Bourdon tube torque measuring device and test method thereof

A torque measurement and spring tube technology, applied in the field of spring tube torque measurement devices, can solve the problems of waste of resources, non-universal use, poor economic benefits, etc., and achieve the effects of simple overall structure, improved use efficiency, and accurate data measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several changes and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

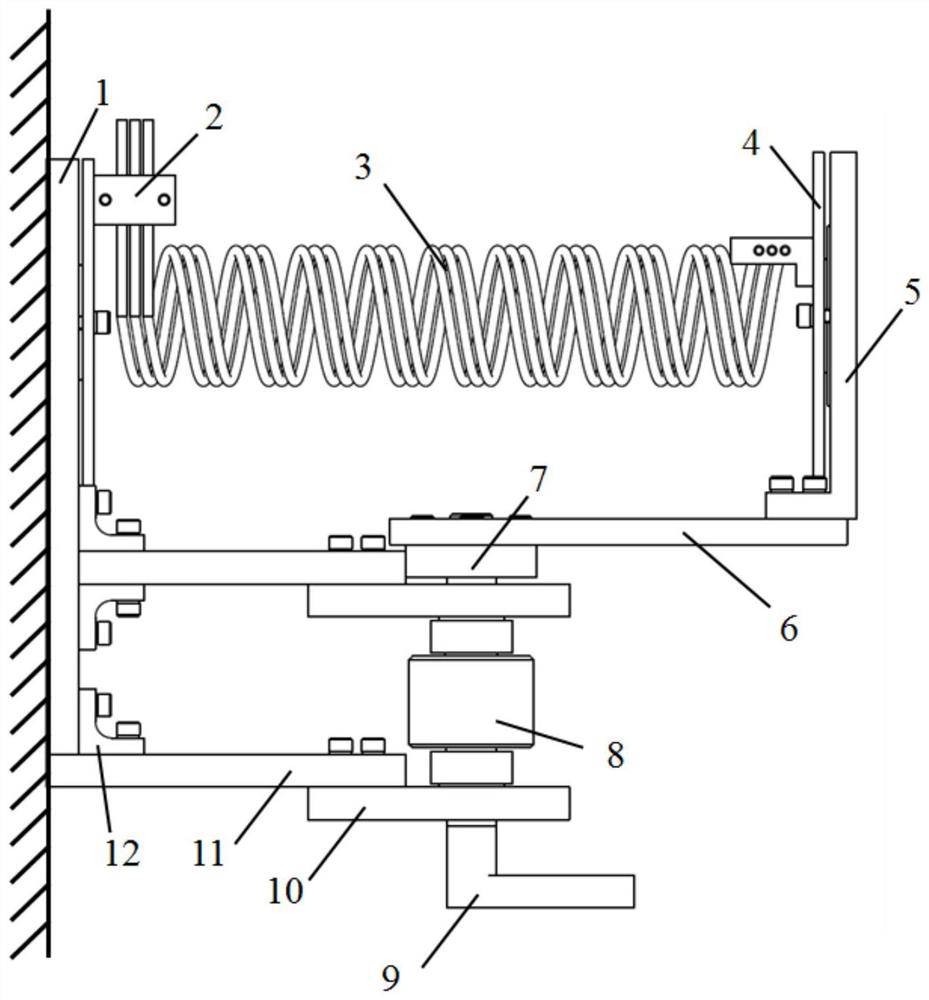

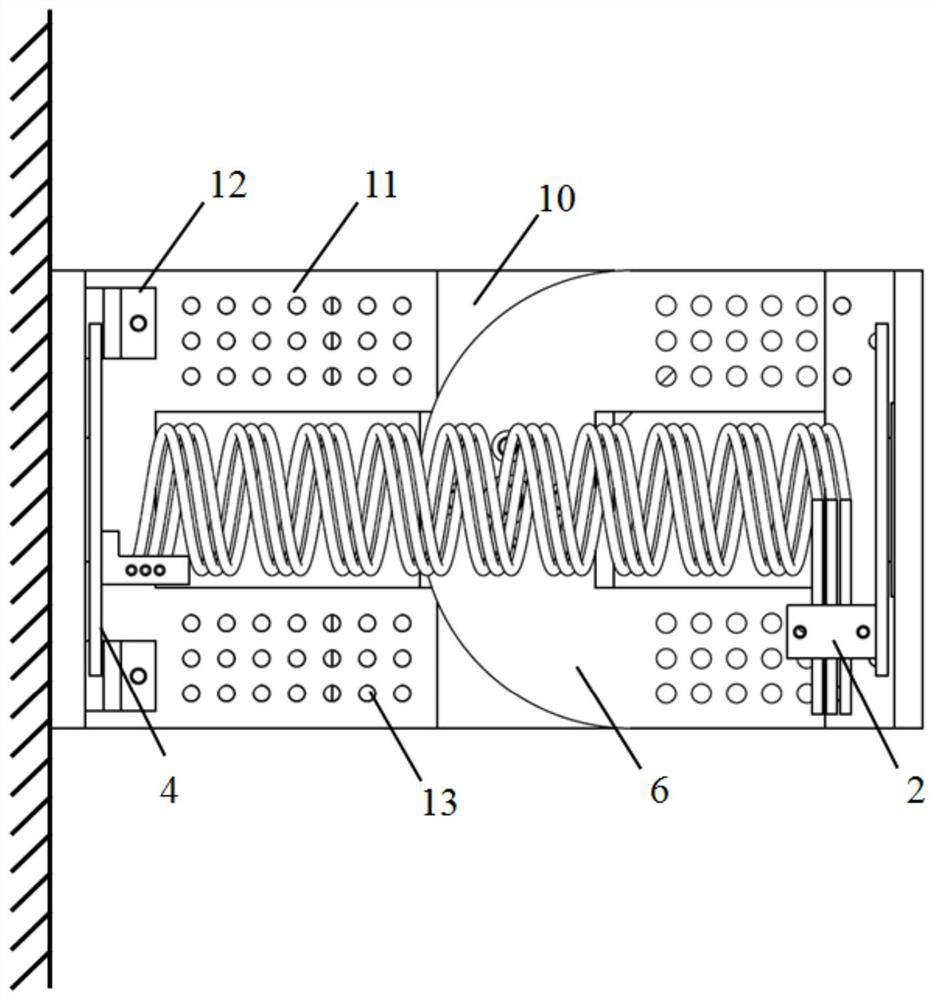

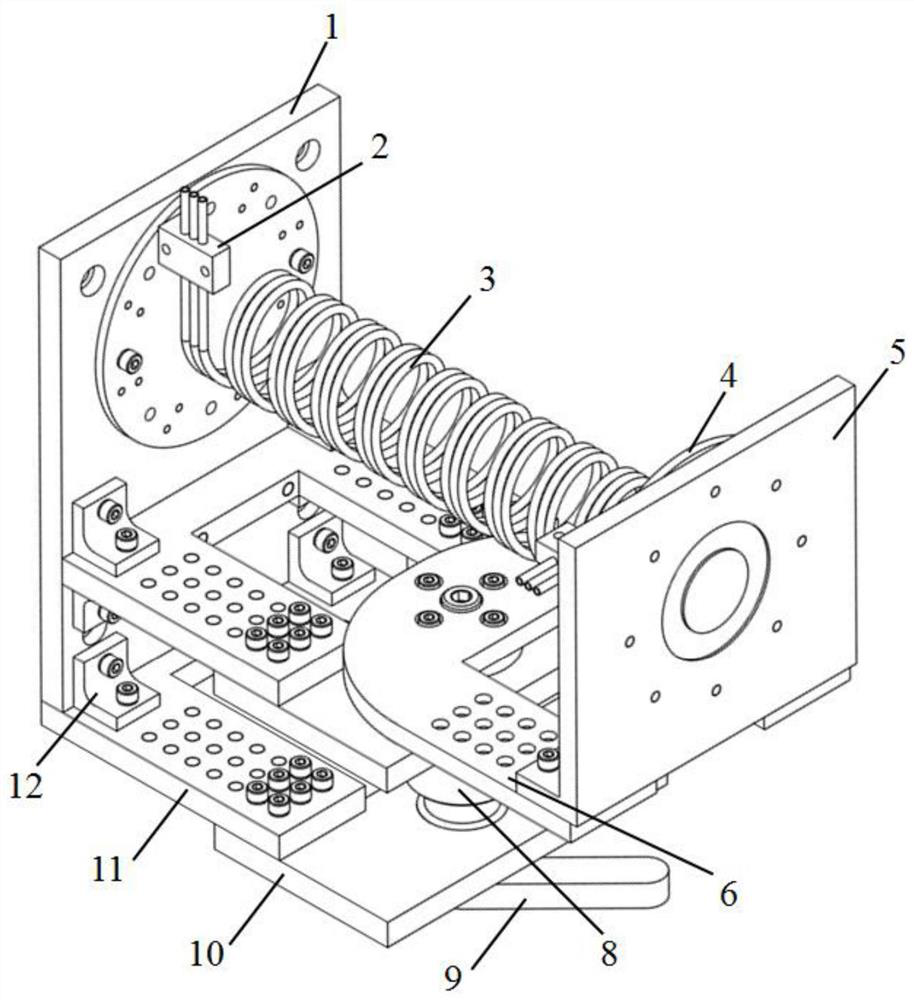

[0031] Such as Figure 1 to Figure 3 As shown, a spring tube torque measuring device and its test method of the present invention, the mechanism includes a bottom base 1, a clamp 2, a spring tube 3, a rotating table 4, a top base 5, a horizontal support plate 6, a rotating shaft 7, a torque Sensor 8, handle 9, lower support plate 10, upper support plate 11, deck 12, screw 13. The bottom base 1 is fixed on the vertical table, and the spring tube 3 is fixed on the turntable 4 through clamping 2. The turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com