Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Easy and efficient measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

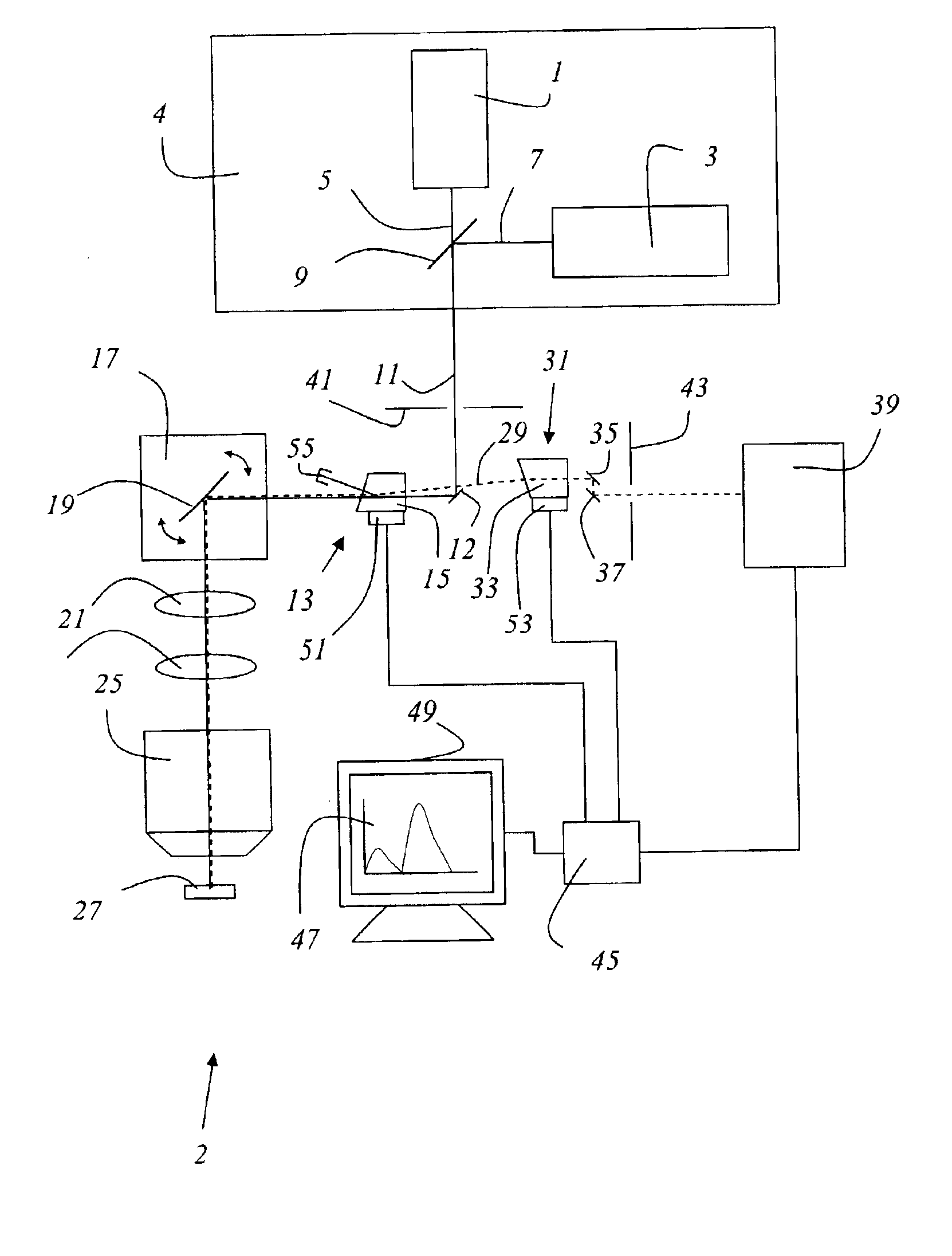

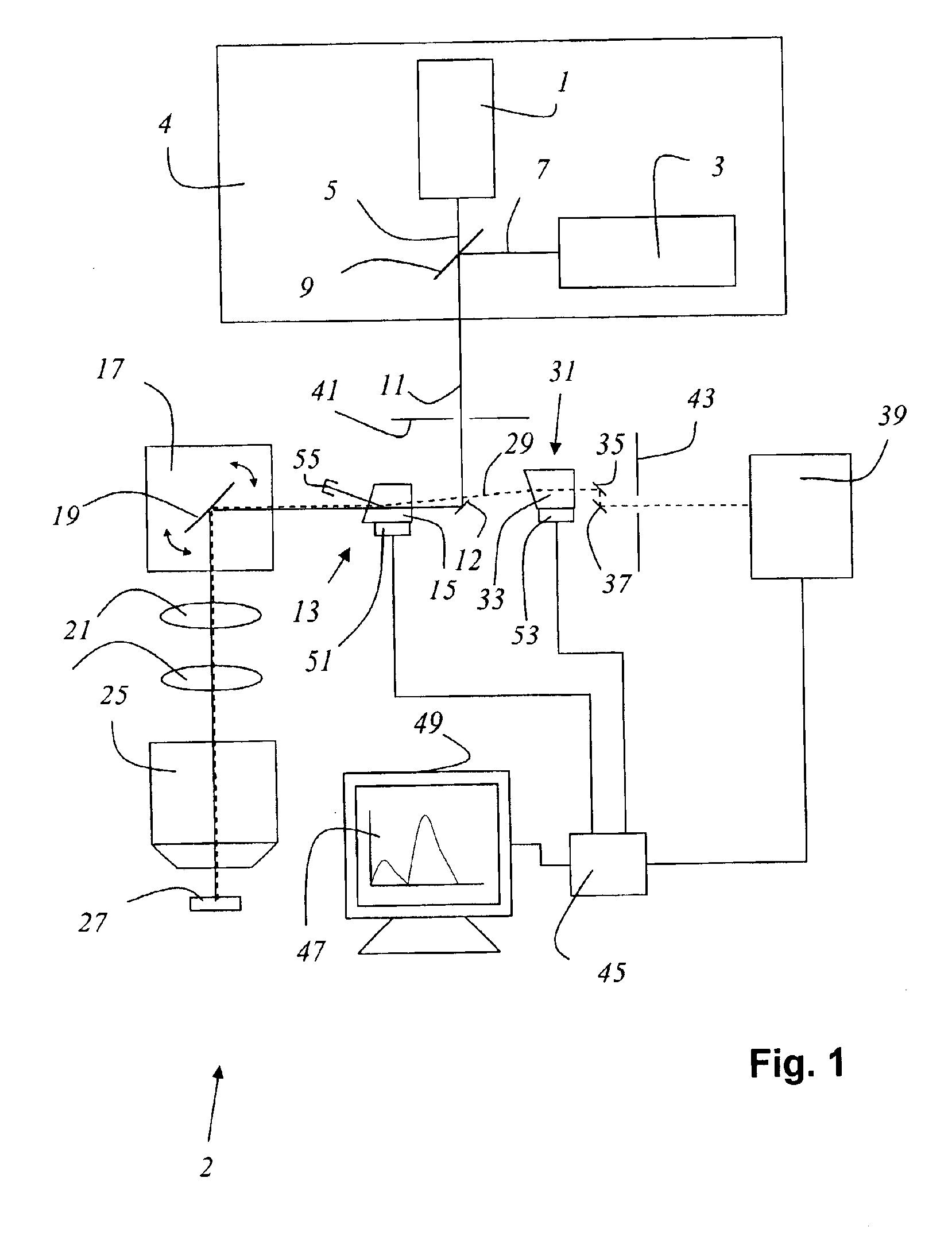

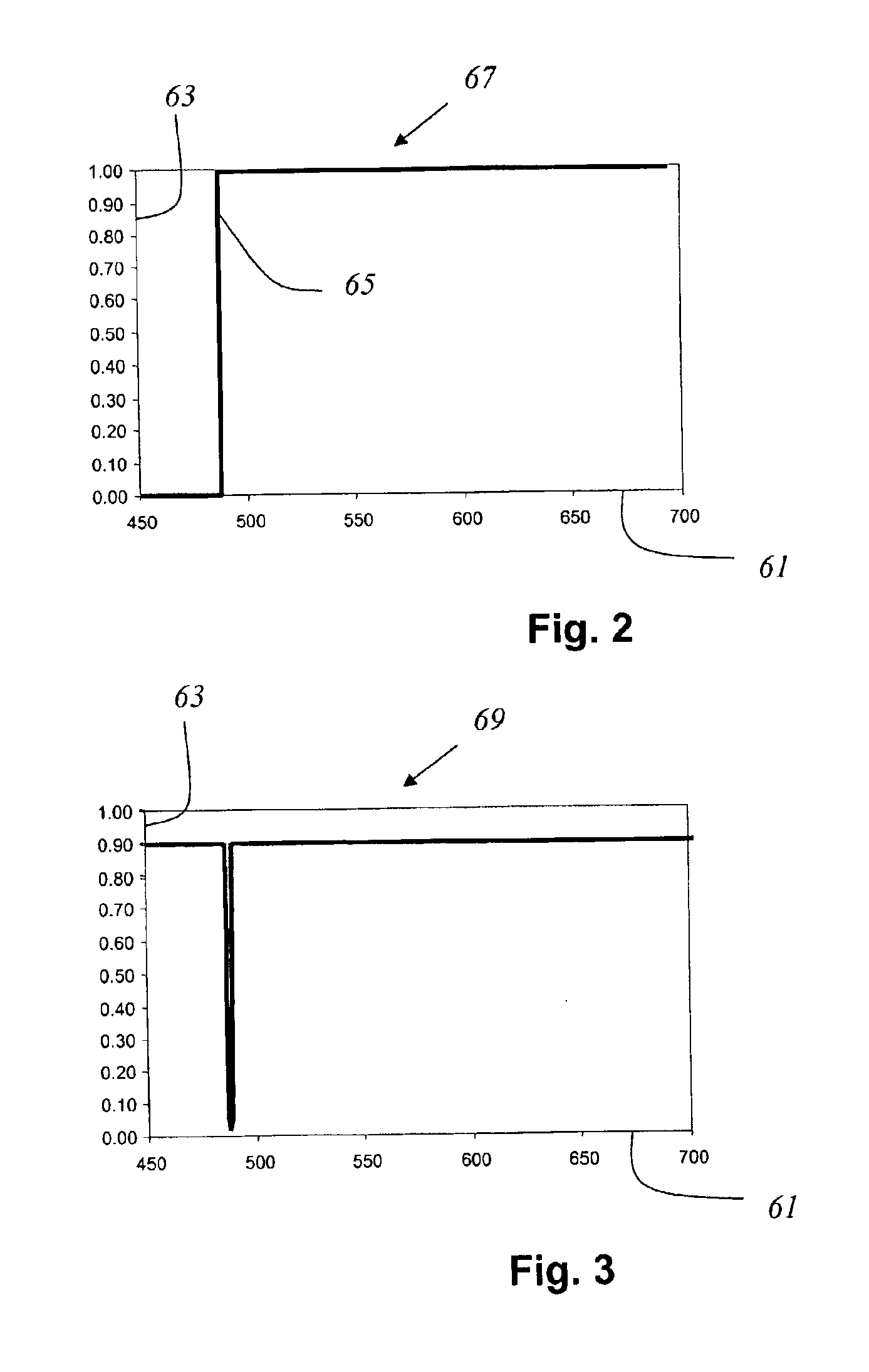

Microscope, flow cytometer, and method for examination of a specimen

InactiveUS6867899B2Quick switchAvoid large gapsMicroscopesNon-linear opticsAcousto-opticsSpectrometer

A microscope with a light source that emits light for illumination of a specimen and with a spectrometer that receives detection light proceeding from the specimen, has an optical arrangement which has an acoustooptical component, and which directs the light of the light source to the specimen and delivers the detection light proceeding from the specimen to a spectrometer in spectrally undivided fashion. A flow cytometer and a method for examination of a specimen are also disclosed.

Owner:LEICA MICROSYSTEMS CMS GMBH

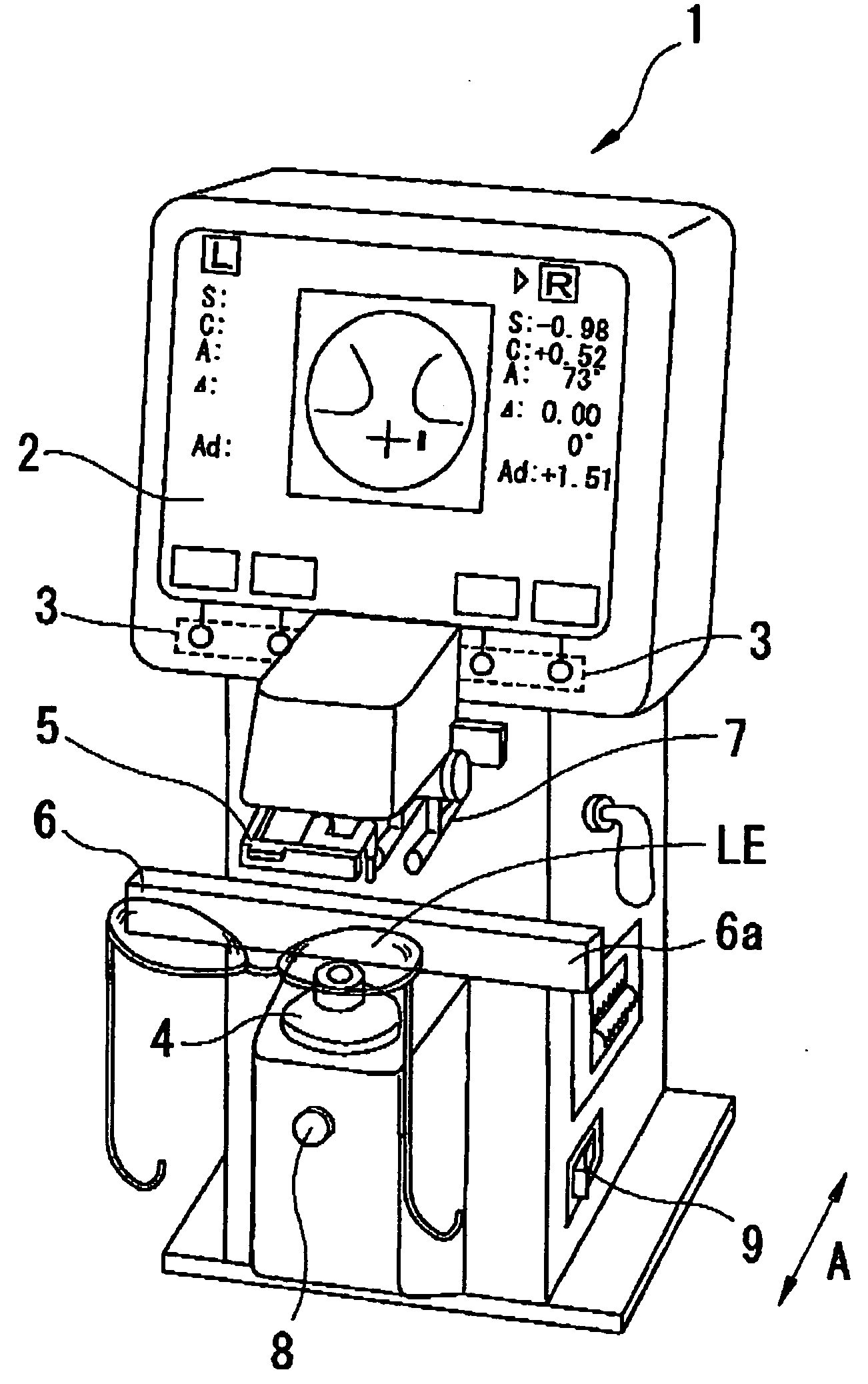

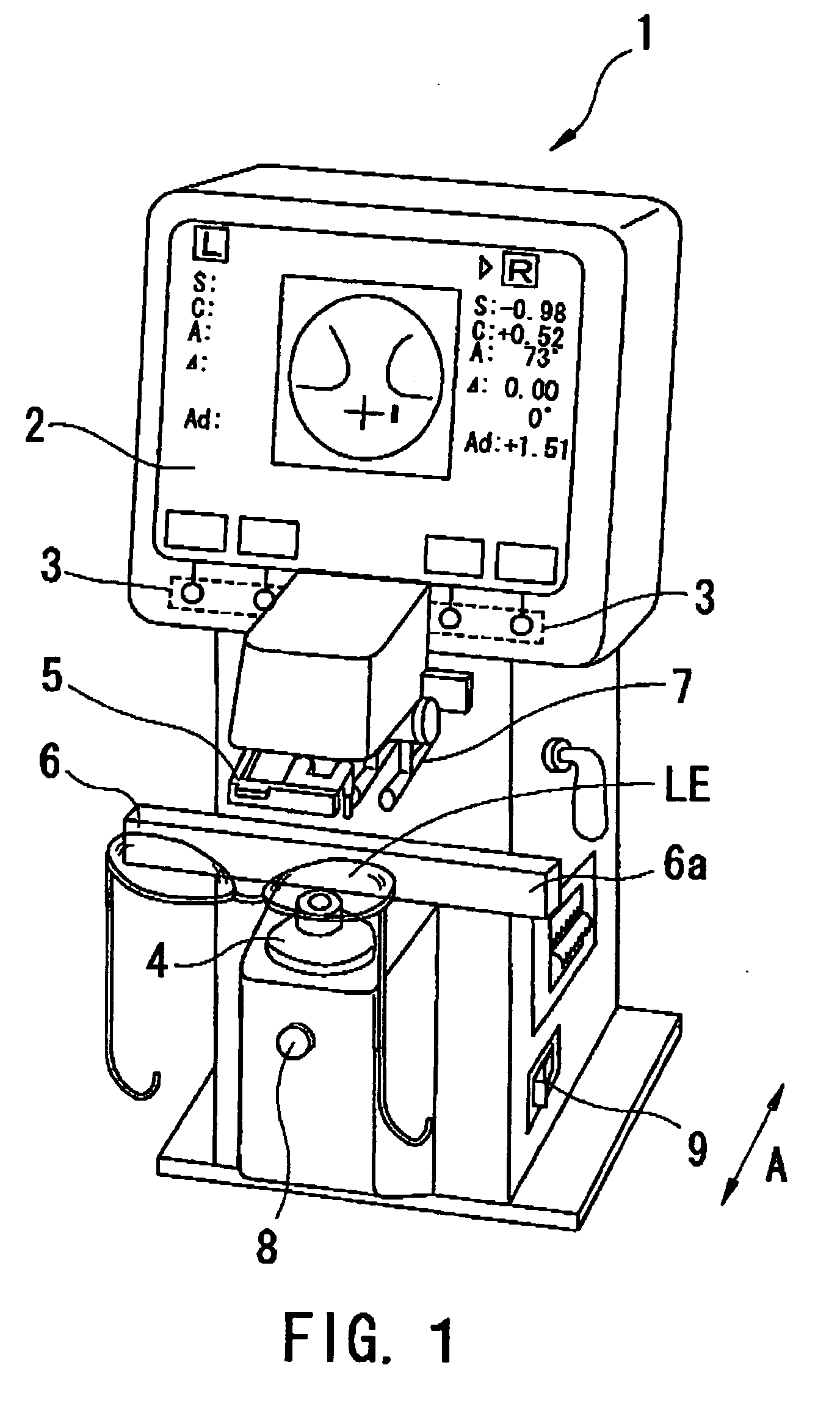

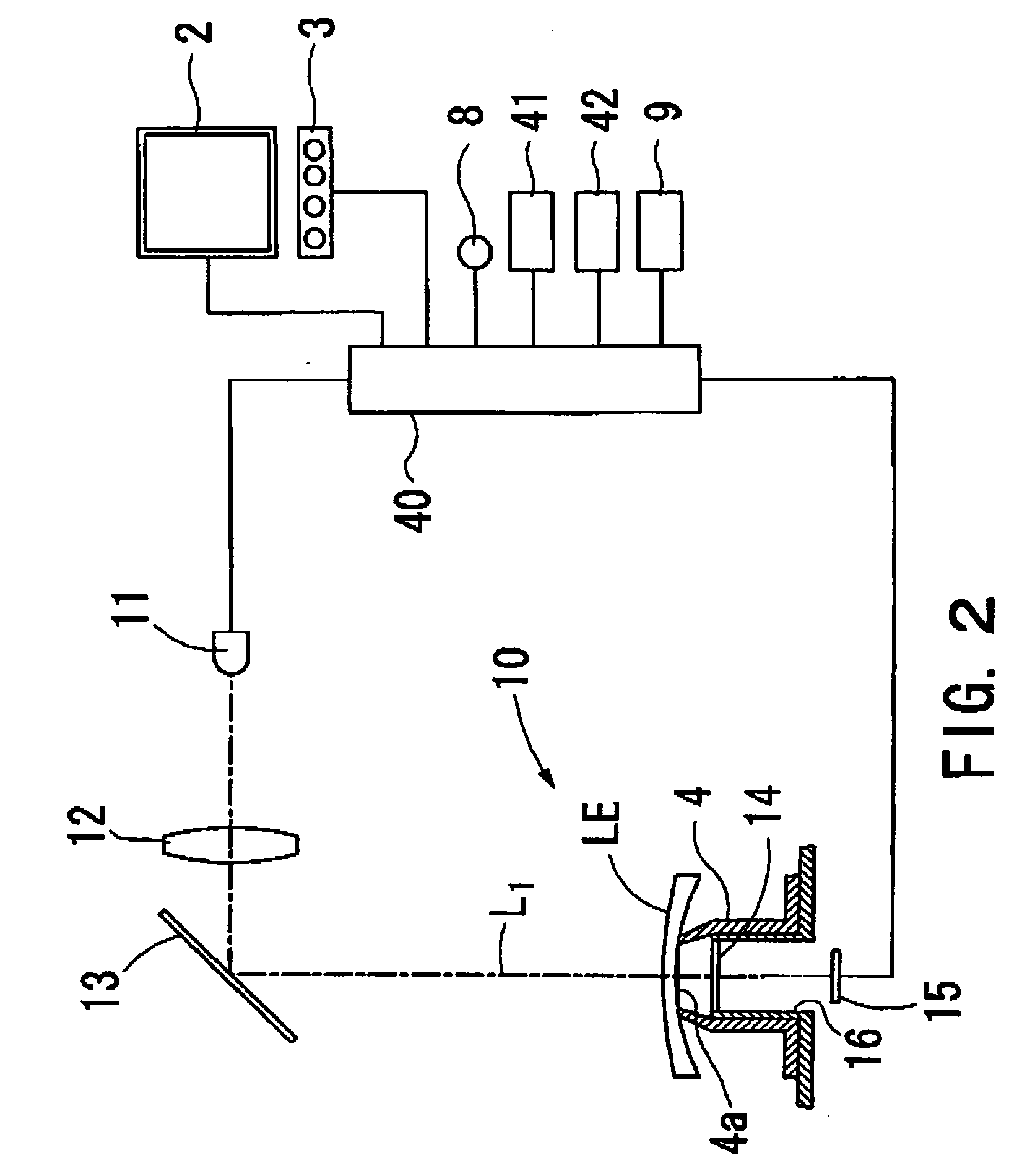

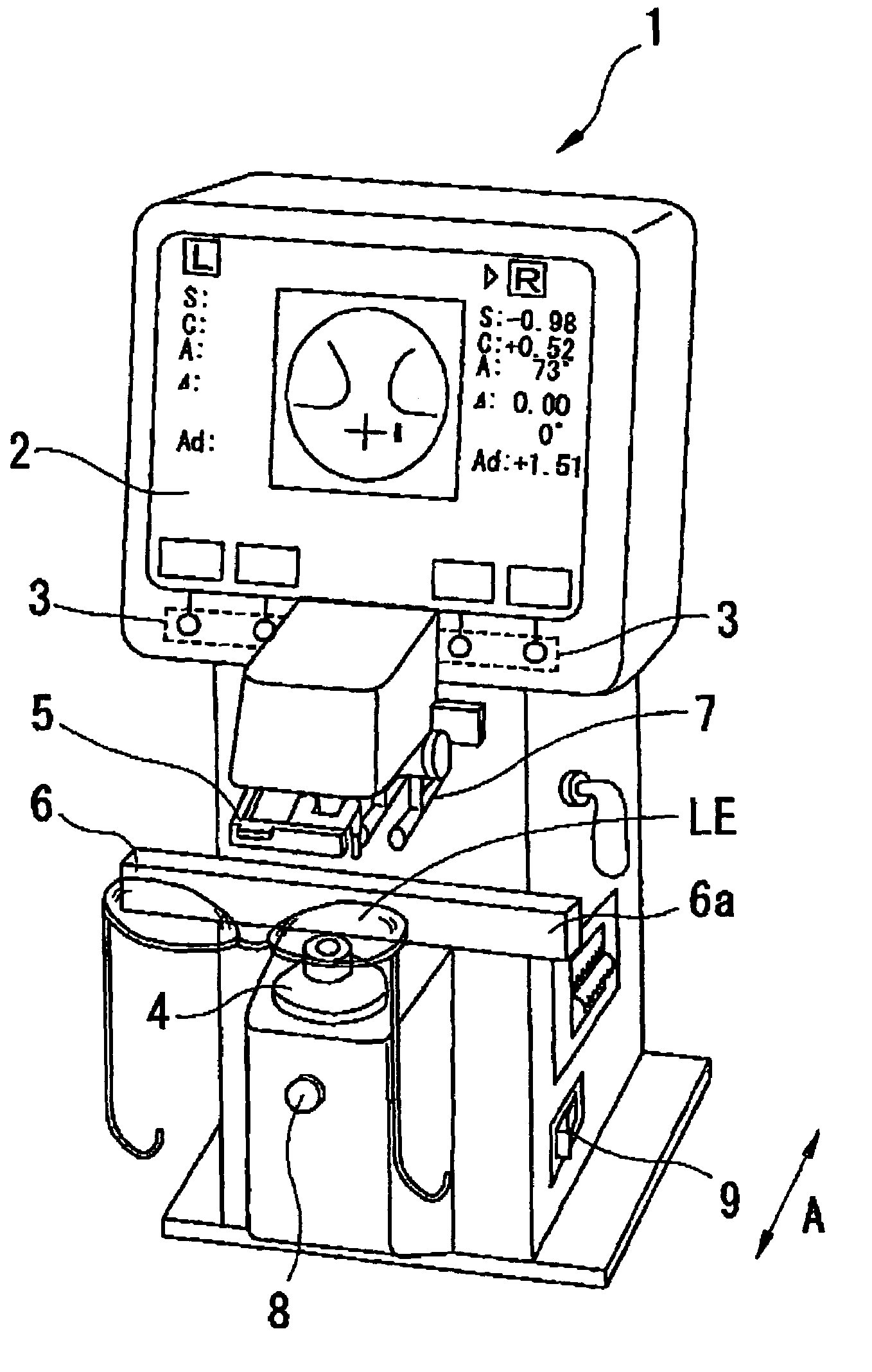

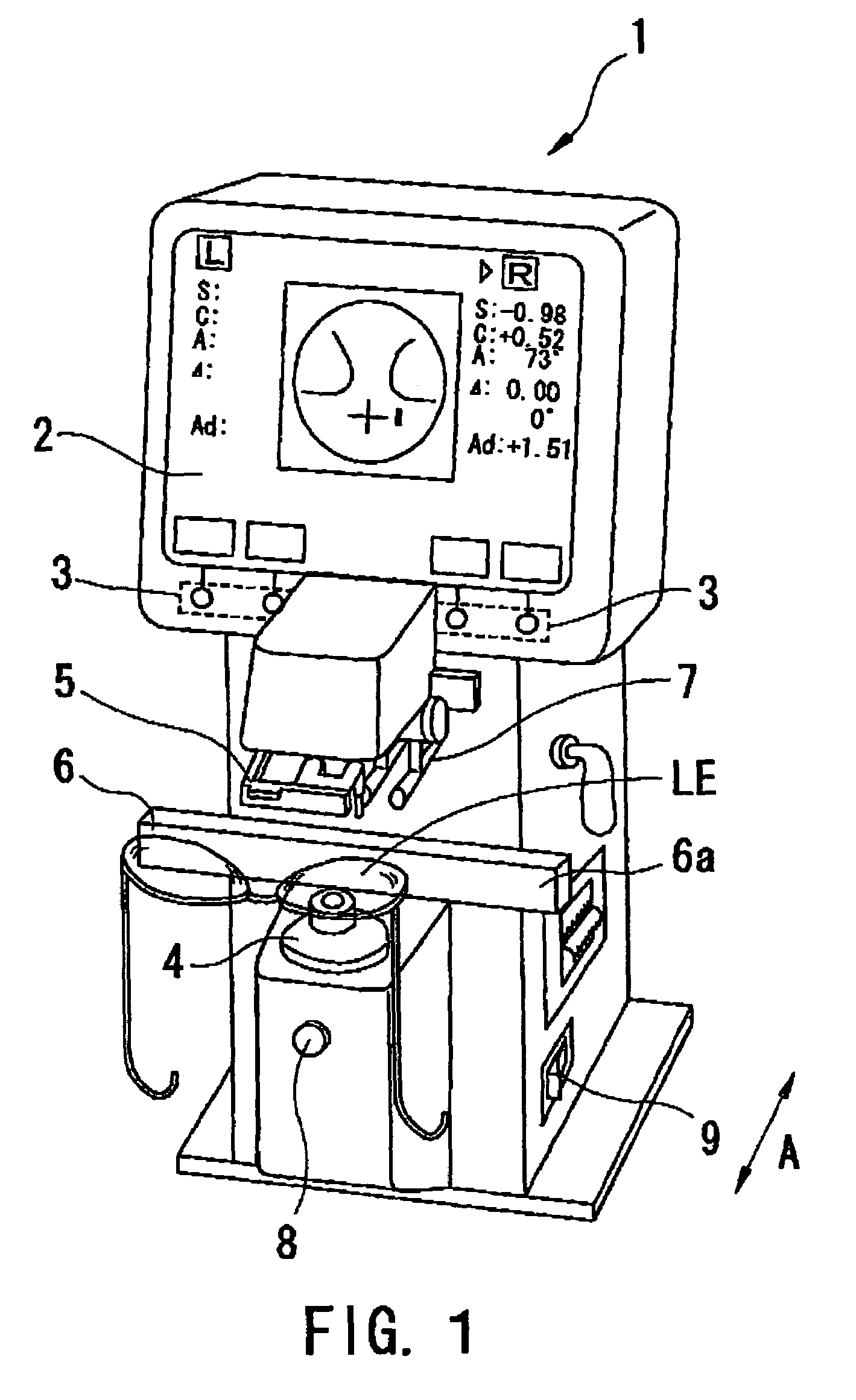

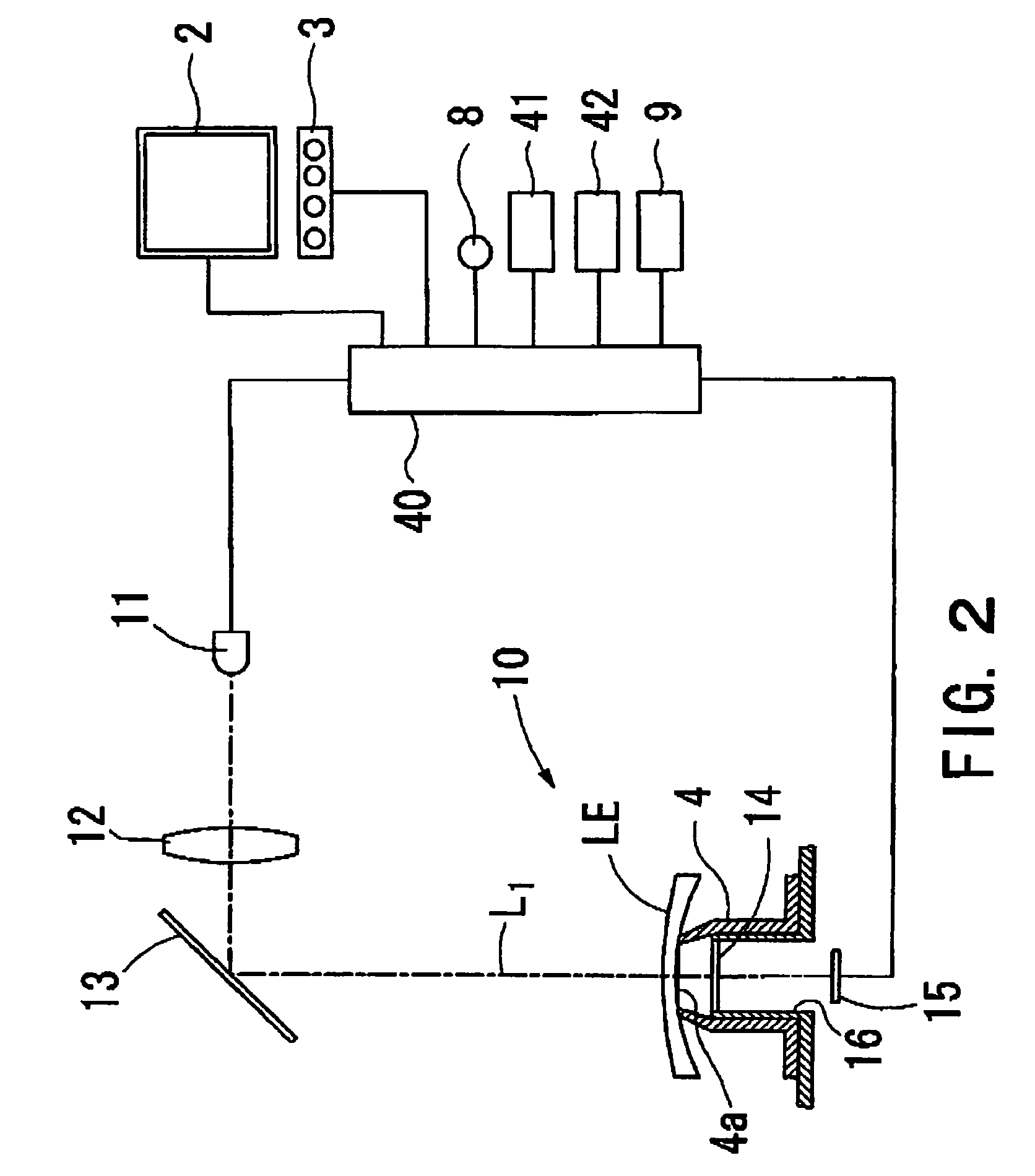

Lens meter

InactiveUS20050190360A1Easy and efficient measurementMeasuring even a progressive lens and the like easily and efficientlyUsing optical meansRefractive power measurementCoordinate changePower application

A lens meter obtaining 0D-reference-coordinates of target-images not detected in a reference state and measuring even progressive lenses, has a lens rest, an optical system having an optical axis, a light source, measurement targets and a photo-sensor, a part calculating optical characteristics based on coordinates-change of target-images in a measurement state with the lens on the rest and axis from those in a reference state without the lens thereon, and an information memory. The part makes the memory store image-coordinates not detected in the reference state obtained during assembly / adjustment, and based on image-coordinates detected in the reference state after power application and before measurement and stored coordinates, obtains image-coordinates not detected in the reference state after power application and before measurement, and calculates characteristics based on coordinates-change of target-images detected in the measurement state from those detected in the reference state before measurement and obtained image-coordinates.

Owner:NIDEK CO LTD

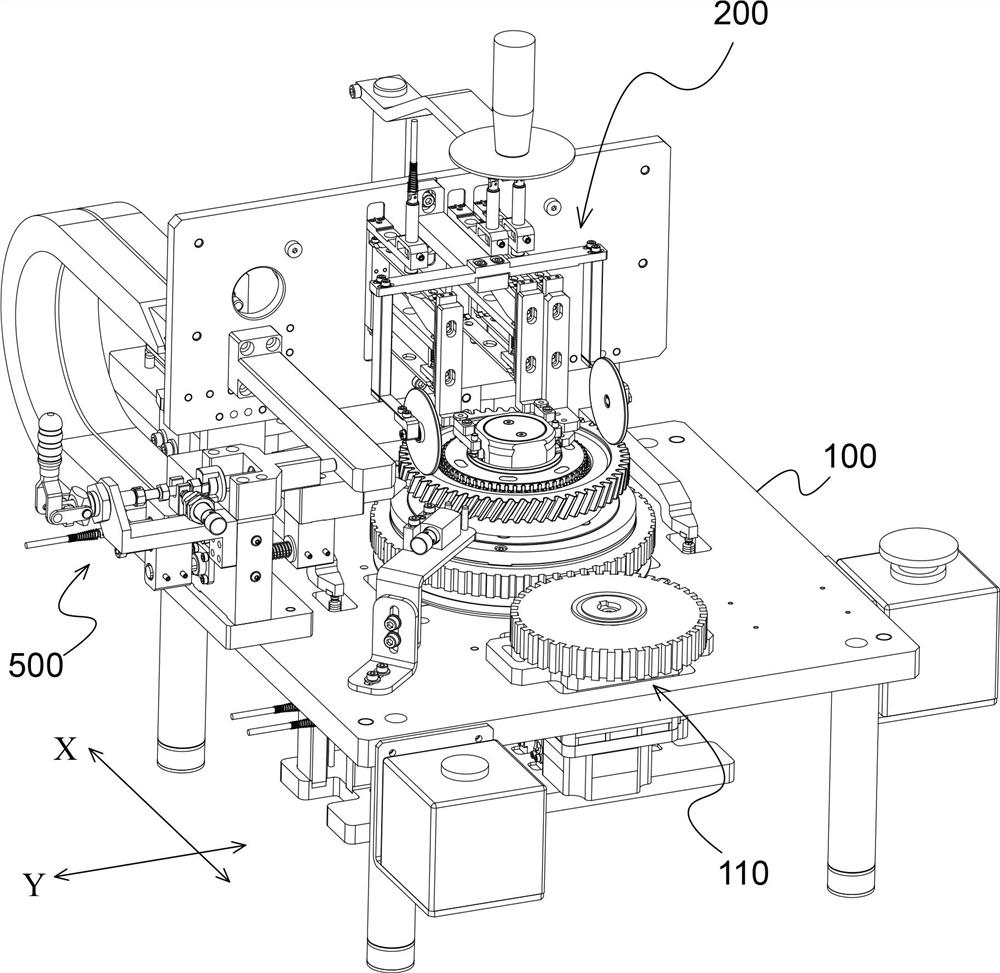

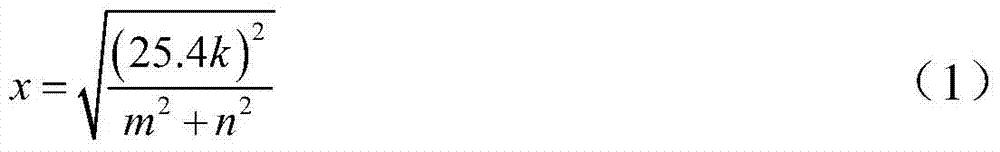

Method of using gear measuring center to measure and evaluate gear surface roughness

ActiveCN108007326ARealize measurementImprove accuracyMechanical roughness/irregularity measurementsGear wheelSample length

A method of using a gear measuring center to measure and evaluate gear surface roughness is disclosed. On a gear measurement center, a roughness sensor probe and correlation data processing software are combined and used so as to realize a measurement and evaluation method of gear surface roughness. A measurement direction belongs to involute profile direction measurement, and a top clamping modeis adopted so that a problem caused by manual adjusting needed by stylus coarse positioning is avoided. Under a generative movement condition of the gear measurement center, a stylus only carries outrectilinear motion along with bending of a gear surface. A gear-surface uniformly-spaced sampling principle is used to carry out sampling and acquired traced profile discrete points are uniformly andequally spaced. During a roughness measurement process, sampling lengths and evaluation lengths of a measurement position, a measurement result and an evaluation process are selected equivalently, a corresponding method and a data table are given, actual operation is convenient and measurement precision is guaranteed, problems that uniform sampling, reasonable evaluation and the like can not be realized on a gear surface are avoided and a technical problem that gear surface roughness analysis and evaluation can not be performed is solved.

Owner:FIRST TRACTOR

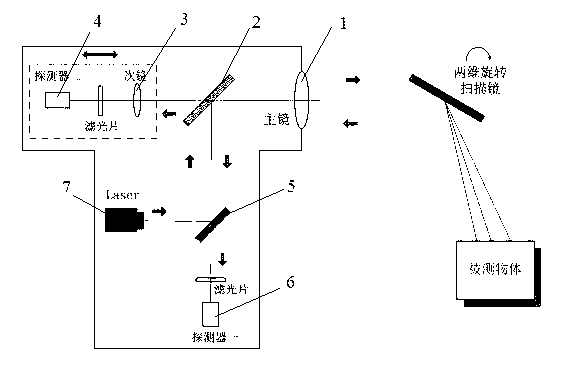

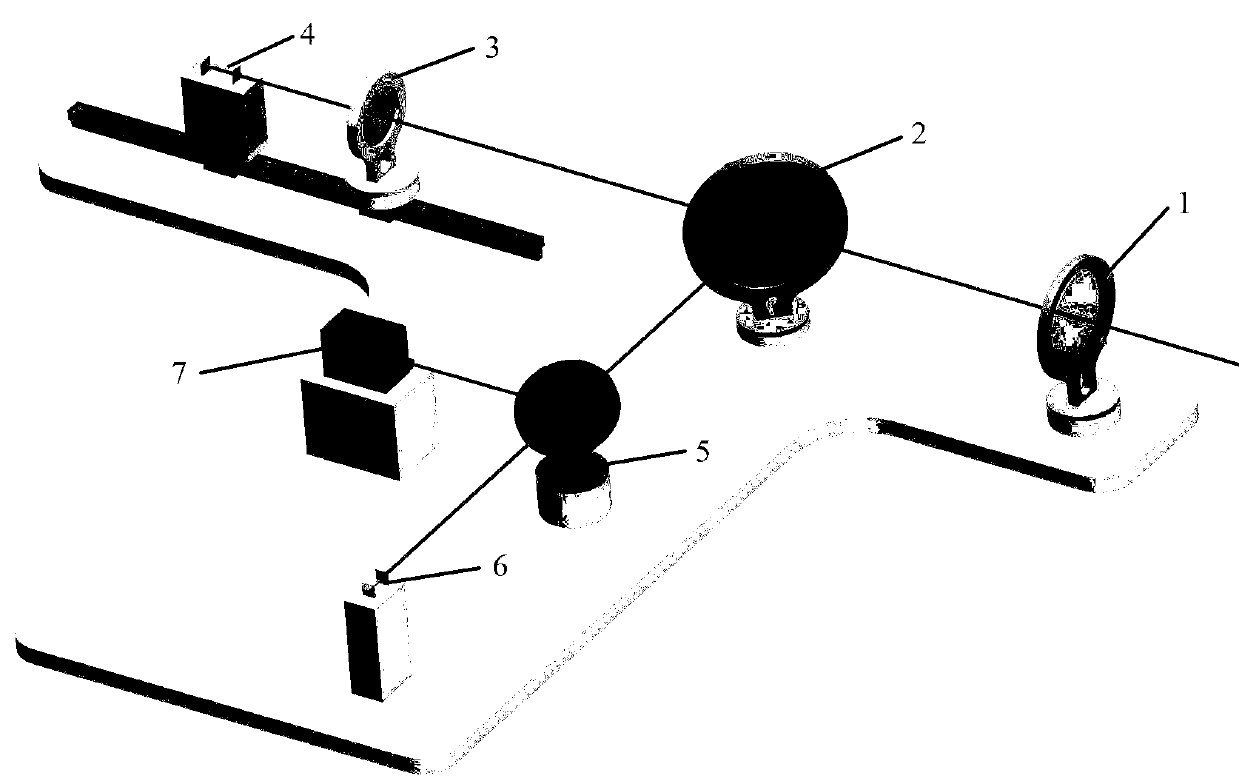

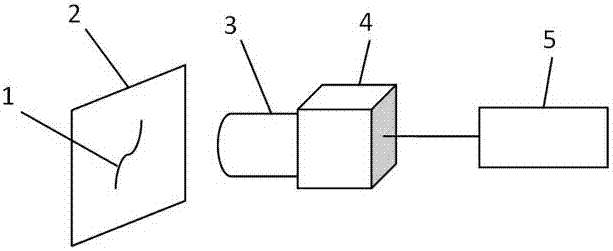

Double-field variable-focus three-dimensional measurement system

InactiveCN103134444AHigh precision extractionQuickly acquire 3D informationUsing optical meansReal variableMotor drive

The invention relates to a double-field variable-focus three-dimensional measurement system. The system comprises a primary-secondary mirror imaging measuring system, a two-dimensional tracking rotating-mirror device and an adaptive control system. The primary-secondary mirror imaging measuring system is composed of a telephoto subsystem, a short-focus subsystem and a launching light source. The telephoto is composed of a main lens, a first spectroscope, a second spectroscope and a detector. The short-focus system is composed of the main lens, the first spectroscope, the second spectroscope and the detector. The two-dimensional tracking rotating-mirror device is composed of a reflector, a electric rotating motor, a regulating handle, an upper half shaft, a lower half shaft and a horizontal shaft. The adaptive control system is composed of a computer, an input and output (I / O) control circuit, an electromotor and a signal processing and controlling circuit. The system has the advantages of being tight in arrangement, high in measuring efficiency, convenient to measure and is suitable for the three-dimensional measuring of moving and static objects.

Owner:TONGJI UNIV

Lens meter

InactiveUS7209224B2Measuring even a progressive lens and the like easily and efficientlyEasy and efficient measurementUsing optical meansRefractive power measurementCoordinate changePower application

A lens meter obtaining 0D-reference-coordinates of target-images not detected in a reference state and measuring even progressive lenses, has a lens rest, an optical system having an optical axis, a light source, measurement targets and a photo-sensor, a part calculating optical characteristics based on coordinates-change of target-images in a measurement state with the lens on the rest and axis from those in a reference state without the lens thereon, and an information memory. The part makes the memory store image-coordinates not detected in the reference state obtained during assembly / adjustment, and based on image-coordinates detected in the reference state after power application and before measurement and stored coordinates, obtains image-coordinates not detected in the reference state after power application and before measurement, and calculates characteristics based on coordinates-change of target-images detected in the measurement state from those detected in the reference state before measurement and obtained image-coordinates.

Owner:NIDEK CO LTD

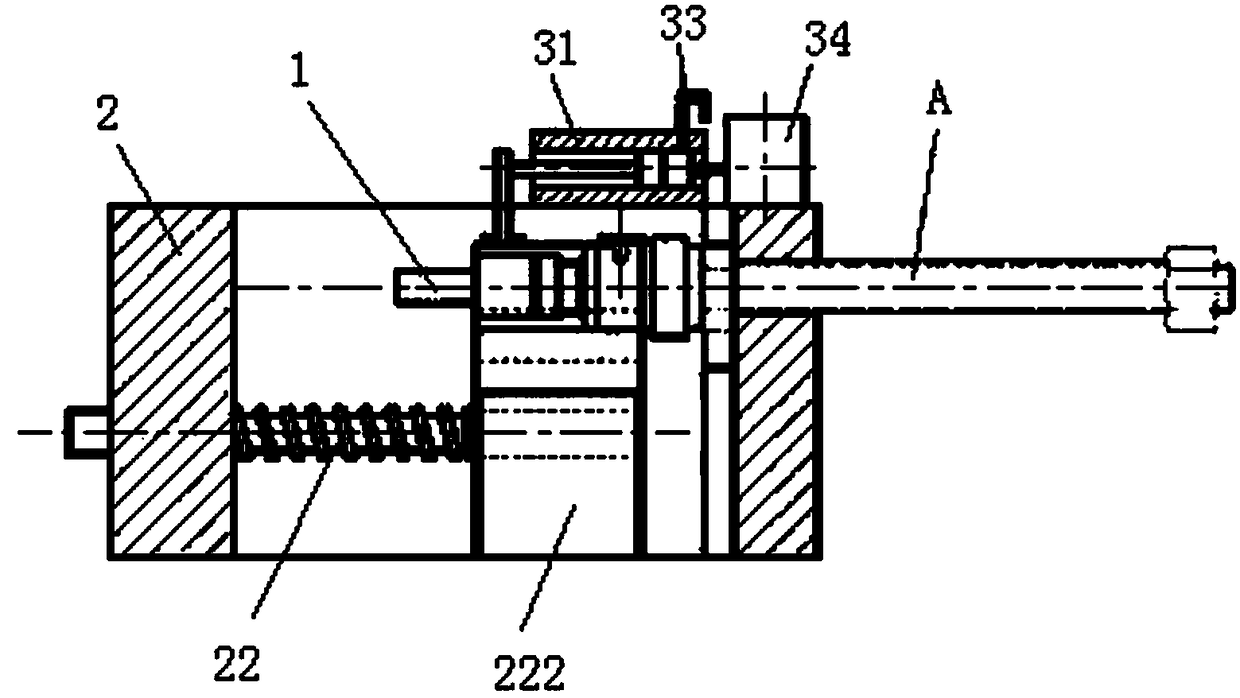

Ultrasonic measurement device capable of automatically applying coupling agent and work method of ultrasonic measurement device

PendingCN109444264AChange the pressing forceCompression force does not changeAnalysing solids using sonic/ultrasonic/infrasonic wavesMeasurement deviceCoupling

The invention discloses an ultrasonic measurement device capable of automatically applying a coupling agent. The device comprises an ultrasonic probe, a mounting casing and a spraying assembly, wherein the ultrasonic probe is arranged in the mounting casing and is detachably connected with the mounting casing; the spraying assembly is fixedly arranged on the mounting casing and is movably connected with the ultrasonic probe; during measurement, after an external to-be-tested bolt is clamped on the mounting casing, the ultrasonic probe presses the head of the external to-be-tested bolt; meanwhile, the spraying assembly automatically smears the coupling agent on the binding surface of the ultrasonic probe and the external to-be-tested bolt. Compared with the prior art, a bolt measuring device provided by the invention automatically applies the coupling agent while the external to-be-tested bolt is clamped, so that the problem of influence on the coupling relationship between ultrasonic waves and the external to-be-tested bolt because of indefinite quantity, unevenness and the like of manual smearing of the coupling agent is avoided, convenience and high efficiency of bolt measurementprocess are ensured, and a measurement result is reliable.

Owner:SHENZHEN GESHEM TECH CO LTD

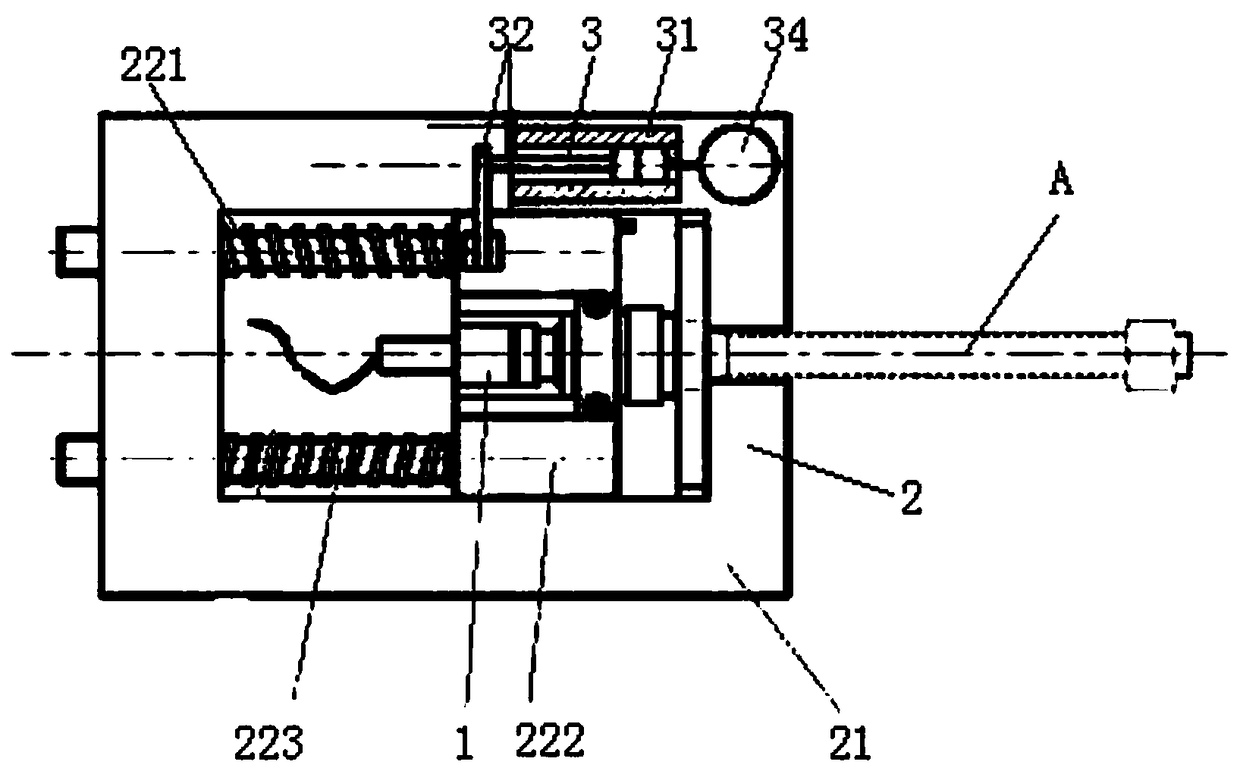

Device and method for measuring dispersal impulse current characteristics of grounding electrode

ActiveCN103018536AEasy and efficient measurementCurrent/voltage measurementShielded cableData acquisition

The invention discloses a device for measuring dispersal impulse current characteristics of a grounding electrode. The device comprises an impulse current generator, a hemispheric test flume, a simulated grounding electrode, a current sensor array, copper pins, a high-speed data acquisition card, a control and processing module and a display module. An input end of the impulse current generator is respectively connected with a 220V power frequency power source and a current injection point of the simulated grounding electrode through leads, the simulated grounding electrode is buried in the hemispheric test flume, the current sensor array is arranged at each point to be measured in soil around the simulated grounding electrode, the copper pins of the current sensor array are axially perpendicular to the simulated grounding electrode, a signal output end of the current sensor array is connected with an input end of the high-speed data acquisition card through a coaxial shielded cable, and the control and processing module is connected with the high-speed data acquisition card and the display module. The device is high in measurement efficiency of a dispersal impulse current rule of the grounding electrode and is simple, convenient and feasible in measurement process. The invention further discloses a method for measuring the dispersal impulse current characteristics of the grounding electrode by applying the device.

Owner:NINGBO ELECTRIC POWER BUREA +1

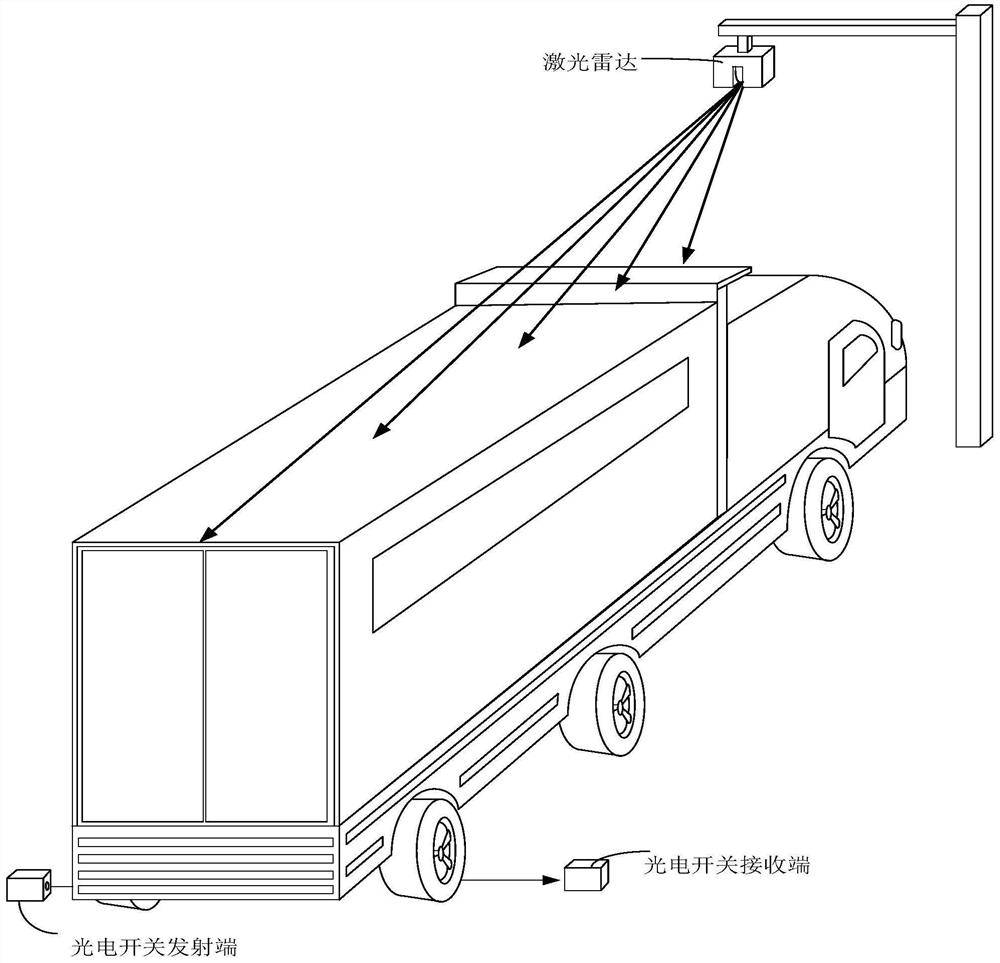

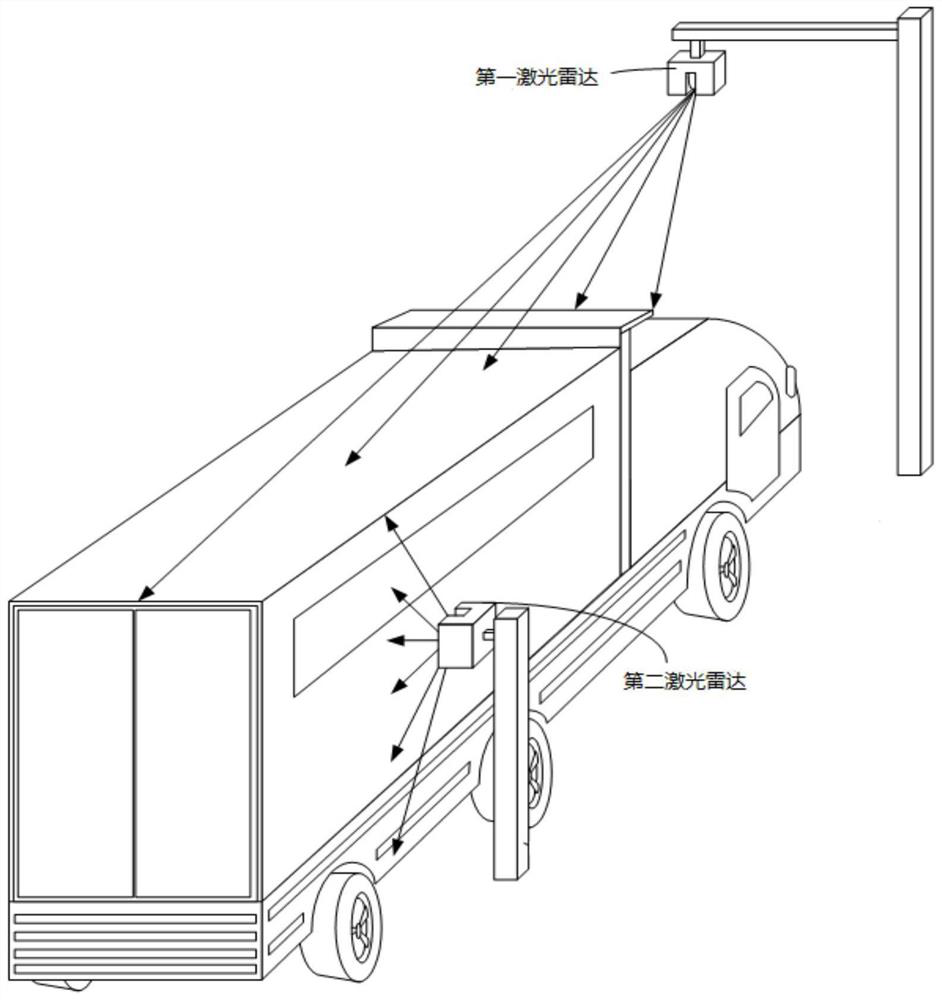

Automobile axle distance measuring method

PendingCN112255641AEasy and efficient measurementThere will be no misjudgmentVehicle testingElectromagnetic wave reradiationAutomotive engineeringWheelbase

The invention relates to the technical field of automobile detection, and discloses an automobile axle distance measuring method. The method adopts non-contact measurement, and comprises the followingsteps of scanning the head of an automobile by using a first laser radar and scanning the side body of the automobile by using a second laser radar in an automobile advancing process; and combining data measured by the first laser radar and data measured by the second laser radar to obtain three-dimensional coordinate data of the automobile, converting the three-dimensional coordinate data to obtain a two-dimensional graph of the side surface of an automobile tire, finally processing a two-dimensional graph to obtain the position and a contour of the automobile tire, and calculating to acquire the axle distance of the automobile. The measurement process is more convenient and efficient, the measurement result is not affected by other parts of the automobile, the measurement result is moreaccurate, direct judgment and output can be achieved, and the method can be suitable for vehicles of various brands and models.

Owner:成都新成汽车检测设备有限公司

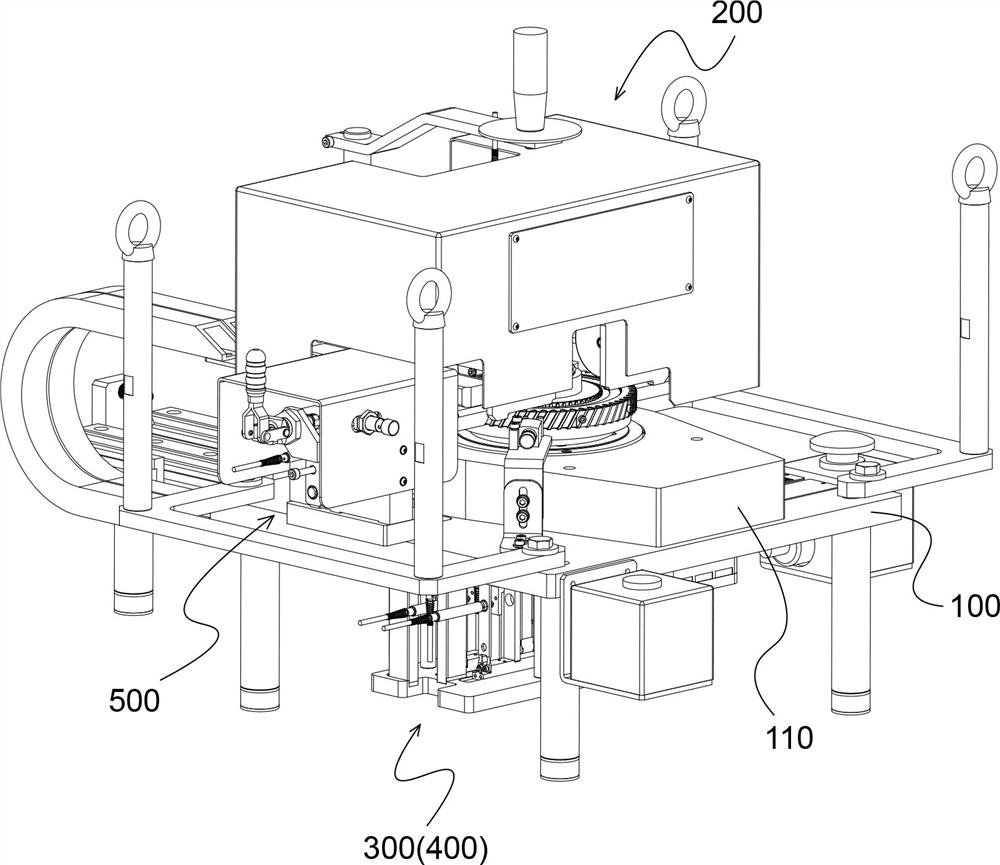

Gear detection bench

ActiveCN111735400AEasy and efficient measurementUsing electrical meansUsing optical meansMotor driveGear wheel

The invention relates to the field of machine manufacturing. The invention discloses a gear detection bench. The gear detection bench comprises: a gear detection bench, a first detection mechanism which is used for detecting the height of the upper end face of a gear to be detected, a second detection mechanism which is used for detecting the height of the lower end face of the gear to be detected, a third detection mechanism which is used for detecting the inner diameter of the gear to be detected, and a fourth detection mechanism which is used for detecting the outer diameter of the gear tobe detected. The workbench comprises a driving mechanism which is used for positioning and driving the to-be-tested gear to rotate. The driving mechanism comprises a motor, a driving gear and a rotating disc, the motor drives the rotating disc through the driving gear, the rotating discis provided with a joint structure jointed with the periphery of the bottom of the gear to be detected, and the first detection mechanism, the second detection mechanism and the third detection mechanism are arranged to be capable of continuously measuring in the process that the driving mechanism drives the gear to be detected to rotate. According to the technical scheme of the invention, the gear detection bench is higher in integration degree, and can improve the measurement efficiency of gears.

Owner:南京泰普森自动化设备有限公司

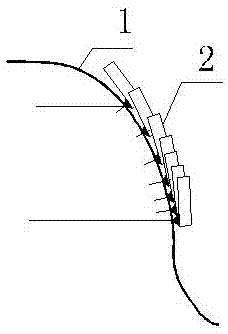

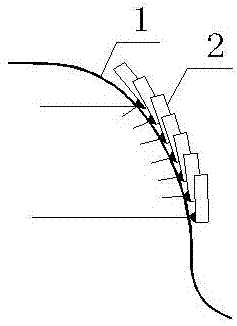

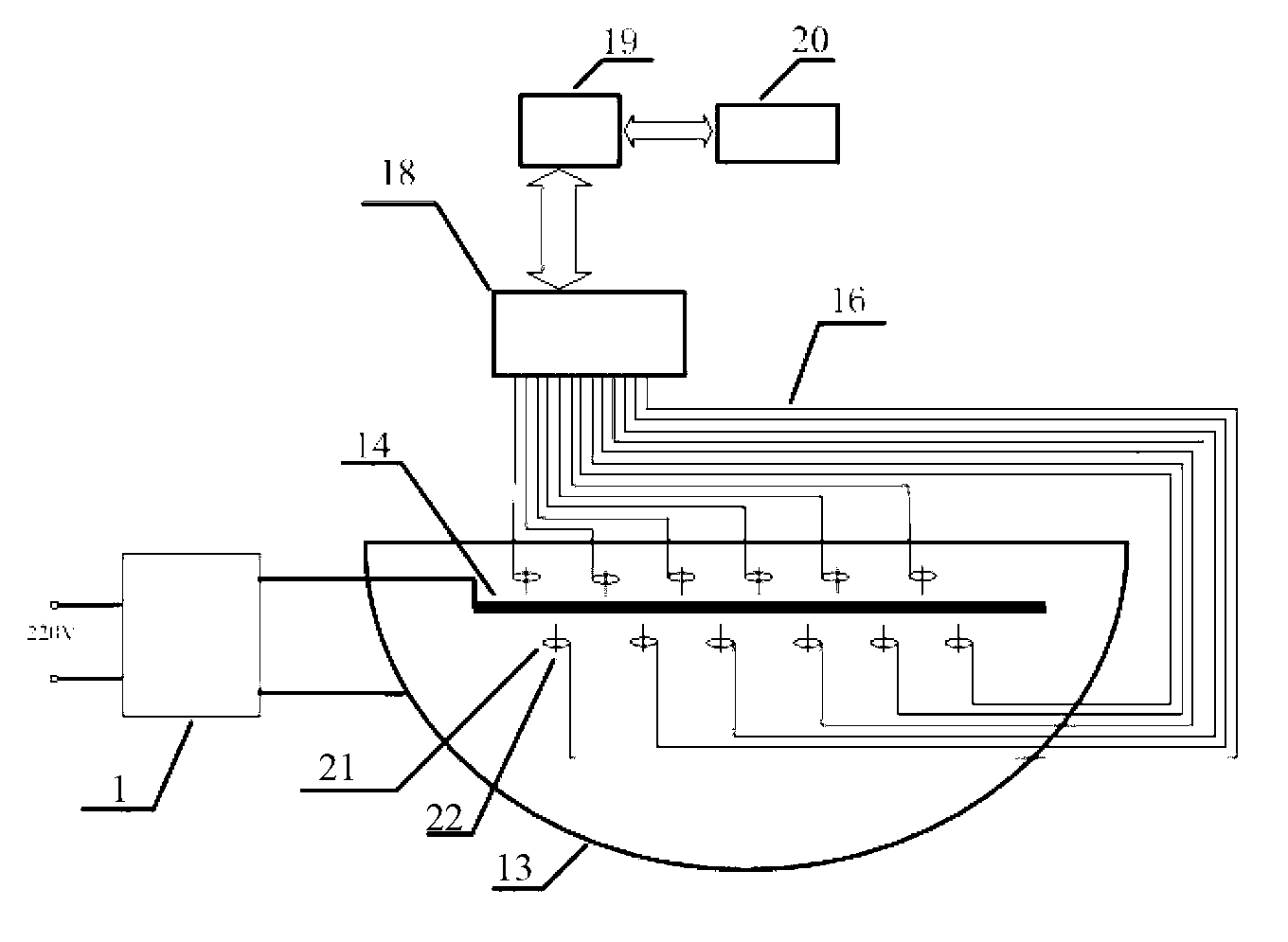

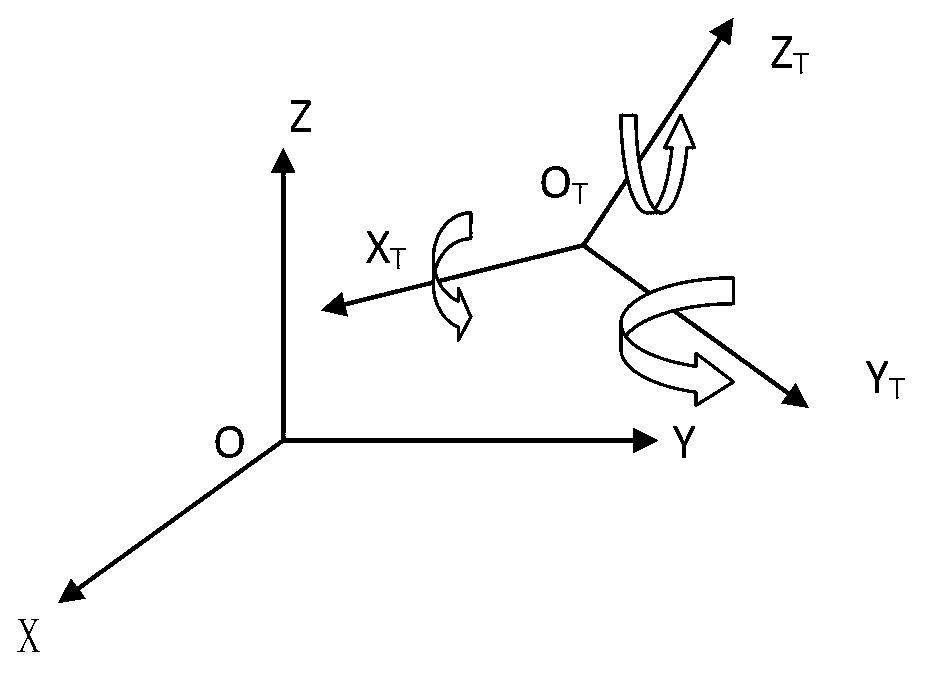

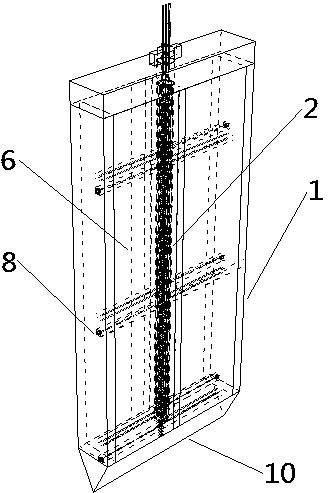

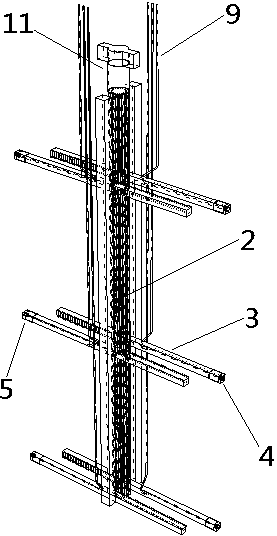

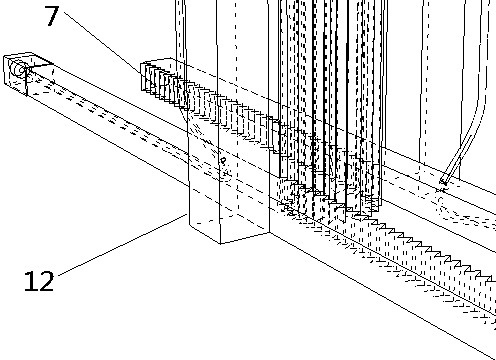

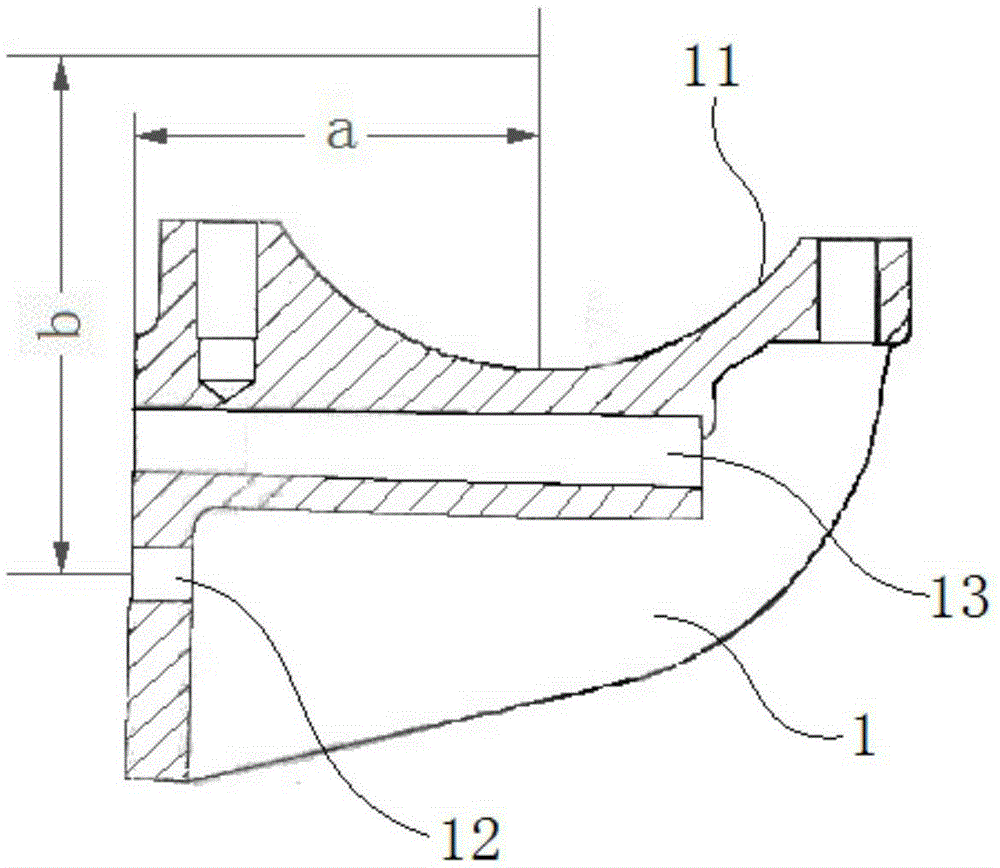

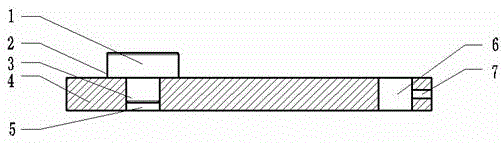

Method for measuring three-dimensional data of autobody and chassis based on optical-electricity encoder

InactiveCN103292694AFlexible rotationEasy and efficient measurementUsing optical meansElectricityMeasurement point

The invention provides a method for measuring three-dimensional data of an autobody and a chassis based on an optical-electricity encoder. The method for measuring the three-dimensional data of the autobody and the chassis based on the optical-electricity encoder is designed to solve the problem that the current mechanical or electronic type measuring method is inconvenient to use and to improve use convenience and measuring efficiency. According to the technical scheme, the method for measuring the three-dimensional data of the autobody and the chassis based on the optical-electricity encoder is characterized in that a measuring arm is composed of a plurality of joints which are connected with one another, wherein a first joint (1), a second joint (2), a third joint (3) and a fourth joint (4) are in the same plane, the fourth joint (4) is perpendicular to the third joint (3), a fifth joint (5) rotates in the plane which is perpendicular to the fourth joint (4), a sixth joint (6) rotates in the plane which is perpendicular to the fifth joint (5), and joint rotating shafts are respectively embedded in the optical-electricity encoder and are used for measuring the rotation angels of the joints. The three-dimensional data of any measurement points of the autobody and the chassis can be measured through angle measurement, coordinate calibration and conversion calculation.

Owner:MIT AUTOMOBILE SERVICE

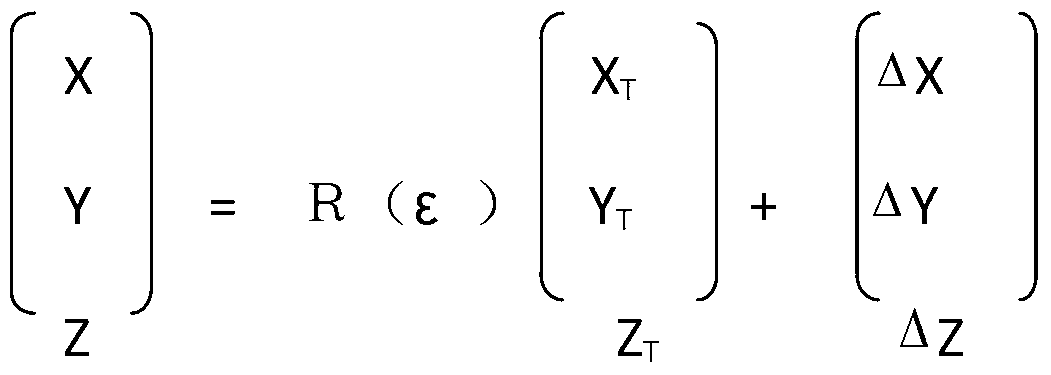

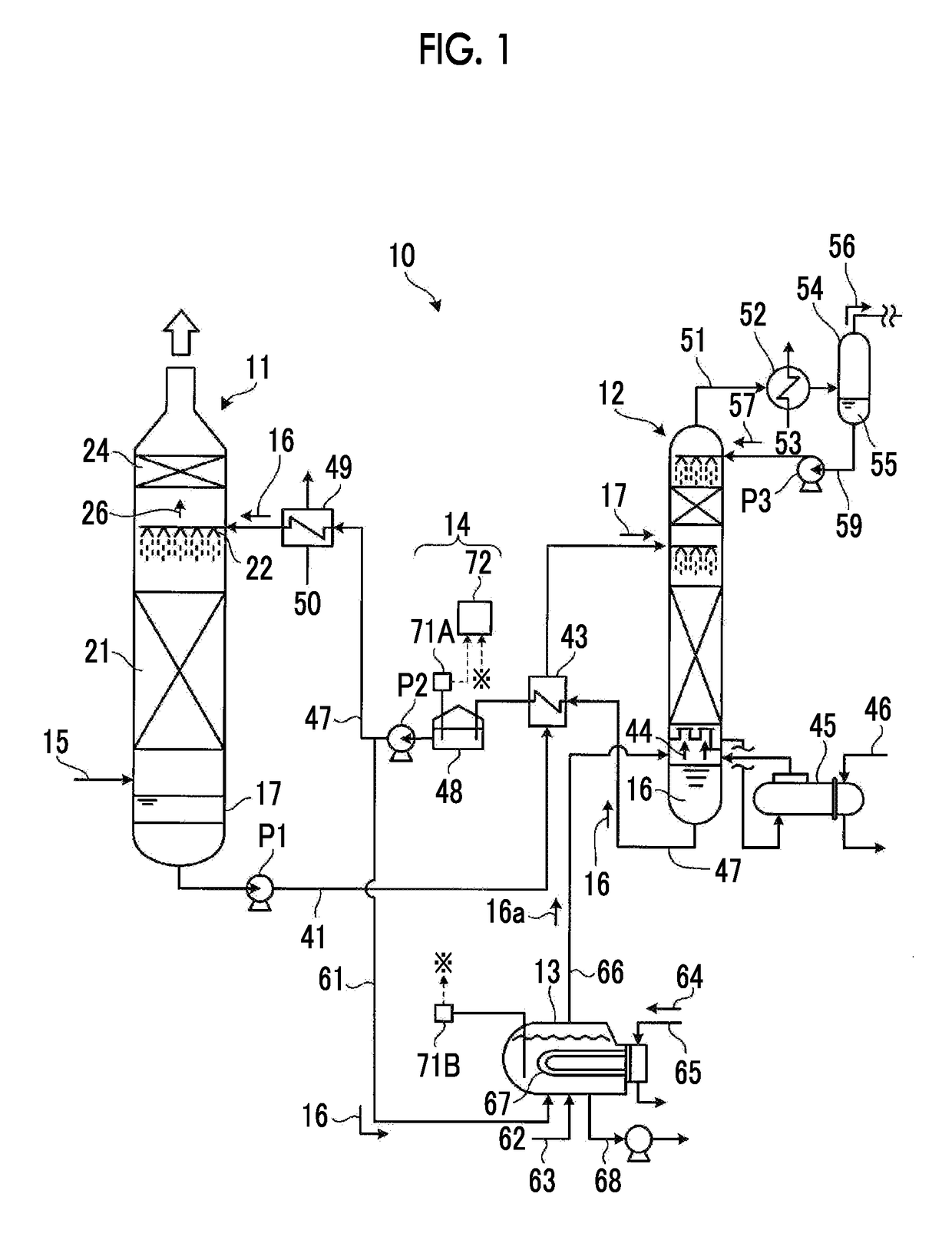

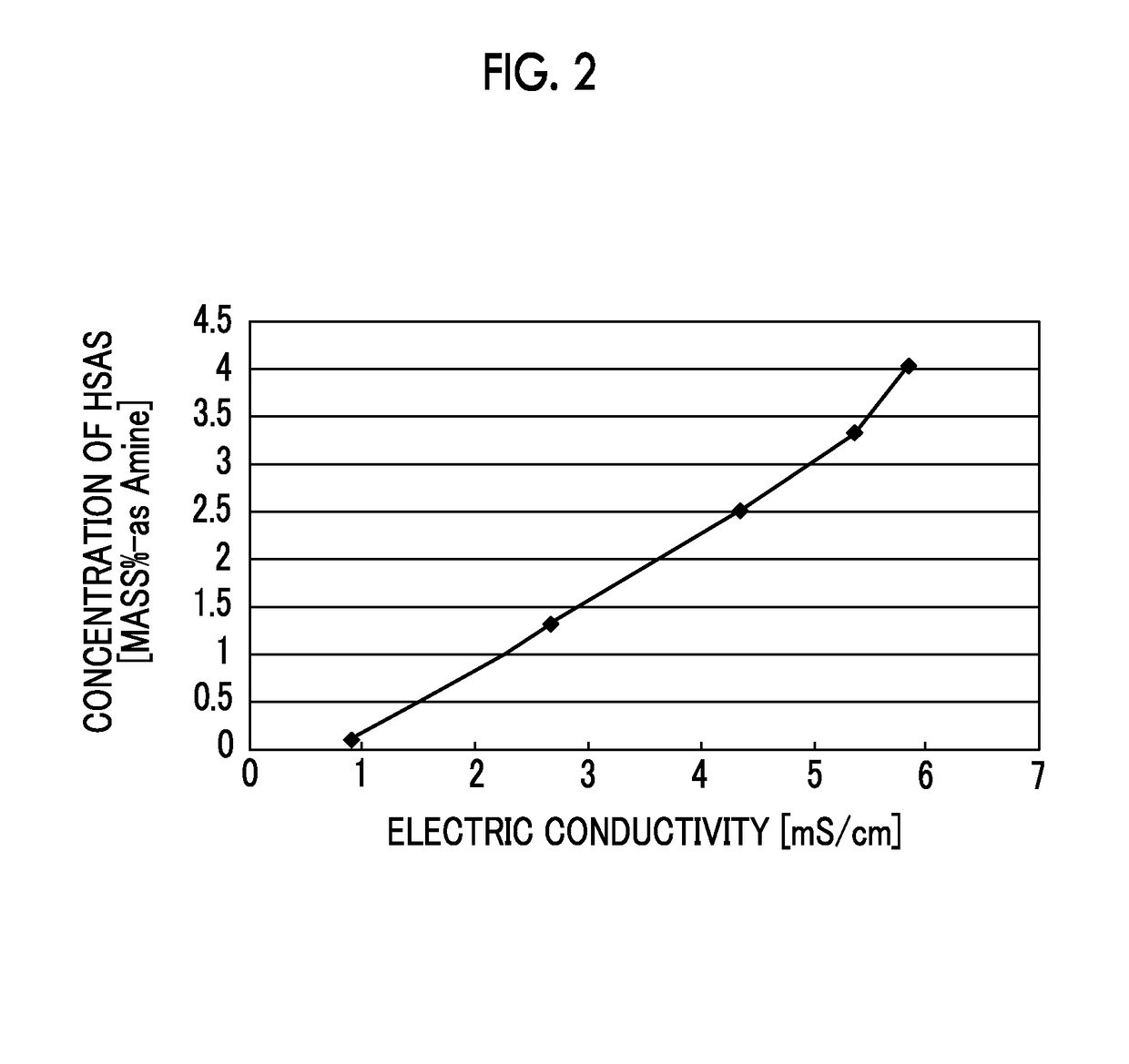

Degradant concentration measurement device and acidic gas removal device

ActiveUS9782720B2Reduce the burden onEasy and efficient measurementProductsGas treatmentMeasurement deviceElectrical resistivity and conductivity

A degradant concentration measurement device 14 according to the invention has an electric conductivity measurement instrument 71A measuring the electric conductivity of a lean solution 16 that is an acidic gas-absorbing solution and detection means 72 obtaining the concentration of a degradant contained in a lean solution 16 from the measured electric conductivity of the lean solution 16 based on the relationship between the previously-obtained electric conductivity of the lean solution 16 and the concentration of the degradant contained in the lean solution 16.

Owner:MITSUBISHI HEAVY IND ENG LTD

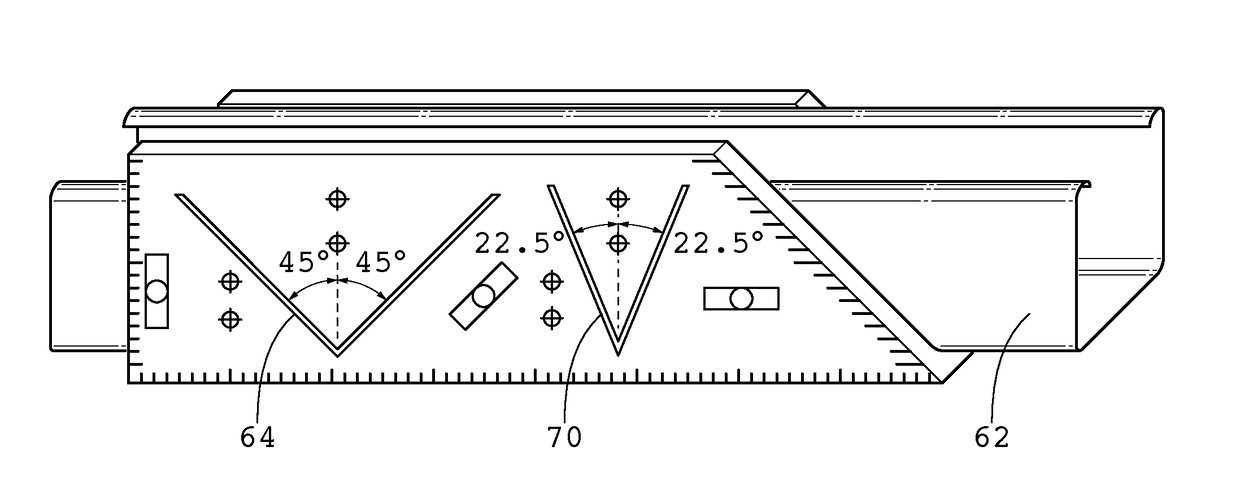

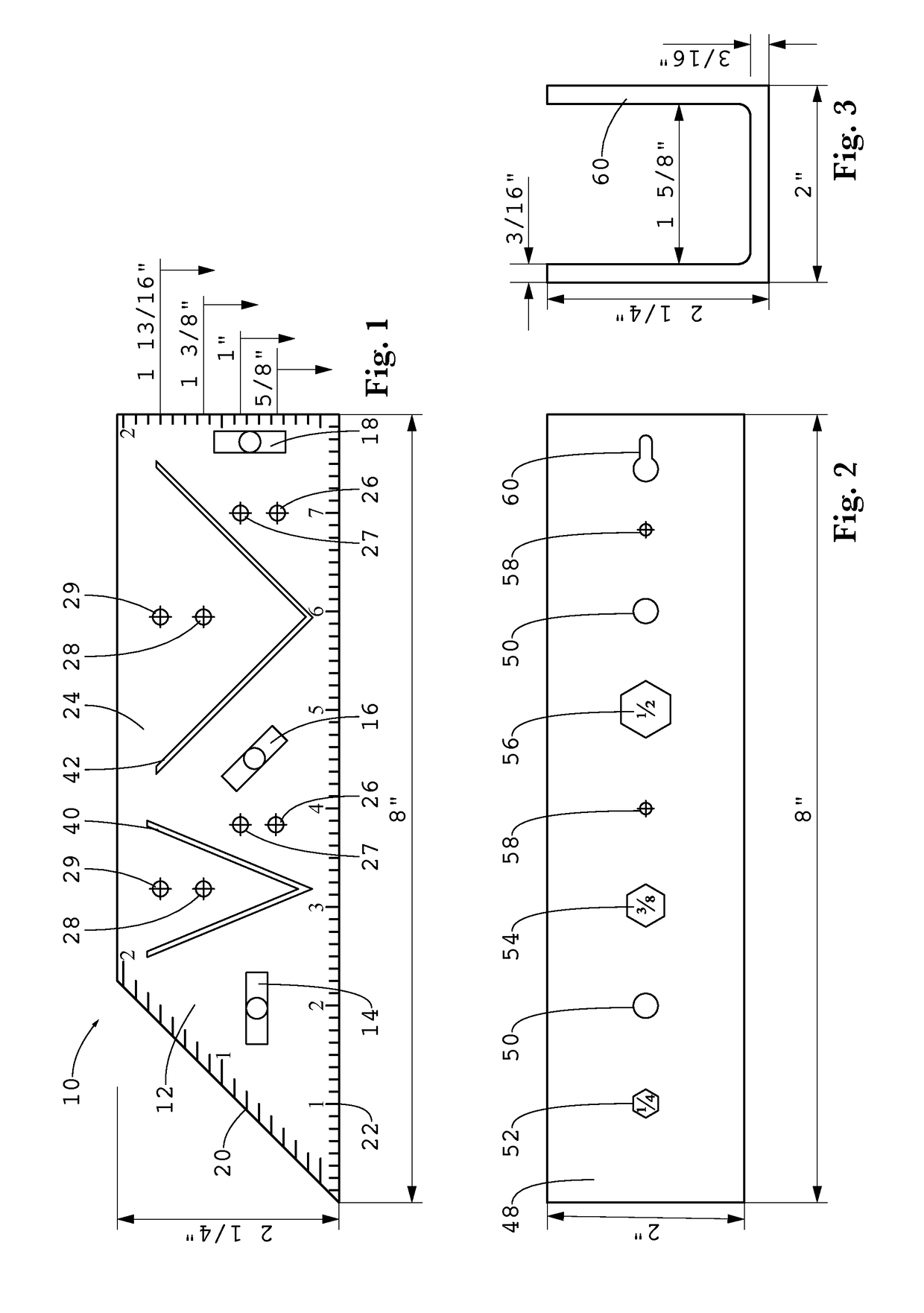

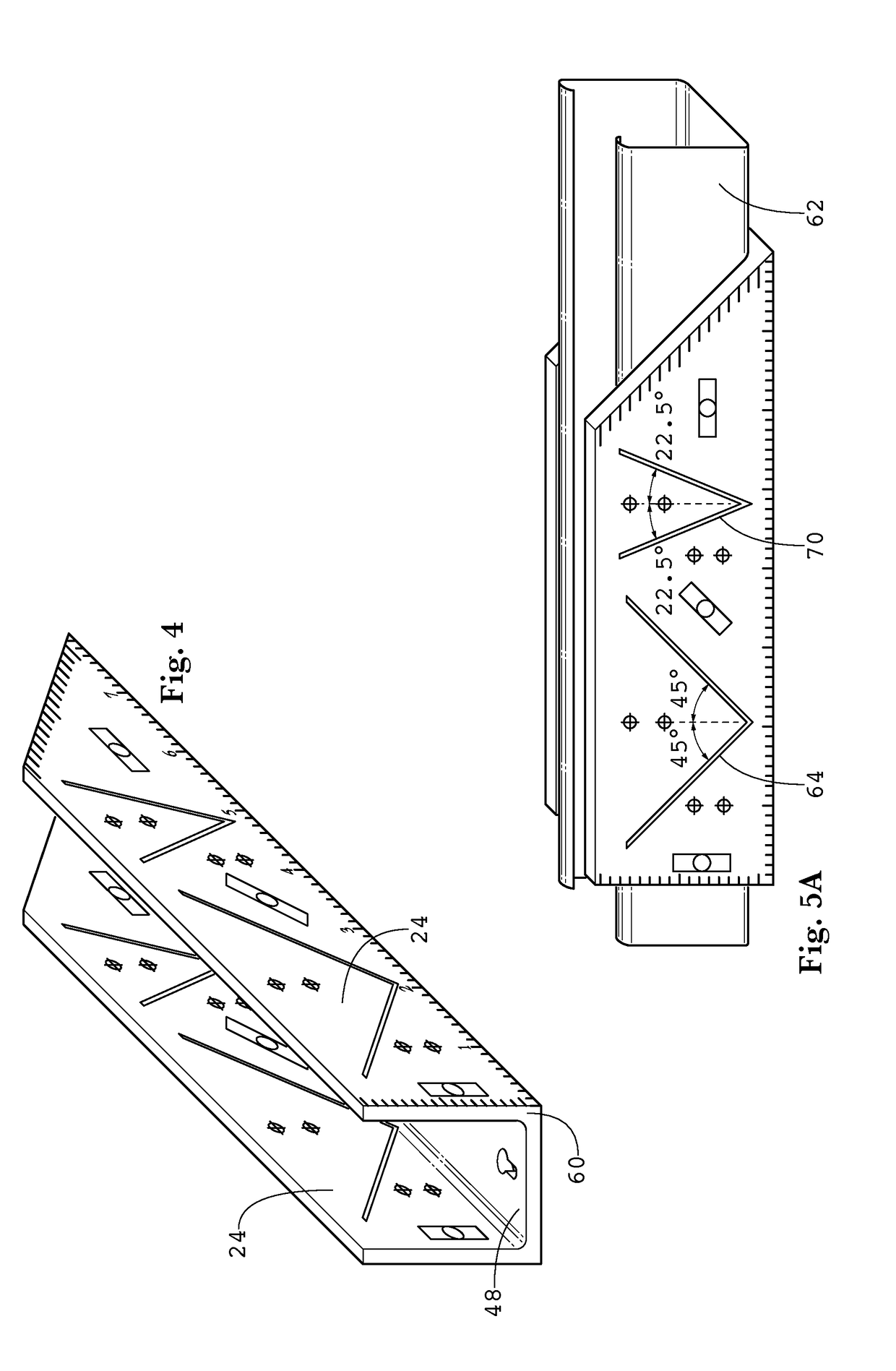

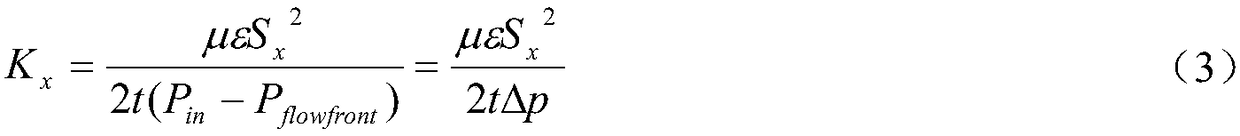

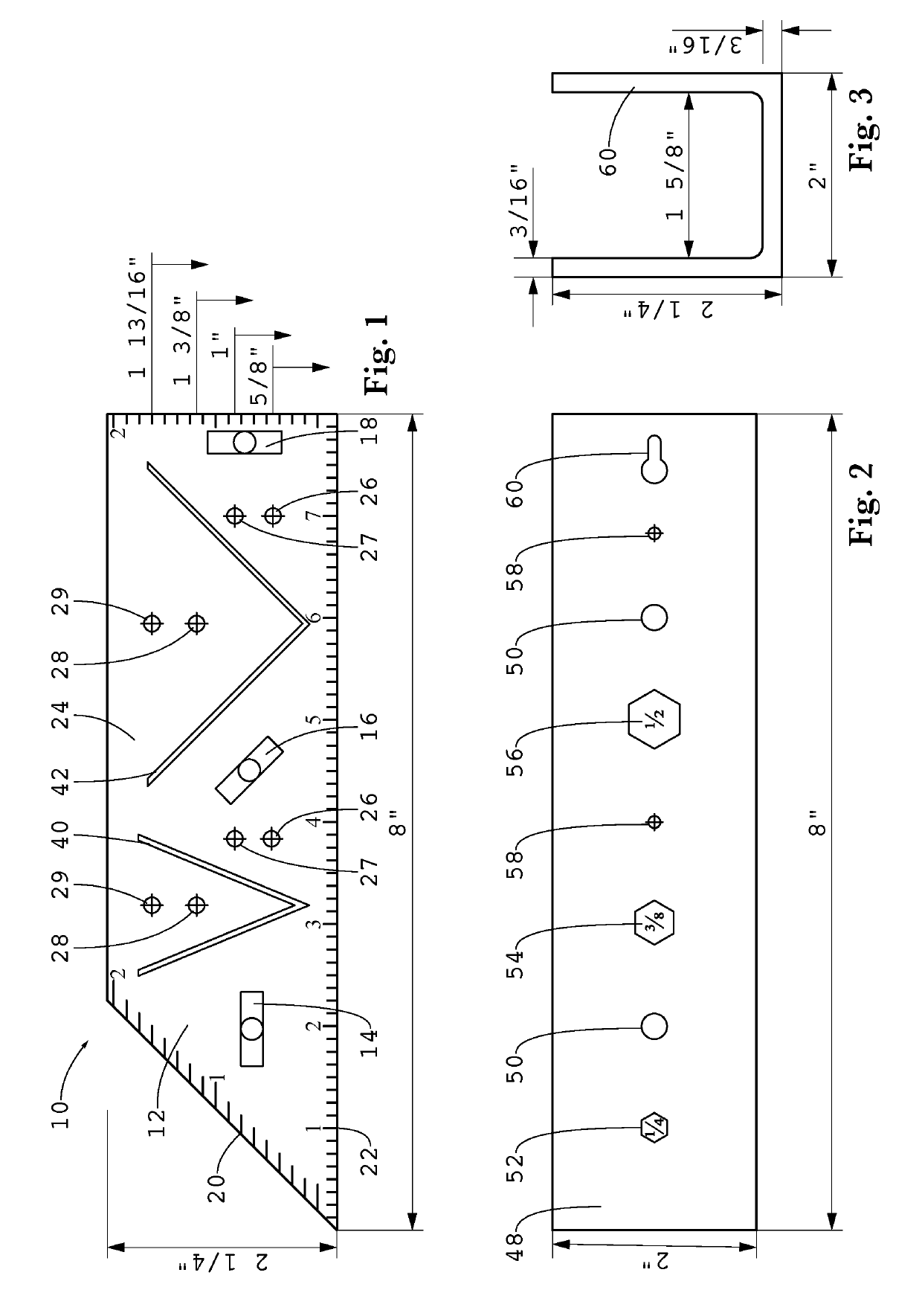

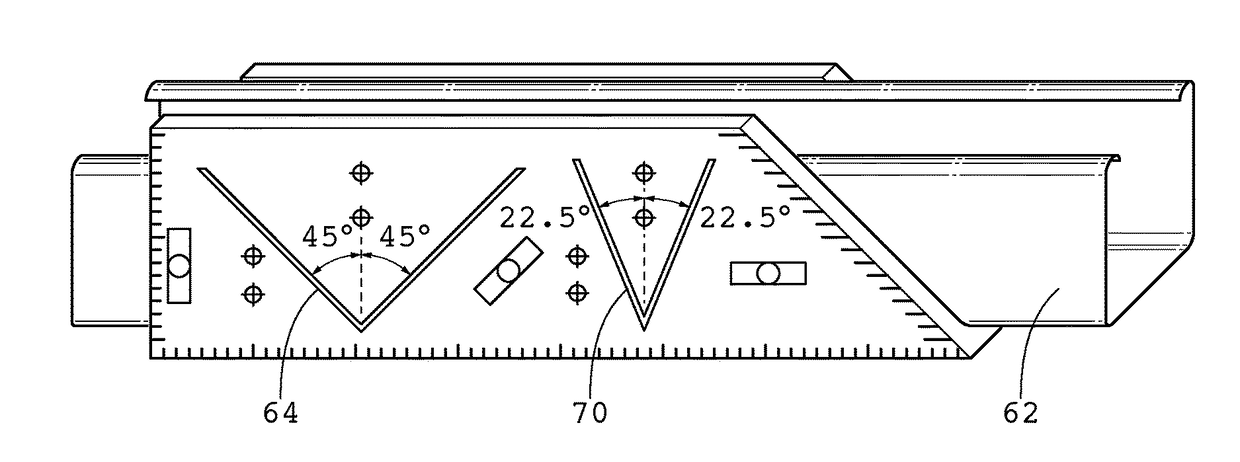

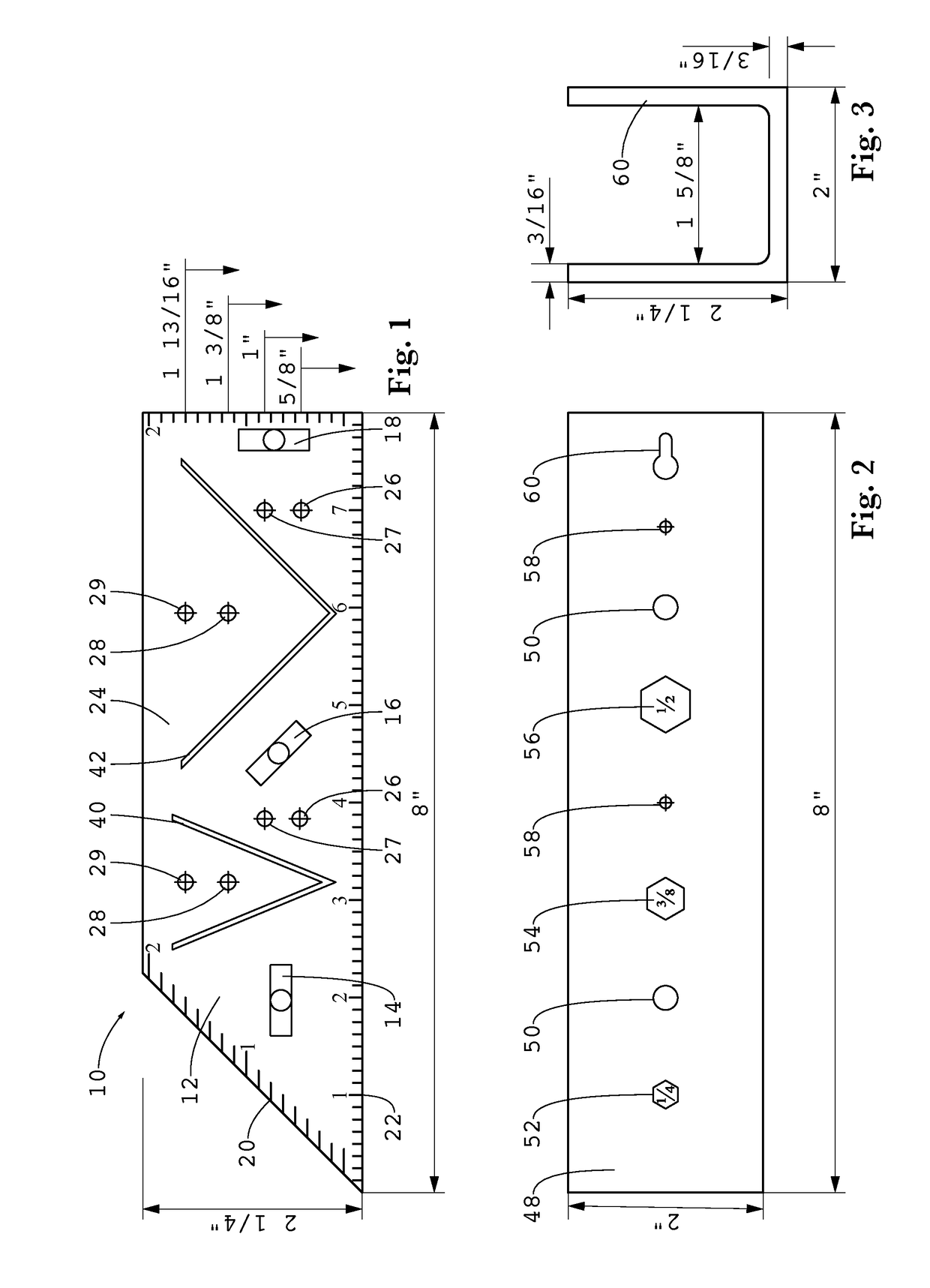

Tool for marking and measuring struts for construction

ActiveUS20180155941A1Mark accuratelyEasy and efficient measurementBuilding material handlingMechanical measuring arrangementsEngineeringMechanical engineering

A tool shaped in a U-shape for accepting a standard U strut. The tool has opening for marking the strut for cutting purposes and hole openings for marking the center of standard struts.

Owner:MENDOZA JUAN

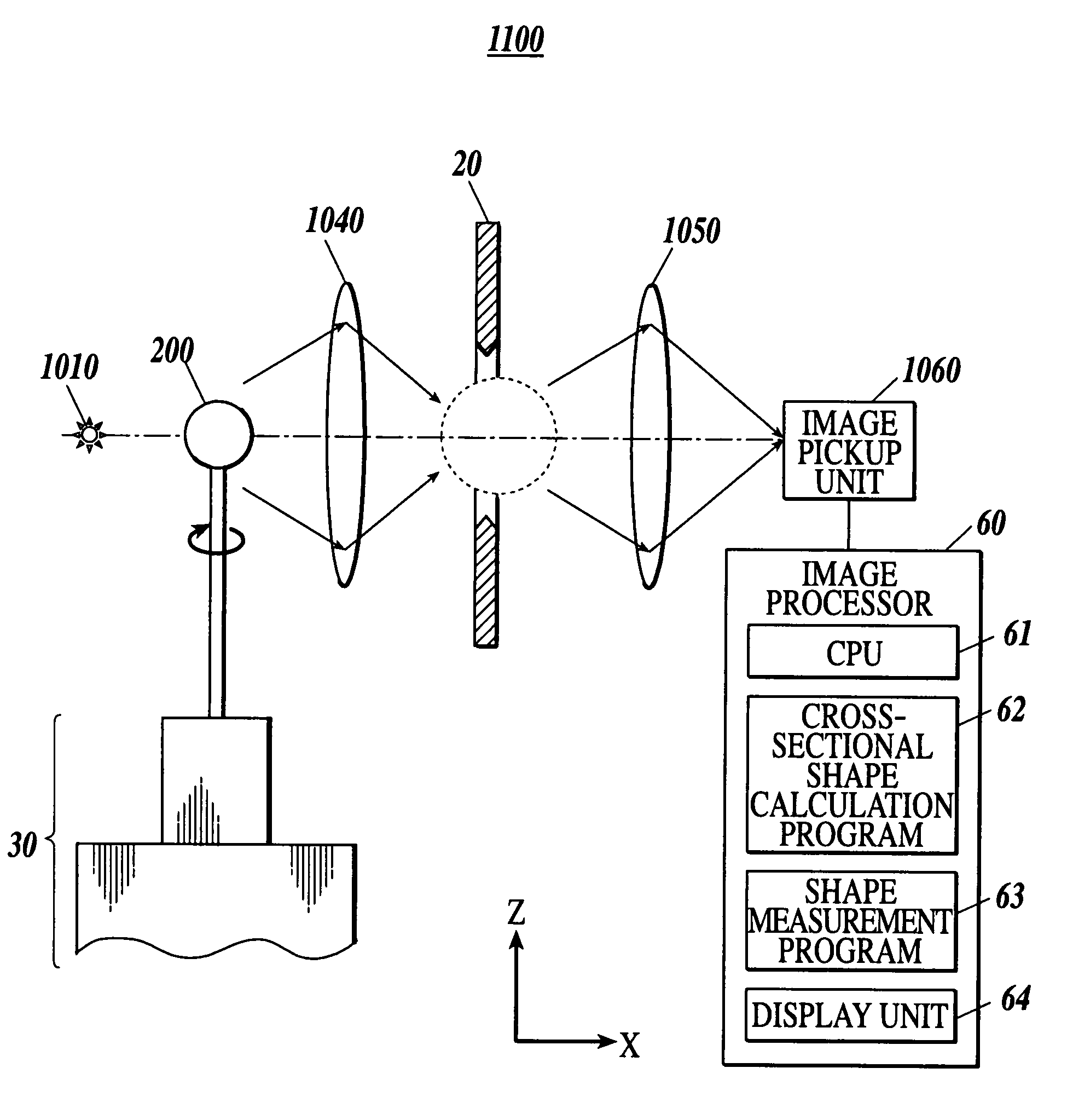

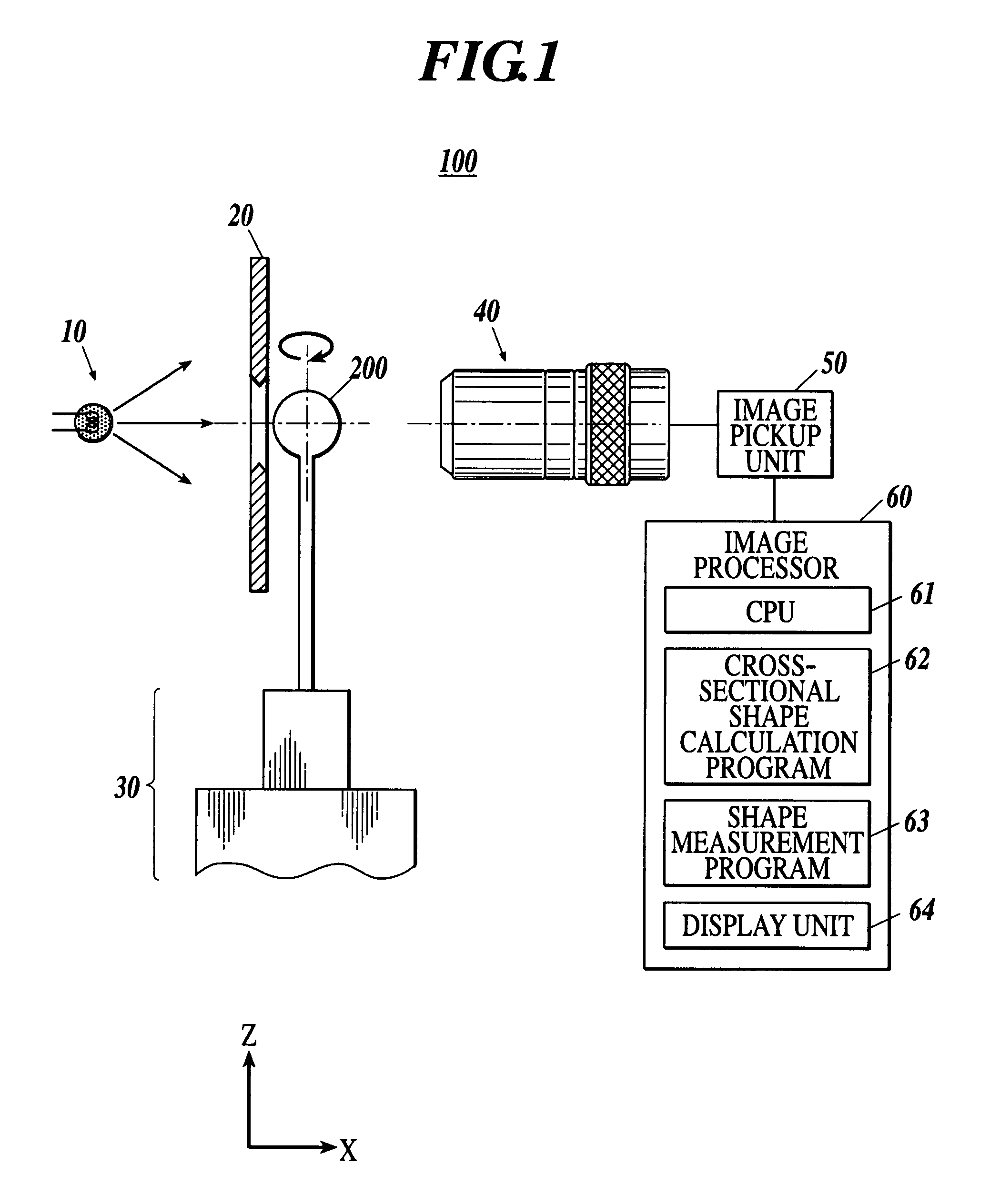

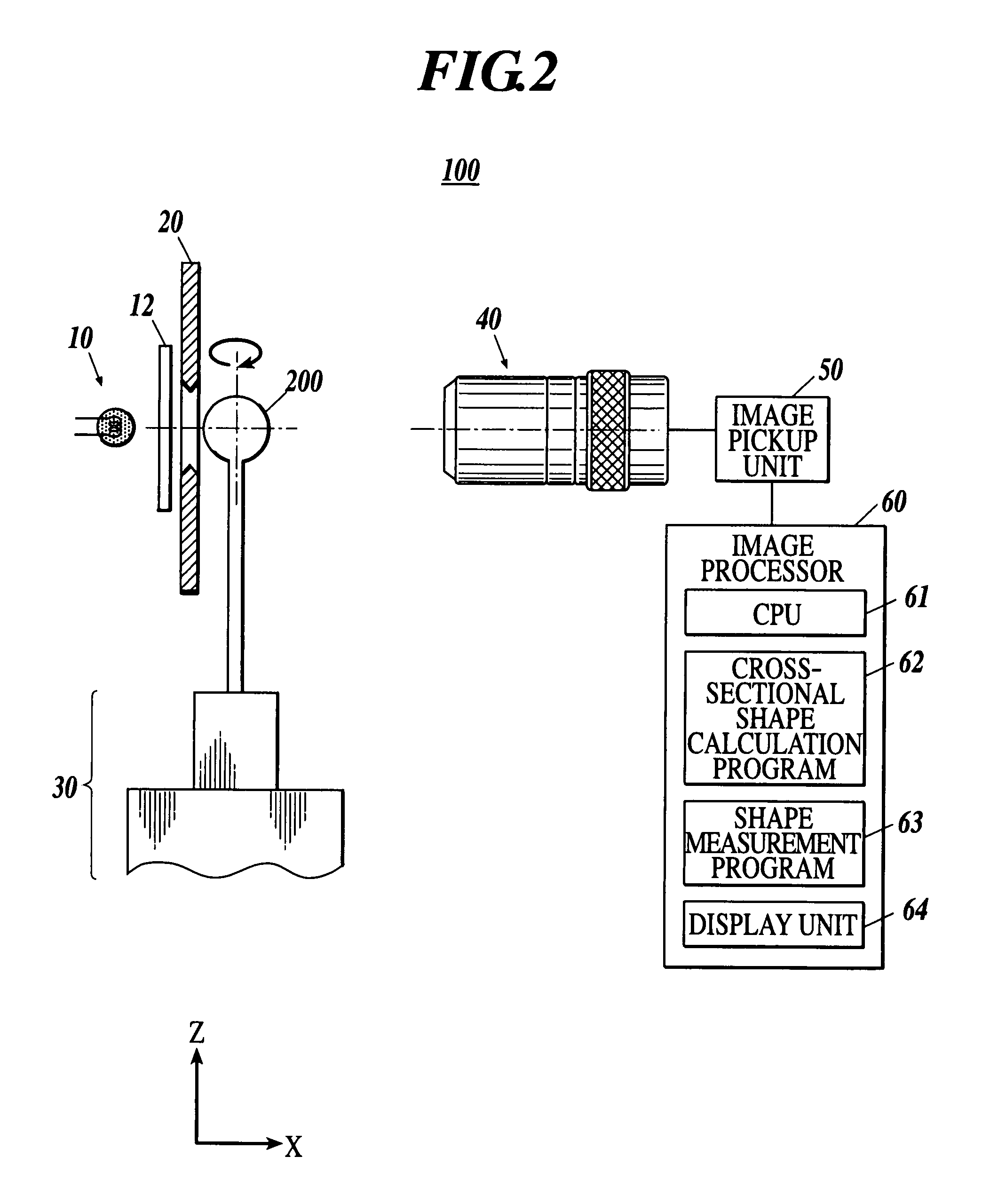

Shape measurement method and shape measurement apparatus

A shape measurement method for measuring a shape of an object to be measured, which has a substantially rotating symmetric shape, includes: placing an aperture having an opening larger than an outer shape of the object to be measured and the object to be measured on an optical axis; taking an image generated by light projected to the object to be measured, by using an image pickup unit; and calculating one cross-sectional shape of the object to be measured based on a light intensity distribution of the image taken by the image pickup unit.

Owner:MITUTOYO CORP

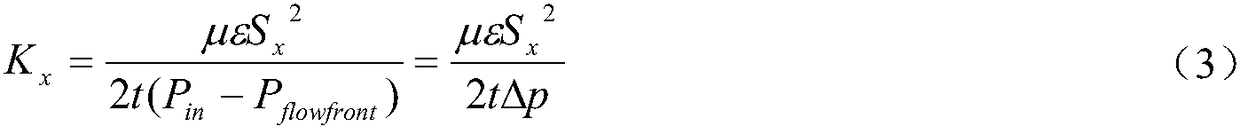

Device and method for measuring fiber permeability of flat plate preform

InactiveCN108982323AEasy and efficient measurementEasy to measurePermeability/surface area analysisFiberMold filling

The invention discloses a device and method for measuring the fiber permeability of a flat plate preform, belong to the field of production of composite laminated plates, and particularly relates to the device and method for measuring the fiber permeability of the flat plate preform. The device and the method aim at overcoming the existing defects. The device and method for measuring the fiber permeability of the flat plate preform have the advantages of being simple in measuring process, easy to operate, simple, convenient to use, efficient and capable of avoiding the cost waste. The method comprises the following steps that after a mold is cleaned, the mold is uniformly coated with a mold release agent, and a fiber preform, mold release cloth and a flow guide net are sequentially laid; sensors are placed in parallel in the resin flowing direction to monitor the resin flowing forward positions; and a vacuum pump is started to vacuumize the mold, resin fills the mold and flows, the fiber preform is impregnated, the resin flowing forward positions corresponding to different moments are recorded by utilizing the sensors, and the recorded mold filling time and the mold filling forwardare substituted into a formula so as to calculate the fiber permeability of the flat plate preform. The device and the method are mainly applied to measurement of the fiber permeability of the flat plate preform.

Owner:NORTHEAST FORESTRY UNIVERSITY

Tool for marking and measuring struts for construction

ActiveUS10260245B2Easy and efficient measurementEasy and efficient installationBuilding material handlingMechanical measuring arrangementsEngineeringMechanical engineering

Owner:MENDOZA JUAN

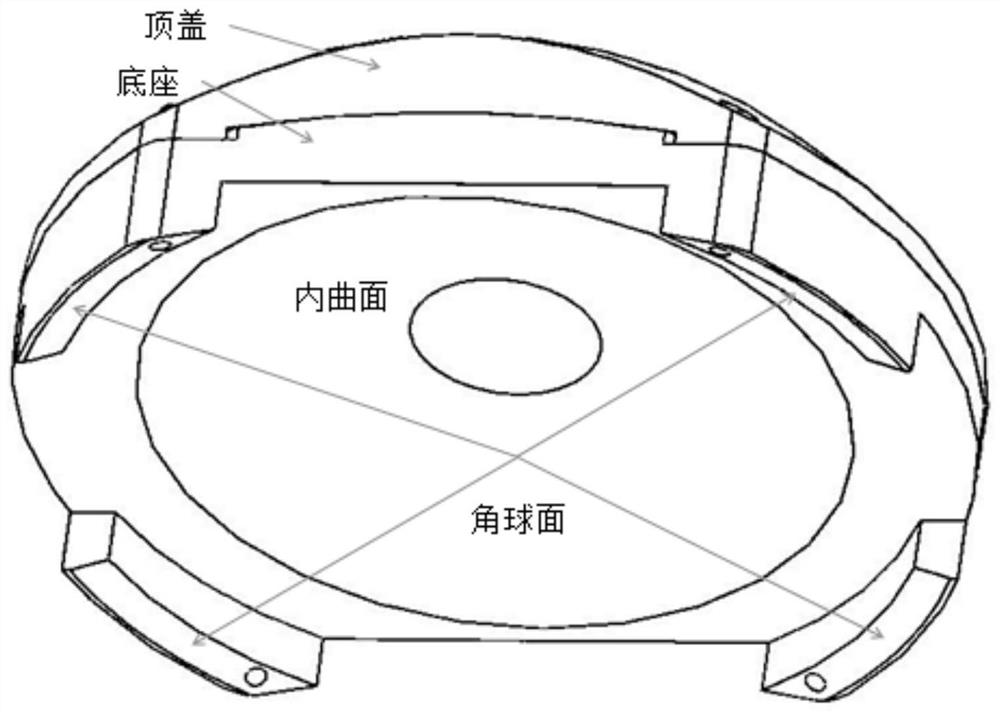

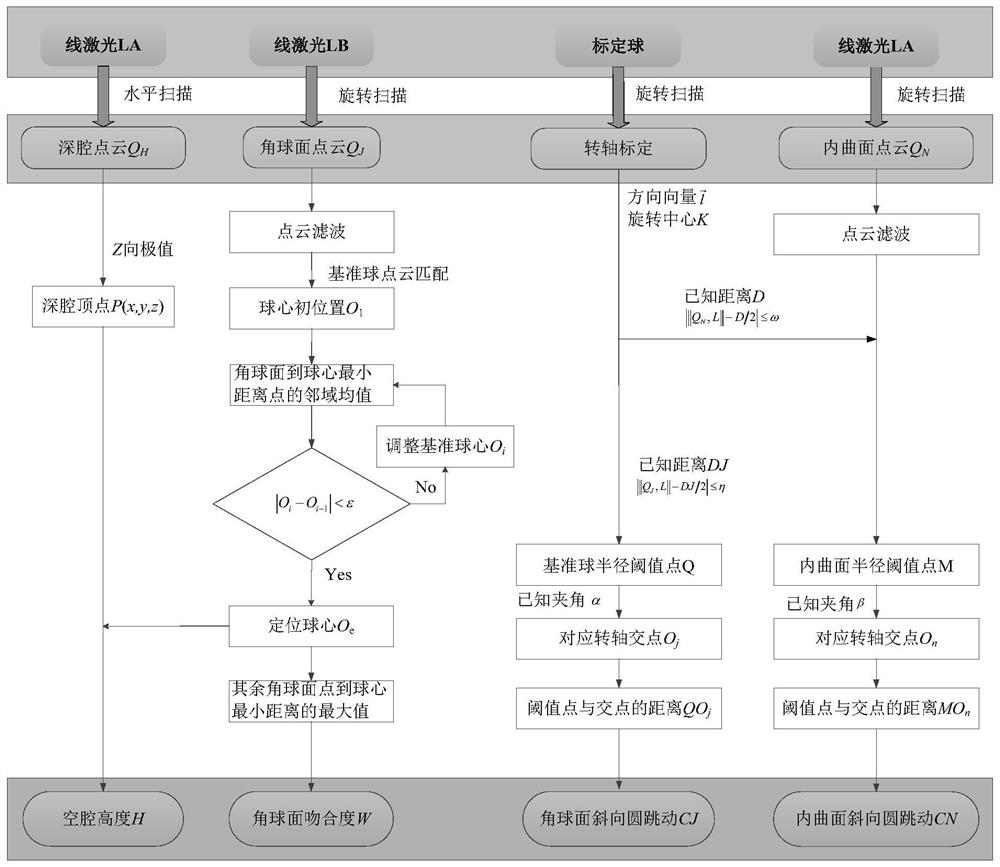

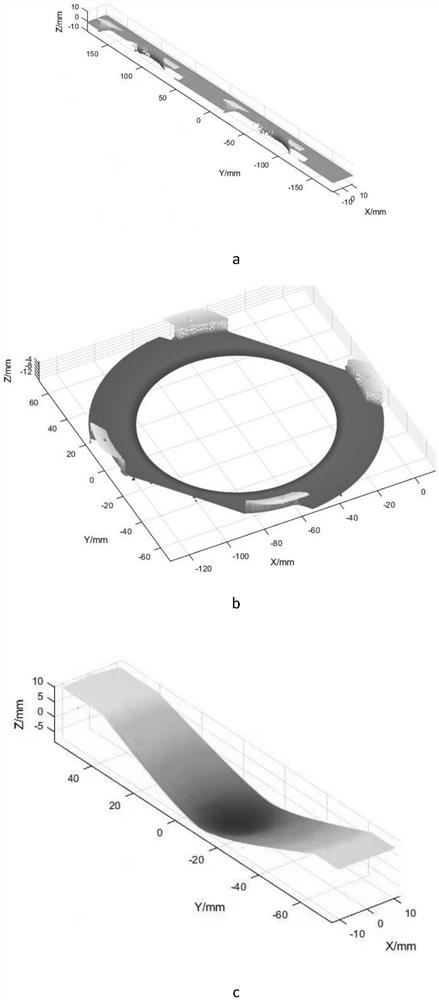

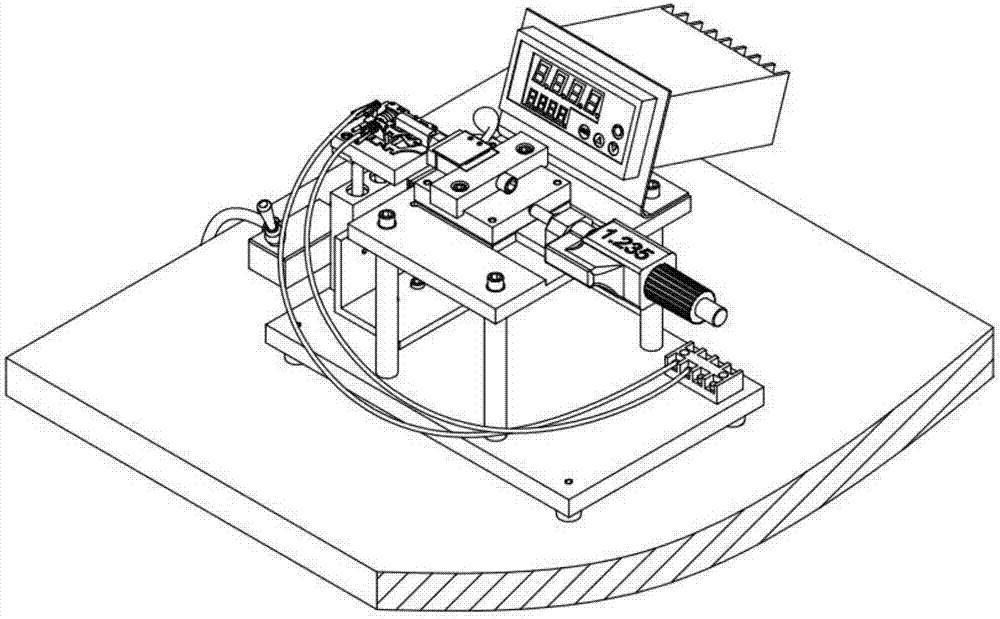

Line laser-based complex heterogeneous product assembly parameter detection method and system

ActiveCN113628210AHigh precisionImprove measurement efficiencyImage enhancementImage analysisPoint cloudRectangular coordinates

The invention discloses a line laser-based complex heterogeneous product assembly parameter detection method and system, and relates to the technical field of laser measurement. The key points of the technical scheme are as follows: placing a high-precision diffuse reflection ceramic standard ball on a rotary table, and carrying out light strip scanning on the standard ball by using a line laser to obtain a direction vector and a rotation center point of a rotating shaft; performing translation scanning on the bottom curved surface area of a complex heterogeneous product and performing rotation scanning on the to-be-detected areas of the angular spherical surface and the inner curved surface to obtain corresponding light bar data, and according to the obtained rotating shaft, performing Cartesian rectangular coordinate conversion to obtain three-dimensional point cloud data of the complex heterogeneous product; segmenting the three-dimensional point cloud data according to regions to obtain an angular spherical point cloud, an inner curved surface point cloud, and a bottom curved surface point cloud; calculating the height of a cavity, an angle spherical fit degree, an angle spherical oblique circle run-out, and an inner curved surface oblique circle run-out. The method has higher measurement efficiency, measurement consistency, and measurement accuracy, and realizes high-precision and high-efficiency measurement of assembly parameters.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

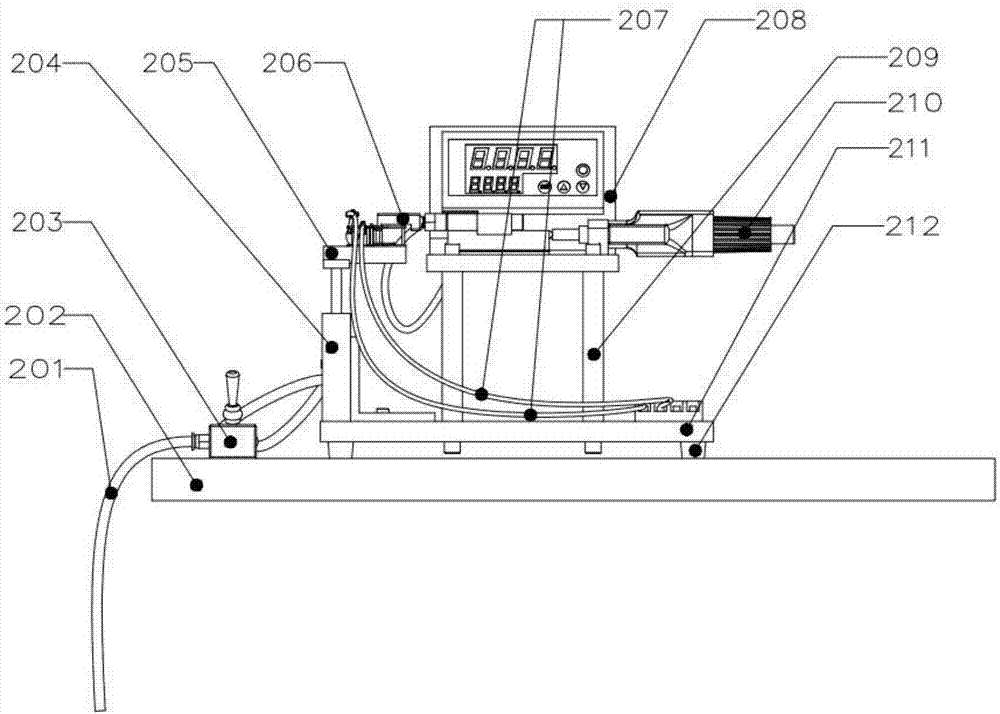

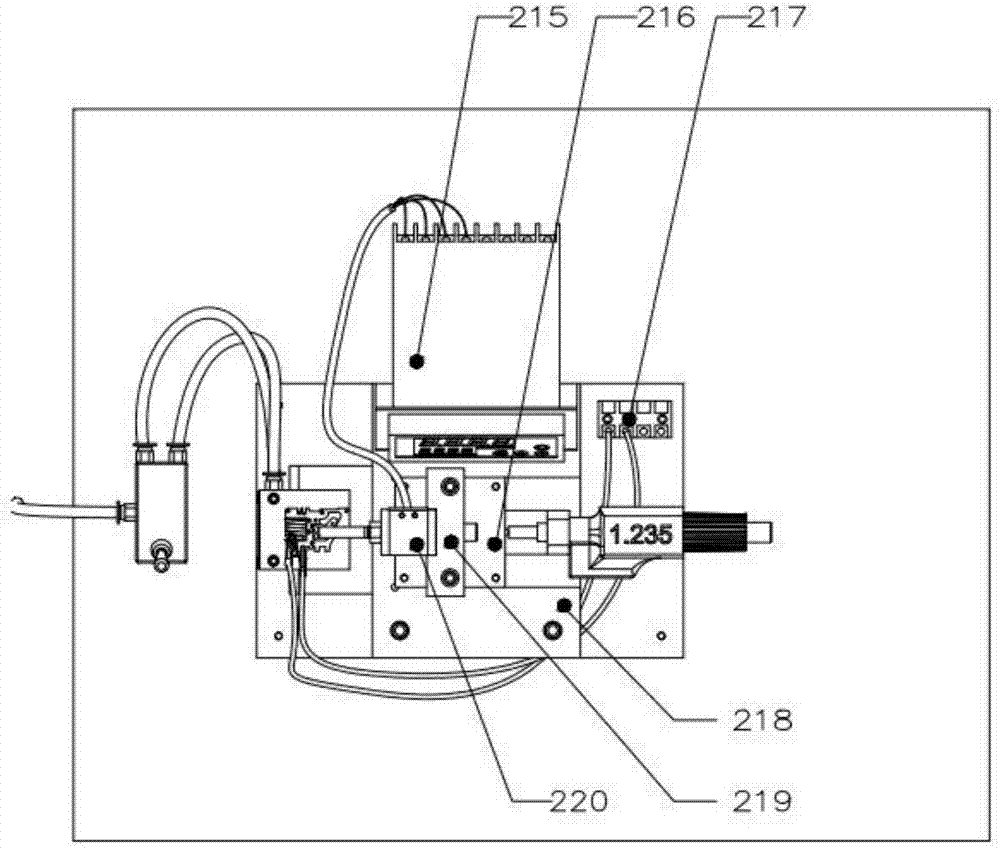

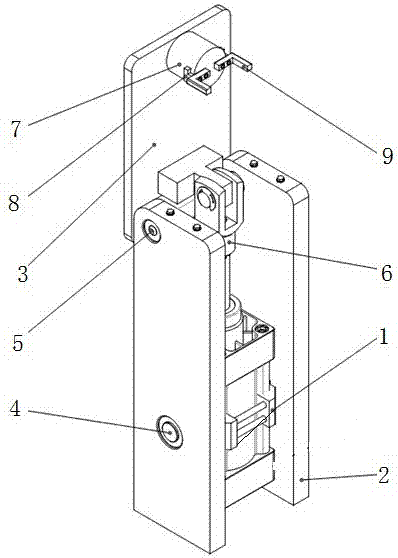

Electromagnetic circuit breaker coil assembly electromagnetic suction measuring device

InactiveCN107422284AEasy and efficient measurementSame qualityMagnetic property measurementsApparatus for force/torque/work measurementElectricityEngineering

The invention provides an electromagnetic circuit breaker coil assembly electromagnetic suction measuring device, which comprises a fixing seat, a pressing head and a force value sensor, wherein the pressing head is fixed at the front end of the force value sensor; a measured assembly is horizontally fixed on the fixing seat; the front end of the pressing head is contacted with an armature of the measured assembly; the force value sensor is fixed on a sensor fixing plate; the sensor fixing plate is arranged on a slip assembly; the slip assembly is fixed on the fixing plate; and the slip assembly adjusts the position of the sensor fixing plate in a front-rear direction through a sliding block adjustment differential head on the slip assembly. A wiring column bar is also arranged, and the wiring column bar is electrically connected with the measured assembly. Through the arrangement of the pressing head and the force value sensor, the electromagnetic suction of the electromagnetic circuit breaker coil assembly can be ensured to be measured conveniently and efficiently, and assemblies in each batch can be ensured to achieve the same quality.

Owner:GUIZHOU ZHENHUA HUALIAN ELECTRONICS

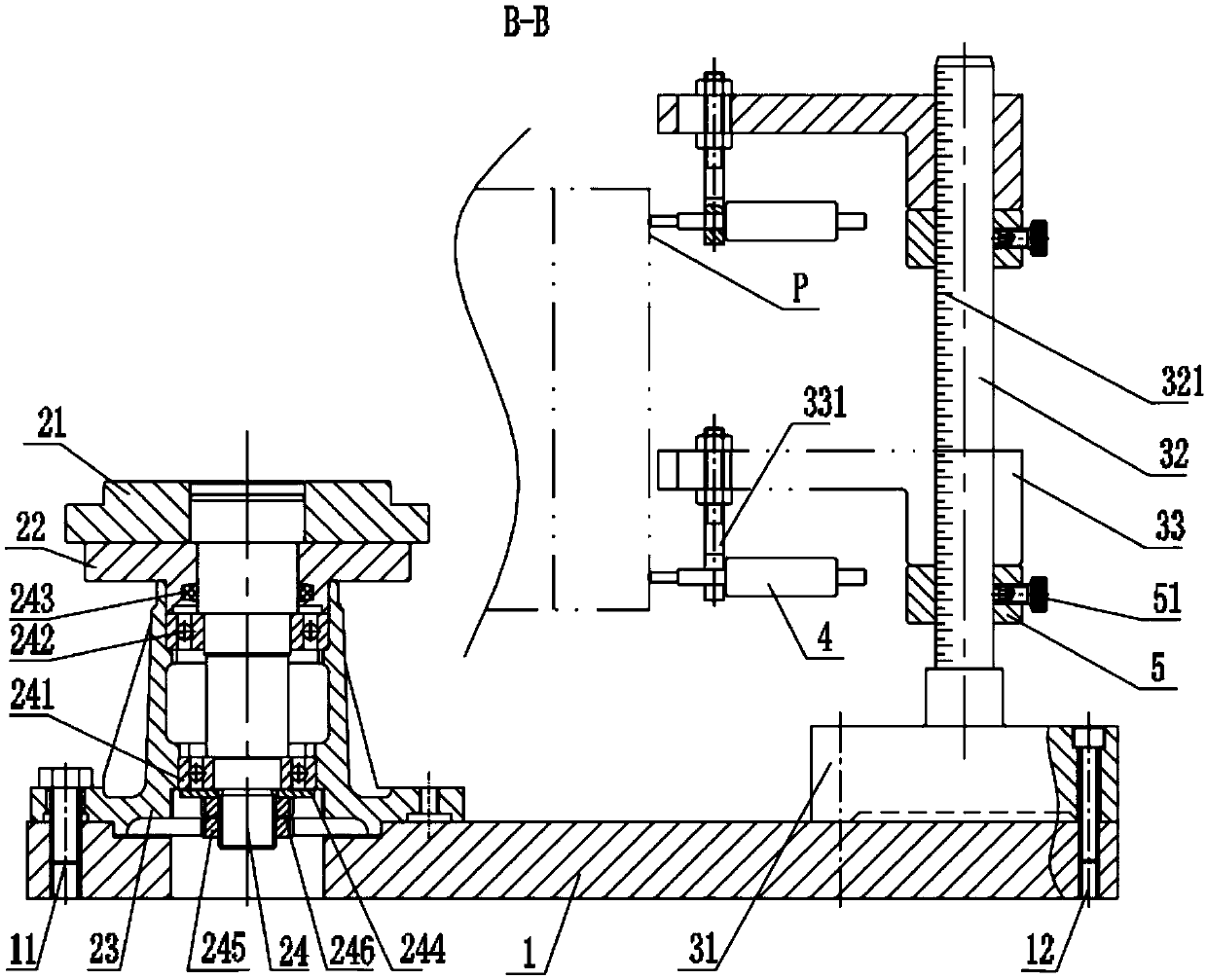

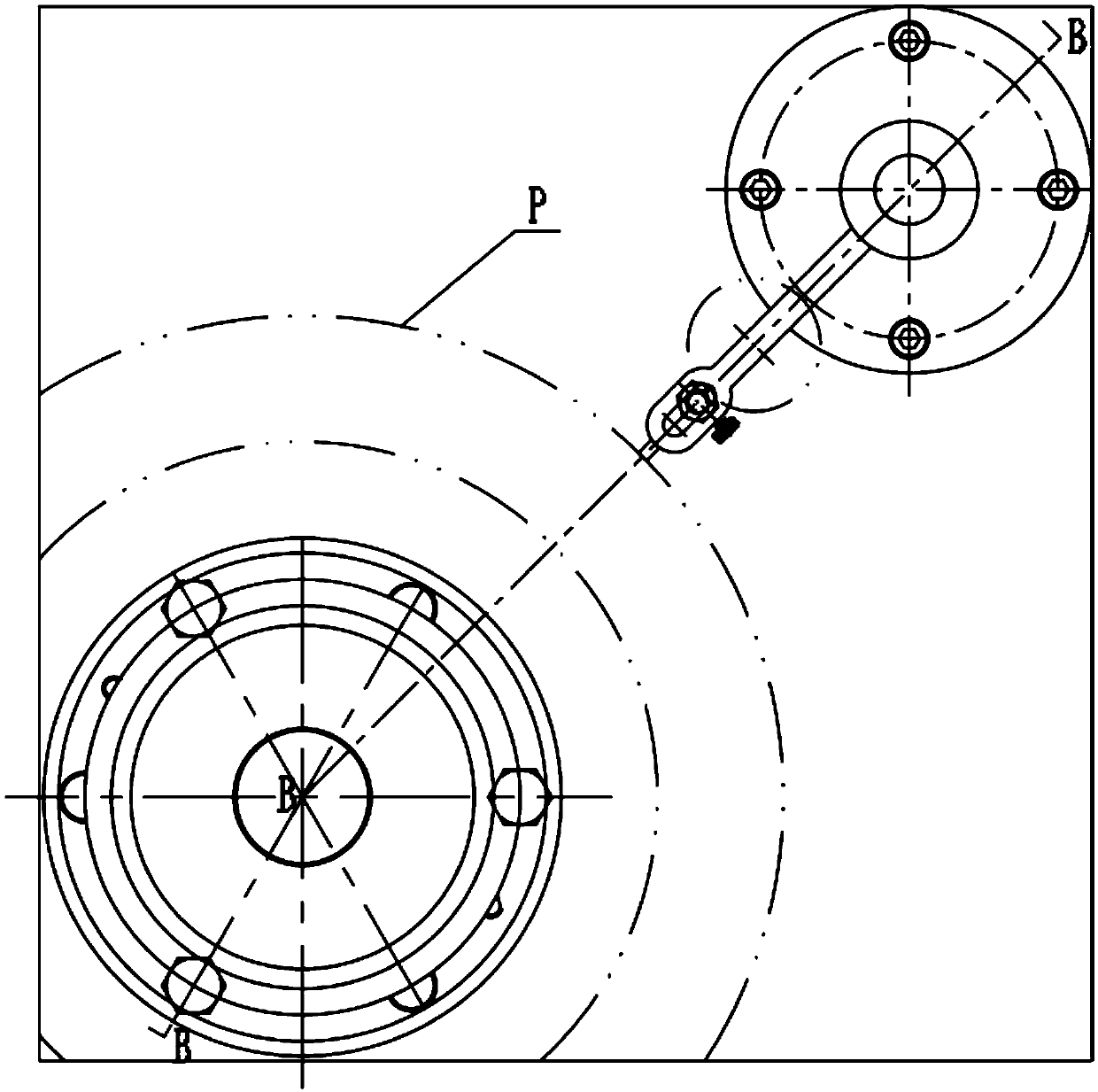

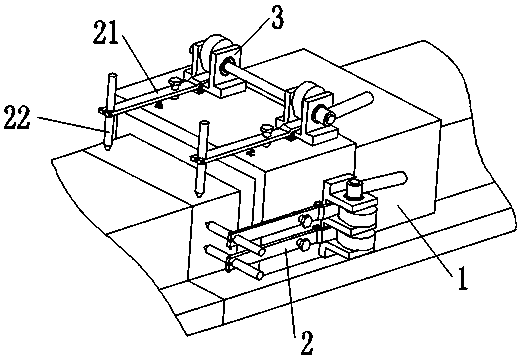

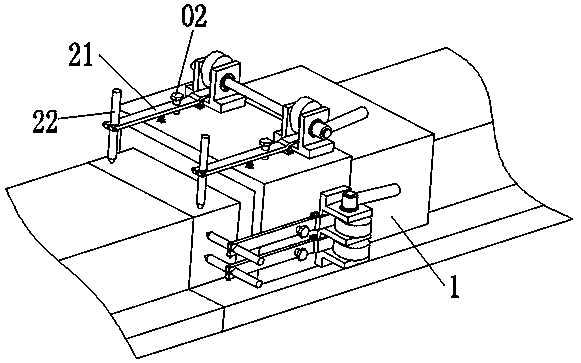

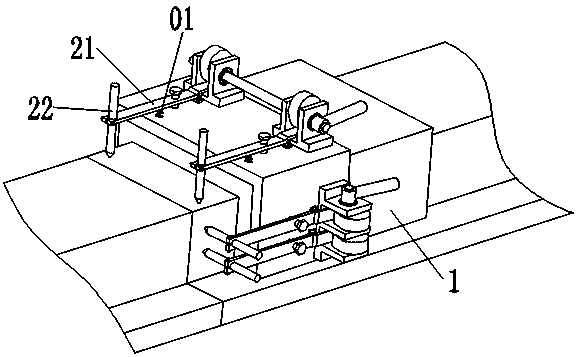

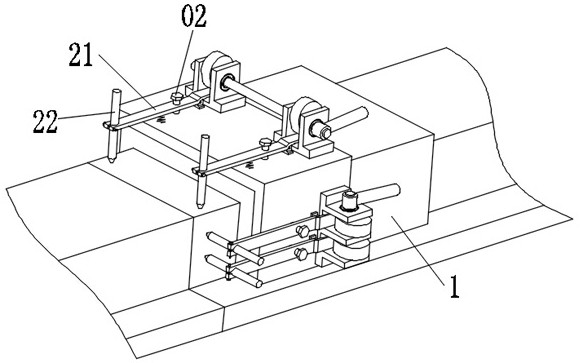

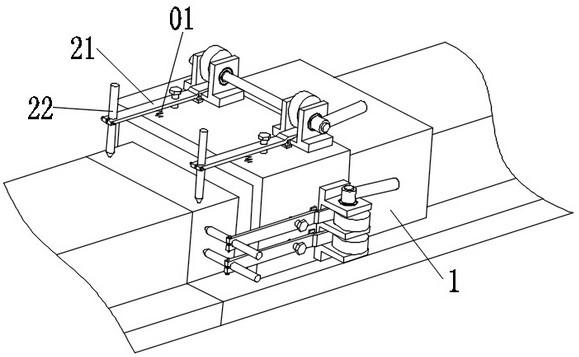

Detection tool for detecting runout and perpendicularity of brake assembly

PendingCN109556478AEasy and efficient measurementAccurate measurementMechanical measuring arrangementsEngineeringMechanical engineering

The invention discloses a detection tool for detecting the runout and the perpendicularity of a brake assembly. The detection tool comprises a detection tool base (1), a detection component seating portion, and a measuring mechanism. The detection component seating portion and the measuring mechanism are both arranged on the base. The measuring mechanism comprises a measuring table seat (31) arranged on the detection tool base (1); a supporting rod (32) arranged on the measuring table seat (31); and two brackets (33) slidably arranged along an axial direction of the supporting rod (32). A dialindicator (4) is arranged on any of the brackets (33). Each dial indicator (4) can slide along the length direction of each bracket (33). The detection tool not only accurately measures the tolerances of the runout and the perpendicularity of the brake assembly, but also measures various specifications of brake assemblies.

Owner:HUNAN YUNDA MACHINERY MFG

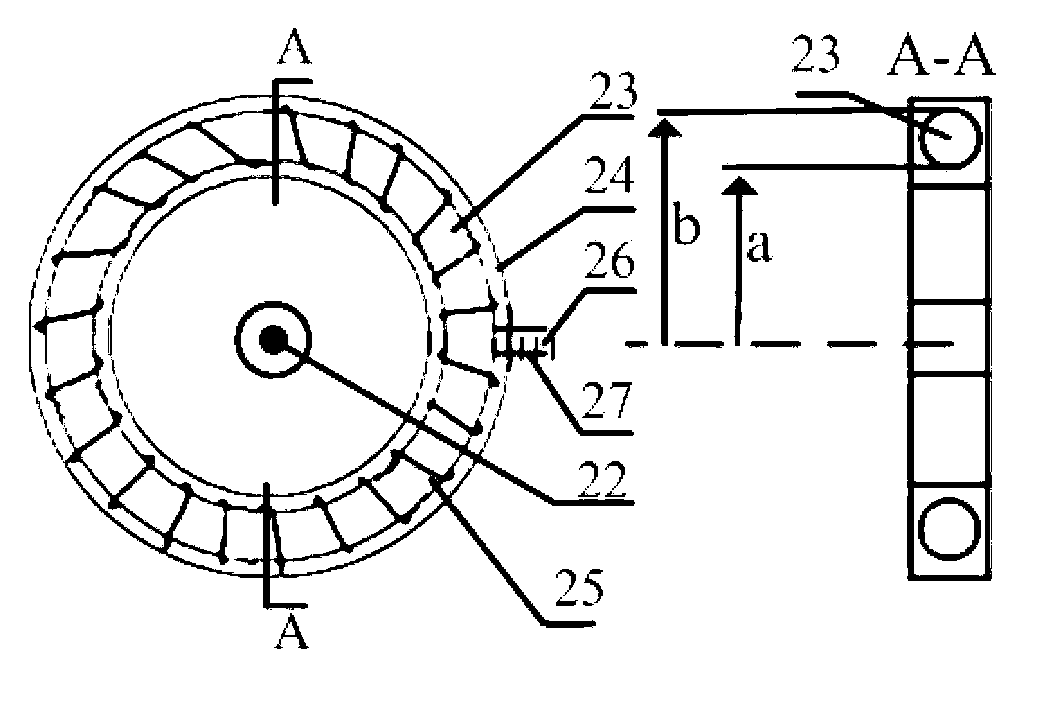

Accumulated snow parameter measurement instrument and using method

PendingCN109668947ASimple and fast operationImprove measurement efficiencyRainfall/precipitation gaugesMechanical depth measurementsMeasurement scalesPhysics

The invention aims to solve the technical problem of how to simply and efficiently measure accumulated snow parameters. An accumulated snow parameter measurement instrument comprises a host and a measurement scale, wherein the measurement scale comprises a main control shaft, measurement rods, a dielectric constant sensor and a temperature sensor; scales are arranged on the outer side of the measurement scale; the measurement scale is hollow; the main control shaft is vertically inserted into the measurement scale from top to bottom; the main control shaft is cylindrical; a vertical gear is arranged on the outer side of the main control shaft; a pair of measurement rods are arranged on the measurement scale at regular intervals; each pair of the measurement rods are located at the same horizontal height and are horizontally embedded into reserved holes in the measurement scale; the main control shaft is clamped between the measurement rods; the vertical gear matched with a main controlshaft gear is arranged on a contact surface between the measurement rods and the main control shaft; the dielectric constant sensor and the temperature sensor are respectively located at outer ends of the pair of measurement rods; lead wires are used for connecting the sensors with the host. According to the accumulated snow parameter measurement instrument, the accumulated snow parameters can bemeasured by vertically inserting the measurement scale into the bottom of the accumulated snow without the need of digging pits and vertically sectioning; the accumulated snow parameter measurement instrument is simple to operate.

Owner:HUNAN UNIV OF SCI & TECH

Detection tool for fuel injection pump bracket of engine

InactiveCN105258597AEasy and efficient measurementAccurate measurementMechanical measuring arrangementsEngineeringFuel injection

The invention discloses a detection tool for the fuel injection pump bracket of an engine. The detection tool comprises a measuring seat provided with a bottom plate and a side plate, a clamping mechanism and an auxiliary core shaft. The side plate is provided with two positioning pins corresponding to two positioning pin holes in the fuel injection pump bracket. The clamping mechanism is used for fixing the fuel injection pump bracket on the side plate. The diameter of the auxiliary core shaft is the same with the diameter of the inner arc surface of the fuel injection pump bracket. When the auxiliary core shaft is supported on the inner arc surface, the axis of the auxiliary core shaft and the axis of the inner arc surface are in the same line. According to the technical scheme of the invention, two important positioning dimensions of the fuel injection pump bracket can be measured by means of a height gauge only through one-shot clamping process. Therefore, the detection tool is convenient and efficient in measurement, and accurate in measurement result.

Owner:GUANGXI YUCHAI MASCH CO LTD

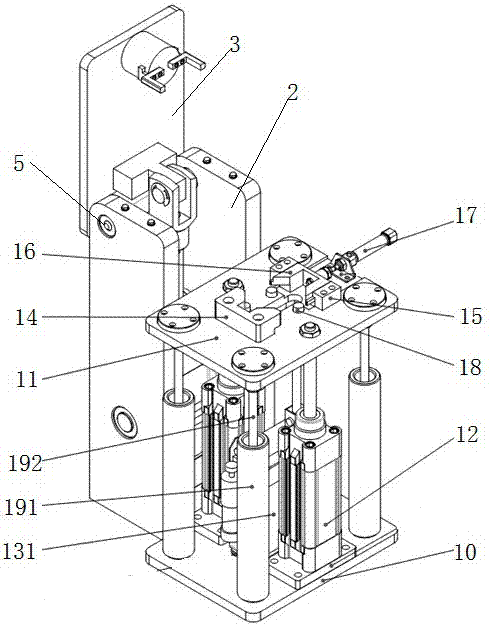

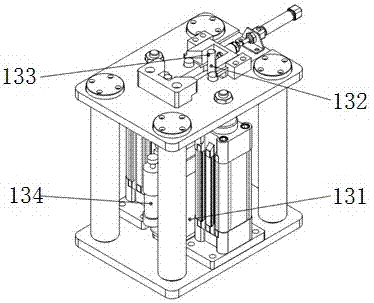

Hole depth measuring device and method

PendingCN111141247AAutomate your measurementsHigh measurement accuracyMechanical measuring arrangementsMeasurement deviceMechanical engineering

The invention provides a hole depth measuring device and method. The hole depth measuring device comprises a rack, a positioning feeding mechanism arranged on the rack and a detecting mechanism arranged above the positioning feeding mechanism. The positioning feeding mechanism comprises a feeding Y-axis module arranged on the rack and a bearing unit in transmission connection with the feeding Y-axis module. The bearing unit bears a product to be measured. The feeding Y-axis module of the positioning feeding mechanism conveys and feeds a product to the position below the detection mechanism, the detection mechanism detects and calculates multiple points on the surface of the product to obtain a datum plane, then the hole depth of the product is measured, the hole depth of the product is obtained, automatic measurement of the hole depth of the product is achieved, measurement is efficient and convenient, and measurement precision is high.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD

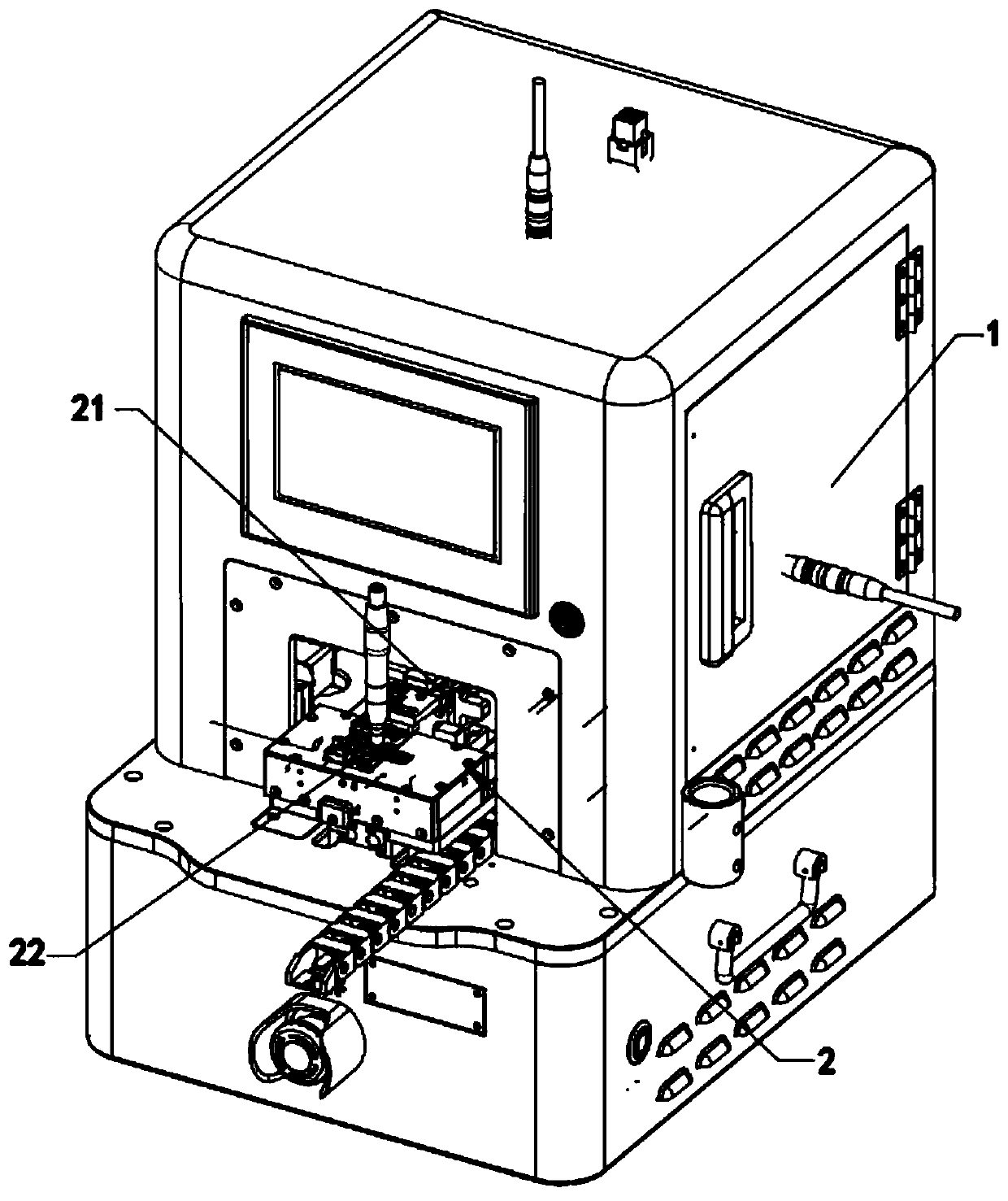

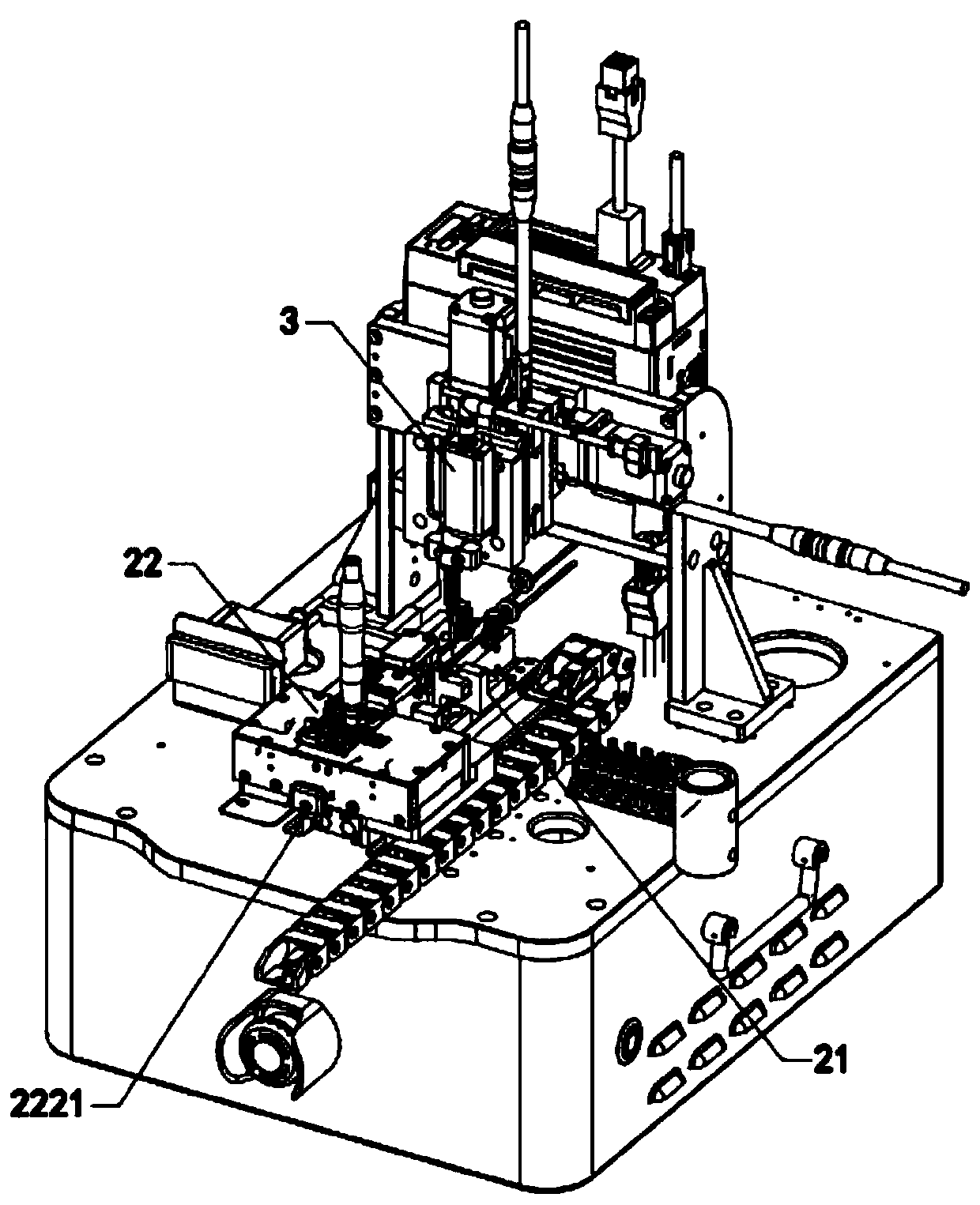

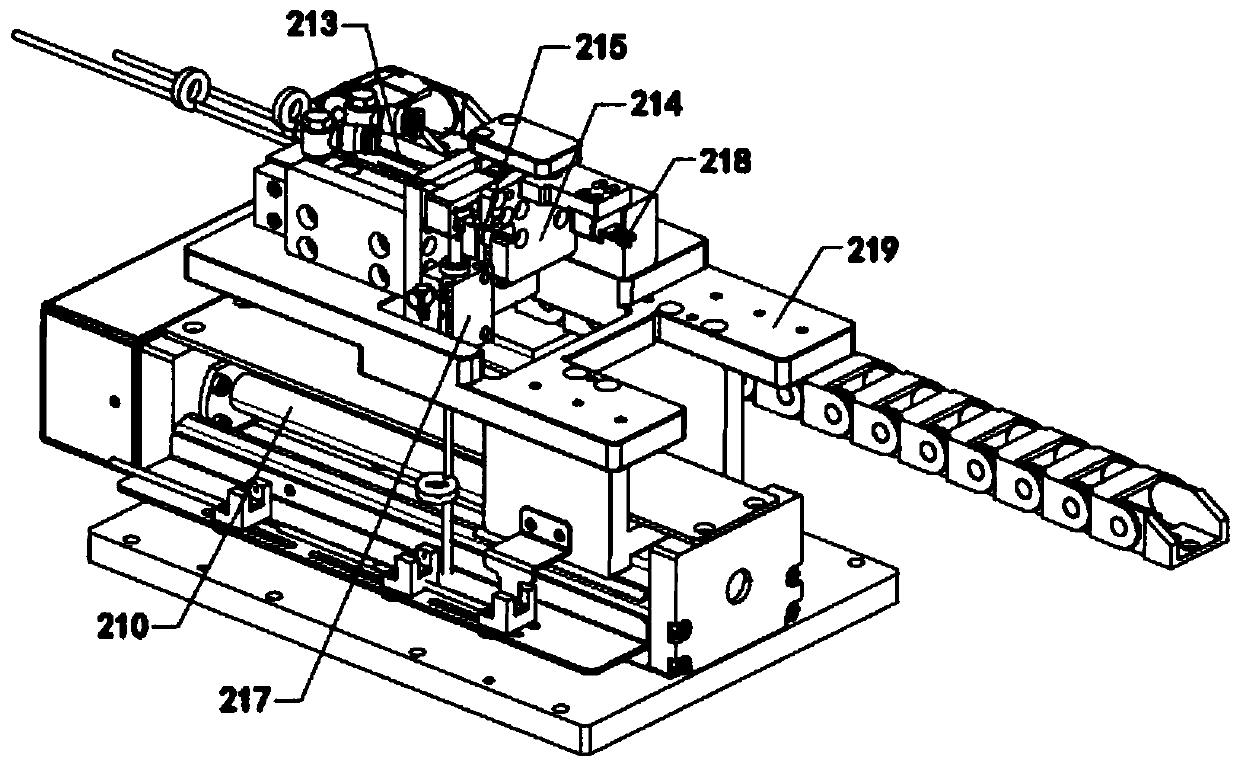

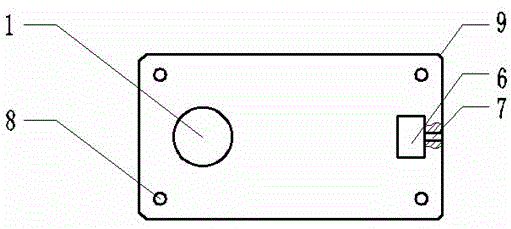

A flip-type online outer diameter automatic measuring device

ActiveCN104515490BRealize automatic feedingAchieve clampingMeasurement devicesMeasurement deviceIndustrial engineering

Owner:SUZHOU ZIJINGANG INTELLIGENT MFG EQUIP

Special gauge for detecting depth of suction hole

InactiveCN105627887AScientific and reasonable structureEasy to useMechanical depth measurementsEngineeringScrew thread

The invention discloses a special gauge for detecting the depth of a suction hole. The gauge comprises a positioning core, a measuring panel, a positioning hole and a measurement pin fixing hole; the positioning hole is formed at the left end of the measurement panel; the positioning core is mounted in the positioning hole; the measurement pin fixing hole is formed at the right end of the measurement panel; a fastening screw thread hole is formed to the right side of the measurement pin fixing hole; fixing holes are formed at the upper surface of the measuring panel; and the four edge corners of the measuring panel are provided with chamfers. The gauge of the invention has the advantages of scientific and reasonable structure and safe and convenient use. The measuring pin fixing hole can be provided with different types of measuring pins, and the fastening screw thread hole can be used in cooperation, and therefore, higher practicability can be realized; the measuring pin can be matched with the positioning core, so that the depth of the suction hole can be detected, and a simple positioning process of the suction hole can be completed; and the gauge is more convenient and efficient in use and measurement, so that wide-range popularization and application of the gauge can be benefitted.

Owner:WUHU YONGWEI REFRIGERATION ACCESSORIES MFG CO LTD

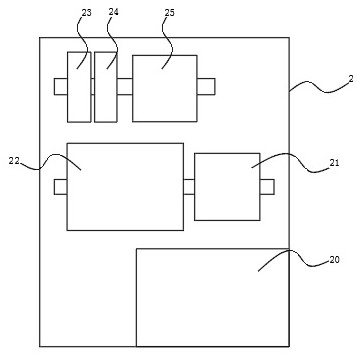

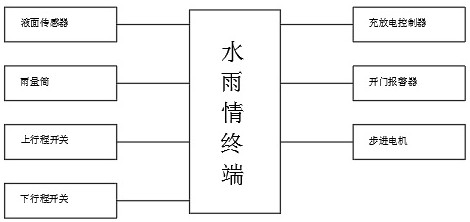

Water conservancy project water rain condition monitoring device

InactiveCN113267234AHigh measurement accuracyEasy and efficient measurementMachines/enginesLevel indicatorsWater useElectrical battery

A water conservancy project water rain condition monitoring device comprises a vertical rod used for supporting and further comprises an equipment box, a lightning arrester and a charging and discharging controller, the equipment box is arranged on one side of the bottom end of the vertical rod, the lightning arrester is installed in the middle of the top end of the vertical rod, a support is fixed to one side of the top of the vertical rod, and a rain gauge is installed at the top end of the middle of the support. A solar cell is installed at one end of the support, a base is arranged on one side of the vertical rod, an upper travel switch is installed at the top end of the base, a lower travel switch is installed at the bottom of the base, a stepping motor is installed on the vertical rod on one side of the support, a speed reducer is installed at one end of the stepping motor, and a lead screw is installed at one end of the speed reducer. The integrated water and rain condition monitoring device for the water conservancy project has the advantages of low cost, simple structure and the like, the convenience of installation and maintenance is improved, the device has the advantages of low cost, high precision, difficulty in data drift and the like, the reliability of water level monitoring is improved, and a door opening alarm is additionally arranged in the equipment box, so that field theft prevention is facilitated.

Owner:杭州思远自动化系统工程有限公司

Drill pipe for measuring soil depth

InactiveCN103727864ASimple structureEasy and efficient measurementMechanical depth measurementsPortable drilling machinesSoil depthDrill bit

The invention provides a drill pipe for measuring the soil depth. The drill pipe comprises a ruler rod, a drill bit, a handle, a screw and a nut. The ruler rod is provided with a drilling hole, the handle is composed of two same thin plates, round holes are formed in the thin plates, the thin plates are provided with two U-type grooves, scales are disposed on the ruler rod, and the drill bit is tapered. The drill pipe for measuring the soil depth is simple in structure, economical and practical, measuring is very convenient and efficient to achieve due to the arrangement of the drill bit and the handle, adjustment is convenient to achieve, and the scales on the drill rod enable a measurer to measure the soil depth in the first time.

Owner:华国洋

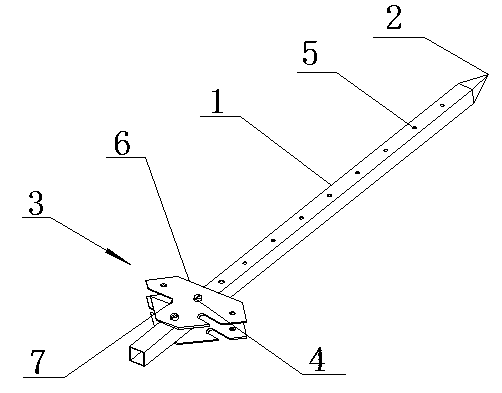

Filament diameter detection device and method

ActiveCN104457598BEasy to operateEasy and efficient measurementUsing optical meansLiquid-crystal displayImaging processing

The invention discloses a filament diameter detection device, comprising: a liquid crystal display, a micro imaging system, an image sensor, and an image processing system; the micro imaging system is aligned with the liquid crystal display, the micro imaging system is connected with the image sensor, and the image sensor will The image formed by the microscope imaging system is transmitted to the image processing system. The filament diameter detection method of the present invention includes the following steps: 1) calculating the image pixel distance between each liquid crystal pixel on the liquid crystal display; 2) calculating the image in the image according to the actual pixel spacing of the liquid crystal display The ratio of the pixel distance to the actual distance; 3) Calculate the pixel diameter of the filament in the liquid crystal display; 4) Calculate the actual diameter of the filament according to the ratio obtained in step 2). The invention is beneficial in that the uniformity and accuracy of each pixel point in the liquid crystal display are fully utilized, the diameter of the filament is measured in a non-contact manner, and the system device is simple and easy to operate.

Owner:SUZHOU JIANGAO OPTOELECTRONICS TECH

Guide rail splicing error measuring device

ActiveCN109631804AAvoid wear and tearEasy and efficient measurementUsing electrical meansUsing optical meansEngineeringElectrical and Electronics engineering

The invention discloses a guide rail splicing error measuring device. The guide rail splicing error measuring device comprises an air floating supporting plate, measuring devices and pressing mechanisms, wherein the measuring devices are arranged on the top of the air floating supporting plate and one adjacent side face on the top of the air floating supporting plate; each measuring device comprises levers and coplanarity sensors, the fulcrum of each lever is installed on the side wall of the air floating supporting plate, the cantilever end of each lever is provided with the coplanarity sensor, and the other end of each lever is provided with the pressing mechanism; and each measuring device comprises two levers which are arranged in parallel. The device has the beneficial effects that the device can continuously measure the coplanarity of multiple guide rails and the coplanarity of the top surfaces and the side surfaces of adjacent guide rails conveniently and efficiently with simpleoperation, and can monitor coplanarity error in real time.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

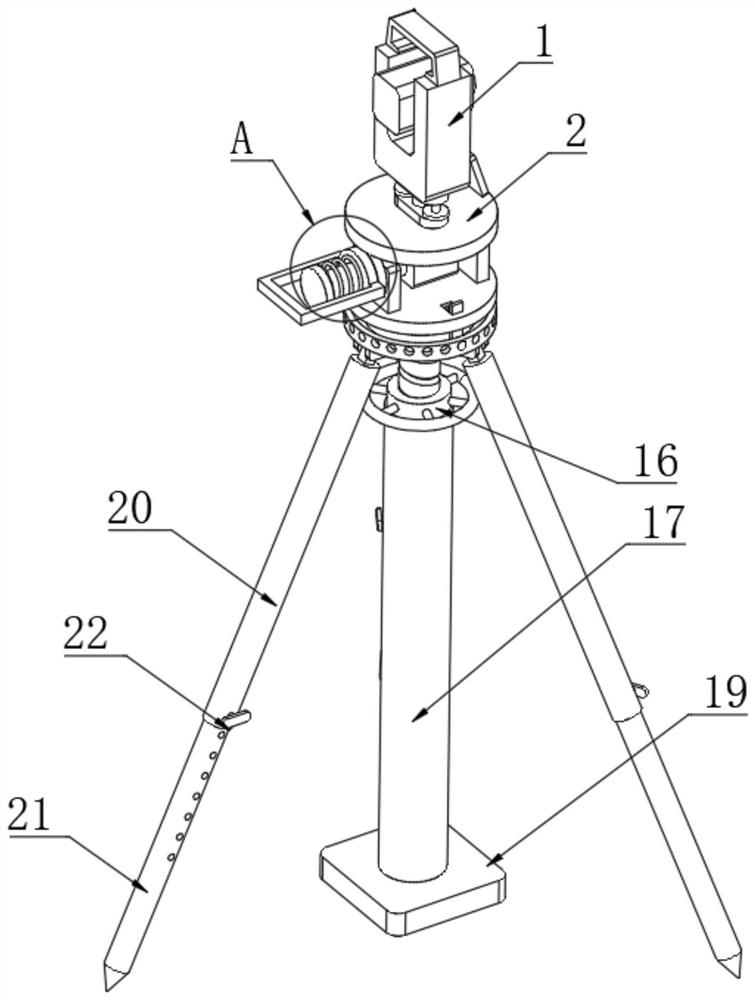

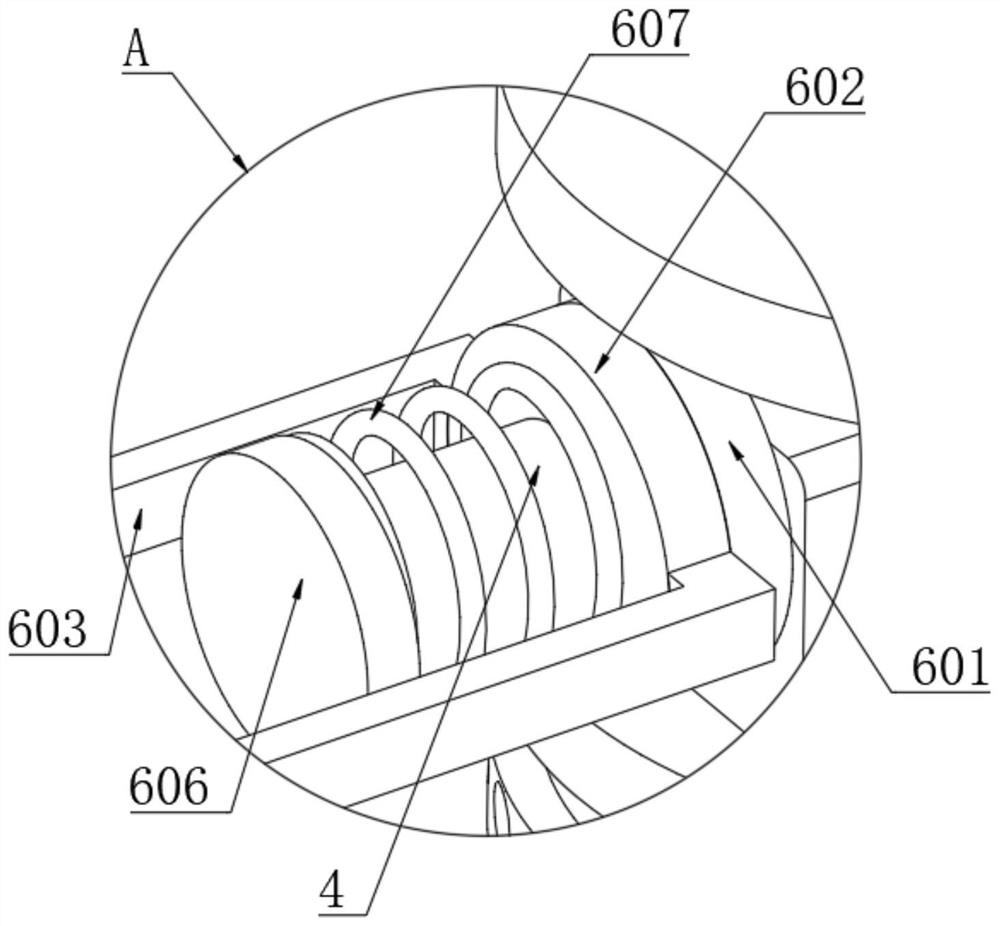

Photoelectric measuring device for photoelectric detection

PendingCN114738610AImprove the accuracy of physical quantity surveying and mappingAdjust levelSurveying instrumentsStands/trestlesEngineeringMechanical engineering

The invention relates to the technical field of photoelectric measurement equipment, and discloses a photoelectric measurement device for photoelectric detection, which comprises a measurer, a fixed table is fixedly arranged at the bottom of the measurer, a connecting block for rotary adjustment is fixedly arranged at the bottom of the fixed table, and a connecting shaft is fixedly arranged on the side surface of the connecting block. The two ends of the connecting shaft penetrate through the connecting blocks, and the connecting shaft is rotationally sleeved with two connecting plates. According to the photoelectric measurement device for photoelectric detection, through arrangement of a connecting block and a connecting shaft, a pull handle is pulled, and the pull handle drives a sliding disc to slide, so that a limiting block is separated from a limiting hole in a fixed disc, the connecting block drives a fixed table to rotate, and angle adjustment is performed on a measurer at the top of the fixed table; the levelness of the measurer is ensured to be adjusted, so that the levelness measurement of the measurer can be ensured, and the physical quantity surveying and mapping precision of the photoelectric measuring device is further improved.

Owner:厦门海洋职业技术学院

A guide rail splicing error measuring device

ActiveCN109631804BAvoid wear and tearEasy and efficient measurementUsing electrical meansUsing optical meansMeasurement deviceCantilever

The invention discloses a guide rail splicing error measuring device. The guide rail splicing error measuring device comprises an air floating supporting plate, measuring devices and pressing mechanisms, wherein the measuring devices are arranged on the top of the air floating supporting plate and one adjacent side face on the top of the air floating supporting plate; each measuring device comprises levers and coplanarity sensors, the fulcrum of each lever is installed on the side wall of the air floating supporting plate, the cantilever end of each lever is provided with the coplanarity sensor, and the other end of each lever is provided with the pressing mechanism; and each measuring device comprises two levers which are arranged in parallel. The device has the beneficial effects that the device can continuously measure the coplanarity of multiple guide rails and the coplanarity of the top surfaces and the side surfaces of adjacent guide rails conveniently and efficiently with simpleoperation, and can monitor coplanarity error in real time.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

Tool for marking and measuring struts for construction

ActiveUS20180334819A9Easy and efficient measurementEasy and efficient installationBuilding material handlingMechanical measuring arrangementsEngineeringMechanical engineering

A tool shaped in a U-shape for accepting a standard U strut. The tool has opening for marking the strut for cutting purposes and hole openings for marking the center of standard struts.

Owner:MENDOZA JUAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com