Novel dynamic compactor and composite foundation construction method achieved through novel dynamic compactor

A construction method and composite foundation technology, which can be applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as difficulty in lifting hammers, low construction efficiency, and large errors in automatic measurement systems, so as to reduce the number of times of ramming and improve construction efficiency. Quality, the effect of reducing the number of fillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The following non-limiting examples illustrate the invention.

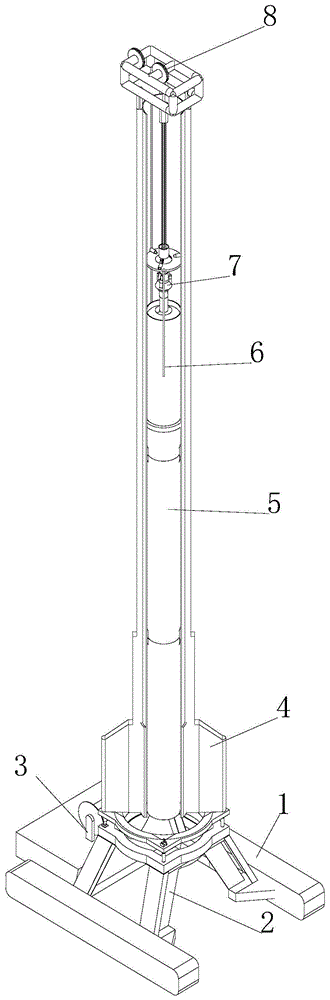

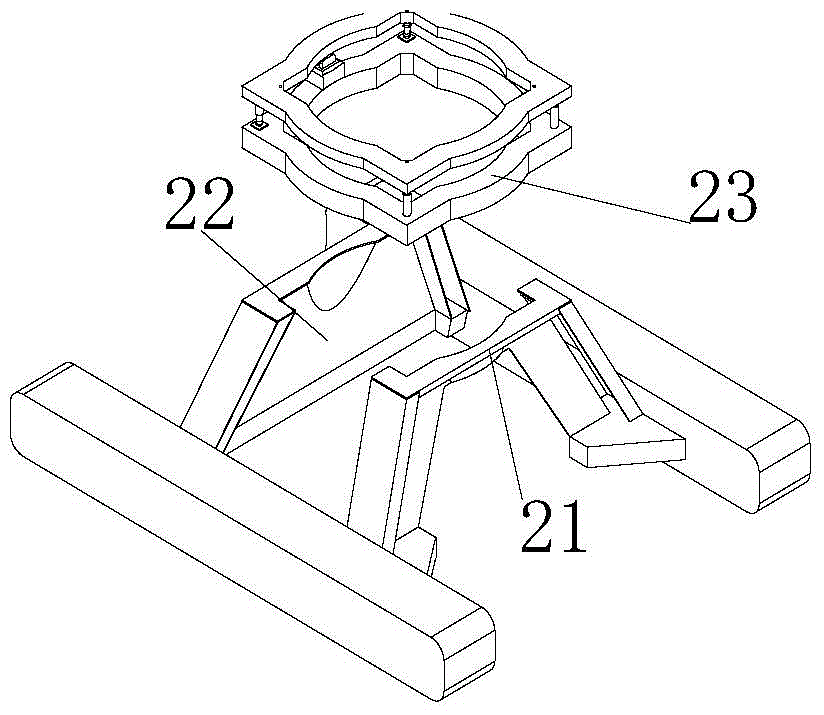

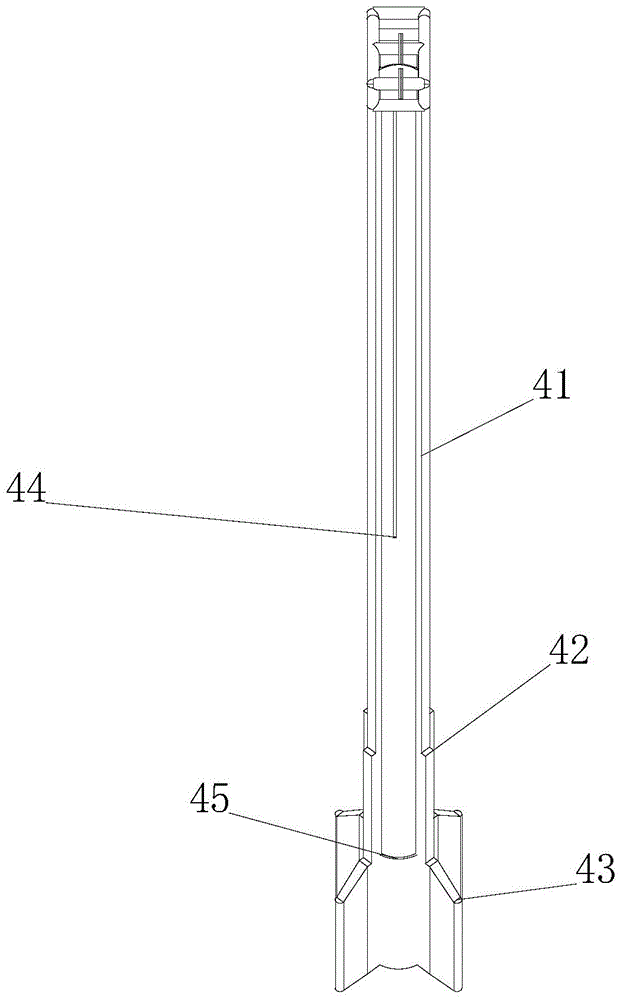

[0062] Such as figure 1 As shown, a new type of dynamic compaction machine includes a leveling base 2, a winch 3, and a main rod 4. The fixed pulley 8 is installed on the top of the main rod 4, and the bottom is installed on the top of the leveling base 2. The hoist 3 is installed on the adjustment On the flat base 2, the main pole 4 is hollow, and also includes a built-in rammer 5, a movable casing 6 and a hook device 7 arranged inside the main pole 4. The built-in rammer 5 is divided into several sections, and each section passes through The detachable connection is achieved by the card position and the latch. The top of the built-in rammer 5 is set in the movable casing 6. The upper part of the hook device 7 is connected to the hoist 3 after passing around the fixed pulley 8 by a cable. The hook device 7 is connected to the built-in rammer. 5 hooks on the top.

[0063] The built-in rammer 5 is divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com