Device and method for measuring numerical control turning machining dynamic cutting force

A measuring device and cutting force technology, applied in metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of complex installation, low measurement accuracy, measurement data error, etc., to reduce the interference of measurement data, Increased accuracy and reliability, results in precise data measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

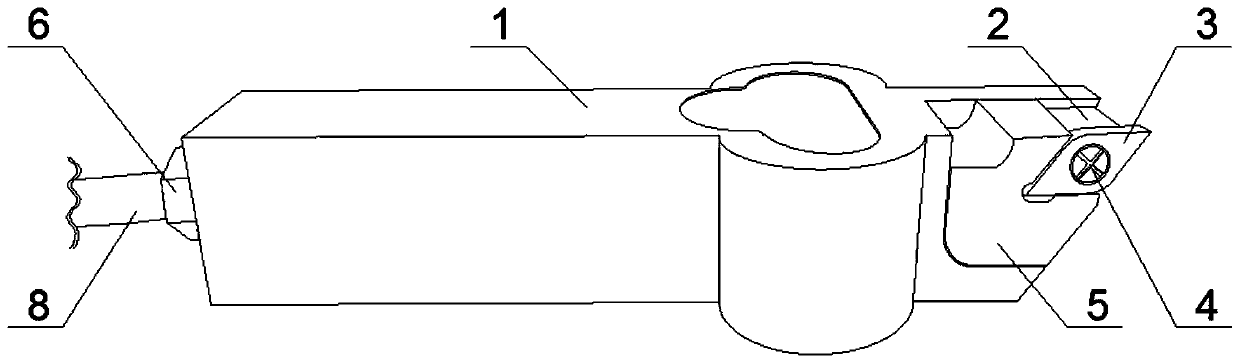

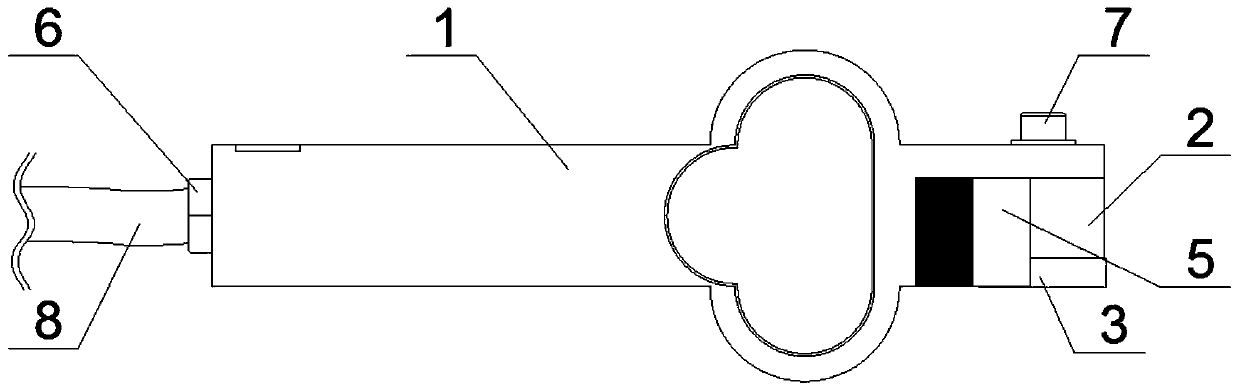

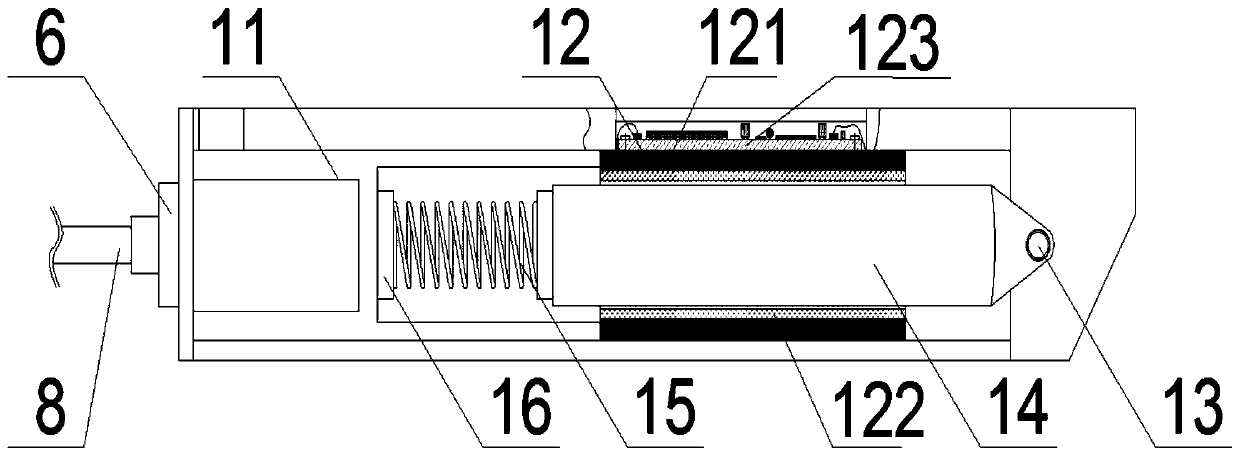

[0039] The invention provides a dynamic cutting force measuring device (referred to as the device, see Figure 1-6), including knife bar 1, fixed knife seat 2, blade 3 and anti-skid pad 5; described anti-skid pad 5 is fixed on the right front end of knife bar 1 outside by fixing bolt 7, is used for assisting fixed blade 3; fixed knife seat 2 It is fixed on the outside of the knife bar 1 and is located at the top right side of the anti-skid pad 5; the blade 3 is threadedly connected to the fixed knife seat 2 through the mounting bolt 4 and is located at the top right side of the anti-slip pad 5;

[0040] It is characterized in that the device also includes a data processing module 11, a force sensor 12, a linkage pin hole 13, an exciting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com