Method for automatically cleaning tools and measuring lengths of tools on line

A tool length, automatic cleaning technology, applied in the direction of manufacturing tools, metal processing equipment, milling machine equipment, etc., can solve the problems of low efficiency, not economical, etc., achieve accurate measurement, reduce the effect of built-up edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

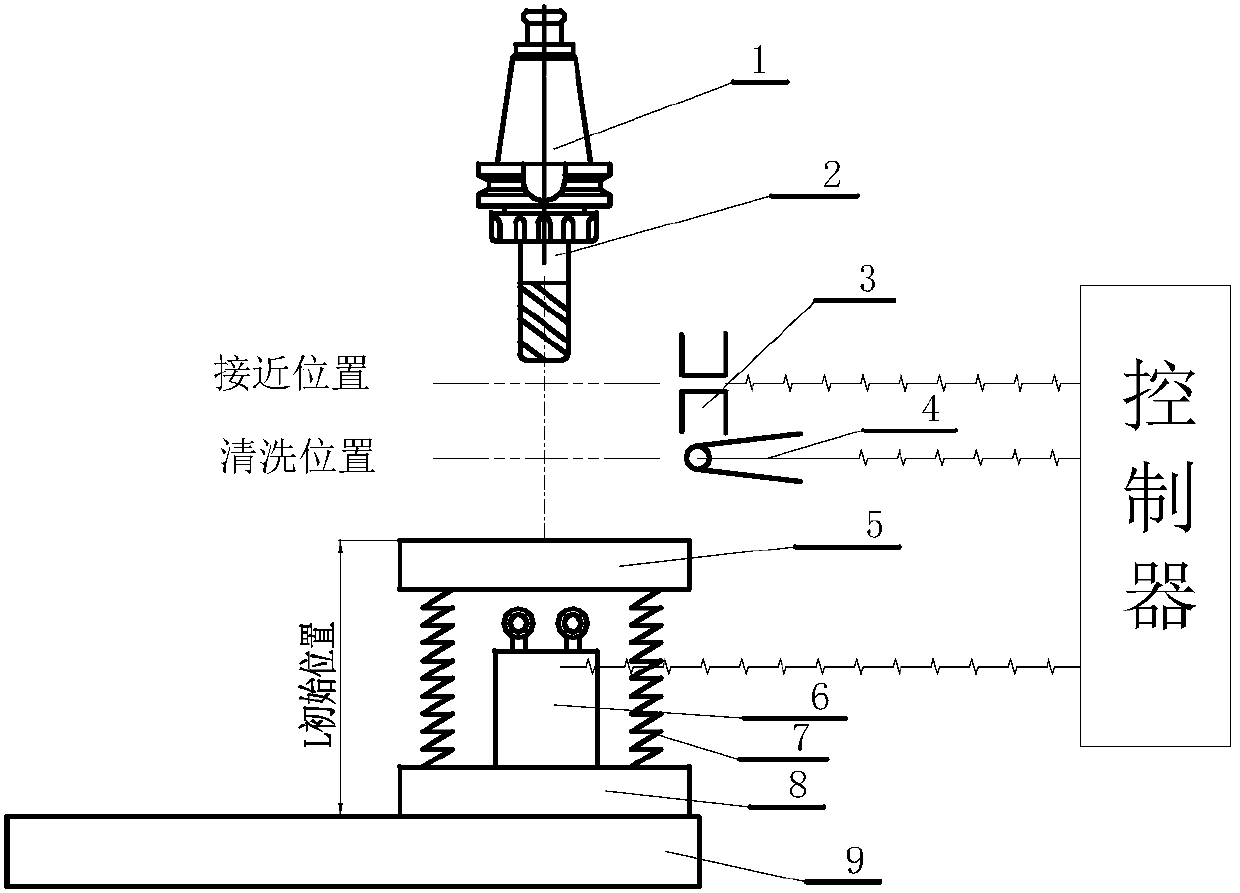

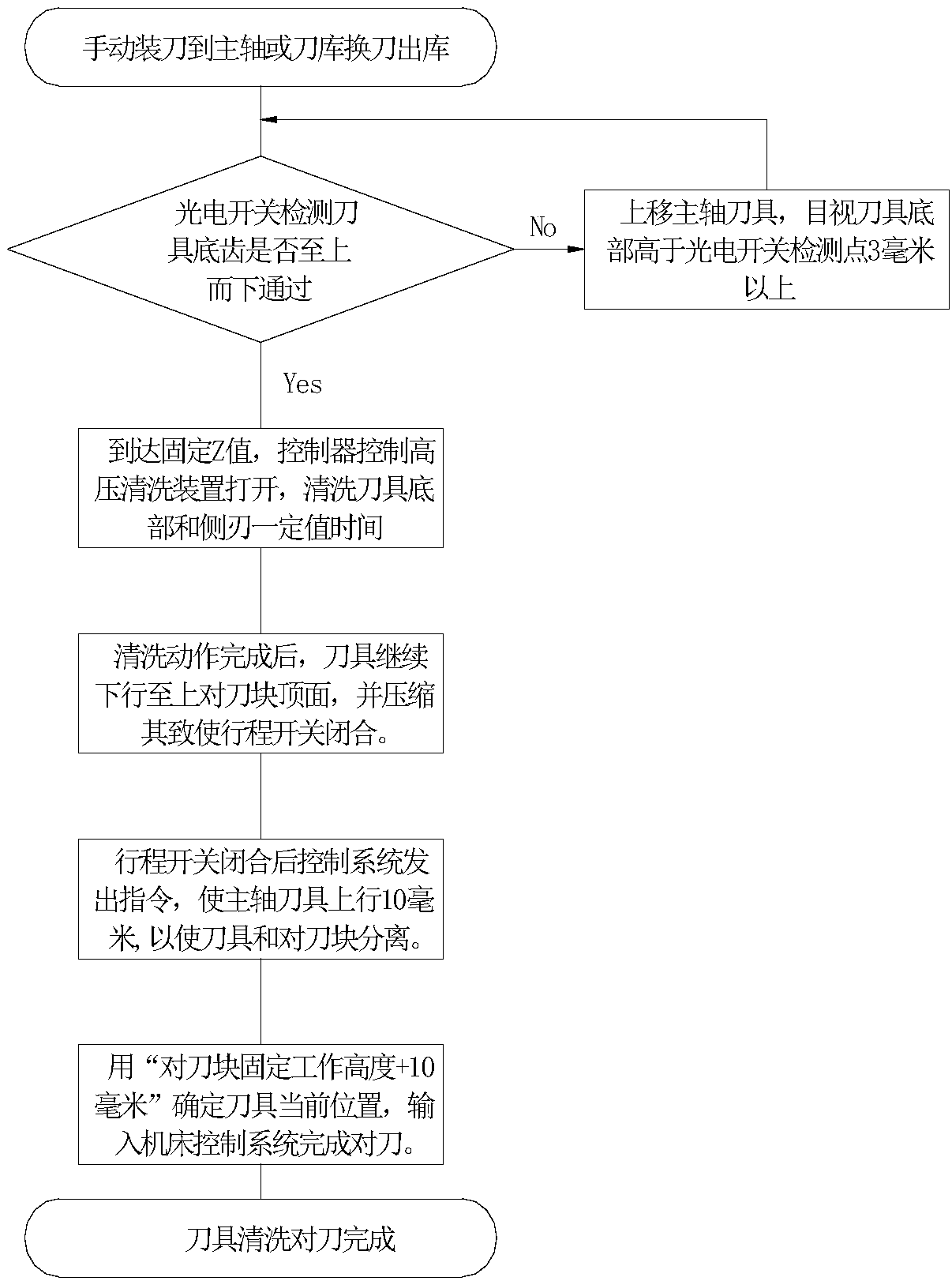

[0018] A method for online automatic cleaning and measuring the length of a tool is applied on a numerically controlled machine tool, and the method includes the following steps:

[0019] 1) Tool cleaning

[0020] The lower tool setting block 8 is a metal plate, and the lower tool setting block 8 is placed on the machining center table 9, and a high-precision travel switch 6 is installed on the lower tool setting block 8;

[0021] The upper tool setting block 5 is a metal plate, the upper tool setting block 5 is located above the lower tool setting block 8, and a return spring 7 is arranged between the upper tool setting block 5 and the lower tool setting block 8;

[0022] The tool 2 is located above the upper tool setting block 5, and a photoelectric position detection switch 3 connected to the CNC machine tool controller is arranged between the tool 2 and the machining center table 9; when the tool 2 moves toward the machining center table 9, it approaches When the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com