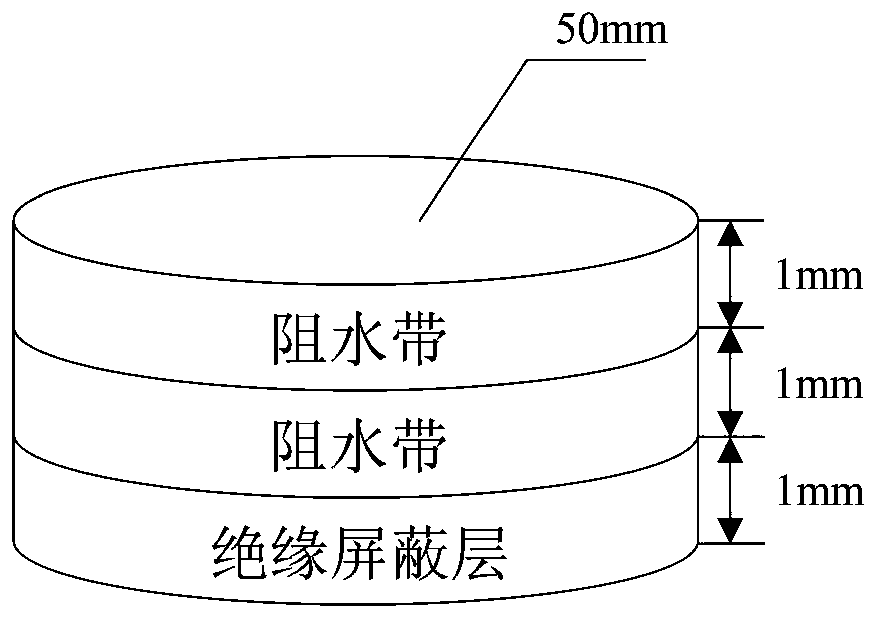

Partial discharge test system for cable buffer layer under extremely uneven electric field

ActiveCN111551833AMeet partial discharge test requirementsEffective shieldingTesting dielectric strengthInstrument screening arrangementsElectric cablesAlternate current

The invention relates to a partial discharge test system for a cable buffer layer under an extremely uneven electric field. The partial discharge test system is mainly characterized by comprising an alternating-current voltage source, a high-voltage electrode, a grounding electrode, a shielding box and a partial discharge acquisition device; the high-voltage electrode, the grounding electrode andthe to-be-tested sample are installed in the shielding box and used for shielding electromagnetic interference signals. The high-voltage electrode is connected with the high-voltage side of the alternating-current voltage source through the protective resistor, the grounding electrode is connected with the ground wire side of the alternating-current voltage source, a to-be-tested sample is placedbetween the high-voltage electrode and the grounding electrode and is in close contact with the high-voltage electrode and the grounding electrode, and the partial discharge acquisition device is installed between the grounding electrode and the ground wire side of the alternating-current voltage source. According to the invention, the high-voltage electrode, the grounding electrode and the to-be-tested sample are installed in the shielding box, so that external noise signals are effectively shielded, data measurement is carried out more accurately, partial discharge pulse waveforms can be analyzed, different types of discharge sources are distinguished through fuzzy clustering analysis, separation of discharge signals is realized, and the partial discharge test requirement is met.

Owner:TIANJIN UNIV

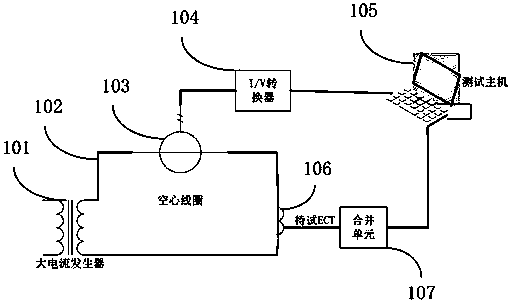

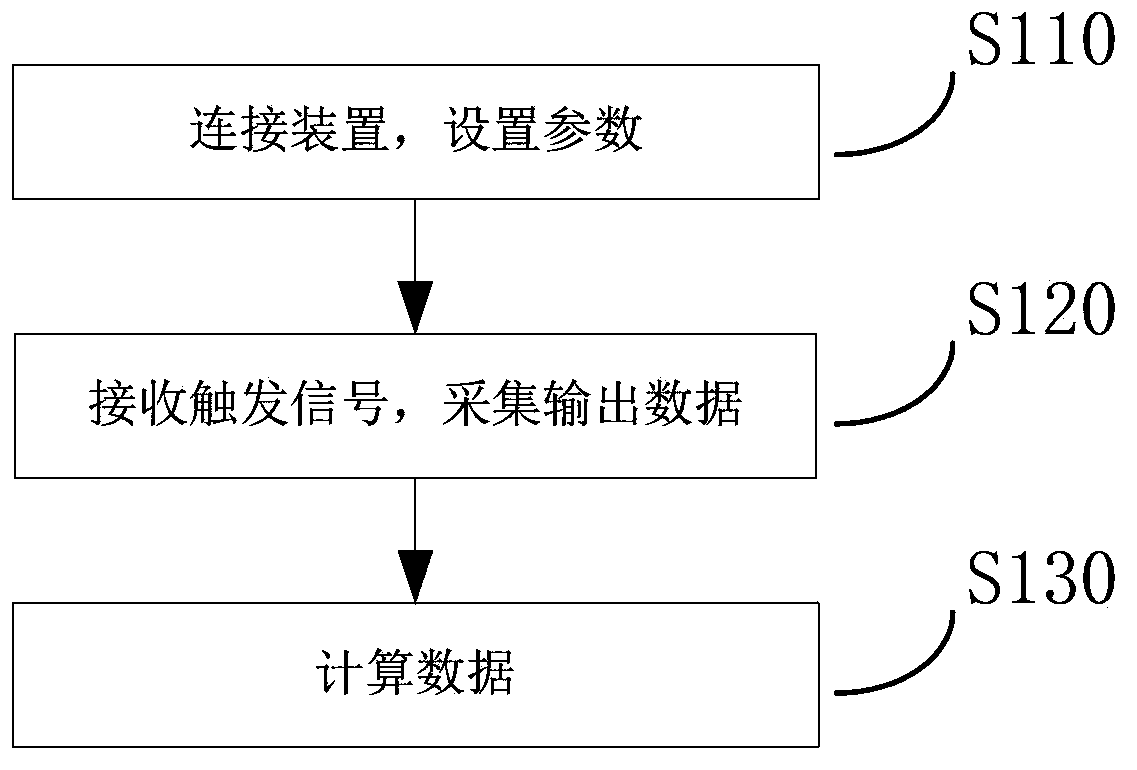

Electronic current transformer short-time current vibration test device and method thereof

ActiveCN103439681ASimple structureAccurate data measurementElectrical measurementsVibration testingEngineeringCurrent generator

The invention provides an electronic current transformer short-time current vibration test device and a method of the electronic current transformer short-time current vibration test device. The test device comprises a large-current generator, a hollow coil, an I / V converter, an ECT to be tested and a test host. The test host continuously records and stores data of a merging unit for more than 10s, at least simultaneously records more than three channels output by the same merging unit, and supports IEC61850-9-1 and IEC61850-9-2LE standards, wherein the channels for storing data can be selected. According to the electronic current transformer short-time current vibration test device and the method of the electronic current transformer short-time current vibration test device, a vibration test can be conducted on primary components of the ECT during the short-time current period, the structure is simple, data can be accurately measured, and the requirement of GB / T20840.8-2007 can be well met.

Owner:STATE GRID CORP OF CHINA +2

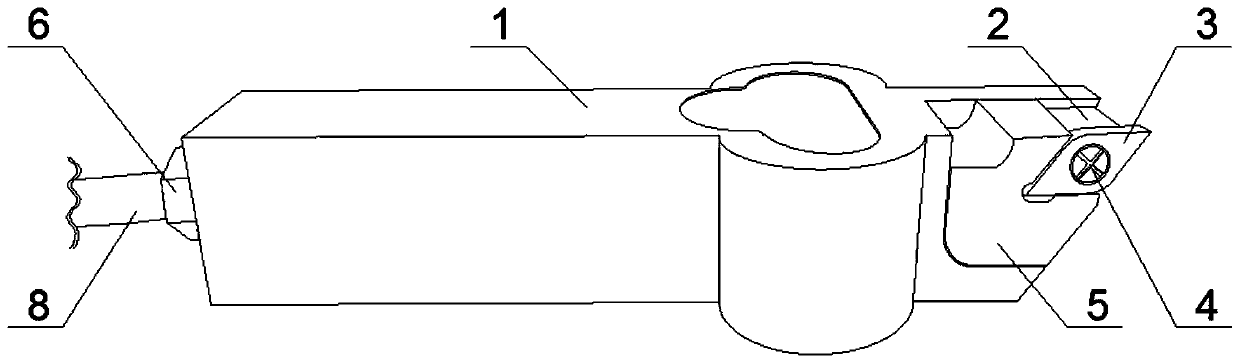

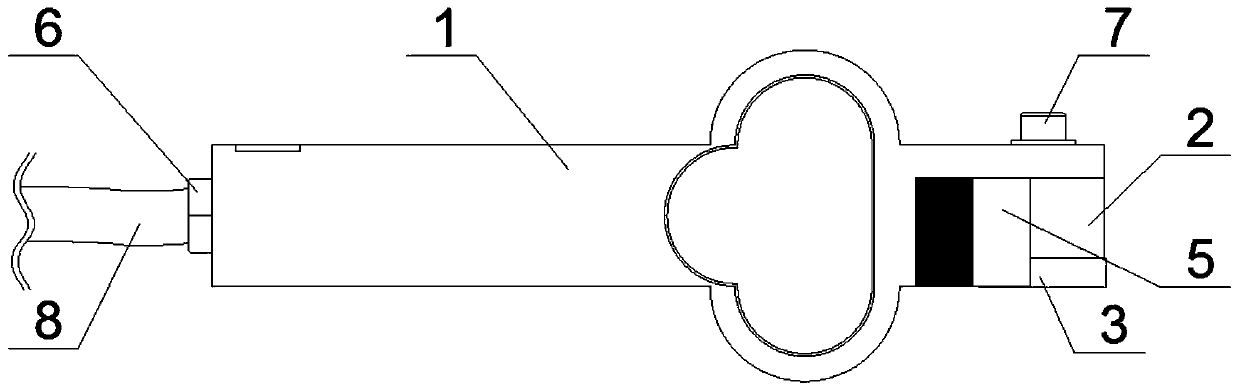

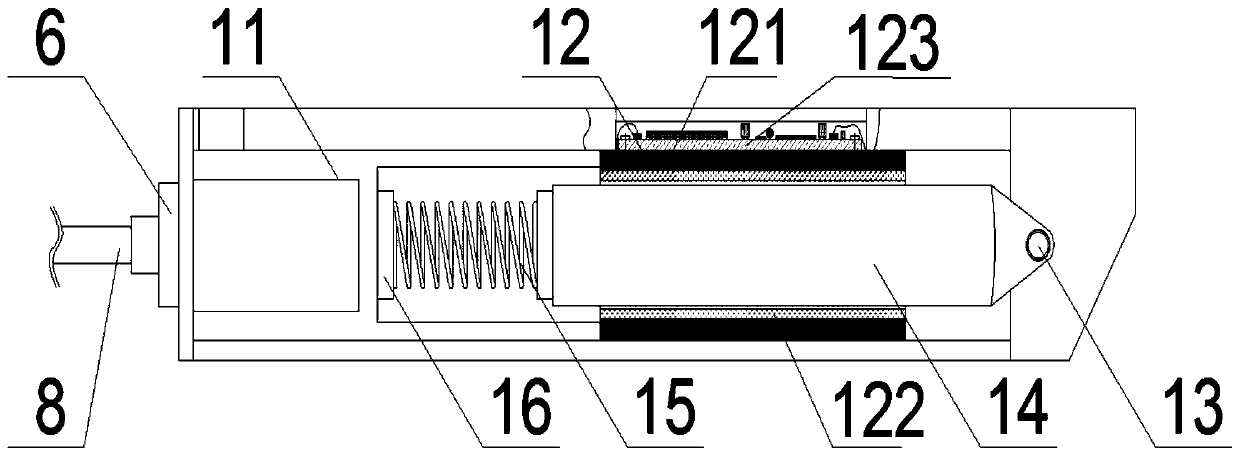

Device and method for measuring numerical control turning machining dynamic cutting force

PendingCN110561194AReal-time access to real force conditionsImprove accuracyMeasurement/indication equipmentsNumerical controlStress conditions

The invention discloses a device and a method for measuring numerical control turning machining dynamic cutting force. The device comprises a cutter bar, a fixed cutter seat, a blade, an anti-skid pad, a data processing module, a force sensor, a shock excitation rod, a limiting spring, a spring base and a data bus, wherein the data processing module, the force sensor, the shock excitation rod, thelimiting spring and the spring base are arranged inside the cutter bar, the force sensor comprises a force sensitive element, a conversion element and a PCB circuit board, and a filter, an amplifierand a power supply module are integrated on the PCB circuit board. The shock excitation rod and the blade arranged inside the cutter bar are connected together through a linkage pin hole and a linkagebolt, in the cutting process, force borne by the blade is transmitted to the shock excitation rod in real time, the shock excitation rod can acquire the real stress condition of the blade in the cutting process in real time, the force sensor is embedded in the interior of the cutter bar in an integrated mode and is positioned around the shock excitation rod, so that the influence of external force on the force sensor can be effectively avoided, and meanwhile, data measuring is accurately carried out on the shock excitation rod.

Owner:HEBEI UNIV OF TECH

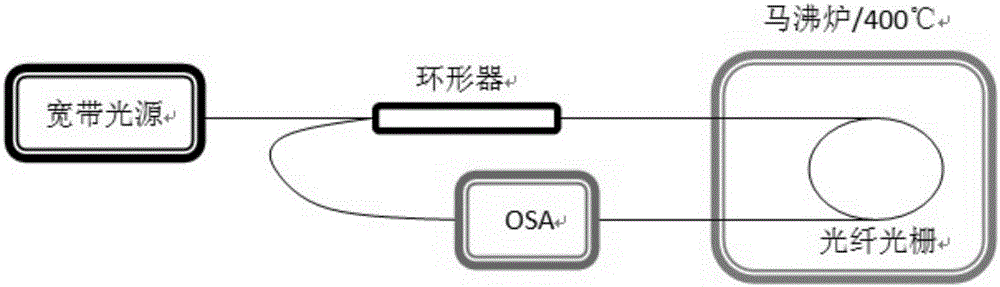

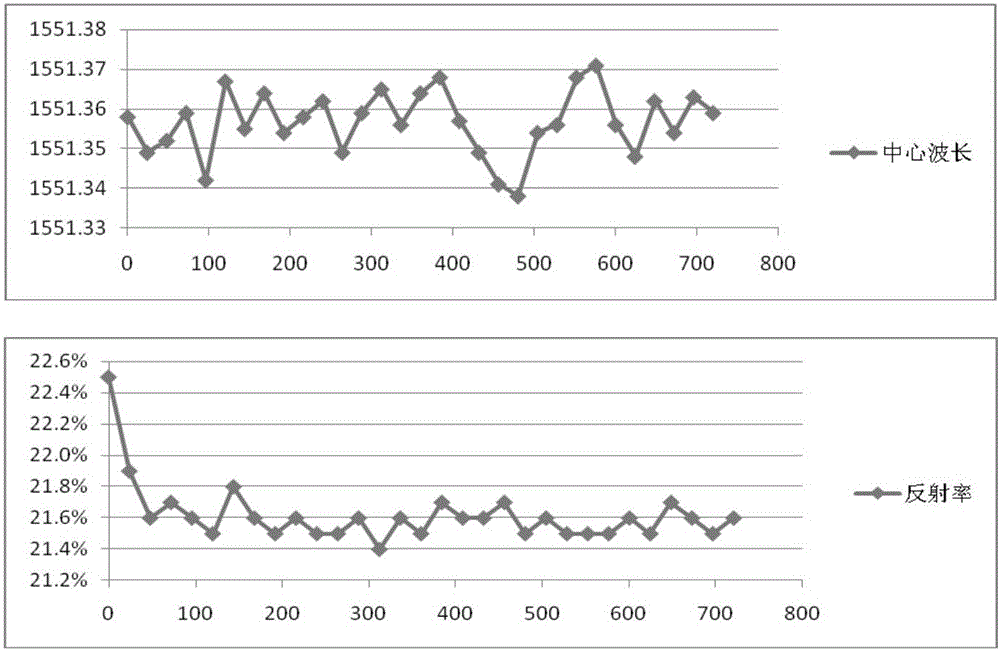

Manufacture method of high temperature resistant fiber grating

InactiveCN106019467AEasy to useAccurate data measurementCladded optical fibreOptical waveguide light guideGratingHigh pressure

The invention provides a manufacture method of a high temperature resistant fiber grating. The manufacture method comprises the steps that hydrogen-carrying treatment is carried out on an ordinary single-mode quartz optical fiber coated with polyimide in a high-pressure environment; the optical fiber is placed into a high-temperature oven for annealing; a grating to be written area of the optical fiber is soaked by concentrated sulfuric acid at high temperature; an ultraviolet laser is used for fiber grating writing; the grating bandwidth growth rate is between 2 pm / s and 4pm / s; after the grating spectral line bandwidth stops growing, exposure is continued for a period of time; polyimide is used to re-coat bare positions of the optical fiber; the fiber grating is placed into the oven at the temperature of 400+ / -10 DEG C for high-temperature heat treatment; and the center wavelength and the reflectivity of the grating spectral line are detected on-line. According to the invention, a sensor manufactured by the high temperature resistant fiber grating can be directly used in a working environment of 400 DEG C; and the sensor designed by the grating has the advantages of simple and direct use and accurate data.

Owner:深圳市畅格光电有限公司

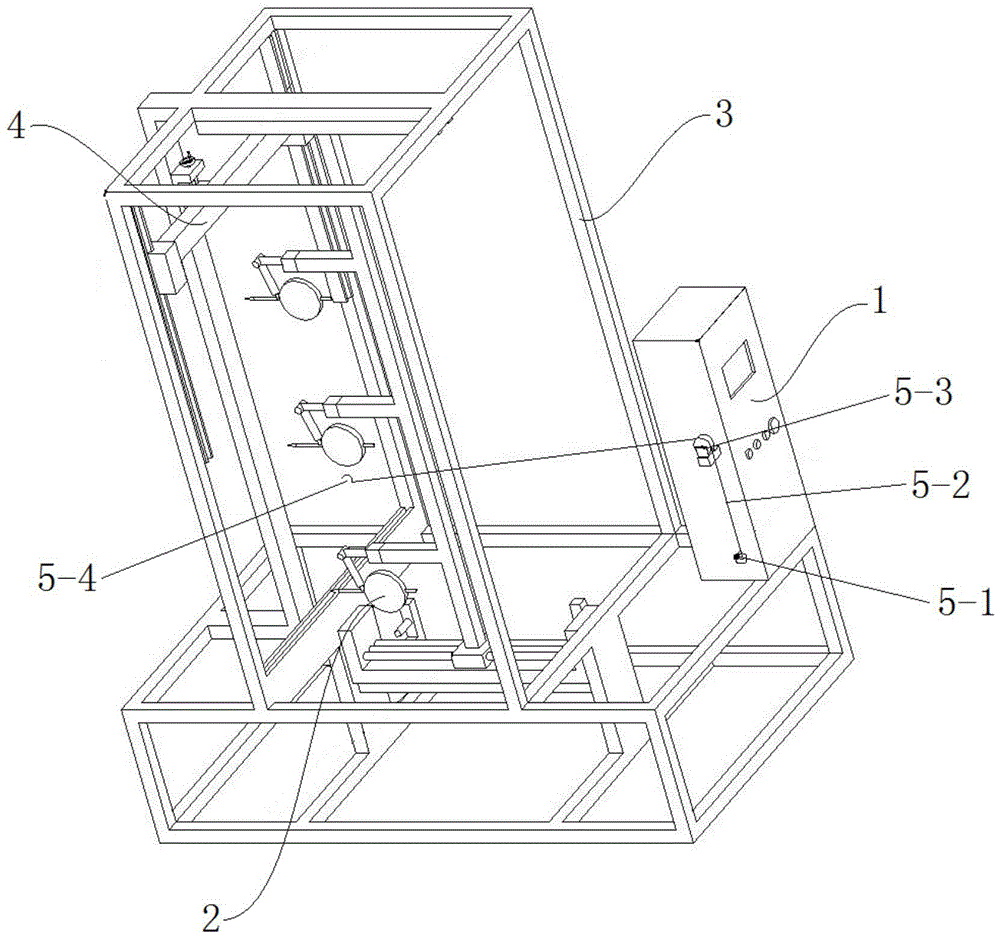

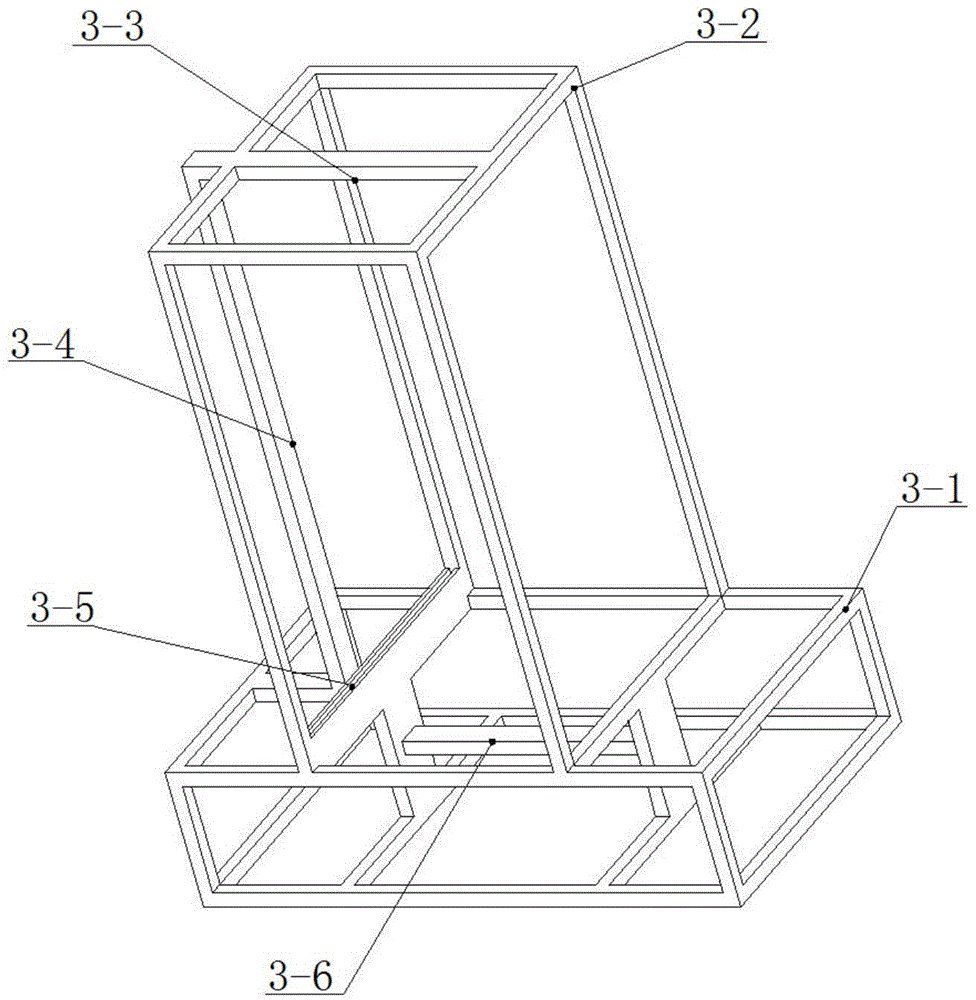

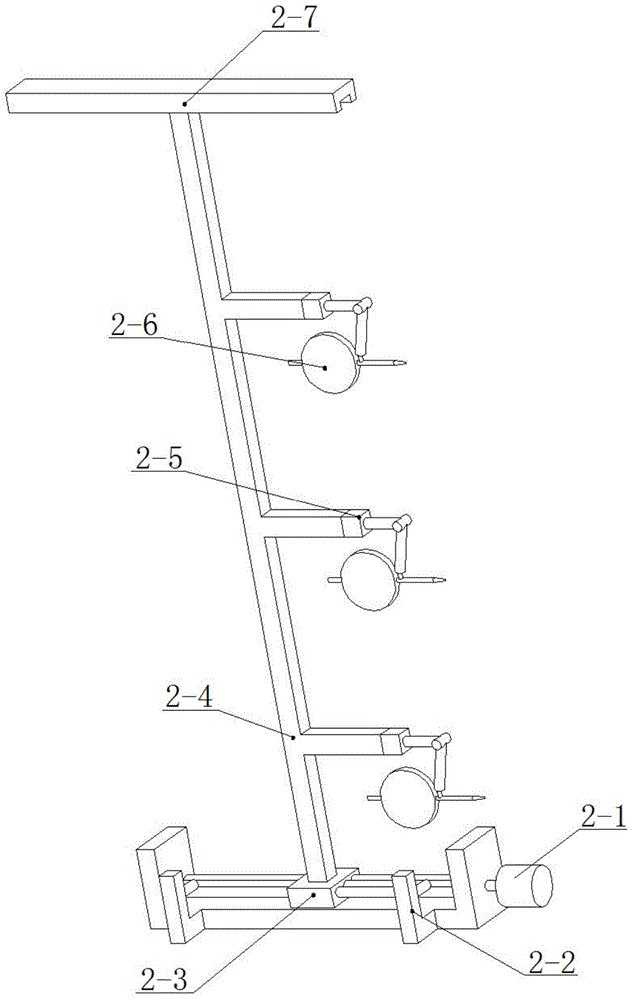

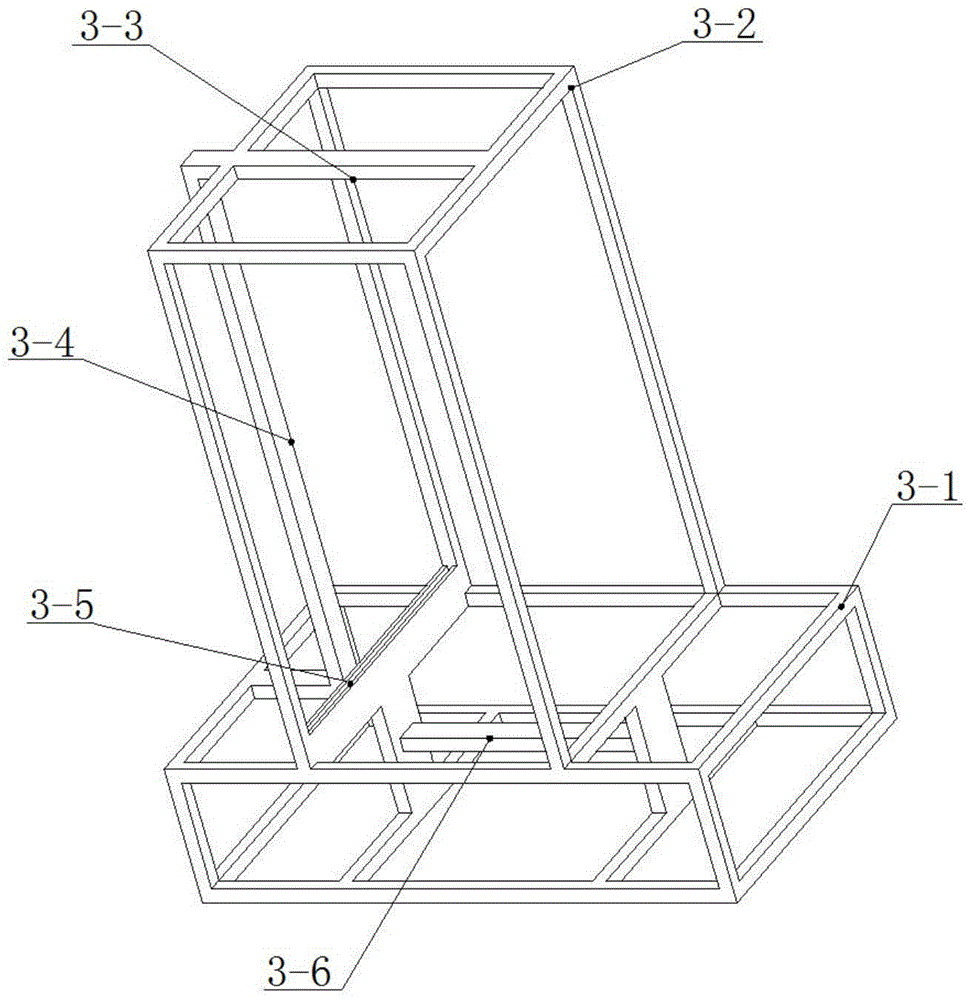

Quality detection device for door/window screen and using method thereof

ActiveCN104655444AEasy to set upThe test results are close to the realStructural/machines measurementDrive motorEngineering

The invention discloses a quality detection device for a door / window screen, belonging to the field of quality detection. The quality detection device disclosed by the invention comprises an overall frame, a screen clamping mechanism, a detection mechanism and a loading mechanism, wherein the screen clamping mechanism adjusts the relative height of a screen fixing rod on the overall frame by utilizing a tensioning mechanism; a screen fixing clamping groove is formed in the overall frame, and the upper and lower sides of a to-be-detected screen are clamped by virtue of the screen fixing clamping groove and the screen fixing rod; the detection mechanism comprises a driving motor, a lead screw sliding table, a support frame, a detection meter bracket, a digital indicator and a sliding rail; the lead screw sliding table is driven by the driving motor and is used for driving the support frame to move along the horizontal direction; a measuring head of the digital indicator faces the to-be-detected screen, and the digital indicator is positioned in the middle of the to-be-detected screen; and the loading mechanism hooks the to-be-detected screen by virtue of a hook so as to realize tension loading of the to-be-detected screen. The special detection device and method are designed according to the screen detection standard, the structure is simple, the detection is convenient, and the intelligent degree is high.

Owner:常州常工院技术转移有限公司

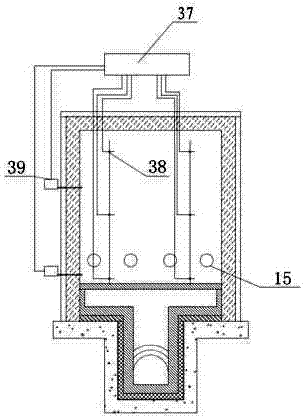

Closed type fumigating and washing instrument for elbow joint segments

InactiveCN105943356APrevent up and down movementPromote recoveryBathing devicesWater storage tankDisplay device

The invention relates to a closed type fumigating and washing instrument for elbow joint segments. The closed type fumigating and washing instrument for elbow joint segments comprises a fumigating and washing sleeve, a control cabinet, an air pump, a liquid supply pump, a heating device, a liquid storage tank and a water storage tank. The fumigating and washing sleeve is correspondingly connected with the liquid storage tank and the water storage tank through two liquid return pipes respectively. The liquid supply pump is connected with the liquid storage tank and the water storage tank through first liquid supply pipelines, and is connected with the fumigating and washing sleeve through a second liquid supply pipeline. An air pressure sensor, a temperature sensor, a differential valve, two fixing pipes and a display device are arranged on the fumigating and washing sleeve, and inflation and deflation contraction sets are arranged on the inner walls of the two fixing pipes. The closed type fumigating and washing instrument for elbow joint segments has the advantages that the fumigating and washing instrument is wide in application range, applicable to users with different arm thicknesses and good in leakproofness; a user can know the current specific fumigating and washing condition conveniently, and data measurement is accurate; closed fumigating and washing of partial elbow joint segments can be achieved, the requirement for scientific and standard treatment can be met, and the temperature and the fumigating and washing pressure can be accurately controlled or set.

Owner:THE AFFILIATED HOSPITAL OF TRADITIONAL CHINESE MEDICAL TO SOUTHWEST MEDICAL UNIV

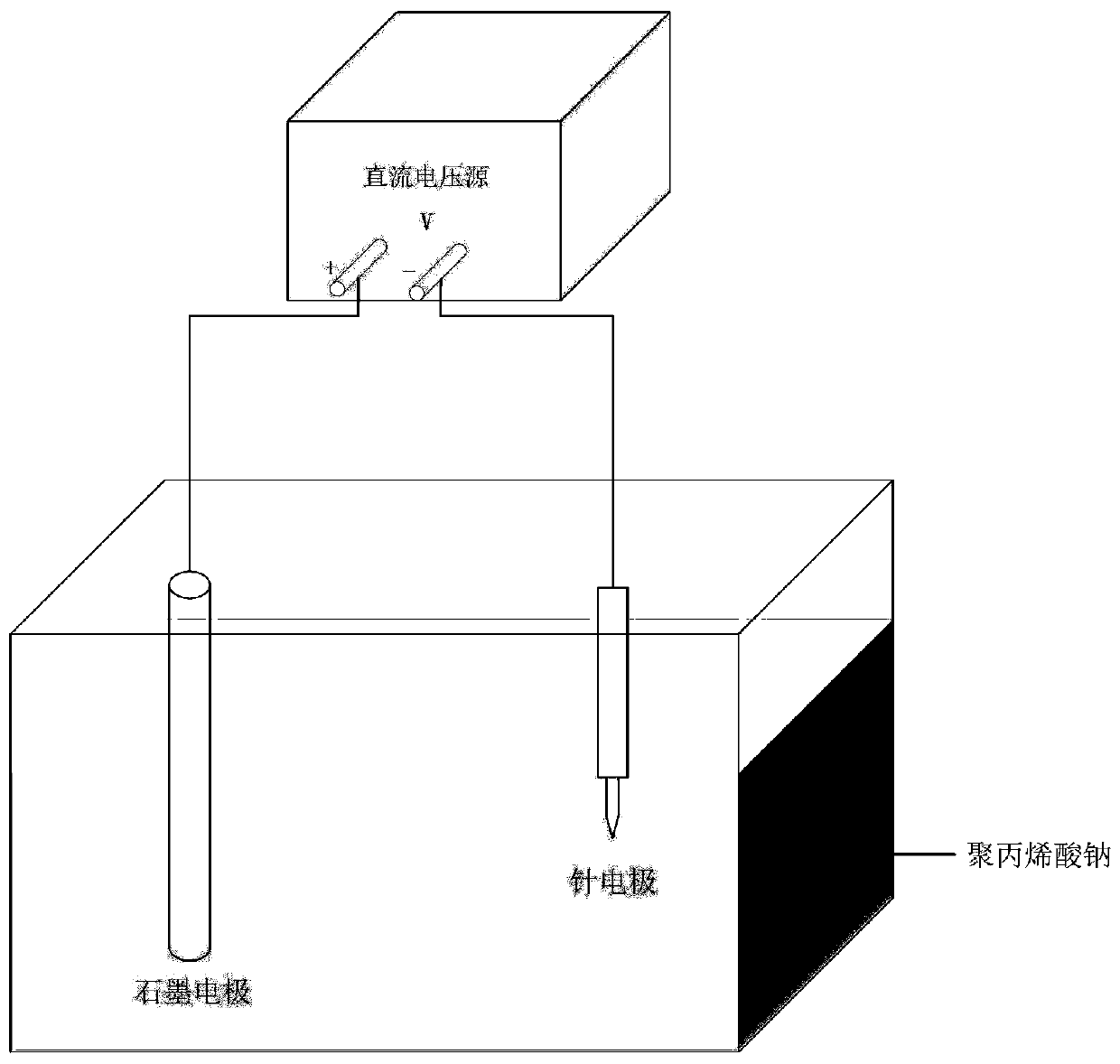

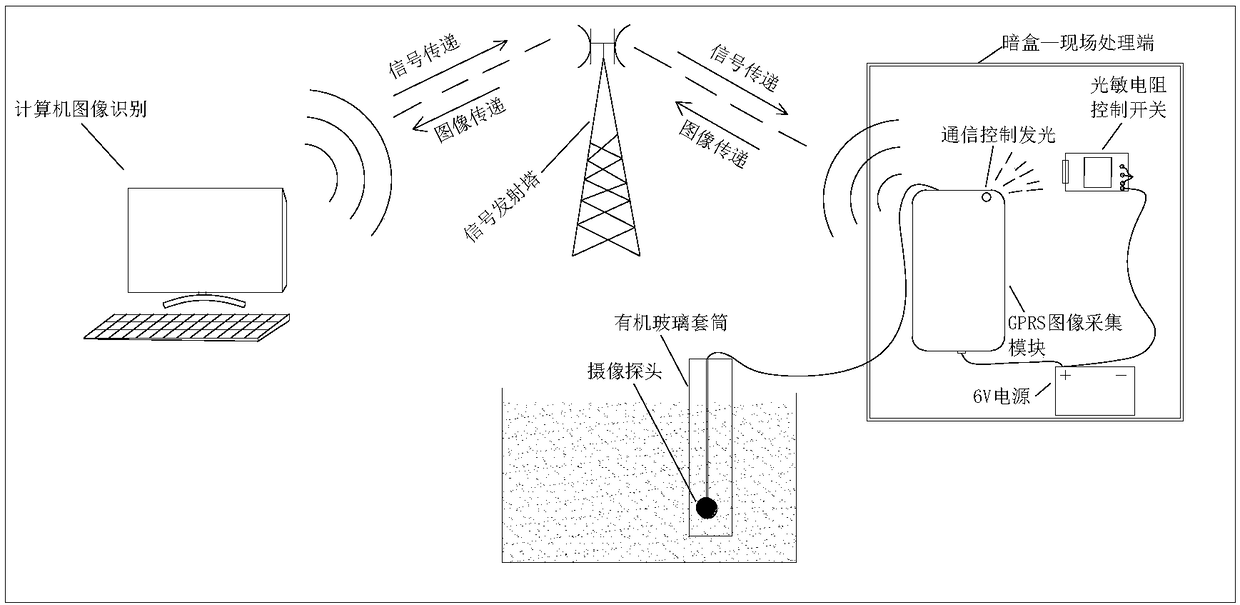

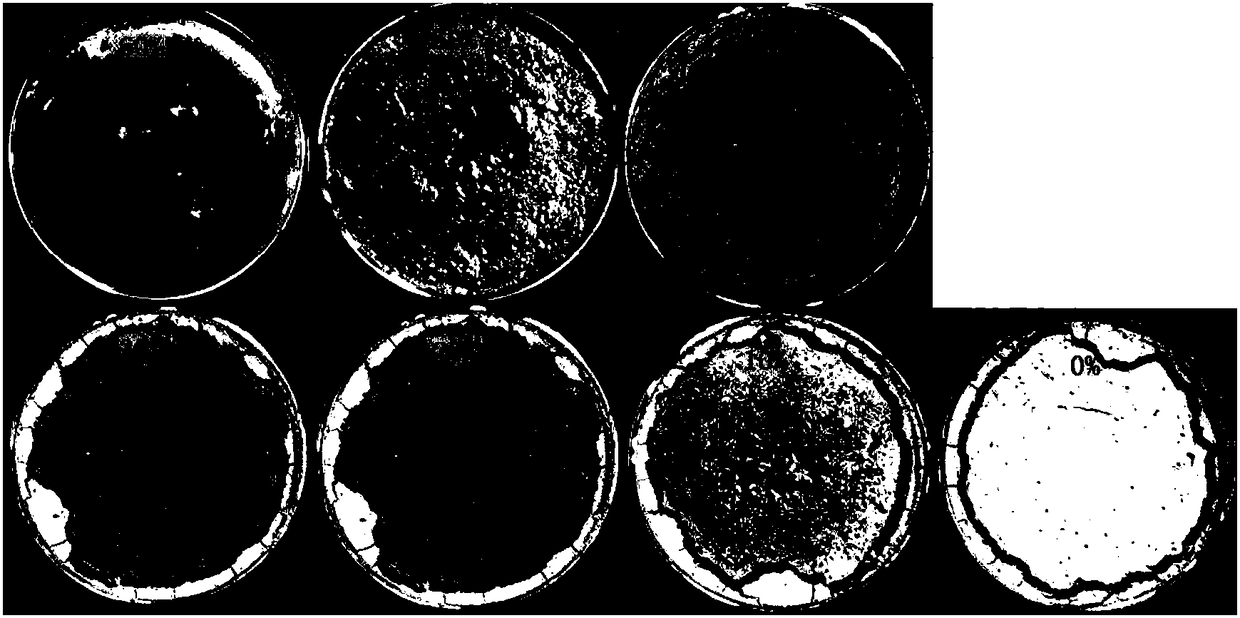

Soil moisture detection method and application thereof

InactiveCN108537851AHigh precisionFast analysisImage enhancementImage analysisAutomatic controlData transmission

The invention discloses a soil moisture detection method and an application thereof, proposes a new idea for measuring the soil moisture according to the soil color, and combines with the image recognition and data transmission functions of a computer for experimental investigation. Through the pixel gray scale analysis of images with different soil moisture contents, a corresponding relational expression of the soil moisture and the gray scale is built, and the moisture values of the same soil are obtained through comparison. The precision of a soil moisture value obtained through an image recognition program will be remarkably improved, and the analysis speed is remarkably improved. The computer image recognition program is used for obtaining the soil moisture value for agricultural production, thereby achieving the automatic control of the irrigation of crops. In the early warning of the geological disasters, the method can be used for forecasting of potential landslide soil or excessive soil moisture, and achieves the advanced preparation and processing.

Owner:HUNAN AGRICULTURAL UNIV

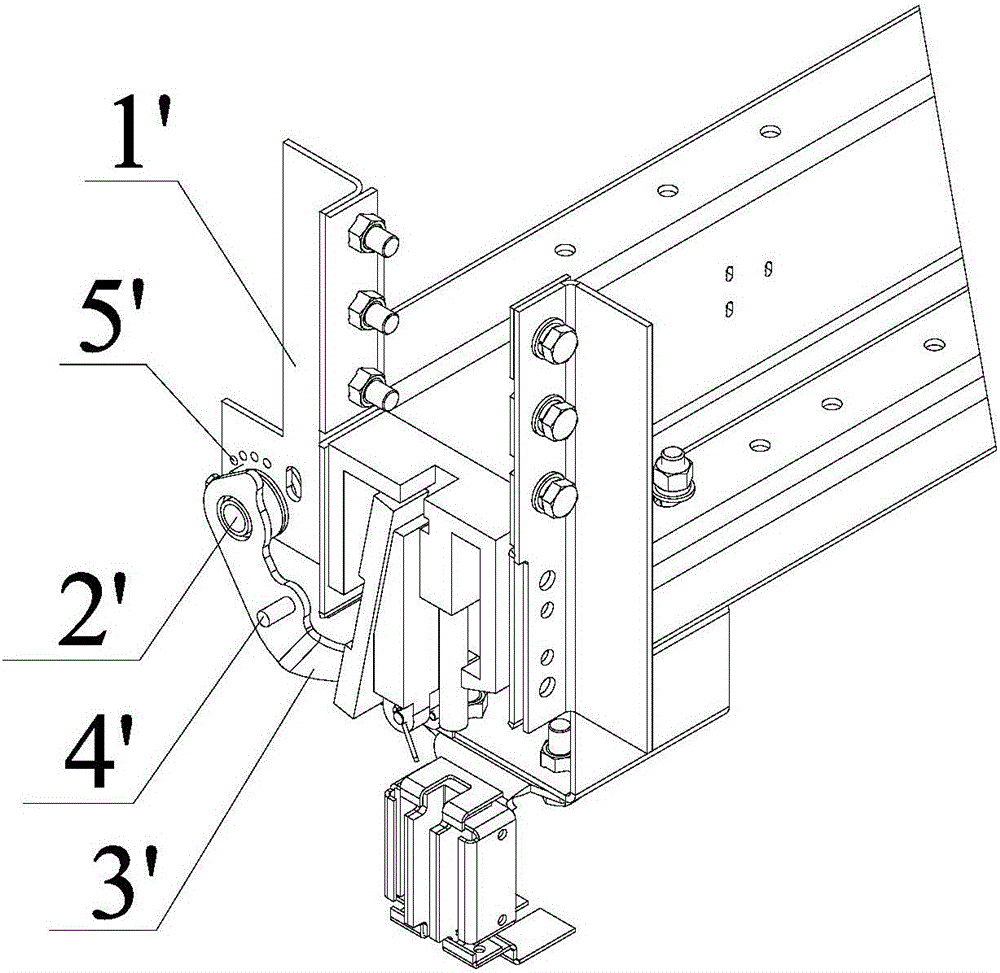

Device for detecting pulling force of safety tongs

The invention relates to the technical field of safety tongs of elevators, and in particular relates to a device for detecting pulling force of safety tongs. The device comprises an electronic tension meter, wherein a pull ring of the electronic tension meter is connected with a hanging assembly for connecting a lifting pin of the safety tongs; the electronic tension meter is connected with a positioning bracket; and the positioning bracket comprises a clamping slot connected with the top of a lower beam linking shaft fixing plate in a clamping manner. According to the device for detecting the pulling force of the safety tongs, a measurement mod and a reference are unified, namely that the upward lifting height and the lifting direction are fixed, and the error rate is low; measurement of data is more precise, so that the reliability of a product is guaranteed; and furthermore, the device is simple and convenient to operate, and a worker does not need to perform lifting operation for a long time, so that the measurement efficiency is improved.

Owner:JOYLIVE ELEVATOR

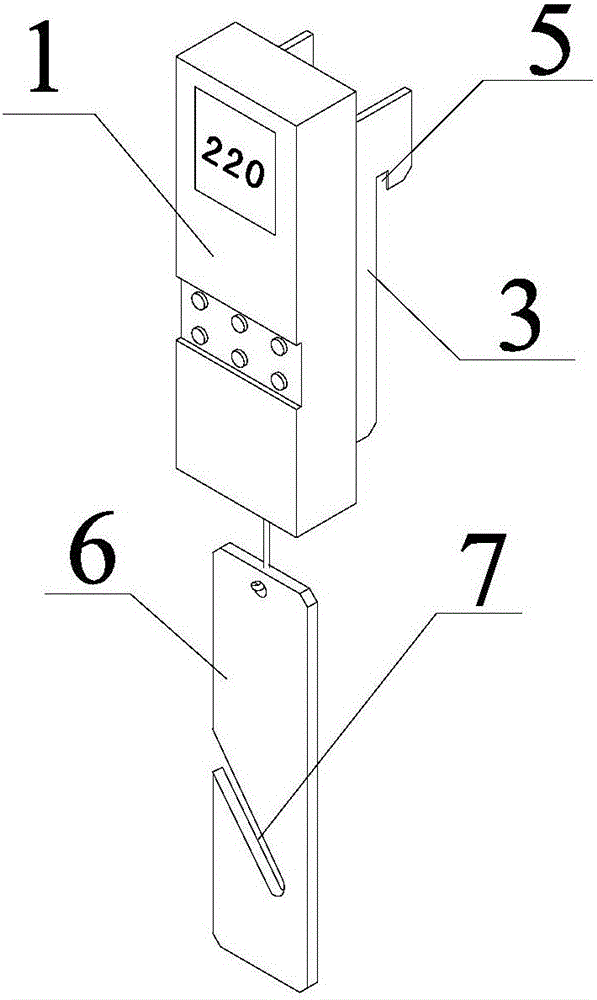

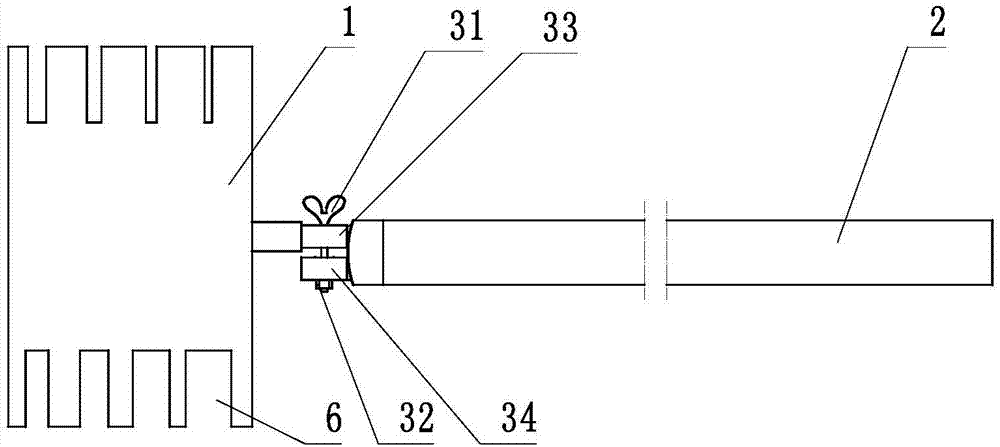

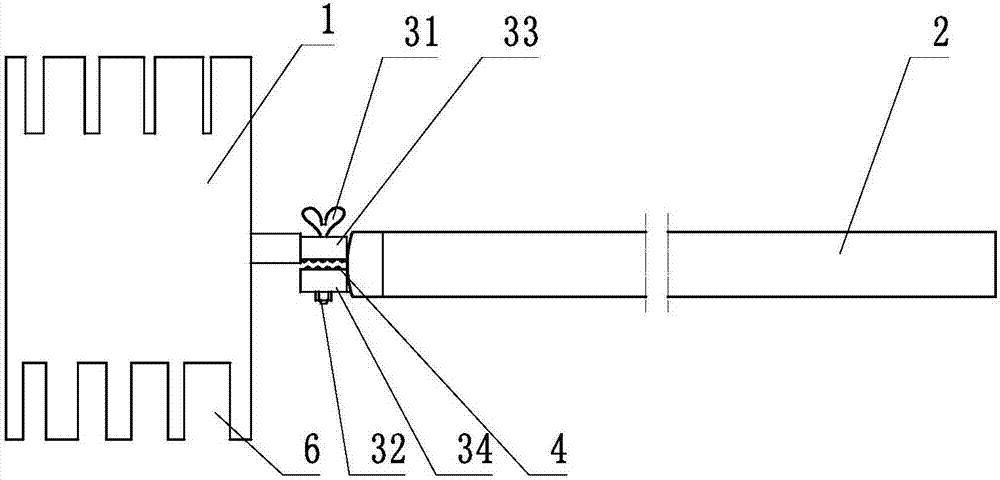

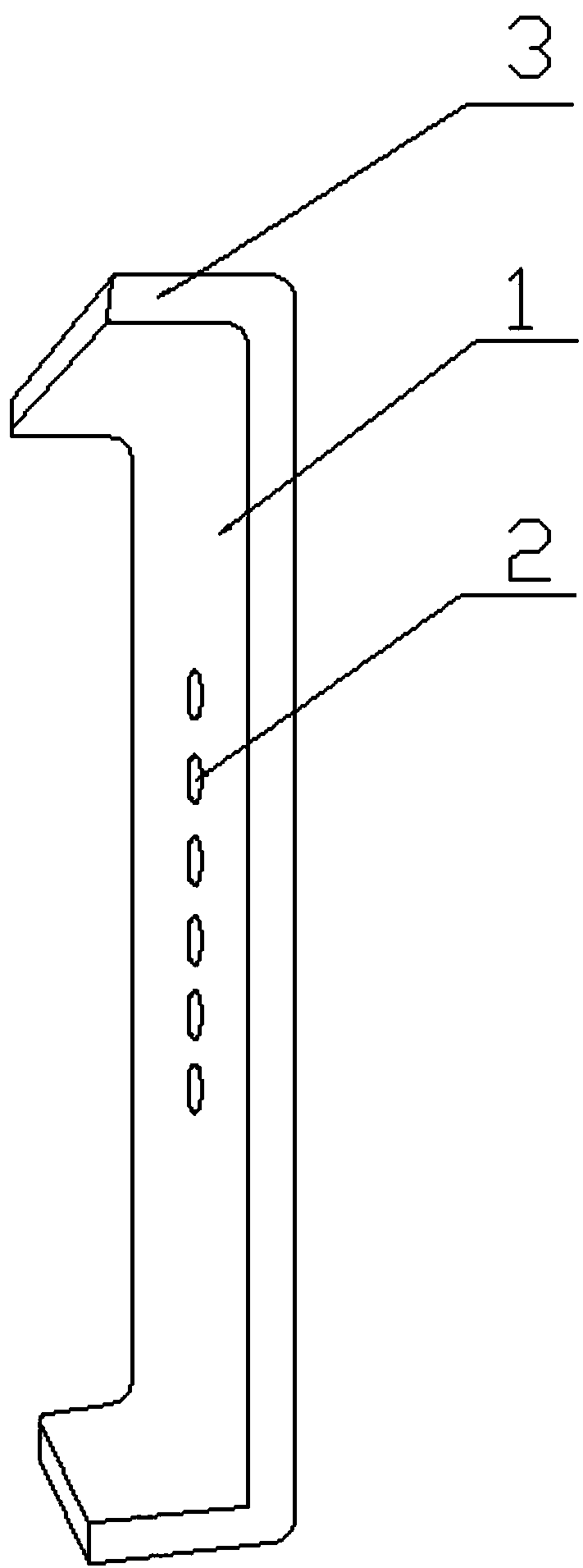

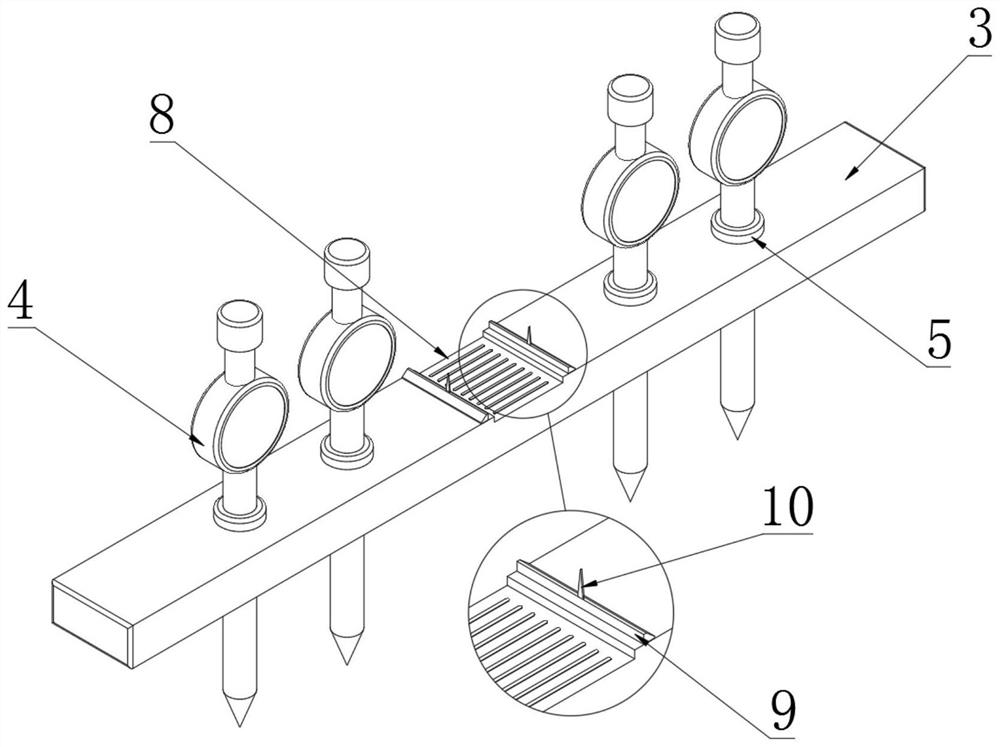

Wire diameter measurement special tool

InactiveCN107036505ASimple structureEasy to operateMechanical diameter measurementsEngineeringDiameter measurement

The invention discloses a wire diameter measurement special tool, which is characterized in that the tool at least comprises a measurement plate (1) and an insulation rod (2). The measurement plate (1) is a plate-shaped body; the edge of the plate-shaped body is provided with a plurality of measuring ports (6); the measuring ports (6) are notches arranged in the edge of the measurement plate (1); the notches are in the shape of U, that is, the opposite two sides are parallel mutually; the distances between the measuring port (6) and the two parallel edges are different; one end of the insulation rod (2) is a free end, and the other end there of is connected with the measurement plate (1) through an adjustment mechanism (3); and the measurement plate (1) and the insulation rod (2) can be in relative rotation around the adjustment mechanism (3). Compared with the prior art, the wire diameter measurement special tool is simple in structure and convenient to operate and carry, can carry out wire diameter measurement work under normal power-on condition, is suitable for measurement requirements in different environments, is accurate in data measurement and improves work efficiency and the like to a greater degree and the like.

Owner:国网新疆电力有限公司博尔塔拉供电公司 +1

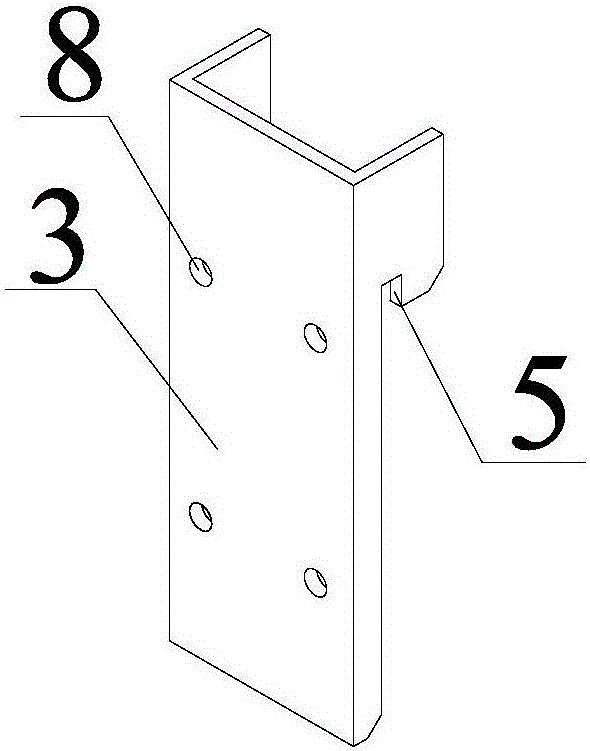

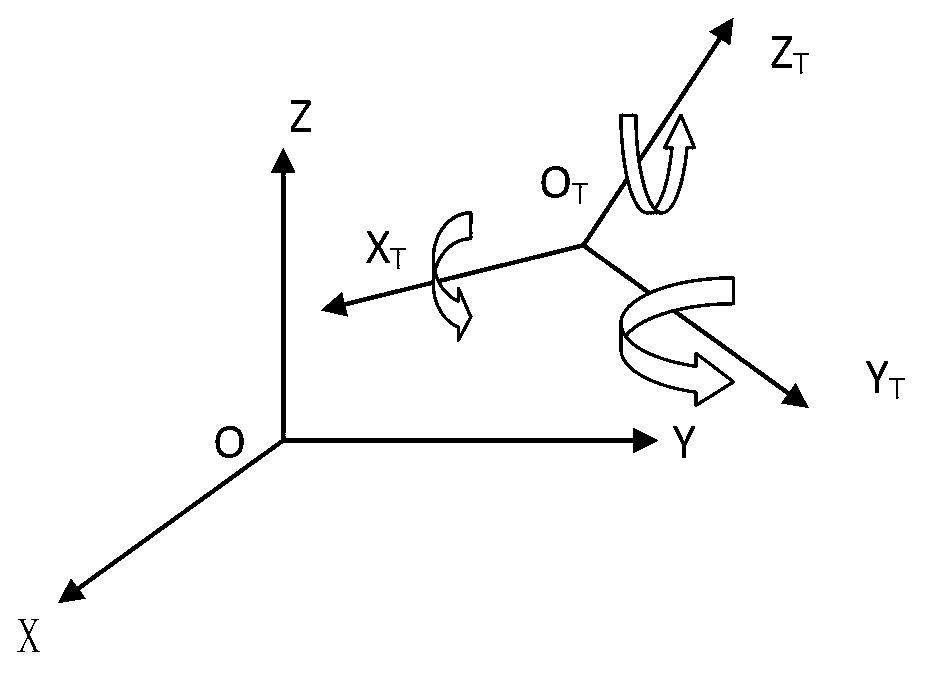

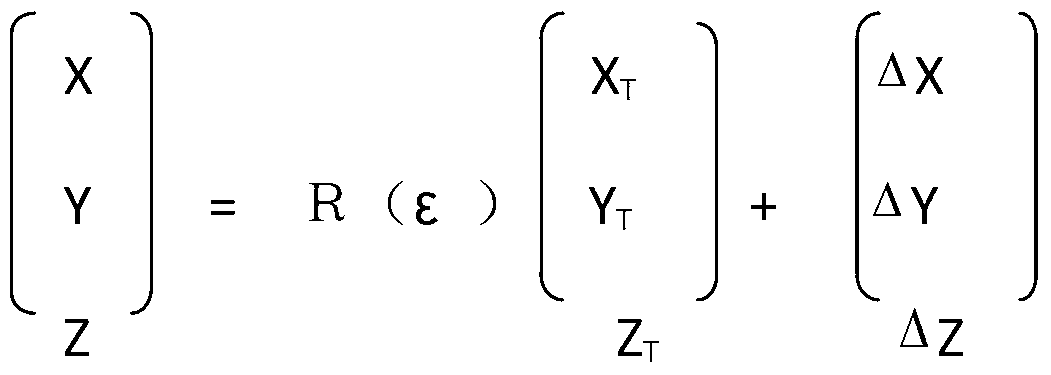

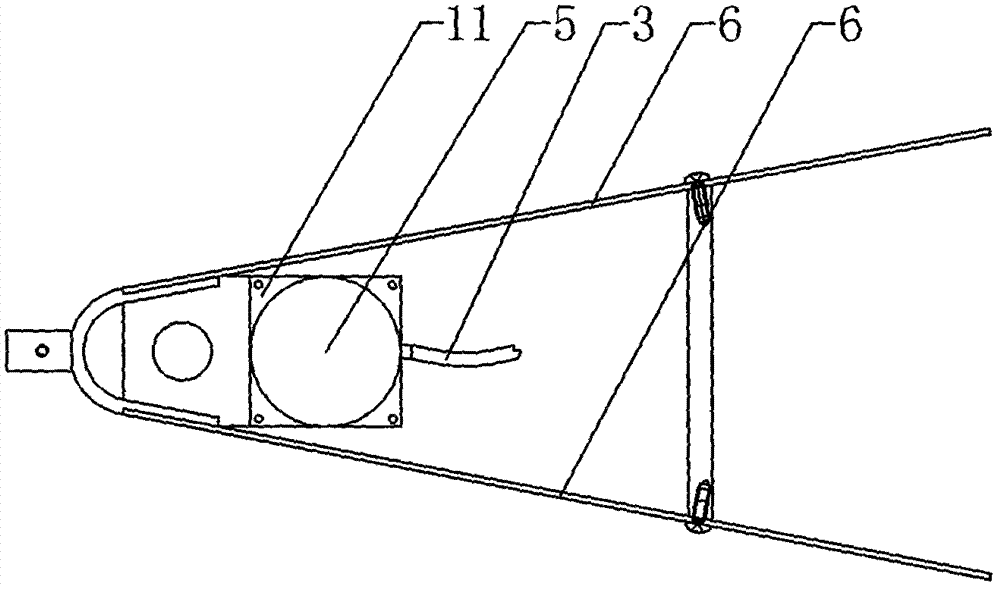

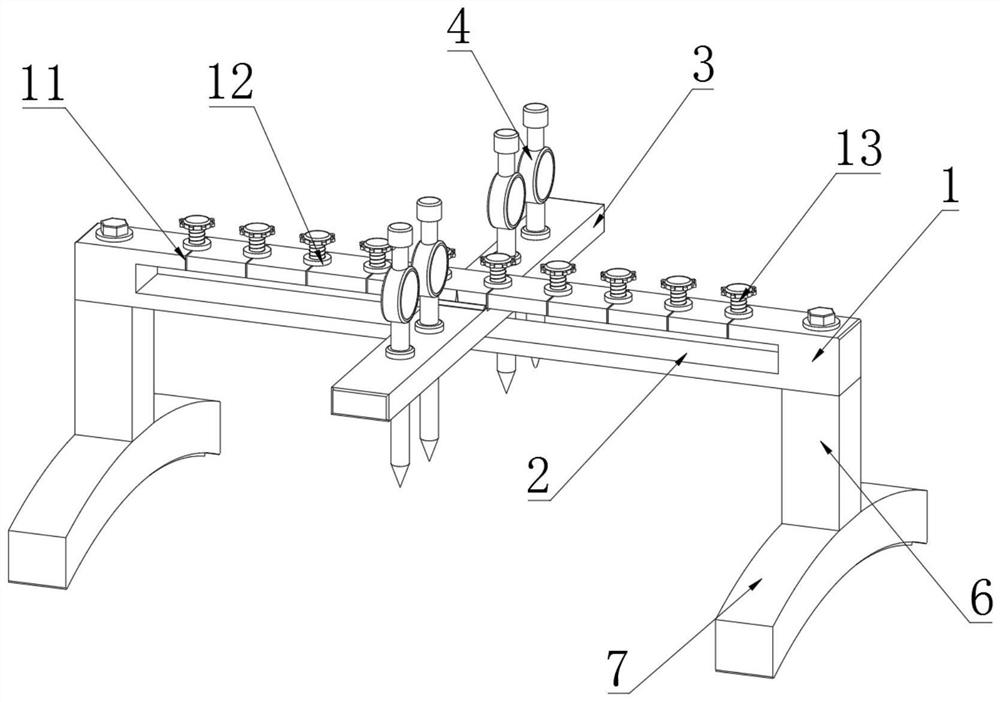

Method for measuring three-dimensional data of autobody and chassis based on optical-electricity encoder

InactiveCN103292694AFlexible rotationEasy and efficient measurementUsing optical meansElectricityMeasurement point

The invention provides a method for measuring three-dimensional data of an autobody and a chassis based on an optical-electricity encoder. The method for measuring the three-dimensional data of the autobody and the chassis based on the optical-electricity encoder is designed to solve the problem that the current mechanical or electronic type measuring method is inconvenient to use and to improve use convenience and measuring efficiency. According to the technical scheme, the method for measuring the three-dimensional data of the autobody and the chassis based on the optical-electricity encoder is characterized in that a measuring arm is composed of a plurality of joints which are connected with one another, wherein a first joint (1), a second joint (2), a third joint (3) and a fourth joint (4) are in the same plane, the fourth joint (4) is perpendicular to the third joint (3), a fifth joint (5) rotates in the plane which is perpendicular to the fourth joint (4), a sixth joint (6) rotates in the plane which is perpendicular to the fifth joint (5), and joint rotating shafts are respectively embedded in the optical-electricity encoder and are used for measuring the rotation angels of the joints. The three-dimensional data of any measurement points of the autobody and the chassis can be measured through angle measurement, coordinate calibration and conversion calculation.

Owner:MIT AUTOMOBILE SERVICE

Method for comprehensively verifying bearing capacity of steel sheet pile

PendingCN111997108AImprove protectionReduce vibration effectsGeometric CADNon-rotating vibration suppressionTotal stationStrain gauge

The invention discloses a method for comprehensively verifying bearing capacity of a steel sheet pile. Instruments mainly comprise an inclinometer, a total station and a strain gauge; the method for comprehensively verifying bearing capacity of the steel sheet pile uses a plurality of calculation methods and a large amount of manual data processing to establish a multi-variable steel sheet pile safety and stability evaluation model, a soil displacement change model along time, a steel sheet pile inclination degree change model along time and a steel sheet pile stress and strain change model along time; the multi-variable steel sheet pile safety and stability evaluation model can solve a safe and stable boundary surface through a large amount of data and the corresponding loss function, thethree time change models can clearly know the current change trend and predict the future change trend, and the method has high efficiency and strong practicability, no specific environmental conditions and other advantages, so the method can be widely applicable to comprehensive analysis of safety and stability problems.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Tablet PC (Personal Computer) type flow velocity and direction meter

InactiveCN104501867AIncrease storage spaceAccurate data measurementMeasurement devicesTransmission systemsTablet computerComputer terminal

The invention provides a tablet PC (Personal Computer) type flow velocity and direction meter. The tablet PC type flow velocity and direction meter comprises a sensor part and a mobile terminal, wherein the sensor part is used for collecting flow velocity and direction signals and is connected with a data forwarding part; the data forwarding part is used for converting the signals collected by the sensor part into wireless signals and sending the wireless signals, and the mobile terminal is used for receiving the wireless signals and processing, displaying and storing the wireless signals. According to the tablet PC type flow velocity and direction meter provided by the invention, the defect that an original detection device is heavy and is not easy to use is improved, and a tablet PC is used as a display carrier for the first time through wireless signal transmission; the tablet PC type flow velocity and direction meter has the advantages that the operation is flexible and easy, the interface can be designed, the storage space is large, the data measurement is accurate, and the like.

Owner:姜松燕

Mechanical seal transient state start/stop sealing property tester

InactiveCN101464203BLower requirementEasy to controlFluid-tightness measurement using fluid/vacuumTransient stateStart stop

Owner:ZHEJIANG UNIV

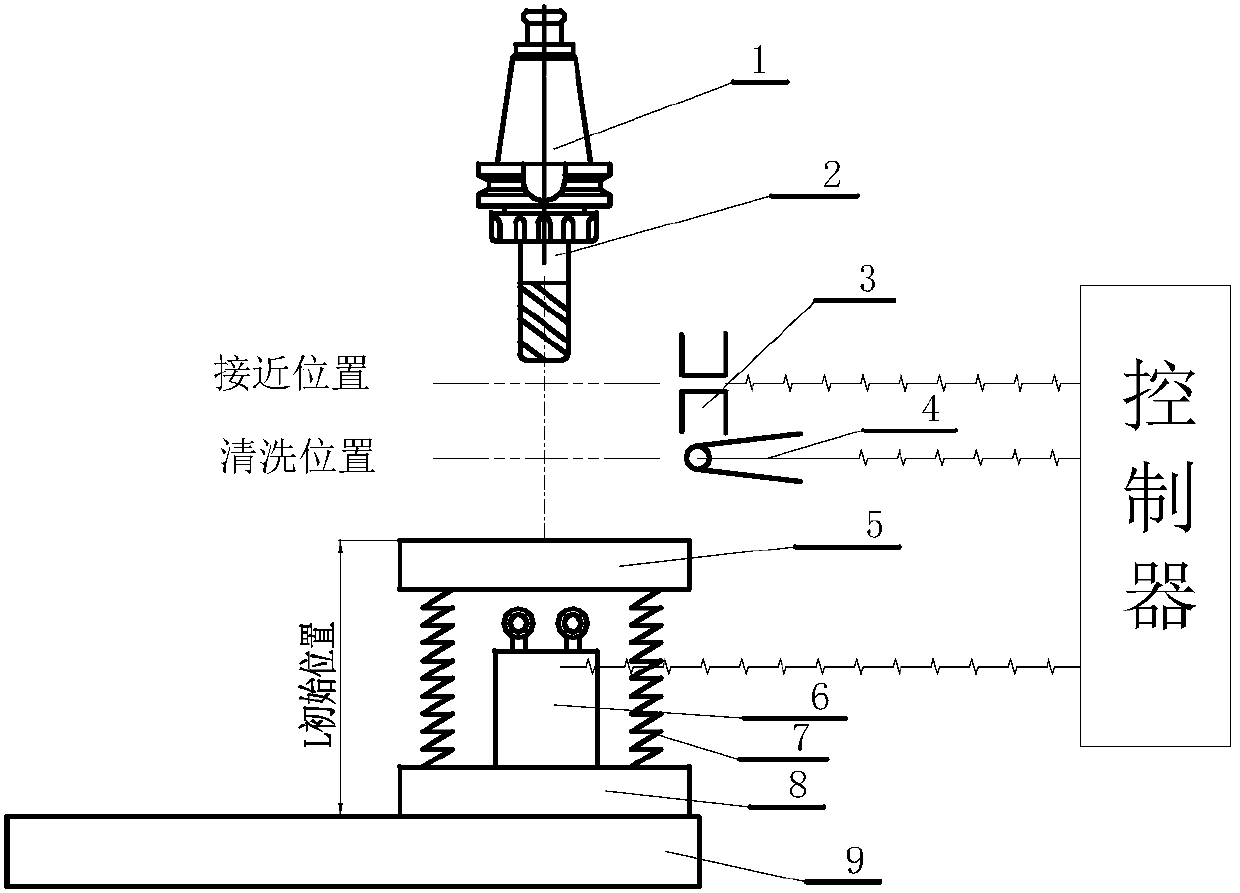

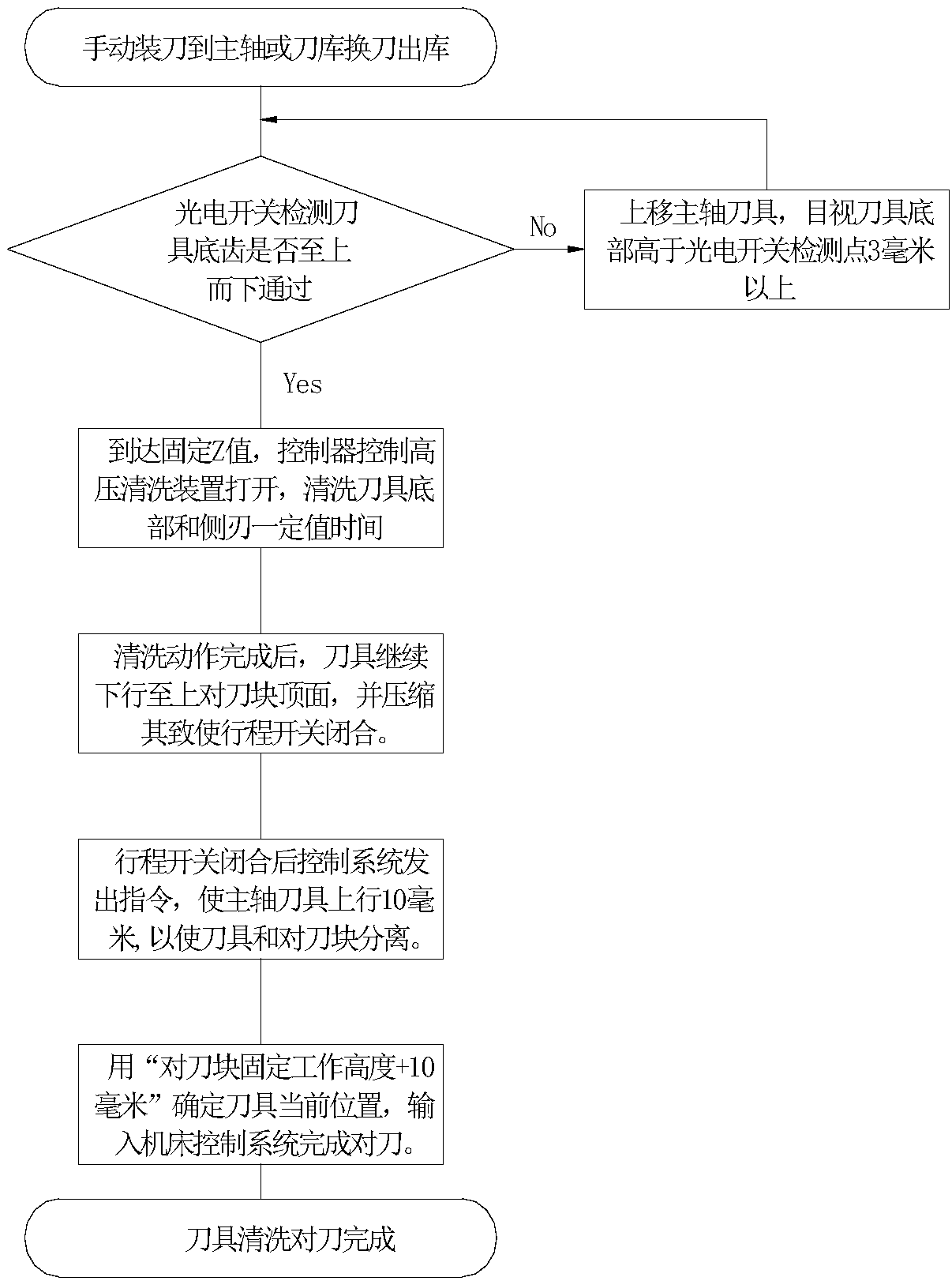

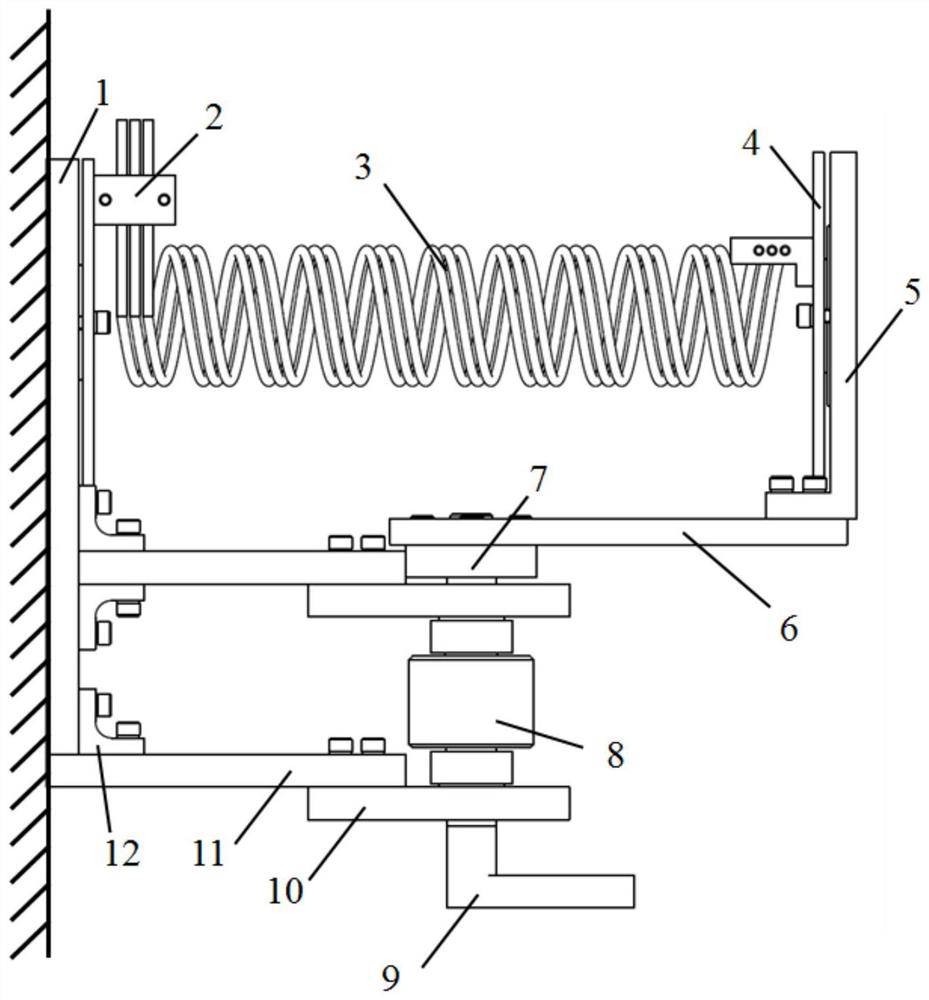

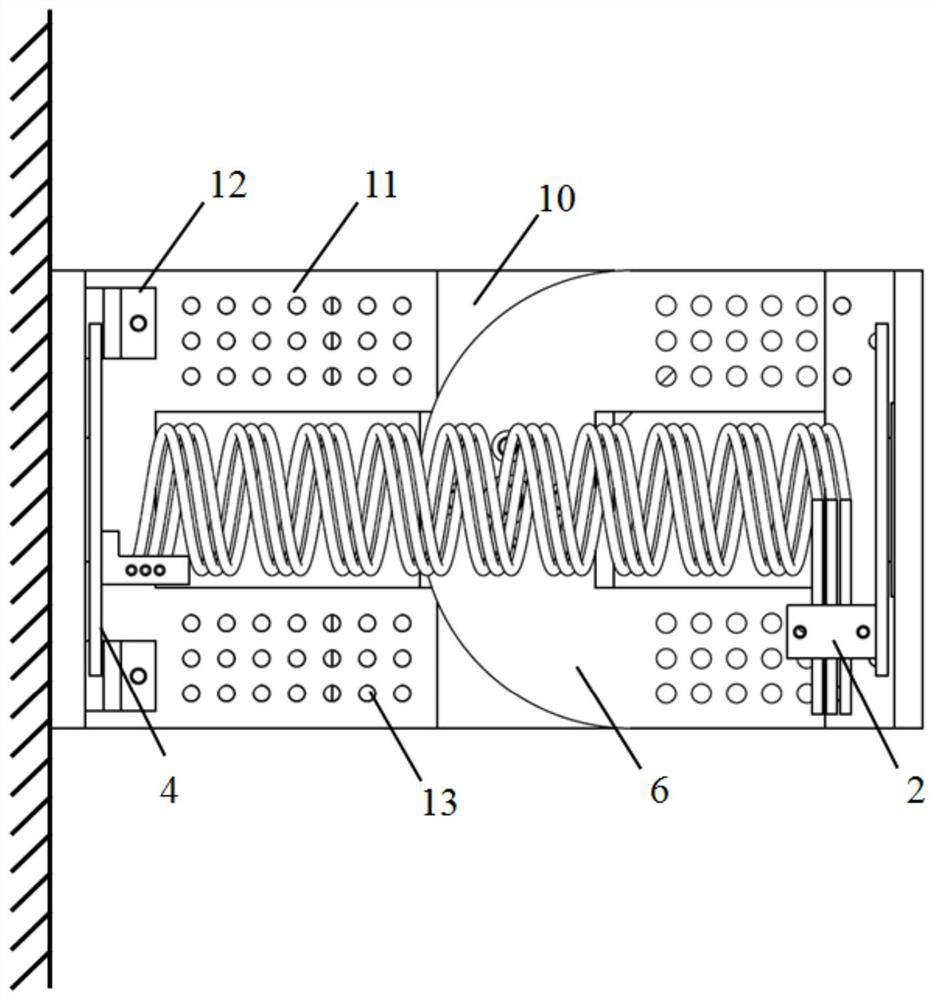

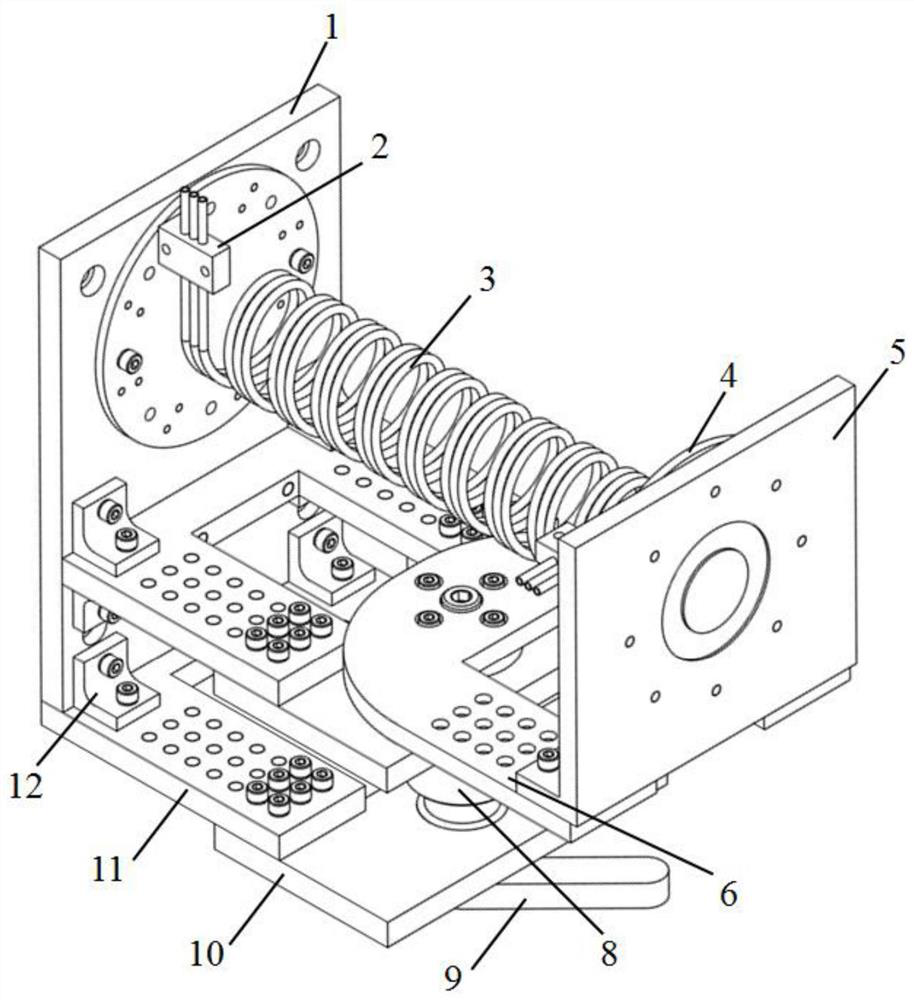

Method for automatically cleaning tools and measuring lengths of tools on line

The invention discloses a method for automatically cleaning tools and measuring lengths of the tools on line, and belongs to the technical field of machine tool clamps. A device is additionally arranged on a numerical-control machine tool, so that in a using process, the numerical-control machine tool can be matched with existing tools of a tool magazine to be equipped with all tools to start processing a part after programming is completed once workpieces are clamped; and a tool setting long instruction is added during primary processing. All the tools are cleaned under high pressure to ensure the effect that scrap iron bonding is avoided, so that built-up edge production probability is also reduced. Tool data measurement is accurate, and interferences of artificial factors are avoided. The method is suitable for high-quality efficient production.

Owner:SHAANXI AVIATION ELECTRICAL

Bourdon tube torque measuring device and test method thereof

ActiveCN113176027ASave resourcesAccurate data measurementMachine part testingForce sensorsRotary stageStructural engineering

The invention provides a bourdon tube torque measuring device and a test method thereof. The bourdon tube torque can be measured through the adjustable torque measuring device, and the bourdon tube torque measuring device comprises a bourdon tube, a base, a rotating table, supporting plates, a clamp, a torque sensor, a rotating shaft, a handle, a clamp seat, a screw, a spring washer and a flat washer; the bottom base is fixed on a vertical table top; the bourdon tube is fixed on the rotating table through the clamp, the rotating table is in bearing fit with the base, the bottom base is respectively connected with the two upper supporting plates and is fixed through the clamp seat, two ends of a torque sensor shaft are connected with the rotating shaft through keys, two ends of the rotating shaft are respectively in bearing fit with the two lower supporting plates, and the upper supporting plates and the lower supporting plates are connected through screws. A top base is connected to one end of the rotating shaft through the horizontal supporting plate, and the other rotating shaft is connected with the handle. According to the invention, a solution is provided for measuring the torques of bourdon tubes with different models and specifications and different angle directions; and data measurement is accurate, operation is easy and convenient, the overall structure is simple, and needed hardware resources are fewer.

Owner:SHANGHAI SATELLITE ENG INST

A quality detection device for door and window gauze and its application method

ActiveCN104655444BEasy to set upThe test results are close to the realStructural/machines measurementDrive motorEngineering

Owner:常州常工院技术转移有限公司

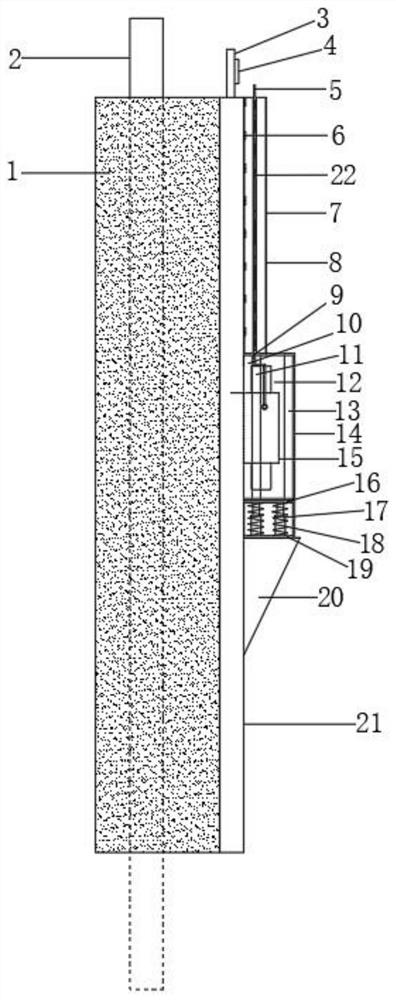

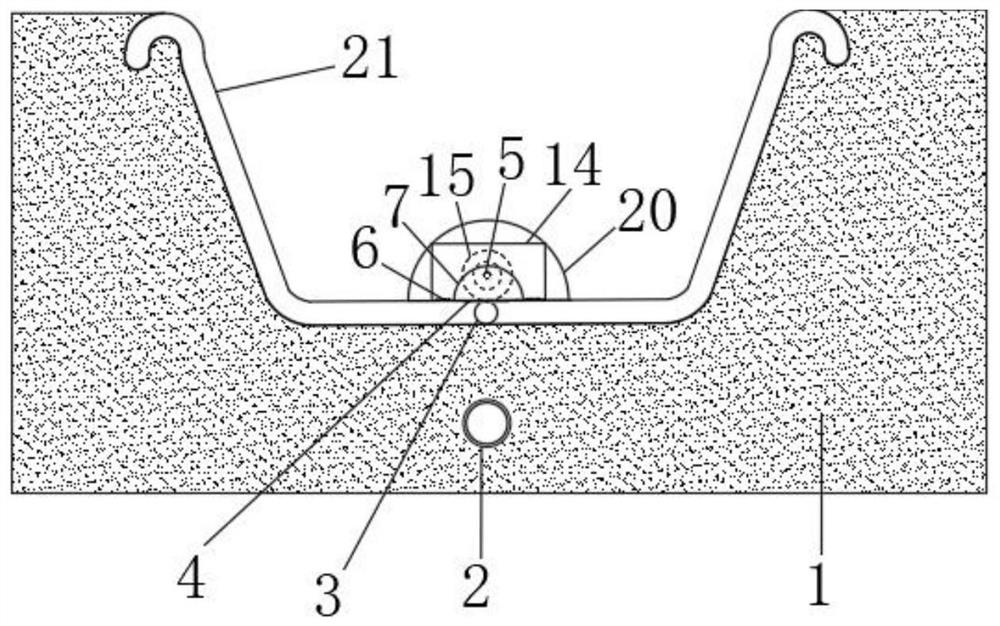

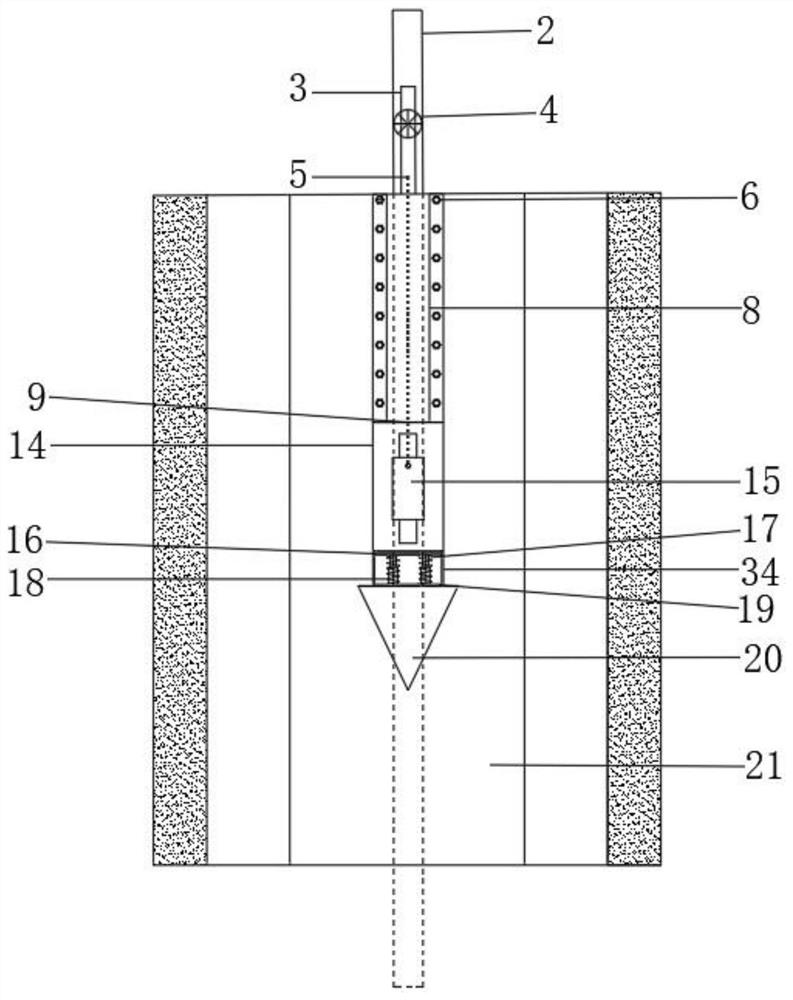

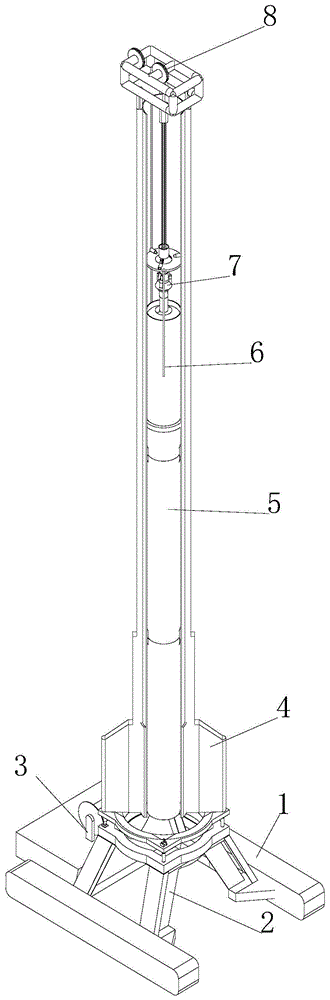

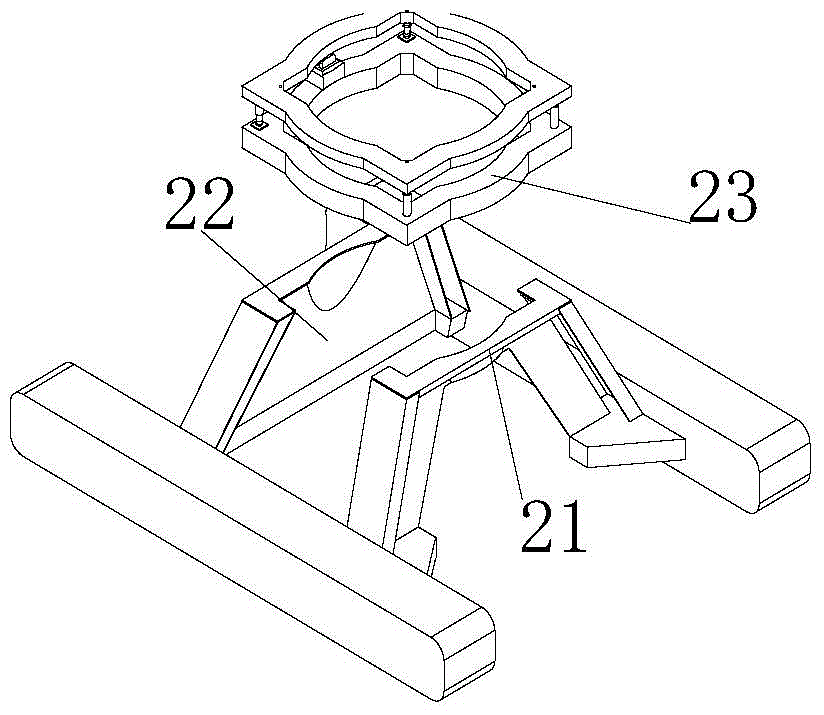

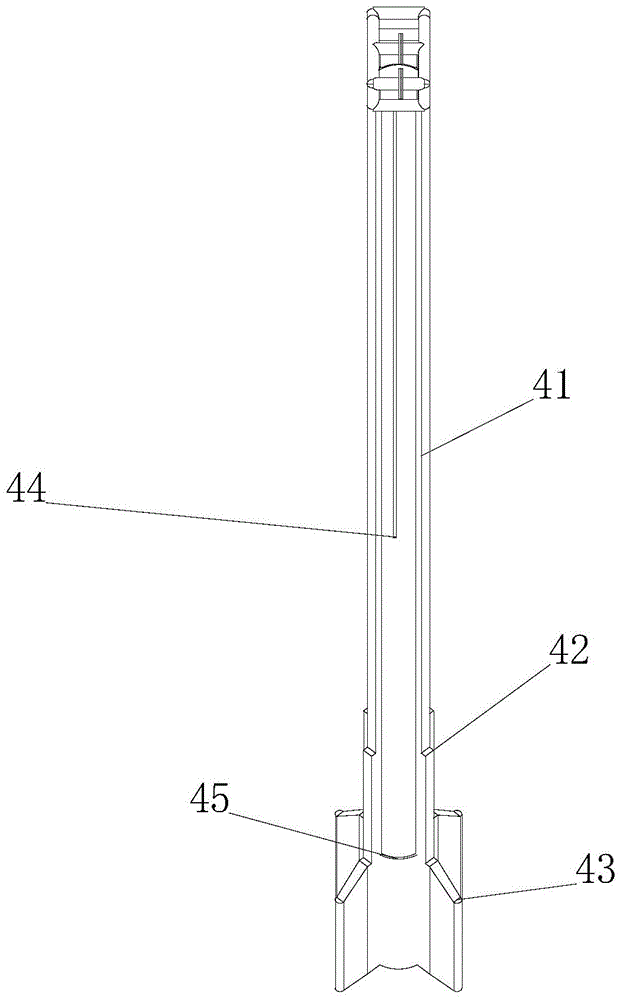

Novel dynamic compactor and composite foundation construction method achieved through novel dynamic compactor

The invention discloses a novel dynamic compactor and a composite foundation construction method achieved through the novel dynamic compactor. The novel dynamic compactor comprises a leveling base. A main rod and a hoisting device are arranged on the leveling base. The novel dynamic compactor is of a cylindrical hollow structure. An internally-arranged rammer is arranged in the main rod. The top of the internally-arranged rammer is connected with a mooring rope through a hook device. The mooring rope is wound around a fixed pulley at the top of the main rod to be connected to the hoisting device. The composite foundation construction method includes the steps of arrangement of point locations according to a construction drawing, arrangement of sand wells, dynamic compaction construction in holes, large-energy-level dynamic compaction, full compaction on a whole construction plant and the like. The novel dynamic compactor has the beneficial effects that data are accurately measured, abrasion is small, and service life is long; the internally-arranged rammer in a segmented manner is adopted, and the rammer is long and thin; and the height is increased, and the ramming energy is improved. The construction method has the beneficial effects that construction energy losses are small, and the reinforcement effect is good.

Owner:SICHUAN JIUDINGZHIYUAN INTPROP OPERATIONS CO LTD

Measuring and cleaning device suitable for microelement detection

InactiveCN103149266AWash thoroughlyAvoid influenceHollow article cleaningMaterial electrochemical variablesVacuum pumpElectromagnetic valve

The invention discloses a measuring and cleaning device suitable for microelement detection and belongs to polarographic chemical analysis and measuring equipment. The measuring and cleaning device suitable for the microelement detection comprises a polarogram measuring disc containing measuring cups, a polarogram electrode and a reagent adding device, wherein the polarogram electrode and the reagent adding device are arranged above the polarogram measuring disc. The measuring and cleaning device suitable for the microelement detection is characterized in that a measuring cup A, a measuring cup B and a measuring cup C are tightly arranged on the same arc which takes a center of the polarogram measuring disc as a center, bottoms of the measuring cups respectively pass through an electromagnetic valve A, an electromagnetic valve B and an electromagnetic valve C to be connected with a sealed communication machine through a guide pipe, a pipeline of the bottom of the communication machine passes through an electromagnetic valve of a waste liquid barrel and is connected with the waste liquid barrel, a plunger vacuum pump is connected with the communication machine, and a stepping motor is arranged below the polarogram measuring disc. The measuring and cleaning device achieves the aim that reagent waste liquid and cleaning waste liquid are collected into the waste liquid barrel under a full-sealing state, and overcomes the defects that in the prior art, mercury volatilizing is easily caused by waste liquid to cause polluting, and cleaning is not easily controlled.

Owner:山东美医林电子仪器有限公司

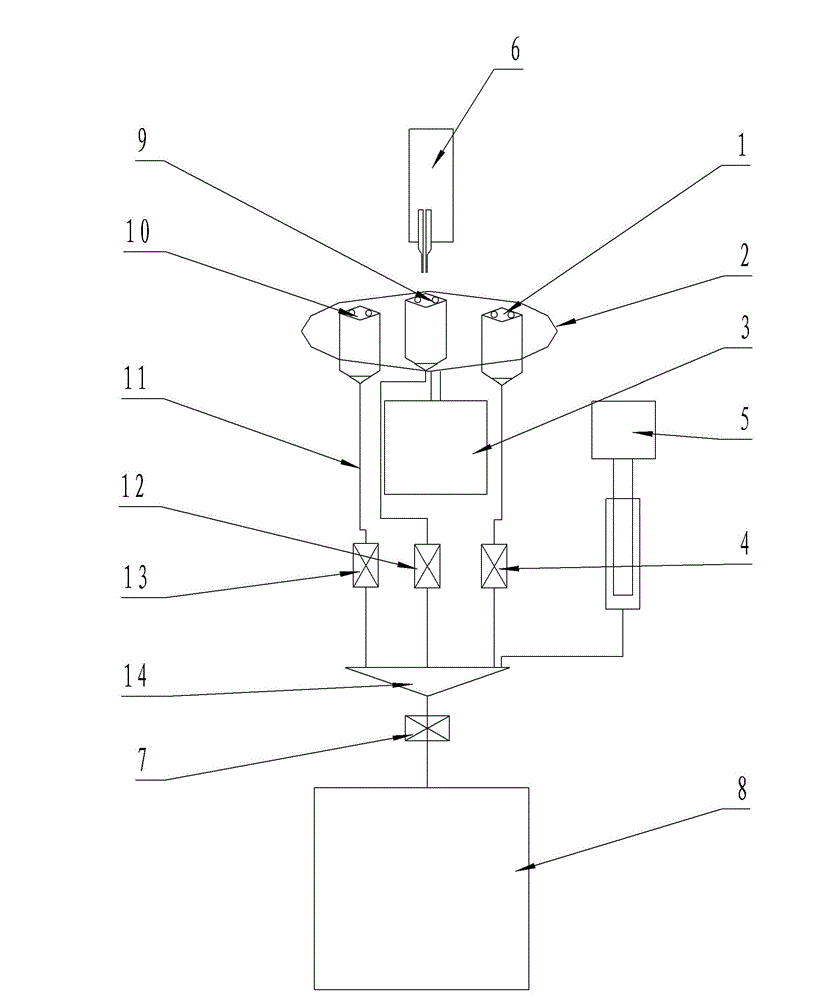

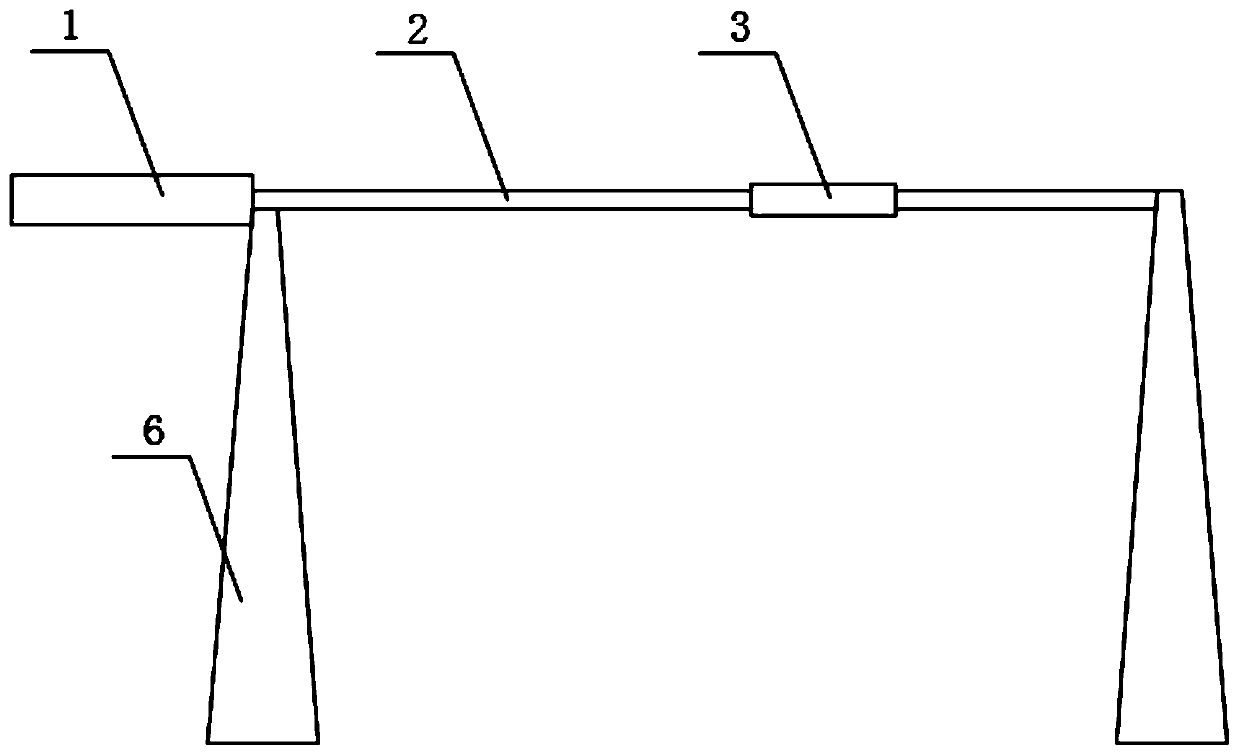

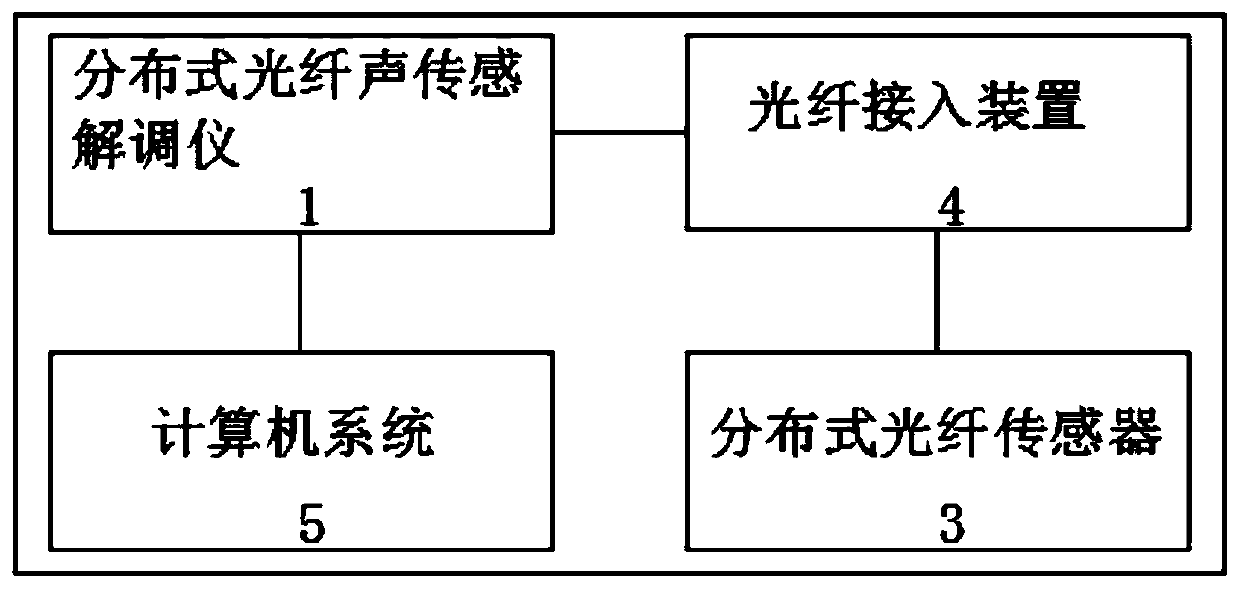

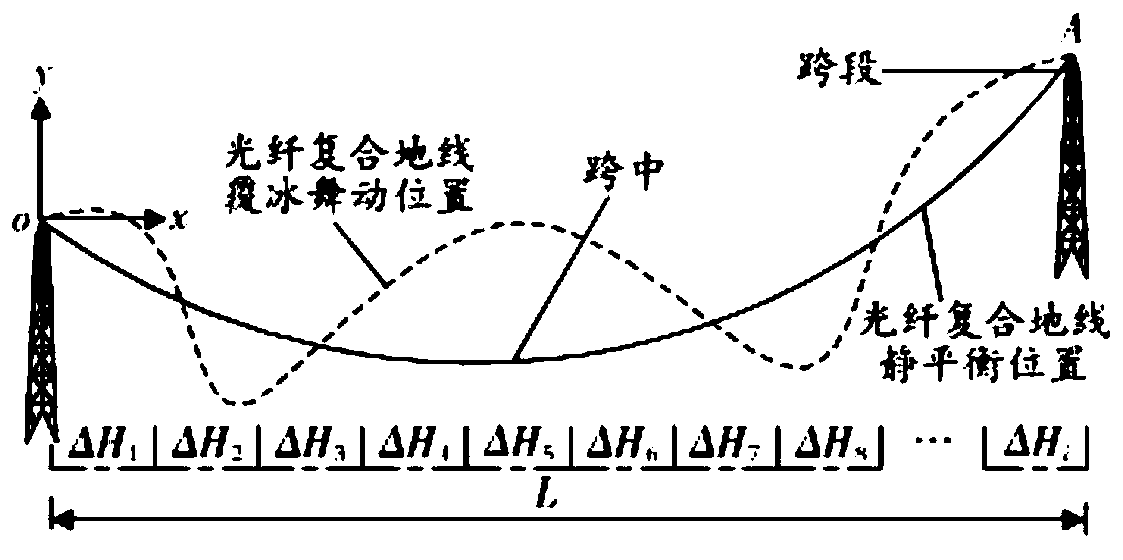

Power transmission line optical fiber composite ground wire icing state monitoring system

PendingCN111189485ALife restrictionImprove stabilityConverting sensor output opticallyRayleigh scatteringTransmission tower

The invention discloses a power transmission line optical fiber composite ground wire icing state monitoring system. The system comprises a distributed optical fiber acoustic sensing demodulator whichis used for transmitting an optical pulse and performing phase demodulation on the reflected Rayleigh scattering light; an optical fiber composite ground wire; a distributed optical fiber sensor which is used for monitoring the strain parameters of each measurement point of the optical fiber composite ground wire; a computer system which is used for receiving the strain parameters, sent by the distributed optical fiber acoustic sensing demodulator, of each measurement point of the distributed optical fiber sensor; a power transmission tower. According to the power transmission line optical fiber composite ground wire icing state monitoring system, no power supply unit exists, the service life of a monitoring device is not limited by the severe environments, and the device stability is high; the internal optical fibers of an OPGW optical cable erected on a line are used as the sensing optical fibers; meanwhile, no extra communication cost exists, and the information security is high; light is used as a sensing medium, the electromagnetic interference is resisted, and the data measurement is accurate; the system is long in monitoring distance, and is in distributed monitoring.

Owner:重庆东电通信技术有限公司

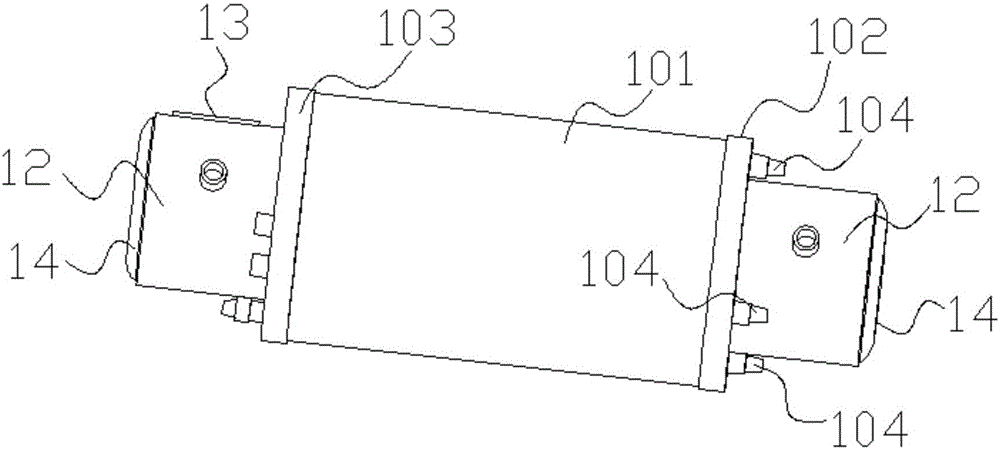

GIL post insulator bursting fault simulation test platform and measurement method

PendingCN112130041AComprehensive observationAccurate data measurementTesting using acoustic measurementsMeasurement instrument housingComputational physicsUltrahigh frequency

The invention discloses a GIL post insulator bursting fault simulation test platform and a measurement method. The platform is characterized in that a GIL test cavity is divided into a left cavity anda right cavity by a gas insulation spacer; the left cavity and the right cavity are respectively provided with a gas-pressure meter and a gas charging and discharging port; the left cavity is connected with a lead-out bushing through a flange; the right cavity is provided with an observation window for observing the bursting process of a GIL post insulator and a detection device for recording thebursting process of the GIL post insulator; and the detection device mainly comprises a temperature detection device, an ultrasonic partial discharge detection device, an ultrahigh frequency partialdischarge detection device, and an SF6 gas decomposition product detection device. By adopting the GIL post insulator bursting fault simulation test platform, while the bursting process of the post insulator is observed, parameters such as the temperature, the partial discharge amount and the vibration of the post insulator are continuously measured at different moments, and a multivariate statistical analysis method is applied to establish an operation correlation matrix to analyze the autocorrelation of each characteristic parameter.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

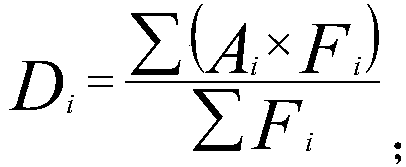

Method for determining blending ratios of milk protein modified polyacrylonitrile fibers to wools

PendingCN109580622APhysical health benefitsThe test process is environmentally friendly and harmlessMaterial analysis by optical meansThird partyAnimal science

The invention discloses a method for determining blending ratios of milk protein modified polyacrylonitrile fibers to wools. The method comprises the steps of: preparing a sample by using a loading appliance for clamping; observing a micro slide body loaded with the sample under a microscope; and respectively recording the total numbers and diameters of milk protein modified polyacrylonitrile fibers and wools in a circular hole, so as to calculate a fiber mass percentage of the components. The method is capable of obtaining results without knowing the content (k value) of milk protein in the milk protein modified polyacrylonitrile fibers, thereby filling the gap of quantitative test method for fiber blending ratios of textiles, providing convenience for third-party laboratories and providing a practicable method for market supervision. The method is a physical test method, so that the whole test process is environment-friendly, harmless and beneficial for the environment and the body health of the inspectors. The test period of the method is about 3 hours, so that the test period is greatly shortened and the detection efficiency is improved.

Owner:镇江市产品质量监督检验中心

Tool clamp and surface roughness test device

PendingCN111085956AHigh precisionReduce labor intensityMeasurement devicesWork holdersPhysicsEngineering

The invention relates to a tool clamp and a surface roughness test device. The tool clamp comprises a fixed base, a rotating base, a driving mechanism and a clamping mechanism. The rotating base is rotatably mounted on the fixed base, the driving mechanism is arranged on the rotating base and is used for driving the rotating base to rotate relative to the fixed base, the clamping mechanism at least comprises three clamping arms and a transmission assembly, the clamping arms are in rotatable connection with the rotating base through the transmission assembly, the clamping arms can synchronouslyand mutually rotate to be close to each other or rotate to be away from each other, when buttons needed to be clamped and fixed are different in size, amplitudes, for rotating to be away from each other, of the clamping arms only need to be correspondingly adjusted, the areas between the clamping arms can be adjusted, it is ensured that the buttons can be placed between the clamping arms, the clamping and fixing needs can be met, and adaptation is high.

Owner:广东康派环创科技有限公司

Experimental device for iron ore pellet roasting process

The invention relates to an experimental method and a device for an iron ore pellet roasting process, belonging to the field of iron manufacture production. In order to research the iron ore pellet roasting process in terms of heat transfer, mass transfer, a roasting process mechanism, and the like, the invention discloses the experimental method and the device, wherein the device comprises a gastank, a draft blower, a combustion chamber, a roasting chamber, a smoke exhaust hood, an electronic balance, a PLC system, an industrial computer, a roasting cup, an electromagnetic disconnecting valve, an electrically operated valve, a manual control valve, a pressure gauge, a flow meter, a thermometer, a gas pipeline, an air pipeline, a combustion chamber high-temperature thermocouple, a roasting chamber high-temperature thermocouple, an annular pressure meter, a burner nozzle subassembly, a secondary air annular nozzle, a smoke gas collection hole, a smoke exhaust pipeline, an exhaust blower, a suspension fork, and the like. The device generates smoke gas with different flow speeds, different temperatures and different gases to roast a pellet material layer in a flow-through way, measures and collects relative data, especially the inner temperature distribution of the pellet material layer, and provides important experiment evidence for the theoretical research and the actual production of the pellet roasting mechanism.

Owner:UNIV OF SCI & TECH BEIJING

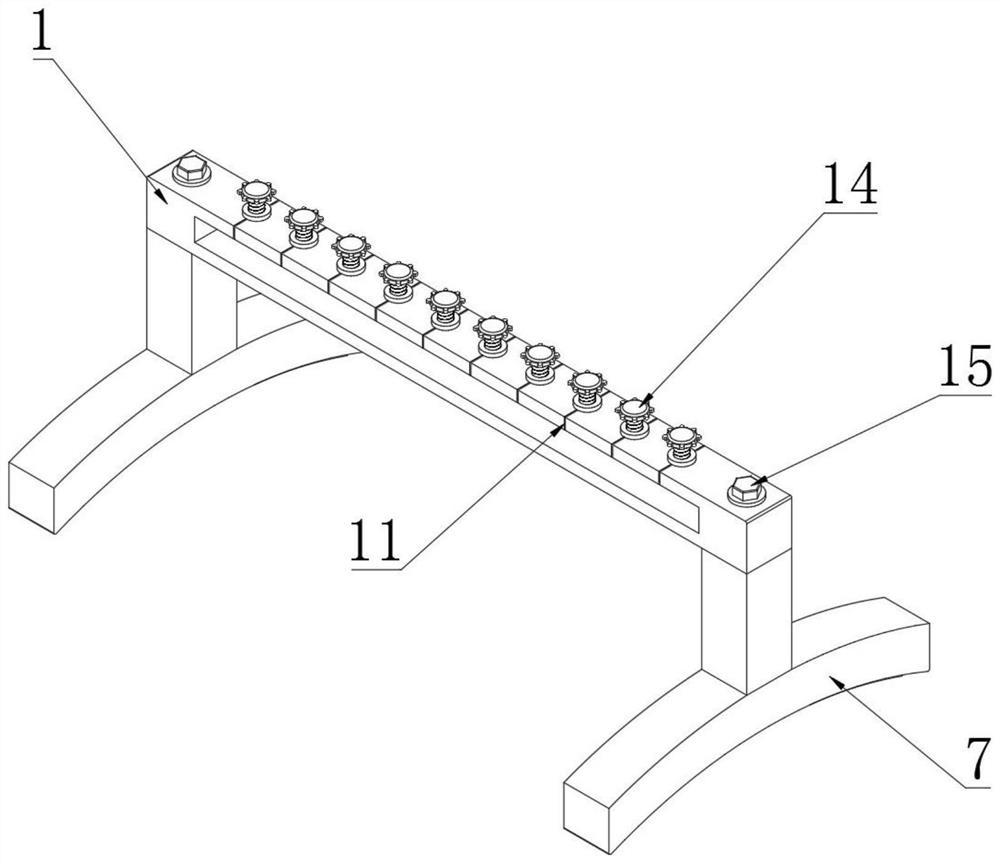

Device for measuring surface shape tolerance of curved surface lining plate of cylindrical surface steel support

PendingCN113091574AEasy to detectHigh measurement accuracyMechanical counters/curvatures measurementsEvaluation resultSample Measure

The invention discloses a device for measuring the surface shape tolerance of a curved surface lining plate of a cylindrical surface steel support, a transverse sliding groove for a longitudinal supporting plate to slide is transversely formed in a transverse supporting frame, connecting holes are formed in the longitudinal supporting plate and located on the two sides of the transverse supporting frame in a penetrating mode, and dial indicators are inserted into the four connecting holes in an embedded mode, and support columns are vertically connected to the bottom ends on two sides of the transverse supporting frame, compared with a traditional sample plate method with a fixed reference, the reference of the measurement method of the device can be changed along with a measured sample, the evaluation result is more convincing during batch measurement in a factory, and compared with a three-coordinate measurement method, although the detection precision is lower than that of the three-coordinate measurement method, however, the device is better in detection convenience, suitable for large-scale measurement and not suitable for samples measured by a traditional two-point method and a three-point method, and the method can be adopted for non-whole cylinders such as semi-cylinders, so that the device can be suitable for measurement of different measurement samples.

Owner:中铁检验认证中心有限公司 +1

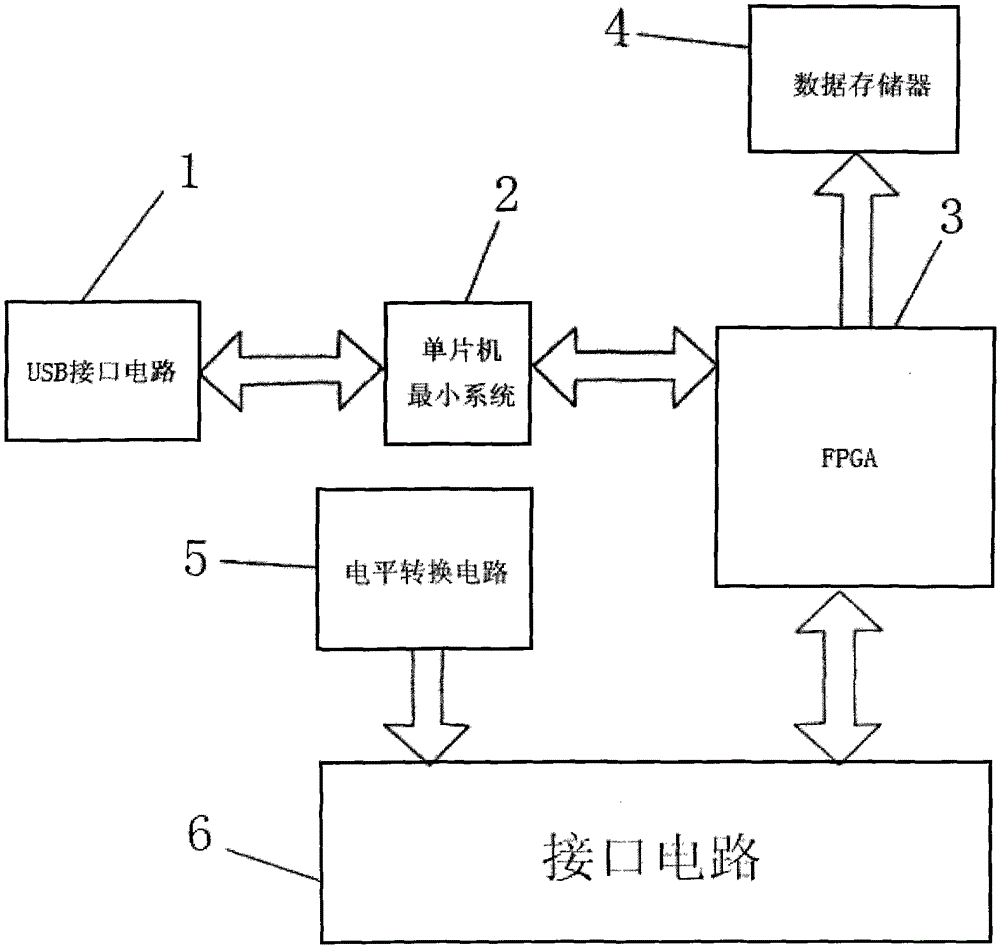

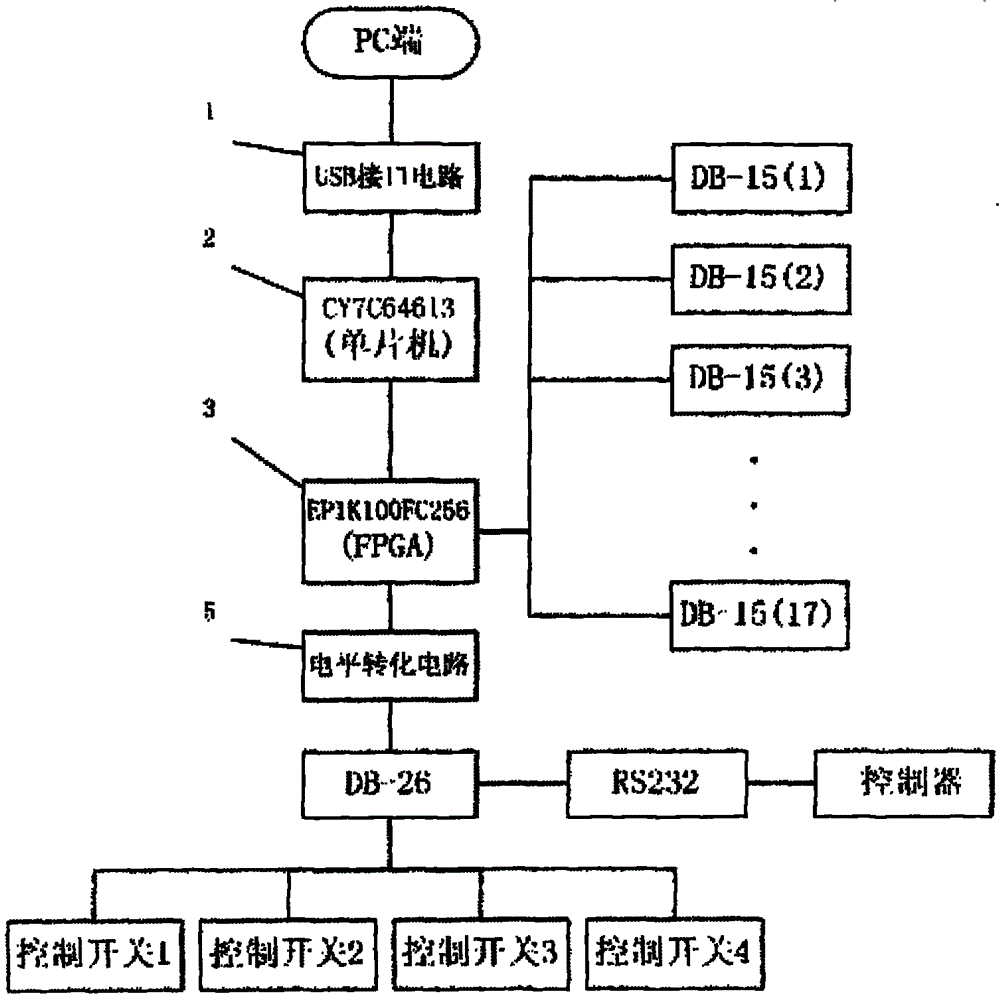

usb probe controller

ActiveCN103885361BEasy to controlAccurate data measurementProgramme controlComputer controlMicrocontrollerControl signal

The invention discloses a USB probe controller which comprises a USB data interface, a single-chip microcomputer, an FPGA, a data storage device, a level conversion circuit, an interface circuit and a peripheral power supply circuit. The interface circuit is respectively connected with a probe controller body, a radio frequency switch circuit and an electronic switch circuit, the USB data interface receives external computer control signals and transmits the external computer control signals to the single-chip microcomputer, the single-chip microcomputer processes and converts the signals into level signals capable of being directly read by the FPGA, the FPGA receives the signals and respectively inputs control signals into the interface circuit or into the interface circuit through the level conversion circuit according to needs, and therefore the radio frequency switch circuit can be switched on and off, and probes can be controlled. According to the USB probe controller, the probes and a plurality of radio frequency interfaces can be controlled, rotation of the probes in a testing system and on-off of the radio frequency interfaces can be directly controlled through a simple and clear desktop application program in a computer, and therefore easy control and more accurate data measurement can be achieved.

Owner:SUNYIELD TECH CO LTD

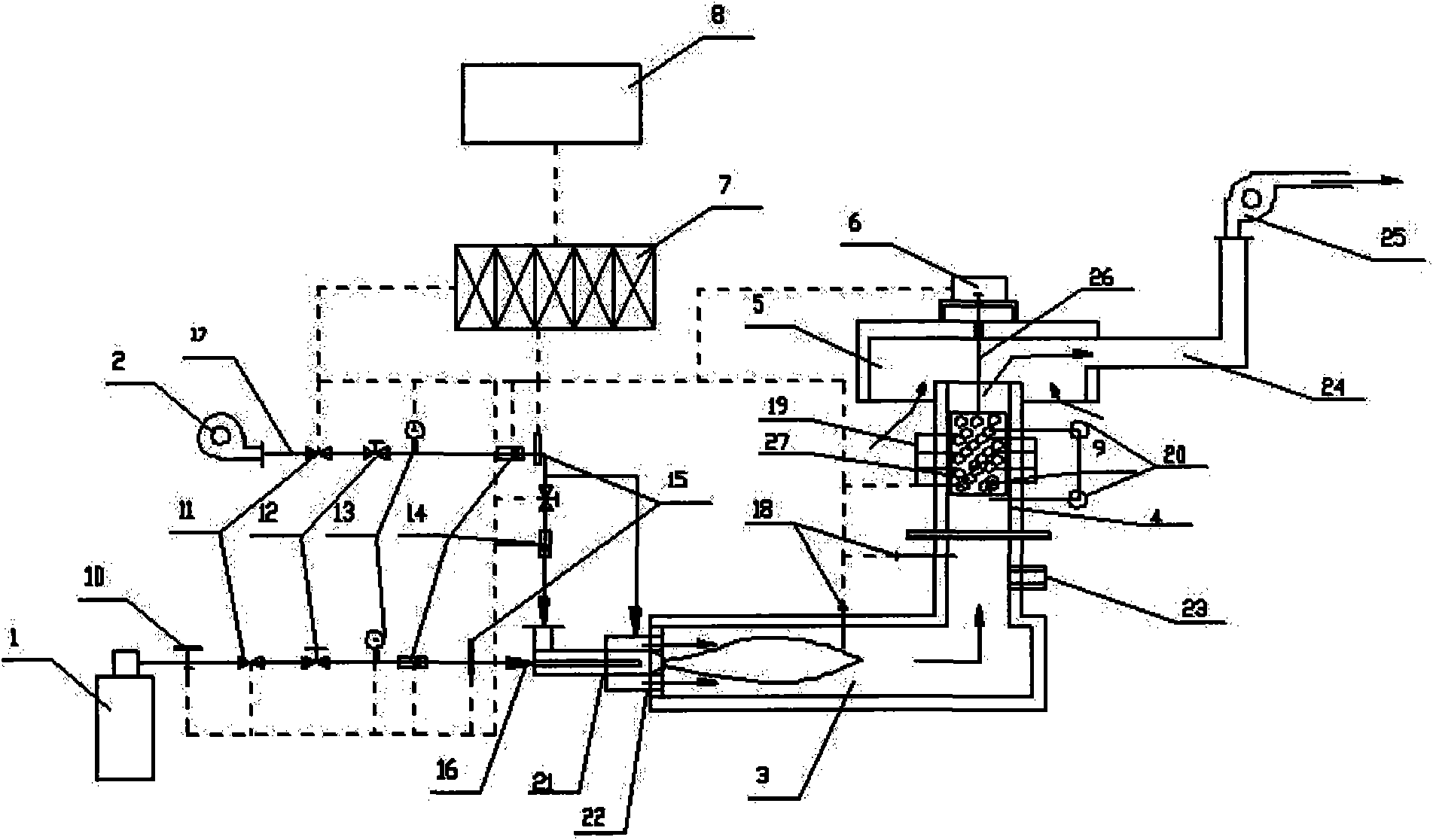

A test device for fire resistance performance of building vertical partition members under water spray protection

ActiveCN104266924BIncrease water spray test functionHigh degree of automationStrength propertiesVideo monitoringAutomatic control

The invention discloses a fire resistance test device for a vertical building partition component in water-spraying protection. The fire resistance test device consists of a device body and smoke exhaust system, a fuel gas heating system, a water supply system, a water draining system, a data measurement and automatic control system, a video monitoring system and a computer, wherein the device body and smoke exhaust system comprises a furnace body, a flue, a chimney and a furnace door; the fuel gas heating system comprises a liquefied petroleum gas tank, a gasifier, an oil-water separator and a burner; the water supply system comprises a water pump, a valve and a spray head; the data measurement and automatic control system comprises a data acquisition controller, a thermocouple, a pressure sensor, a flow sensor, a differential pressure transmitter, a heat flow meter, a temperature controller, a flue regulator and a strain gauge. The fire resistance test device has the advantages as follows: through a unique structure, a water distribution difficulty of the fire resistance test device at high temperature is overcome for the first time in China; the fire resistance test device is safe, high in reliability and accurate in data measurement, can run continuously for a long time, and has a far-reaching guiding significance for a fire protection design technology and an engineering application technology of buildings in China.

Owner:应急管理部天津消防研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com