Experimental device and method for iron ore pellet roasting process

An experimental device and roasting technology, which is applied in the field of ironmaking production, can solve problems such as difficult on-site experimental research on iron ore pellet roasting process, difficult thermal data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

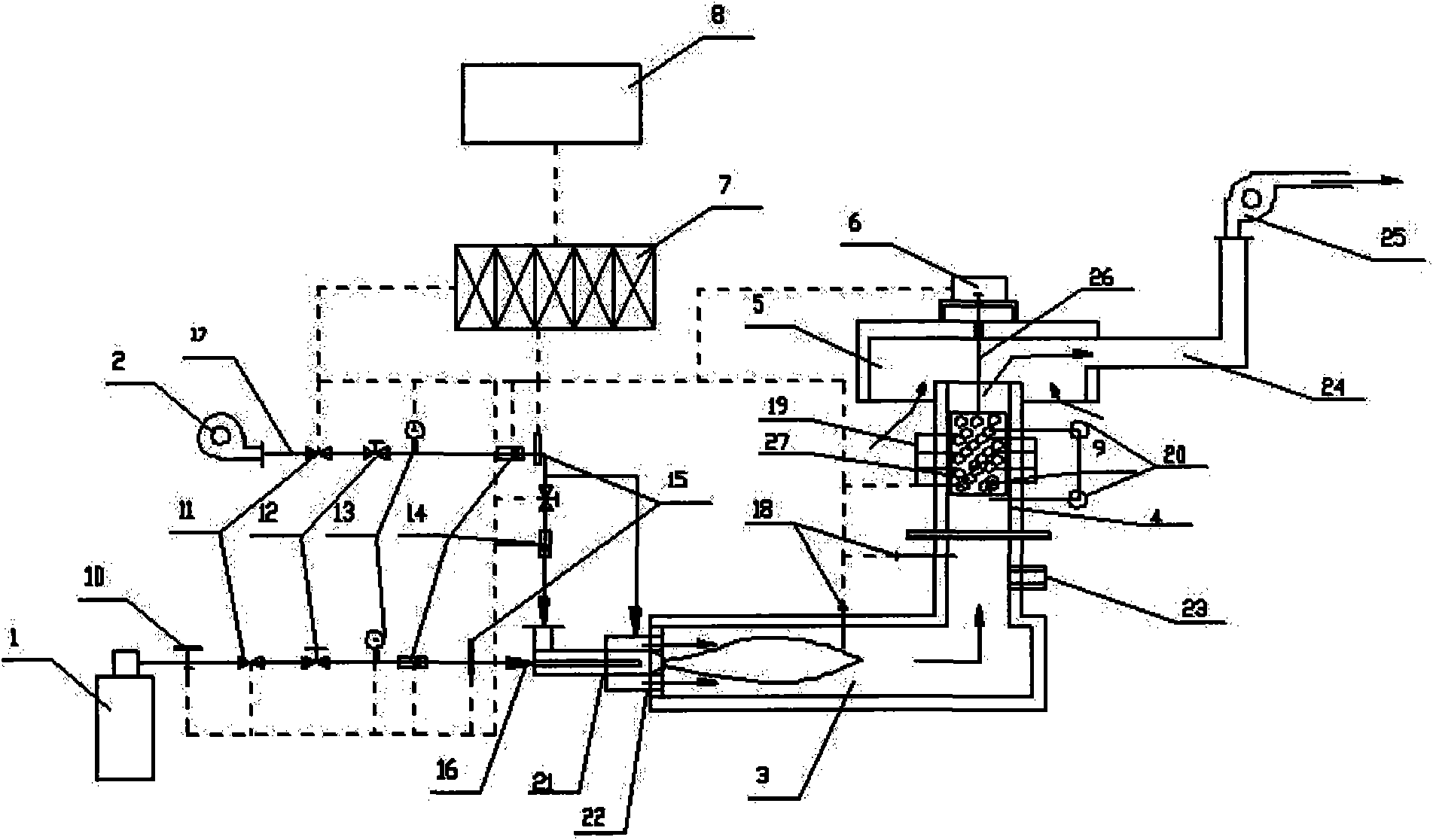

[0021] An experimental device for studying the roasting process of iron ore pellets, consisting of a combustion system, a roasting system, a PLC control system, a data measurement and acquisition system, and a smoke exhaust section, including the following components: gas tank 1, frequency conversion blower 2, combustion chamber 3 , roasting chamber 4, exhaust hood 5, electronic balance 6, PLC system 7, industrial computer 8, roasting cup 9, electromagnetic stop valve 10, electric control valve 11, manual control valve 12, pressure gauge 13, flow meter 14, thermometer 15. Gas pipeline 16, air pipeline 17, combustion chamber high temperature thermocouple 18, roasting chamber high temperature thermocouple 19, annular pressure gauge 20, burner assembly 21, secondary air annular nozzle 22, flue gas collection hole 23, smoke exhaust Pipeline 24, exhaust fan 25, suspension 26, pellet 27.

[0022] 1. The roasting chamber 4 controlled by a swivel arm can move on the experimental platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com