Method for determining blending ratios of milk protein modified polyacrylonitrile fibers to wools

A polyacrylonitrile fiber and milk protein technology, which is applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of unideal test plan and long time consumption, and achieve shortened test cycle, convenient operation and accurate results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for measuring the blending ratio of milk protein modified polyacrylonitrile fiber and wool, comprising the steps of:

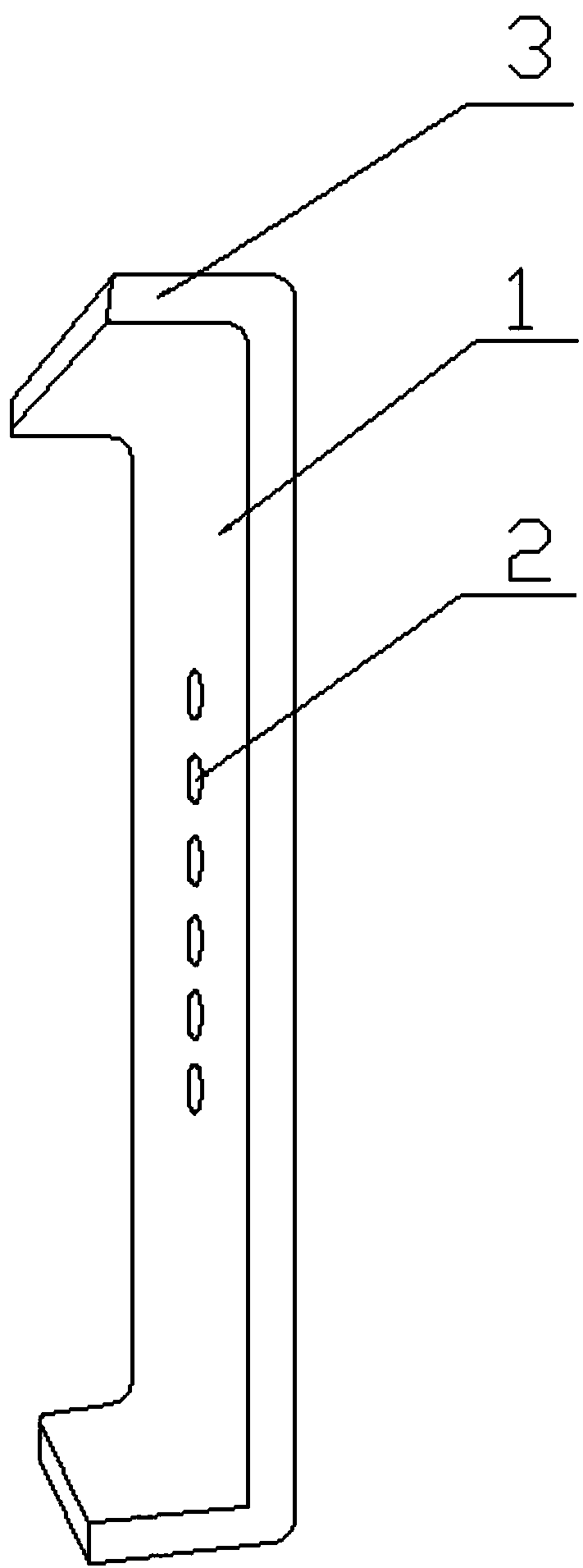

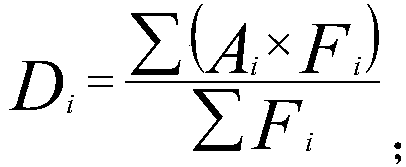

[0040] 1) Sample preparation: clamp a special object carrier, the special object carrier includes a rectangular object carrier body 1 with a thickness of 0.5 mm, the object carrier body 1 is made of aluminum alloy, and the object carrier The two ends of the sheet body 1 are bent downwards to form two vertical folds 3, and a number of round holes are provided along the center line of the length direction of the slide body. The diameter of the round holes 2 is 0.8mm. For the core filler, remove the fibers at eight points in different positions, and finally arrange the fibers into parallel bundles through the method of continuous shrinkage, take one of the bundles, add a certain twist, and pass through the slide body from one side Tighten the round hole on the top from the other side, use a blade to cling to the upper and lower surfaces of the sli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com