Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about "Monocomponent polystyrene artificial filament" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

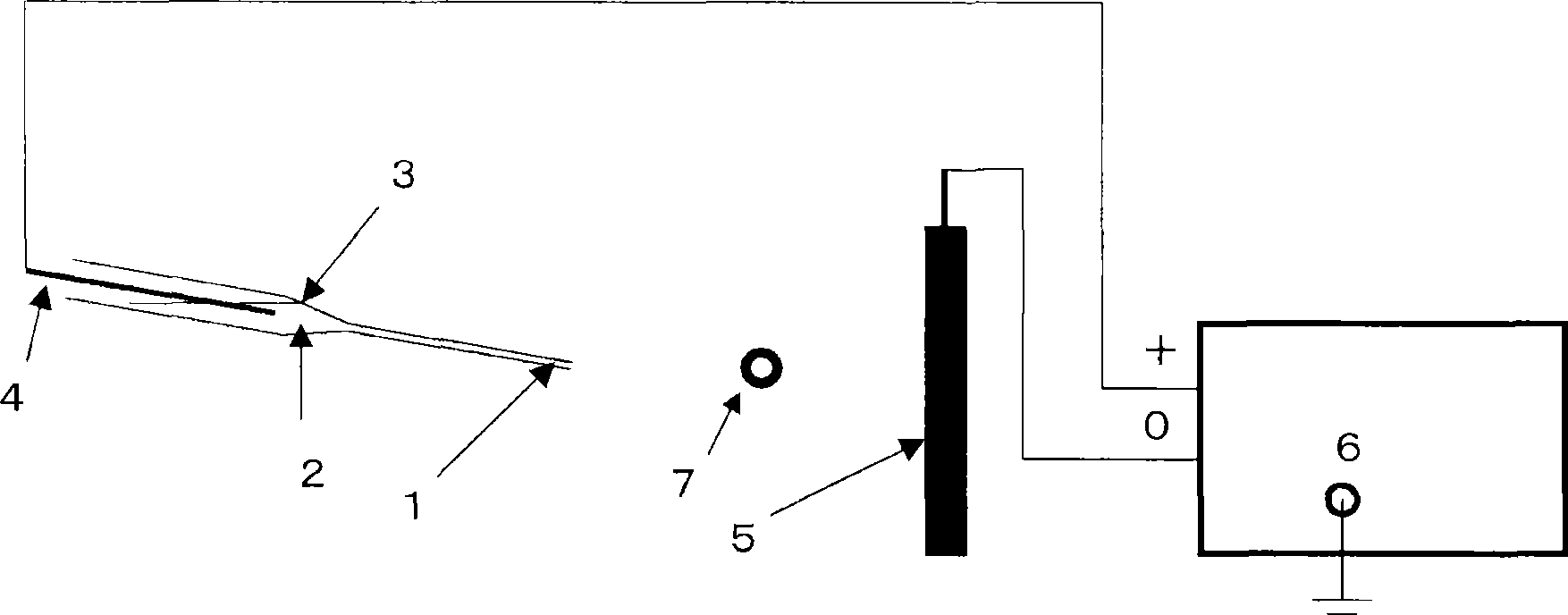

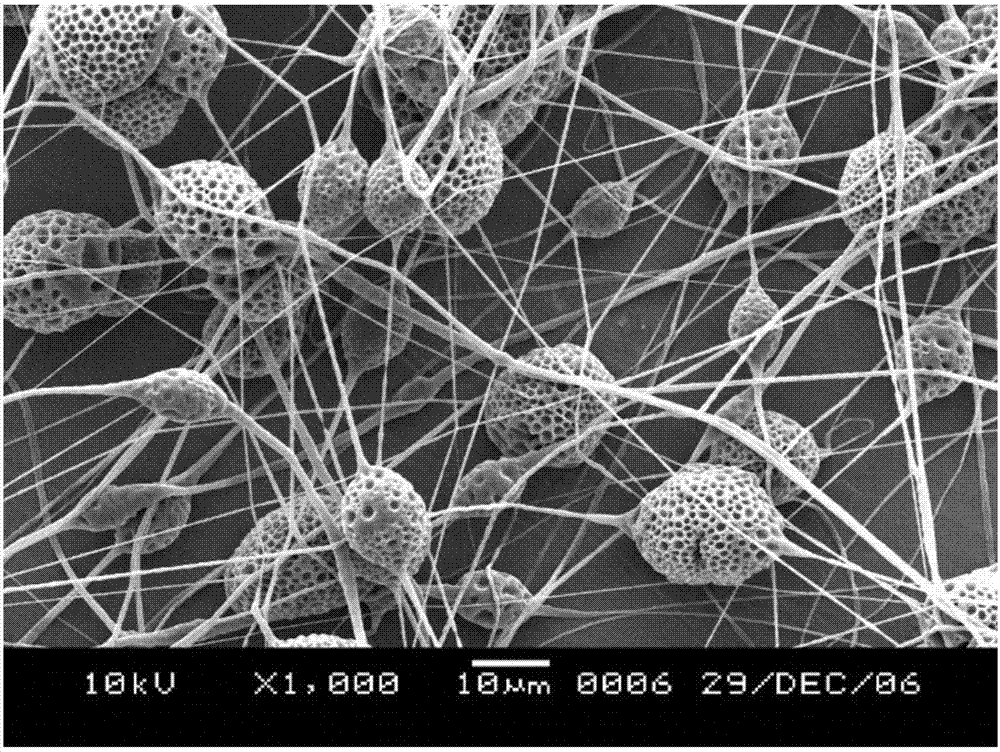

Preparation method for self-assembly of electrospinning rosary-like fibers

ActiveCN103334244AEasy to operateEasy to makeMonocomponent polyethers artificial filamentFilament/thread formingFiberOperability

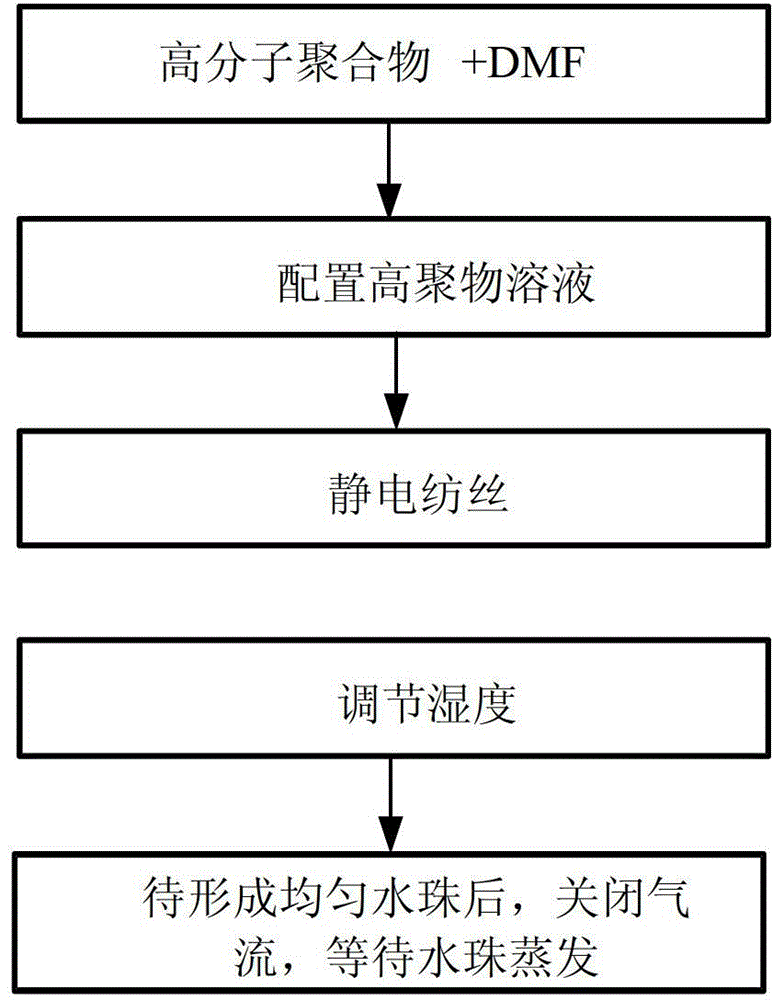

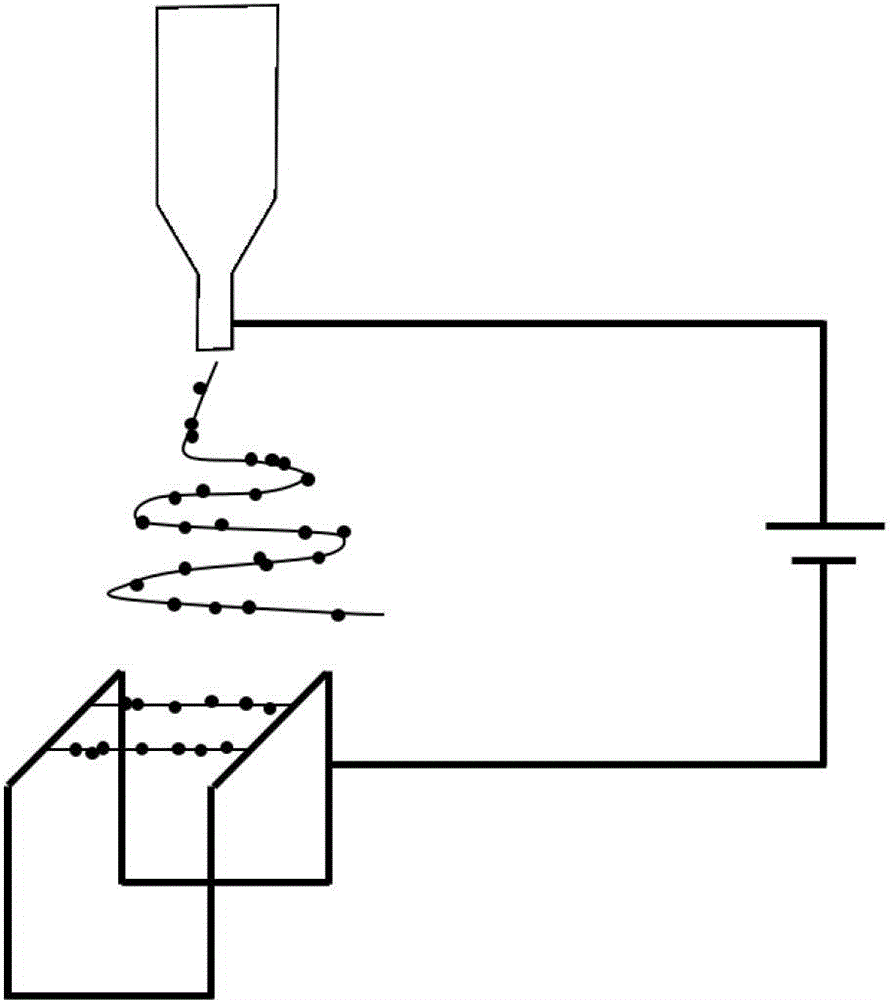

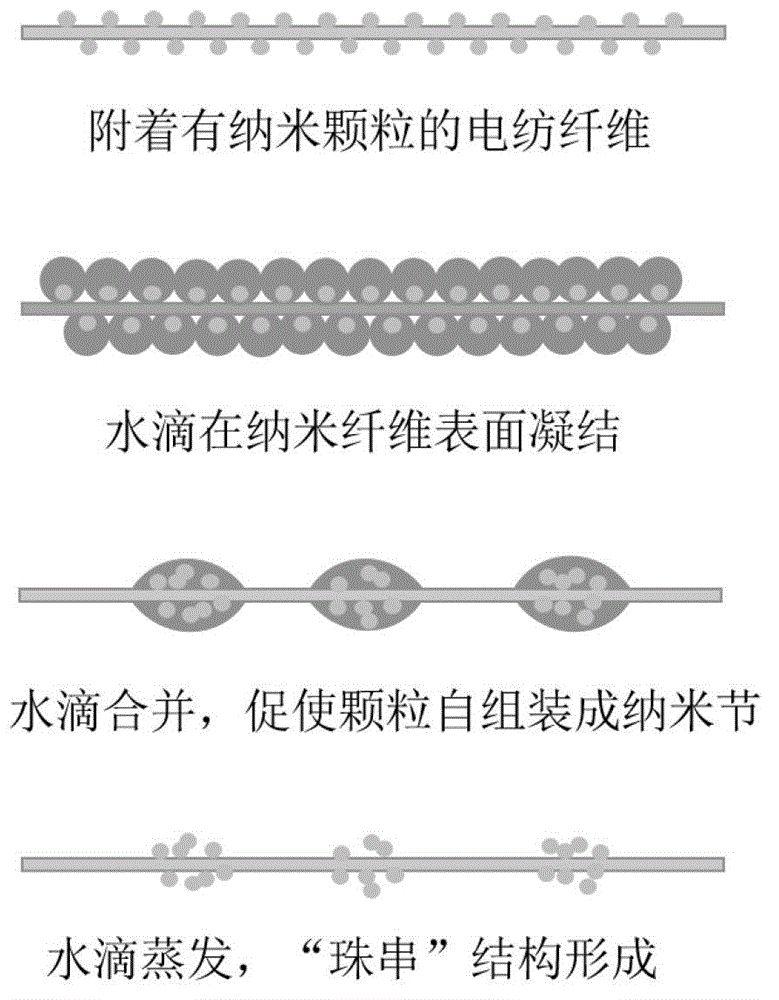

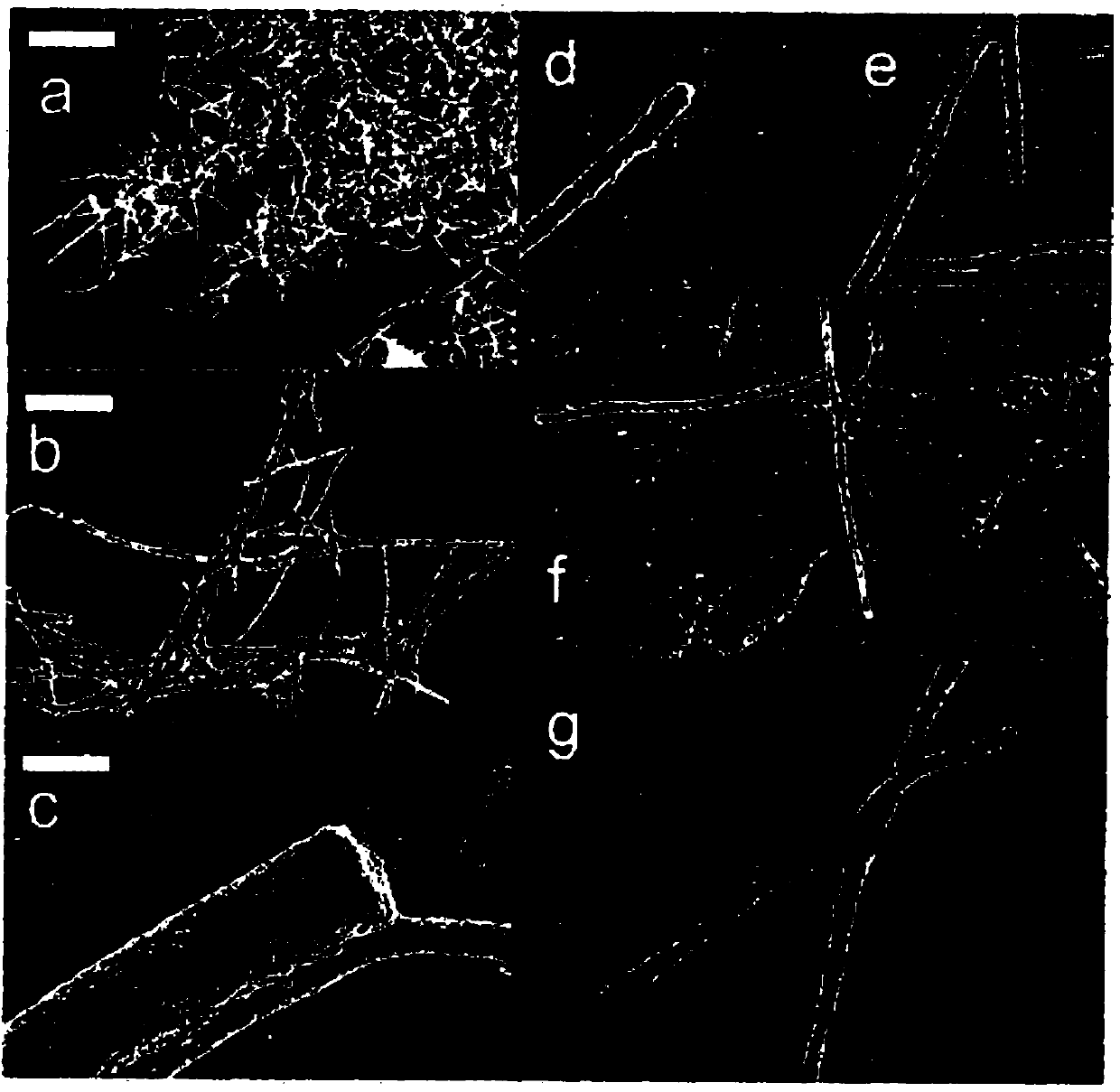

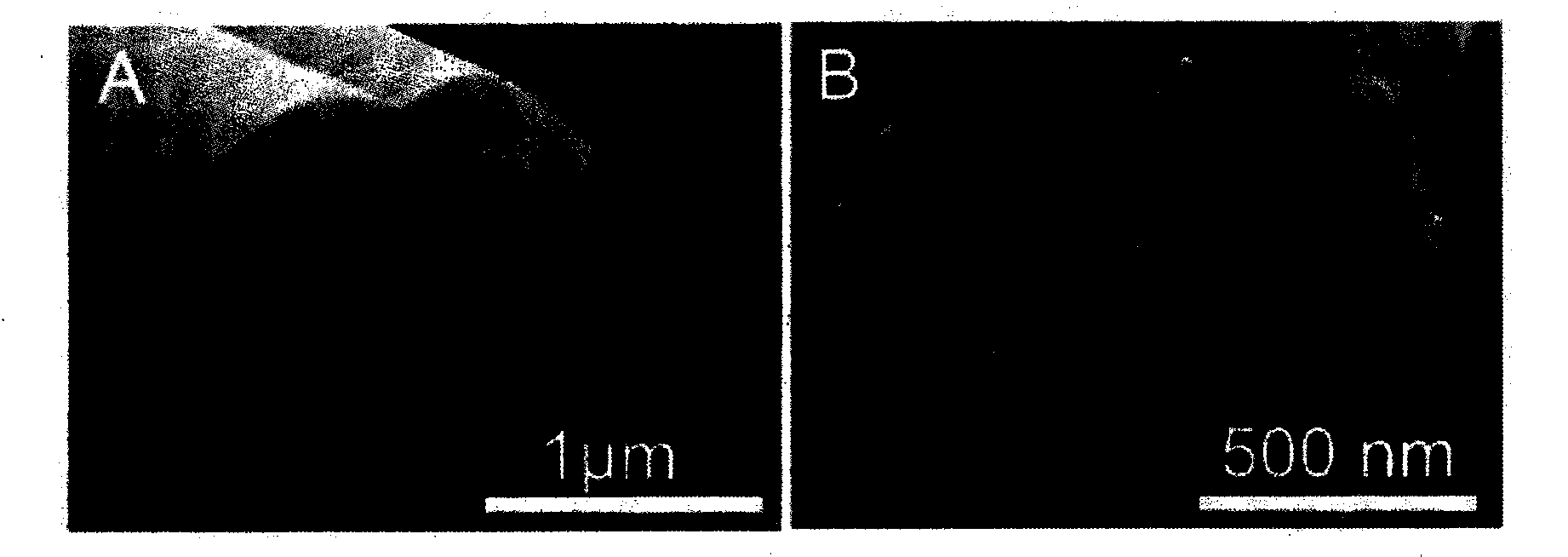

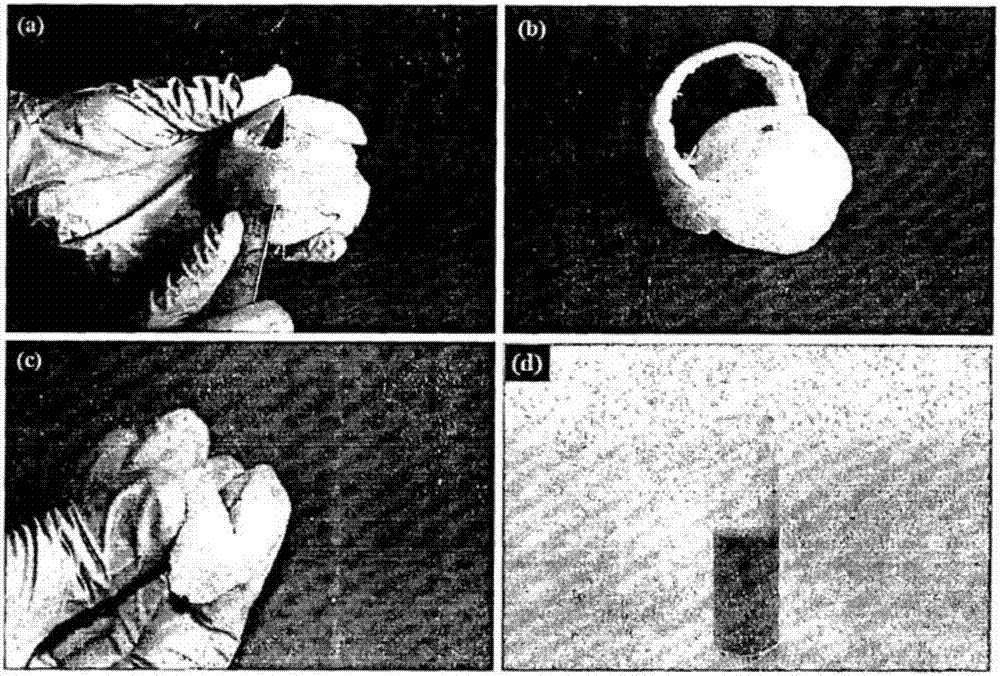

The invention discloses a preparation method for the self-assembly of electrospinning rosary-like fibers, and belongs to the technical field of chemistry and material. By inspired by the situation that a cobweb can be assembled to a spindle structure in the wet environment respectively, a static electricity spinning device is utilized to prepare man-made fibers, and an aluminum bracket is used for receiving, so as to form the man-made fibers with the structure that nano-particles are adhered to surfaces; the man-made fibers are allowed to be assembled to the micron-sized ' rosary' structure respectively in the wet environment. According to the preparation method provided by the invention, the manufacturing process is simpler, the cost is lower, the operability is strong, and the method is suitable for mass productions; the respectively assembled fibers have stable quality and long practicability; the method can be used for collecting fresh water, reducing fog, solving the problem of serious water shortage in deserts and wastelands, and dispersing the steam around airports, street lamps, and signal lamps.

Owner:BEIHANG UNIV

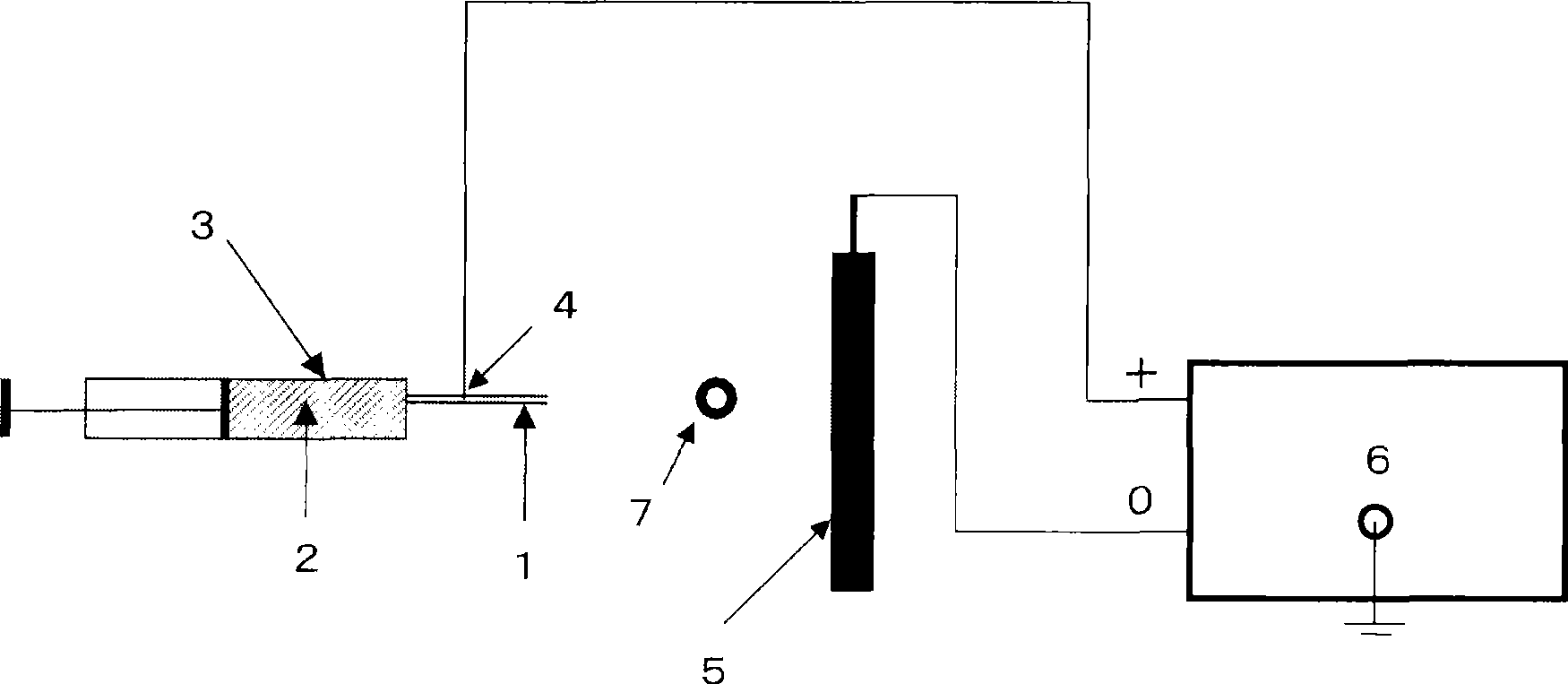

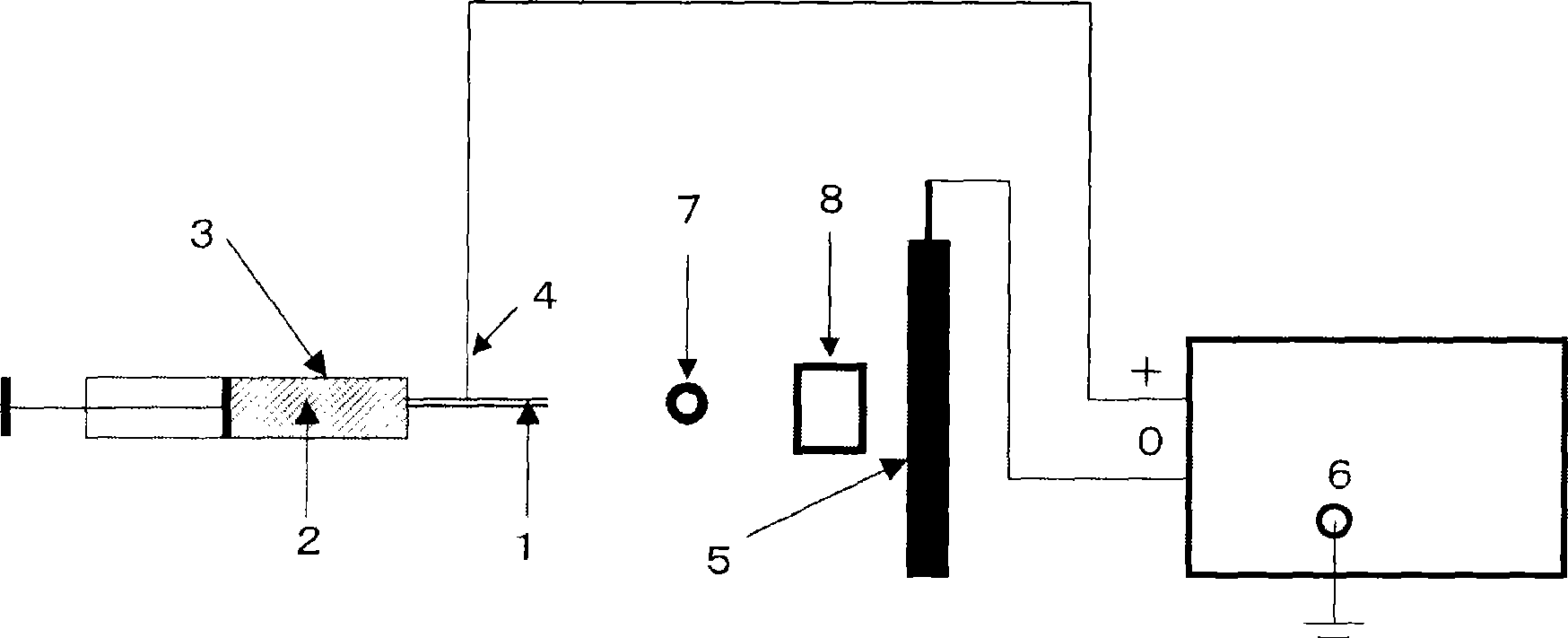

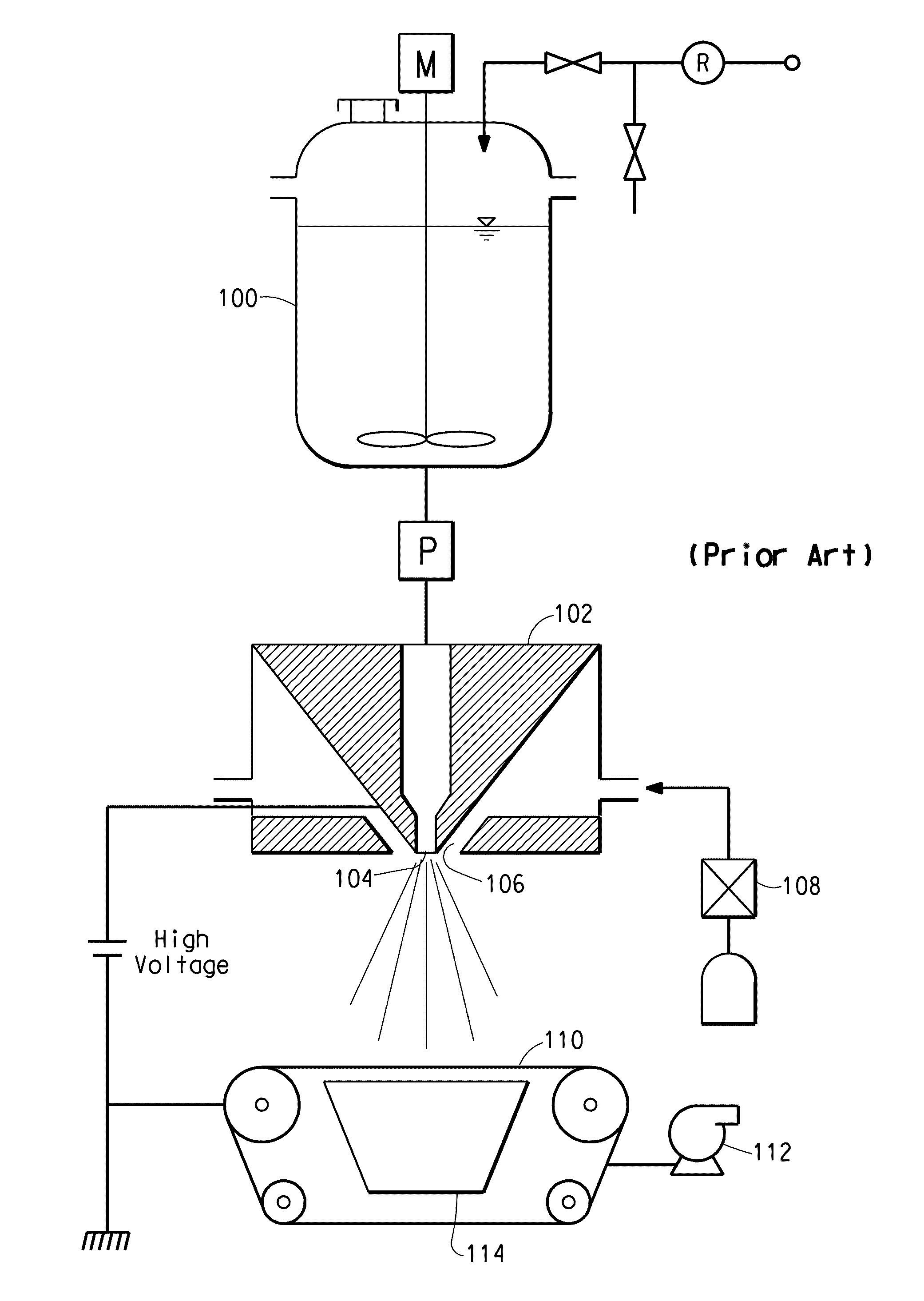

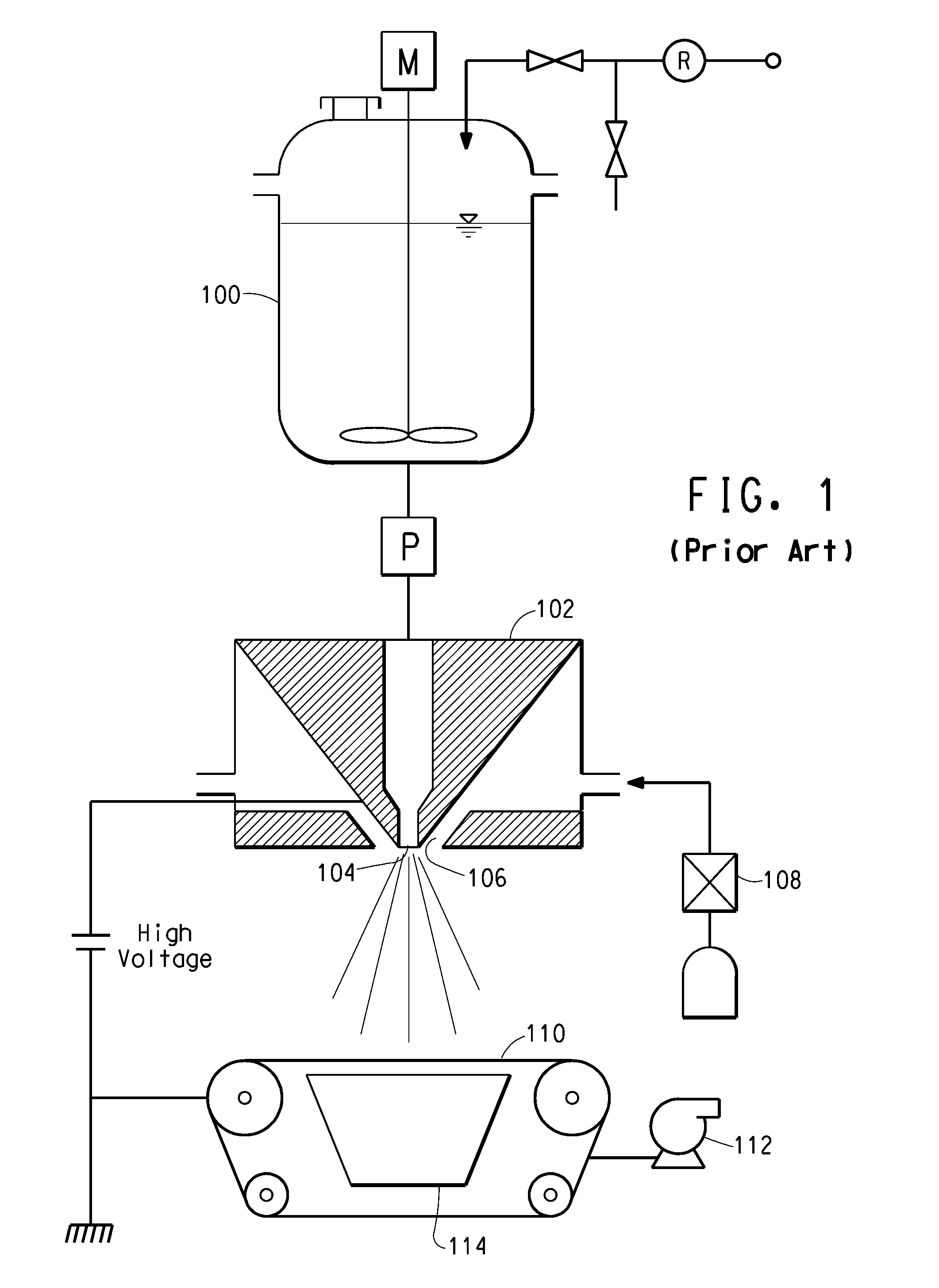

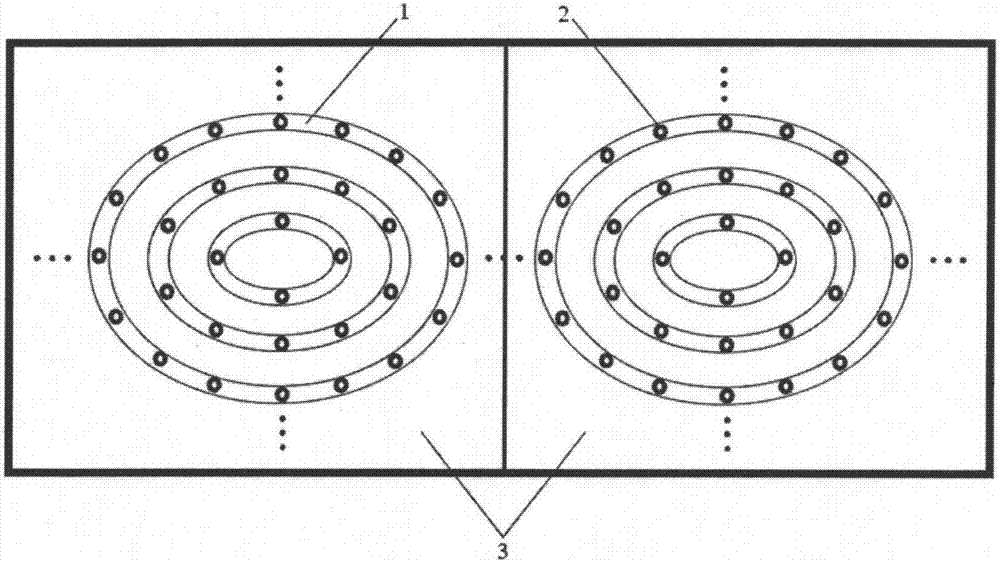

Device and method for preparing regular arranged macromolecular nano-fibre

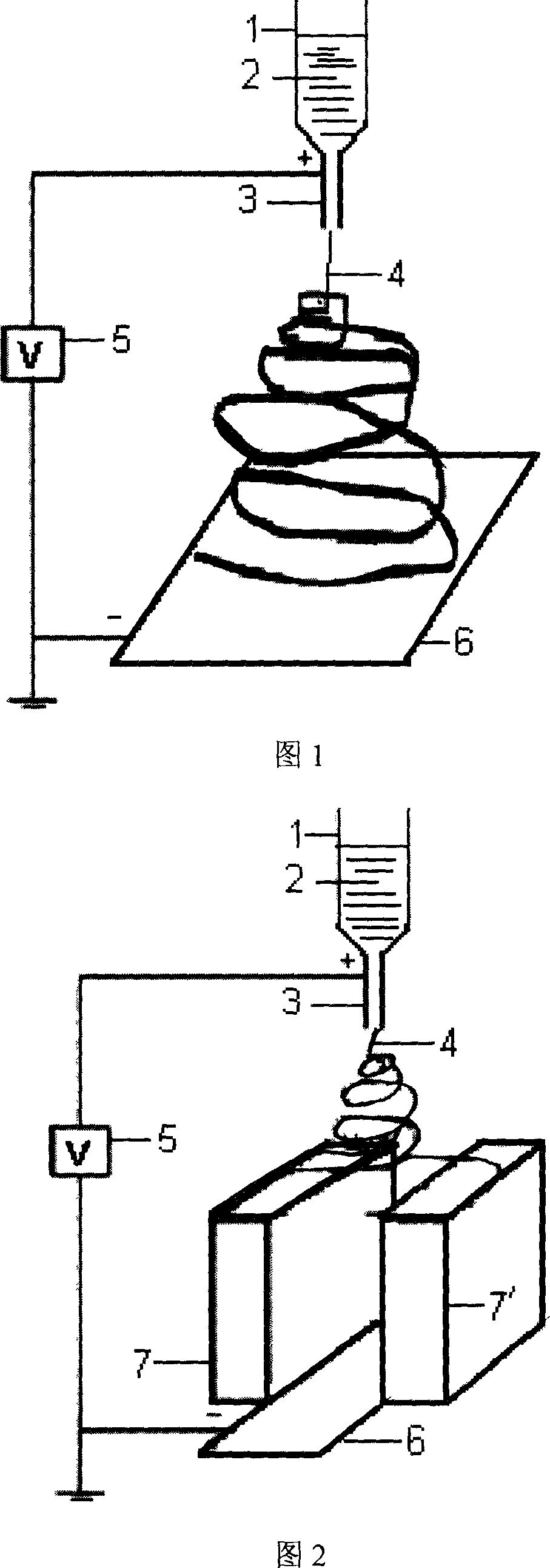

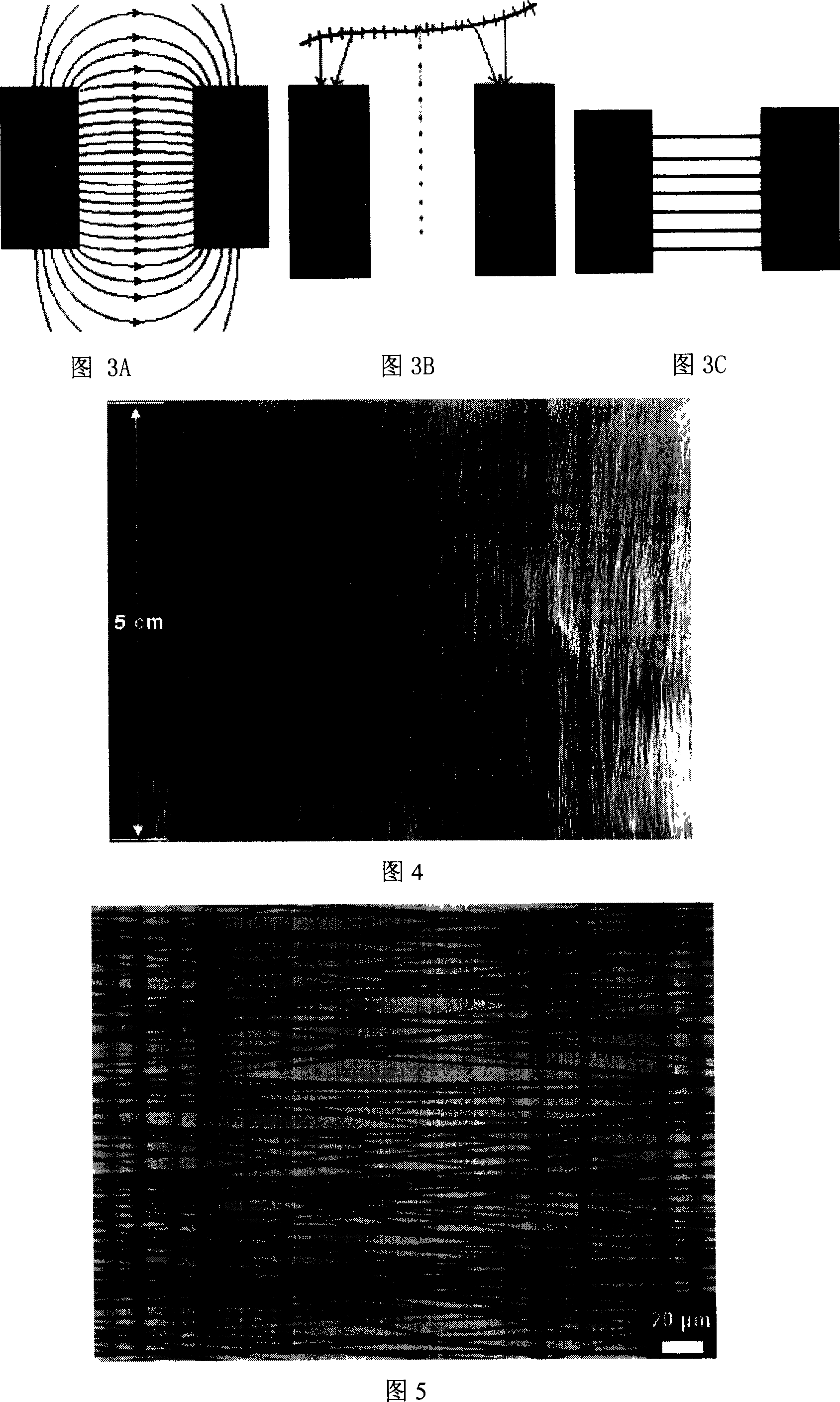

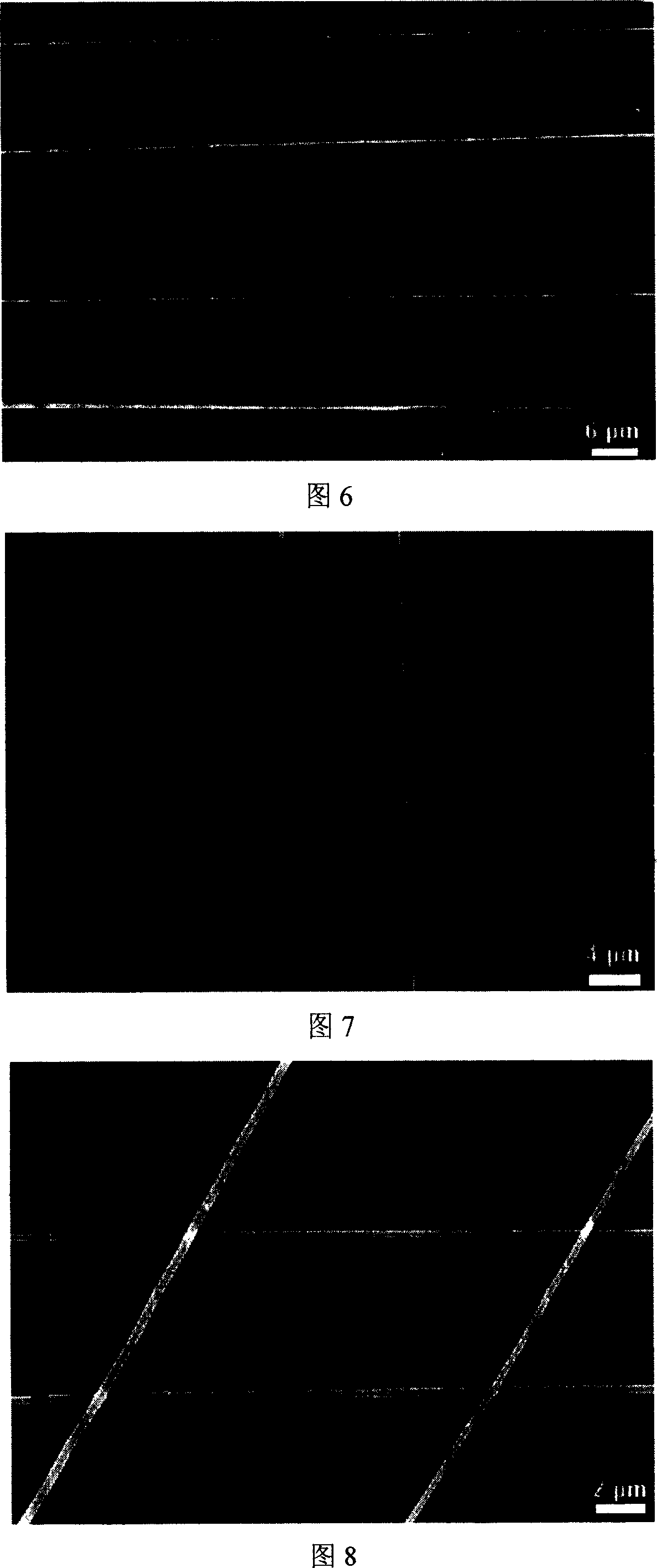

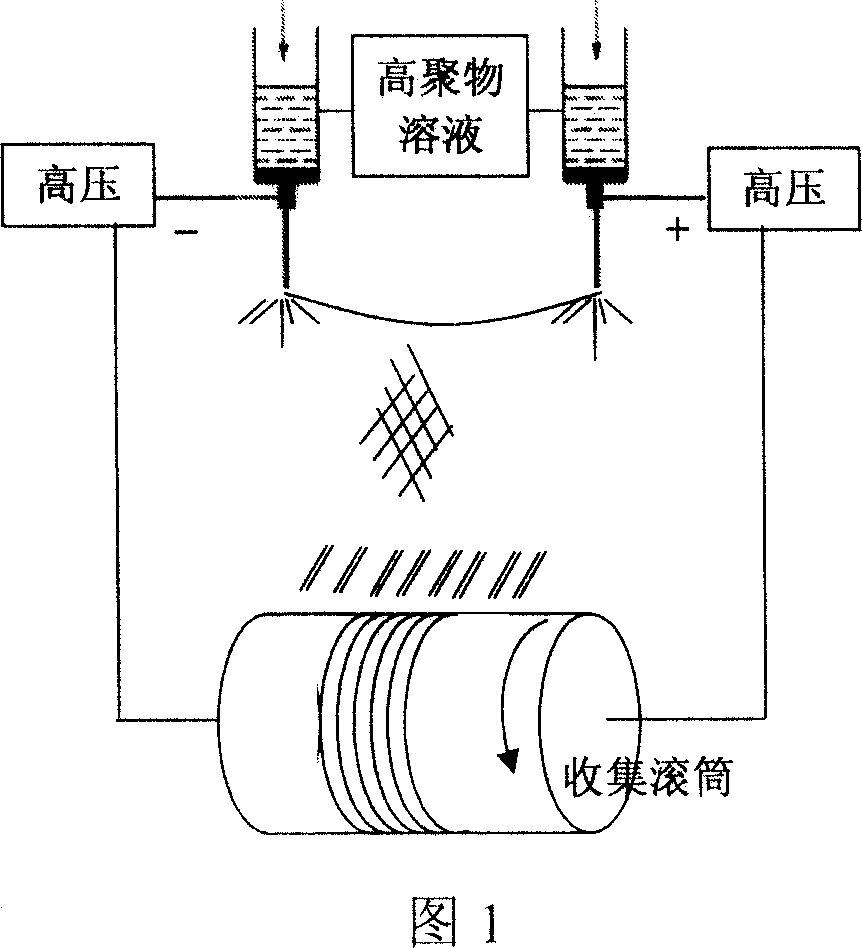

The invention relates to an equipment for preparing polymer nanometer fiber with regular arrangement and the method. The equipment comprises a spraying silk tube for containing polymer solution. A spraying nozzle is sealed and assembled at the end of spraying silk tube. The nozzle is connected with the positive electrode of high pressure generator and is used as anticathode. An aluminum foil is connected with the negative electrode of high pressure generator and is used as cathode, which is grounded at the same time. The aluminum foil is set between a first permanence magnet and a second one. The nozzle is faced to the aluminum foil. The electrical spinning method controlled by magnet is that soluble macromolecules are put into the corresponding solvent and the concentration is adjusted, the polymer solution with good performance for spinning is confected; magnetic nanometer grains are put into the polymer solution and magnetized polymer solution is formed. In the electrical spinning equipment controlled by magnet, the magnetized polymer solution becomes micro-nano continuous fiber under the effect of electric field and at the same time fibers are arranged along the direction of magnetic line under the effect of external magnetic field to form micro-nano fiber material with parallel arrangement.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

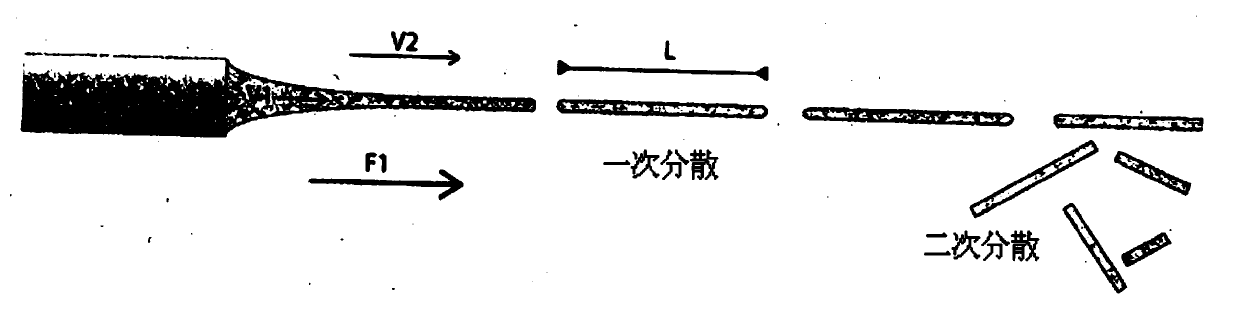

Complex type electrostatic spinning method with positive and negative electrodes in same electric field, and application

InactiveCN101003917AIncrease spinning speedOvercome the defects of single productsFilament/thread formingArtificial filaments from cellulose derivativesComplex typeElectrospinning

Owner:CIVIL AVIATION UNIV OF CHINA

Fibre-forming process and fibres produced by the process

ActiveCN104024494AMonocomponent cellulose artificial filamentMonocomponent fibroin artificial filamentFiberPolymer science

Owner:HEIQ

Polymeric materials providing improved infrared emissivity

IR-emitting or reflecting polymer fibers are formed by blending a high concentration of IR-emitting or reflecting particles with a thermoplastic polymer and meltblowing fibers which have an average diameter of 20 μ or less. The meltblowing process allows for inclusion of a high concentration of the IR-emitting or reflecting particles, yet allows fibers to be formed. These can be formed into a soft, air-permeable, nonwoven web. The fibers can be monocomponent or bicomponent or multicomponent and can be textured or shaped.

Owner:BERRY FILM PROD CO INC

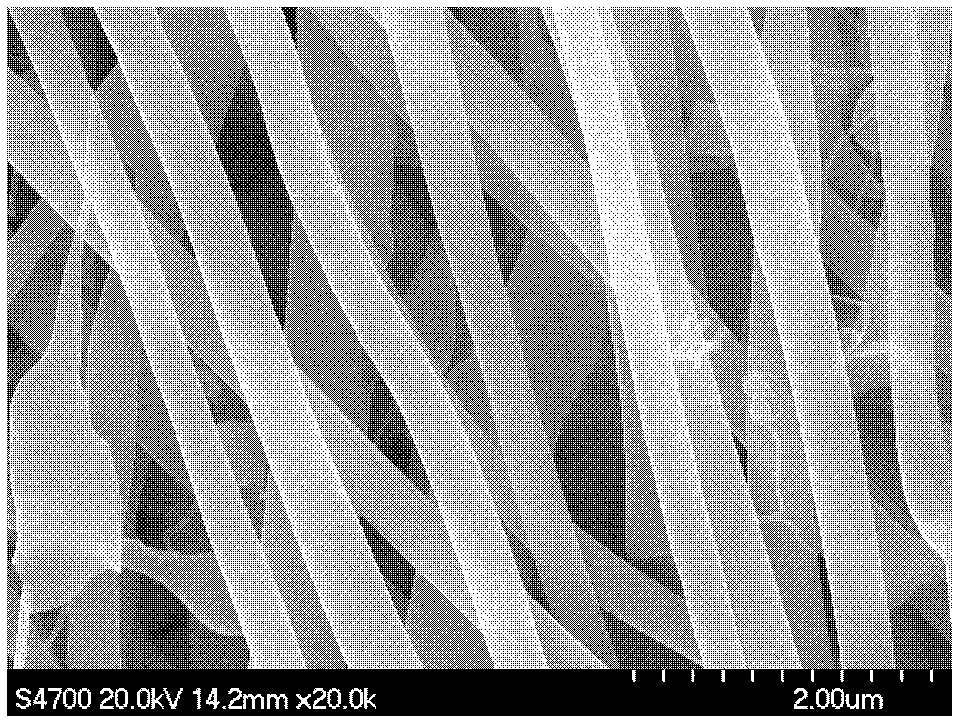

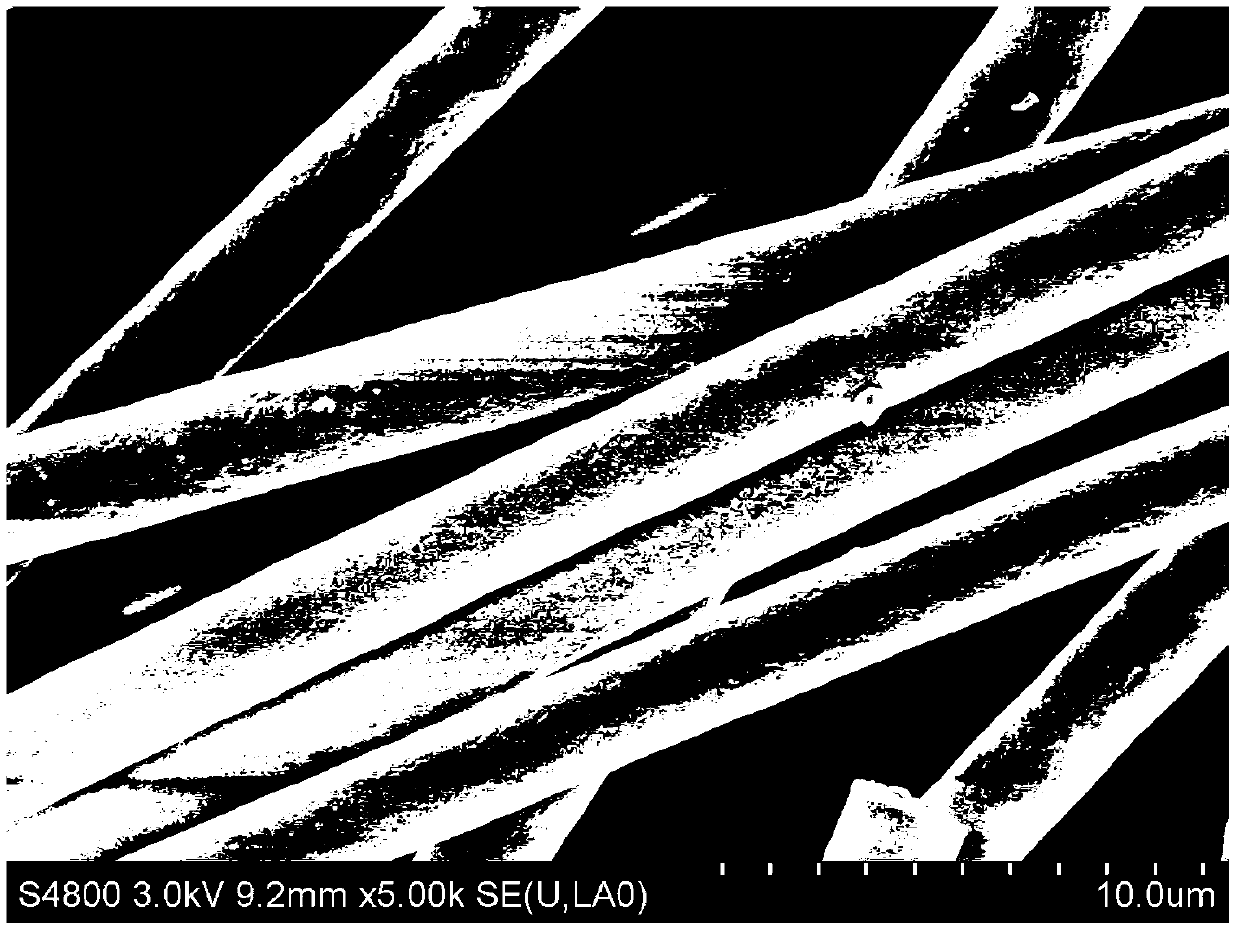

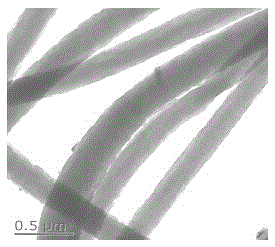

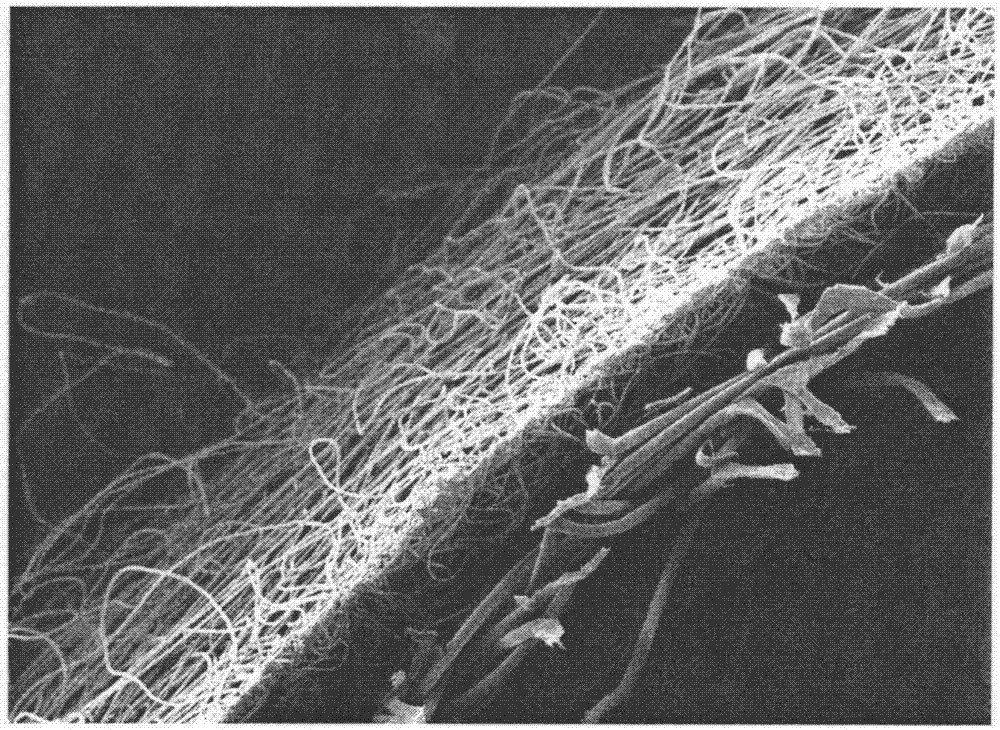

Orientation groove micro/nano-fibres and preparation method for same

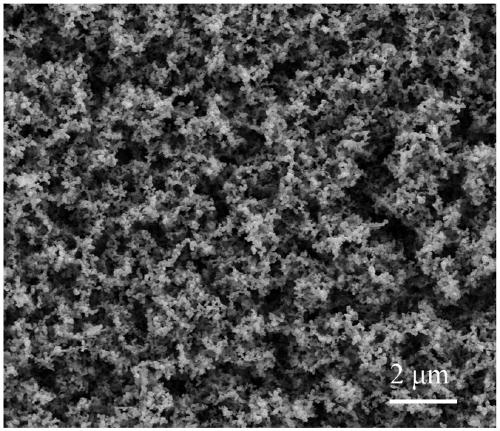

InactiveCN104073895ALarge specific surface areaHigh porosityFilament/thread formingMonocomponent polystyrene artificial filamentFiberPorosity

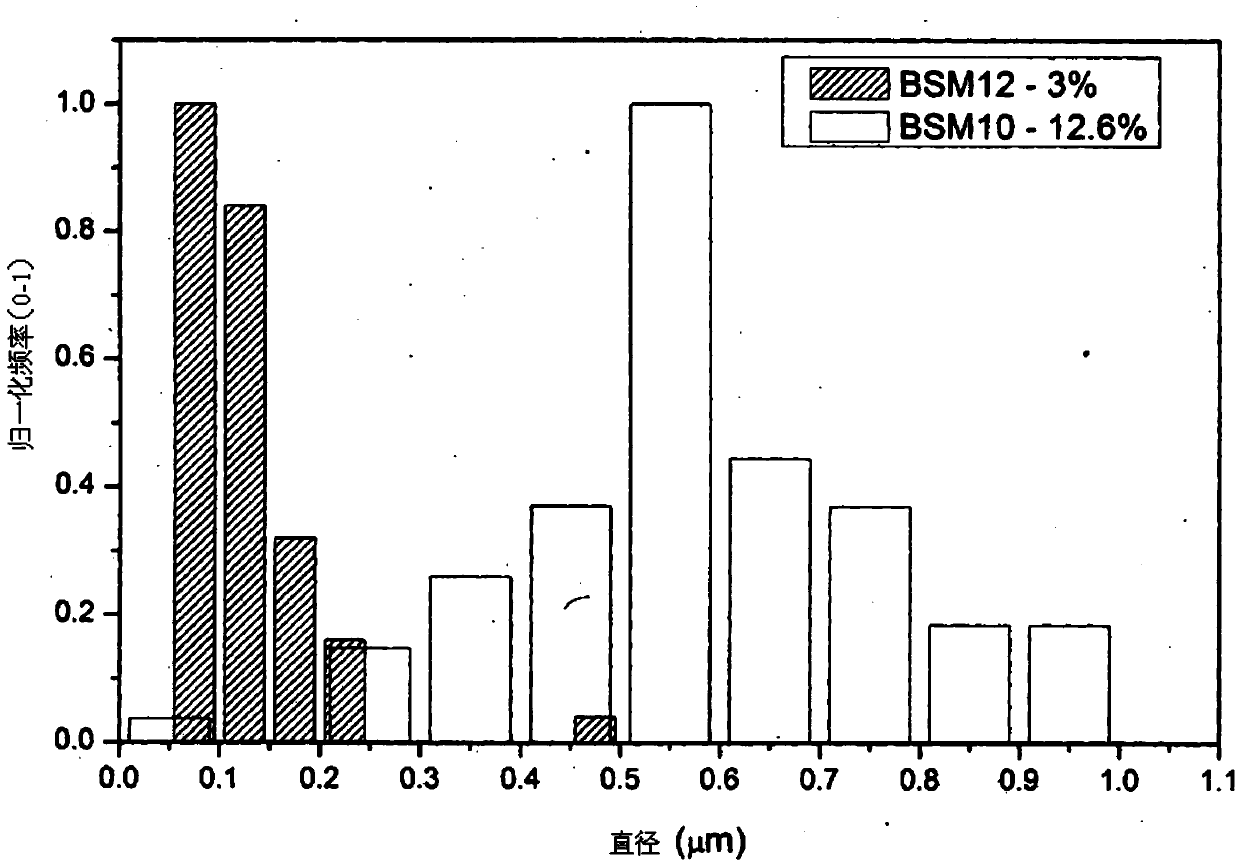

The invention discloses orientation groove micro / nano-fibres and a preparation method for the same. The orientation groove micro / nano-fibres comprise common groove micro / nano-fibres or beaded groove micro / nano-fibres, and the diameters of the fibres are 50 nanometres to 10 microns. The preparation method for the same comprises the following steps of: preparing polymer solution containing a high-volatility solvent and a low-volatility solvent, and preparing micro / nano-fibres by virtue of an electrospinning technique; preparing micro / nano-fibres with different groove structures, for example, different groove quantities, groove depths, groove distances and the like by adjusting process parameters of a solvent ratio, a solution concentration, a relative humidity and the like. The orientation groove micro / nano-fibres disclosed by the invention have the advantages of large specific surface area, high porosity and the like, and have a wide application prospect in the fields of superhydrophobicity, filter, tissue engineering and the like; the preparation method disclosed by the invention is capable of directly preparing the orientation groove micro / nano-fibres without the need of any aftertreatment process, simple to operate, stable in process, low in cost, and capable of realizing batch production.

Owner:DONGHUA UNIV

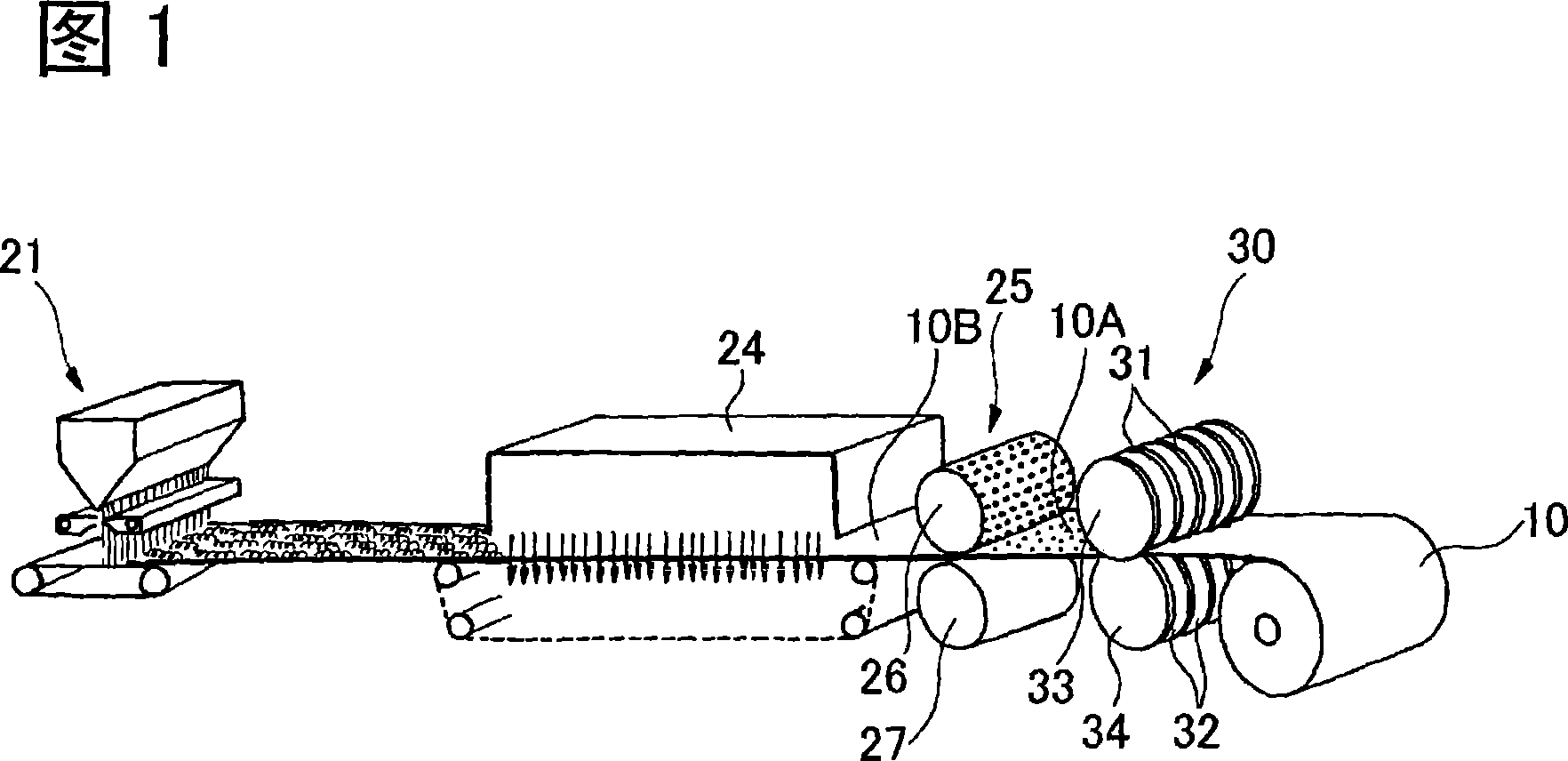

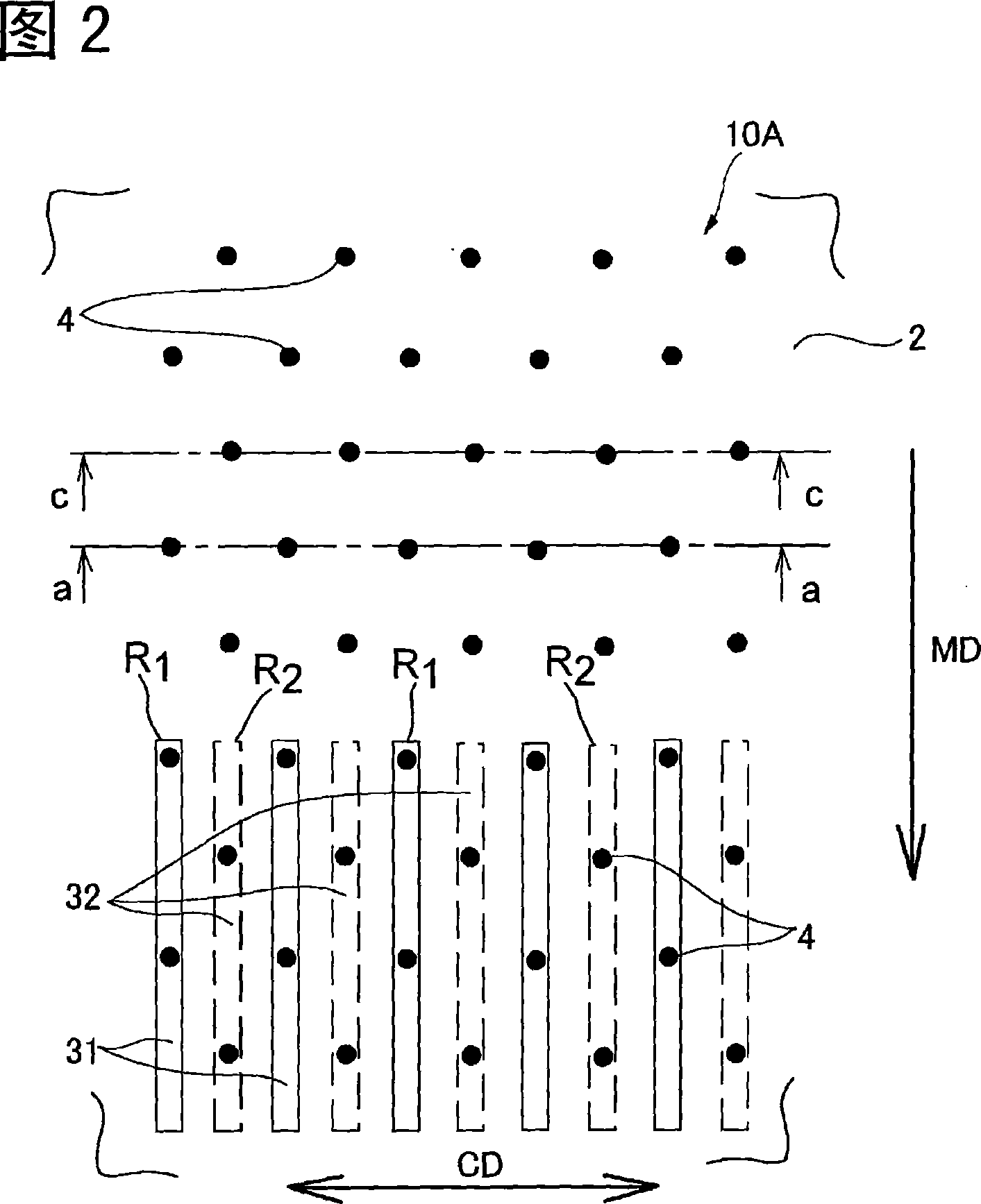

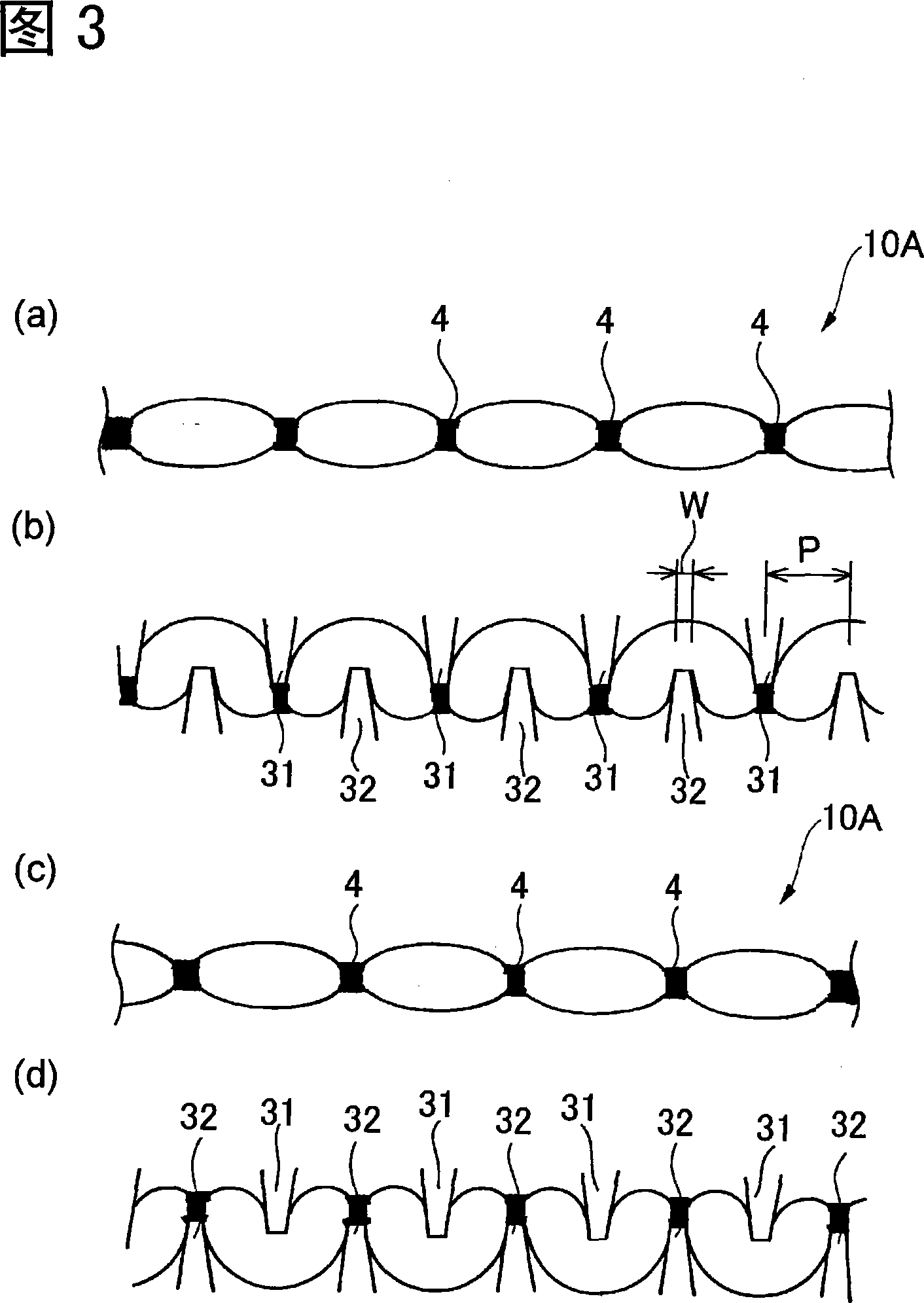

Telescopic nonwoven fabric

InactiveCN101074515AMonocomponent polystyrene artificial filamentNon-woven fabricsDynamic viscoelasticityPolymer science

The invention discloses a Telescopic nonwoven fabric comprises elastic fiber and other elastic fiber or inelastic fiber which is different from the elastic fiber before, the block polymer comprises polymer block A whose main part is aromatic series vinyl-compounds with 10-50 weight % and polymer block B whose main part is the repeated unit in type (1). In the condition of 20 DEG C and 2 Hz, the elasticity storage modulus G' of the dynamic viscoelasticity is 1*104-8*106Pa, and the dynamic loss tangent of the dynamic viscoelasticity tan Delta is below 0.2. In type (1), random one or two in R1-R4 are methyl, the others are hydrogen atom.

Owner:KAO CORP

Scaffold

The object is to provide a scaffold material which has excellent mechanical strength and an excellent capability of growing a cell and is suitable as a cell culture substrate or a prosthesis. Disclosed is a scaffold material for growing a cell. The scaffold material comprises an aggregate of fibers, has a three-dimensional structure composed of two bottom faces and side faces, and satisfies the following requirements (1) to (4): (1) the fibers are oriented in the side-wise direction; (2) each of the fibers has a diameter of 0.05 to 50 [mu]m; (3) each of the fibers is composed mainly of a biocompatible polymer; and (4) the scaffold material has an apparent density of 95 to 350 kg / m<3>.

Owner:TEIJIN LTD

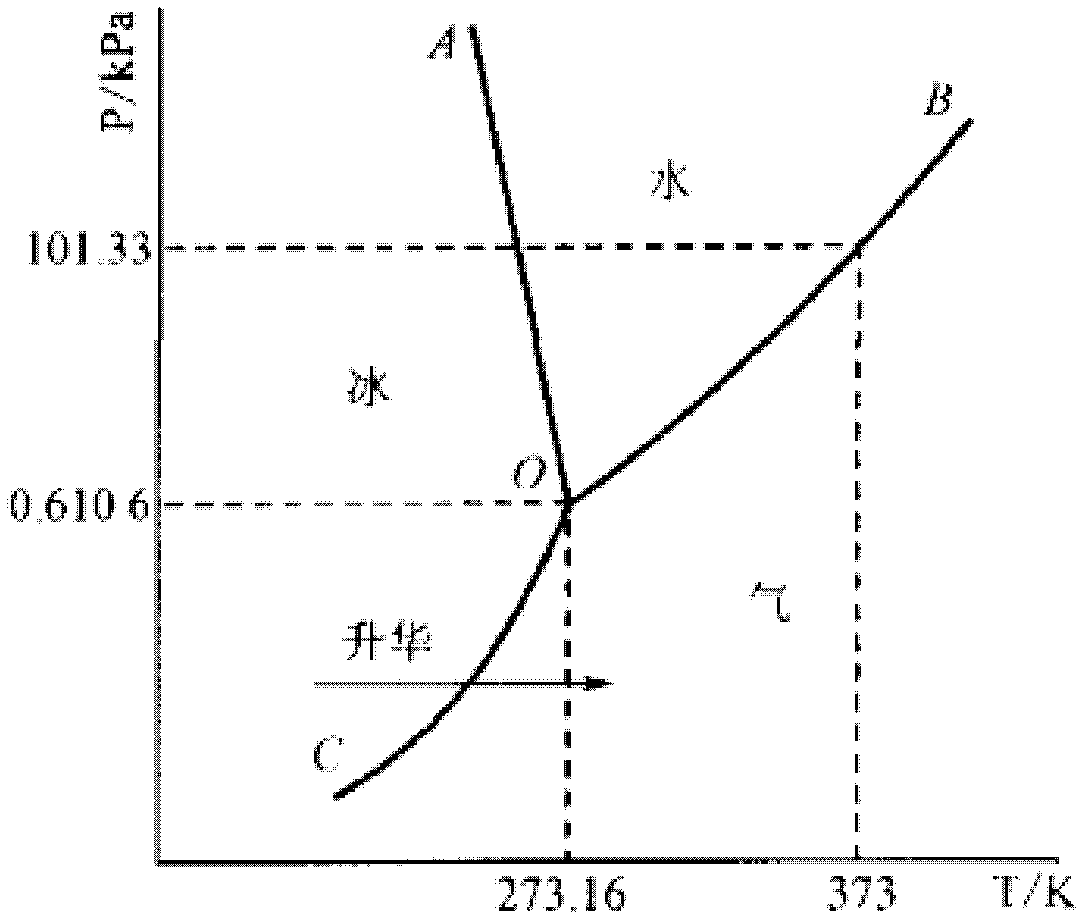

Method for preparing synthetic polymer nano-fiber membrane by freeze-drying

InactiveCN102418161AMonocomponent polyurethanes artificial filamentMonocomponent polyethers artificial filamentFiberPolymer science

The invention relates to a method for preparing a synthetic polymer nano-fiber membrane by freeze-drying. The method comprises the following steps of: dissolving synthetic polymer powder in a corresponding solvent to prepare an extremely diluted solution of which the concentration is 0.001-0.1wt%; after the synthetic polymer is completely dissolved in the solvent, transferring the synthetic polymer solution to a liquid nitrogen freezing device so as to enable the solution to be quickly frozen in the liquid nitrogen environment under the conditions that the temperature is (-10)-(-80) DEG C and the vacuum degree is 1-600Pa; and then, freeze-drying for 12-48 hours by using a freeze-dryer to obtain a synthetic polymer nano-fiber. In the invention, the operation process has mild conditions, simple steps and low cost, is easy to control, and realizes the large batch production of synthetic polymer nano-fiber membranes.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

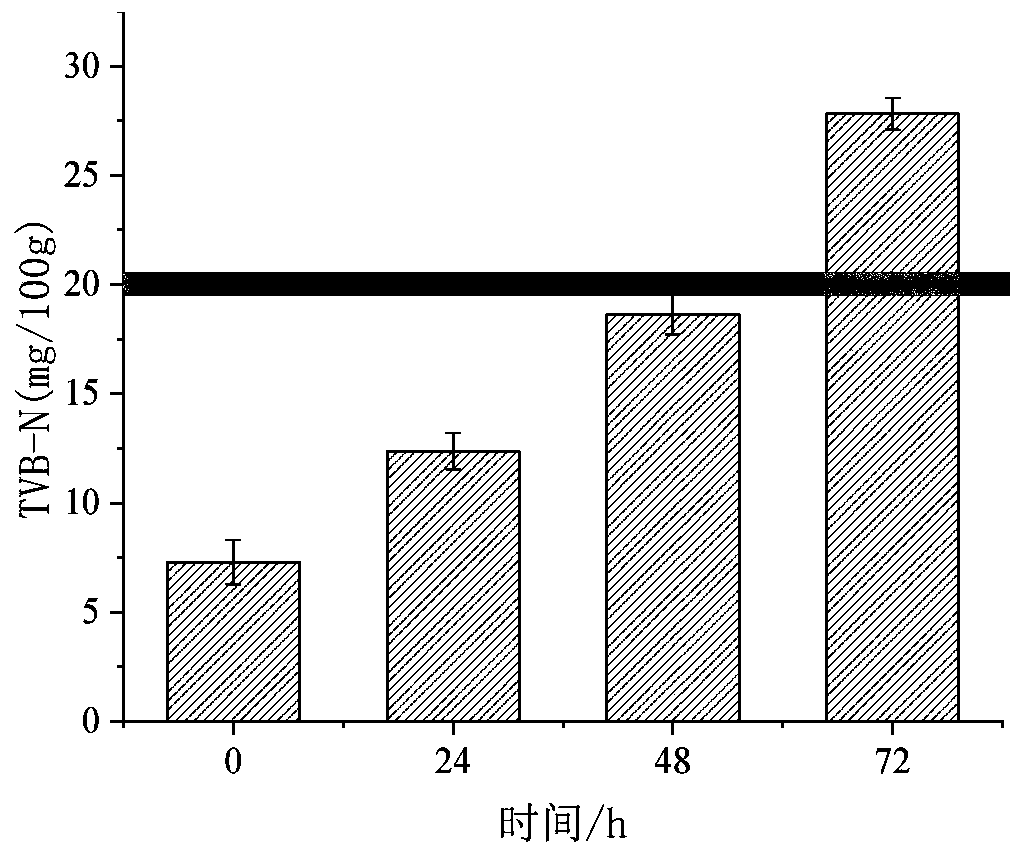

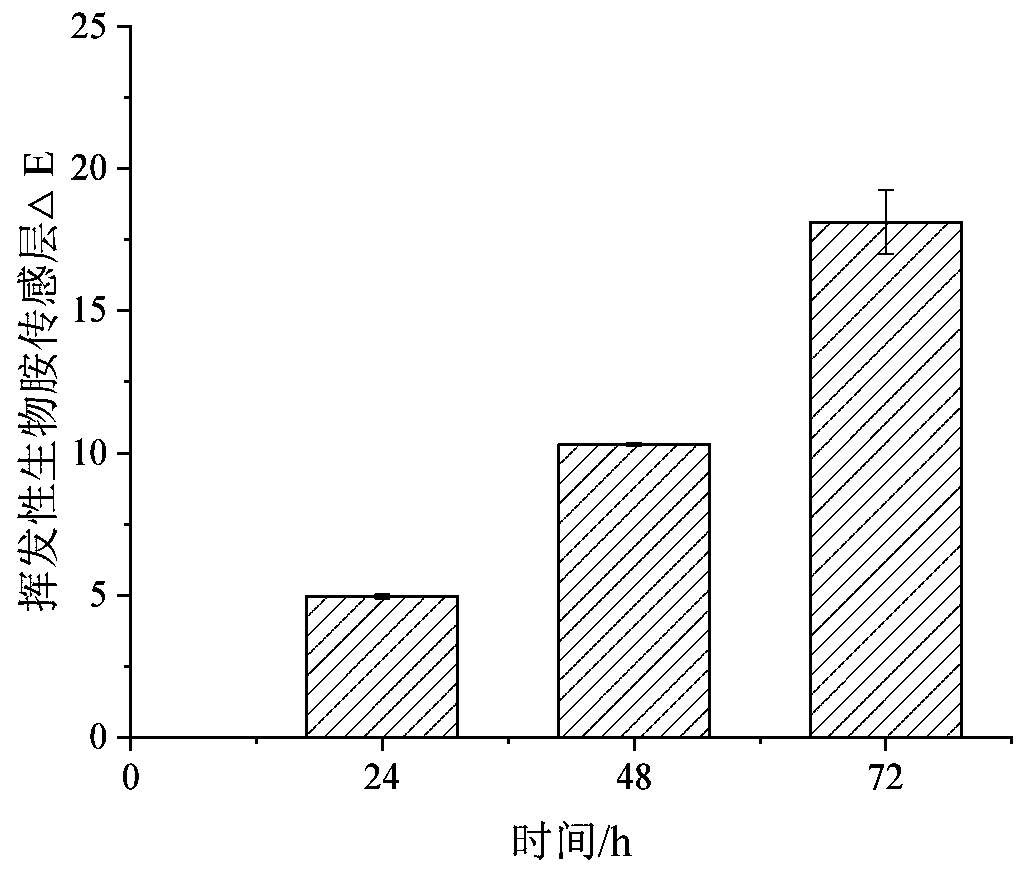

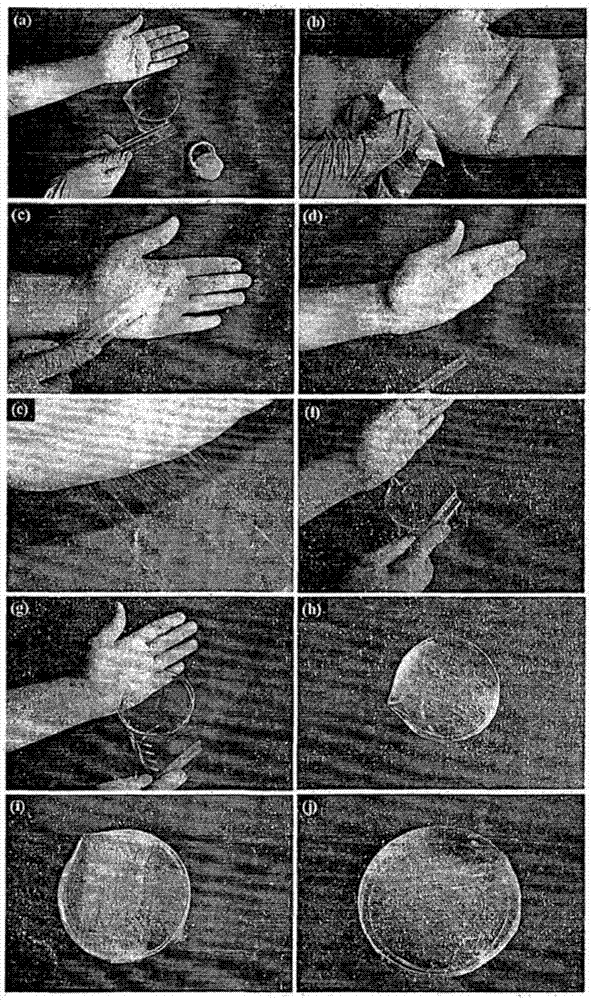

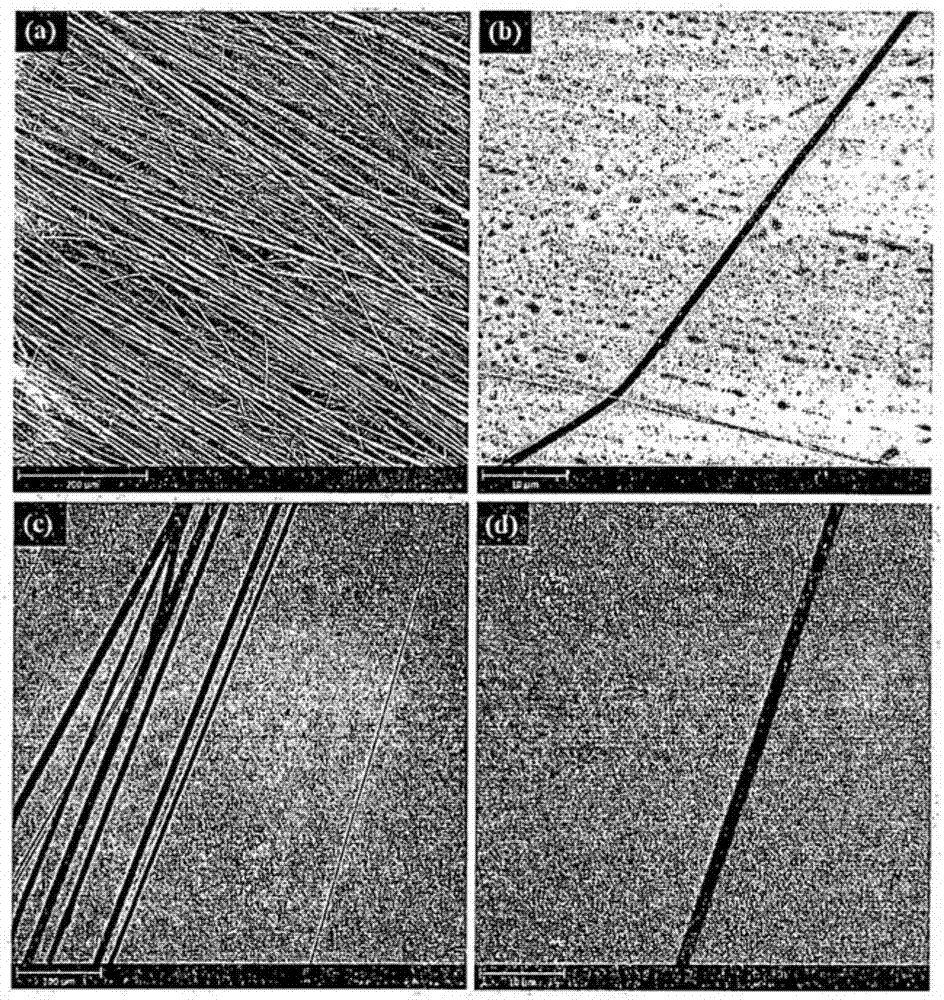

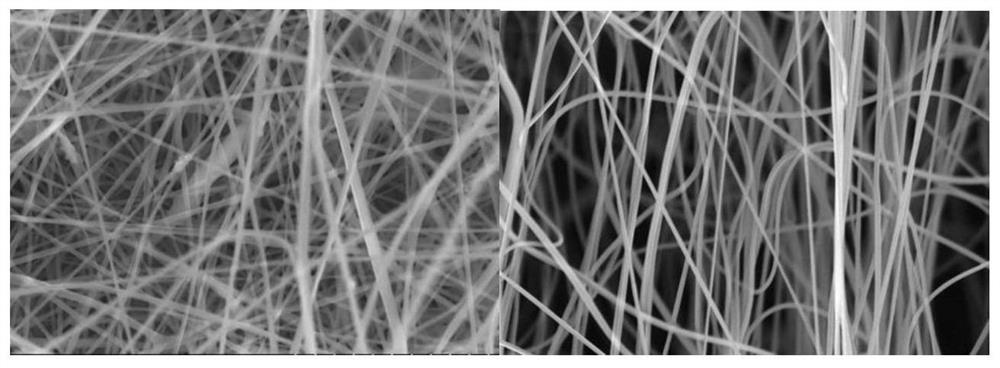

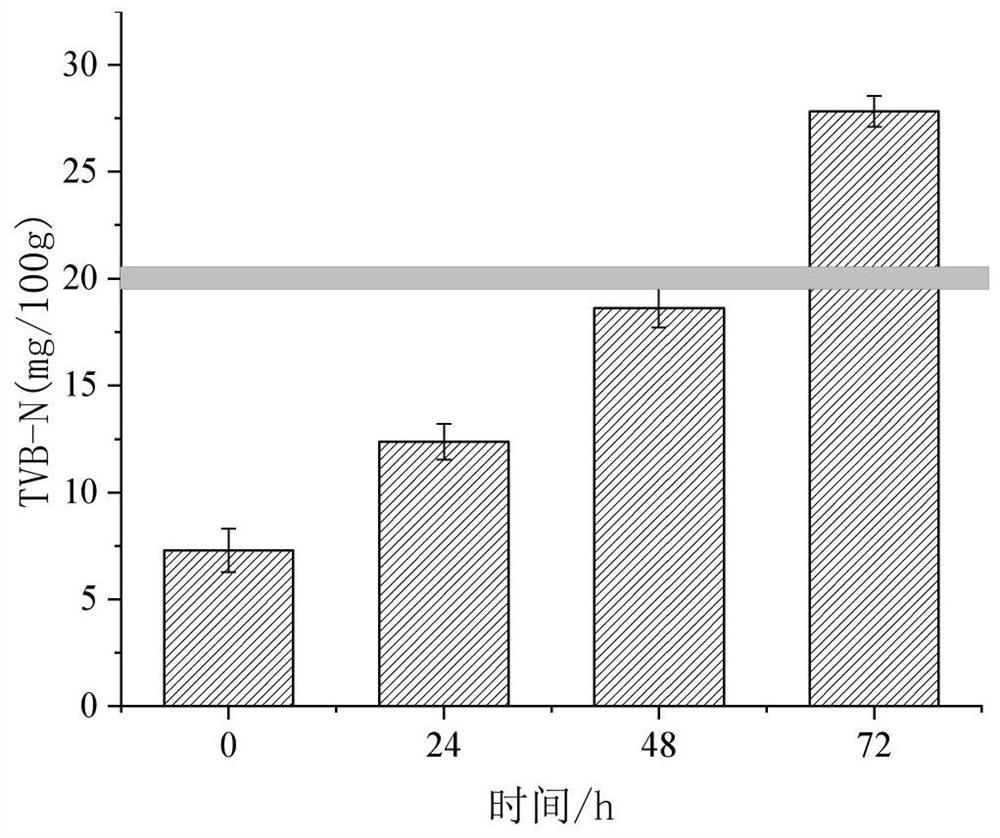

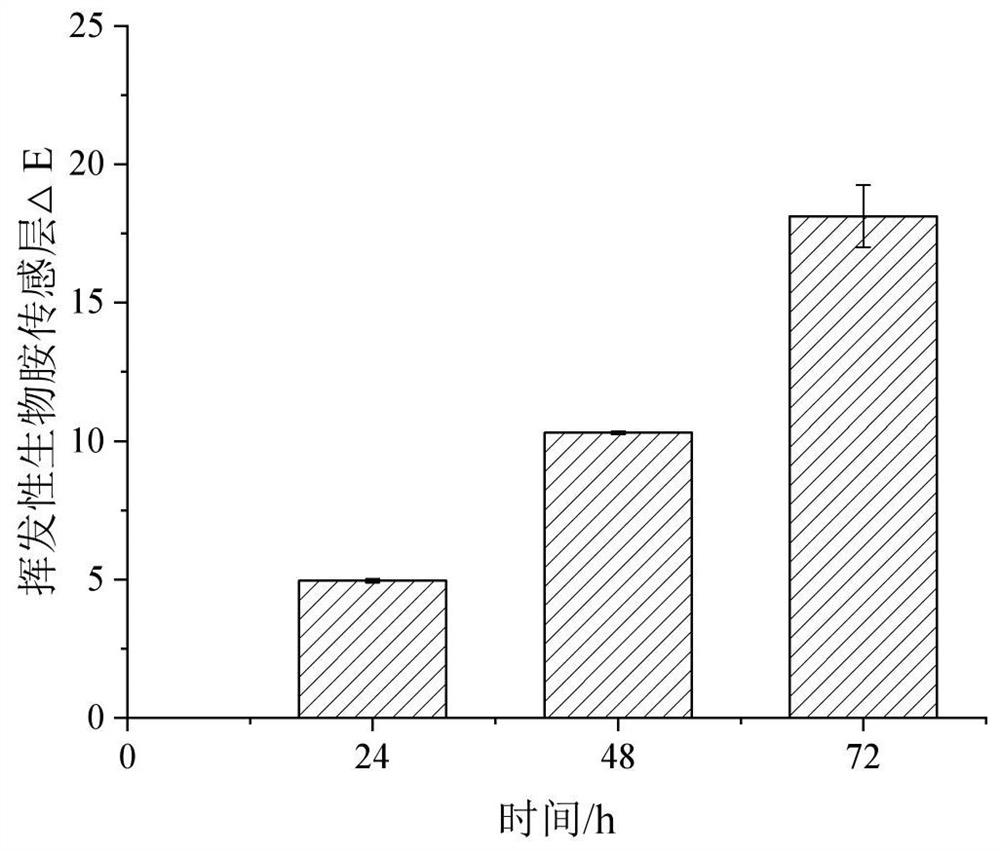

Double-indication intelligent label capable of identifying meat quality and manufacturing method and application of double-indication intelligent label

ActiveCN111472092AMonitor freshness in real timeReal-time monitoring of freshness statusMaterial analysis by observing effect on chemical indicatorMonocomponent polyethers artificial filamentBiotechnologyFiber

The invention relates to a double-indication intelligent label capable of identifying meat quality, a manufacturing method of the double-indication intelligent label and application of the double-indication intelligent label. The manufacturing method of the double-indication intelligent label comprises the steps of preparing a base layer spinning solution, preparing a volatile biogenic amine sensing layer spinning solution, preparing a volatile H2S sensing layer spinning solution, preparing a double-layer fiber membrane and the like. The double-indication intelligent label can provide relevantinformation such as meat types, weights and meat manufacturers, and has multiple functions of prolonging the shelf life of fresh meat, monitoring the freshness of the meat in real time and the like,so that the intelligent label has a very wide application prospect.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY +1

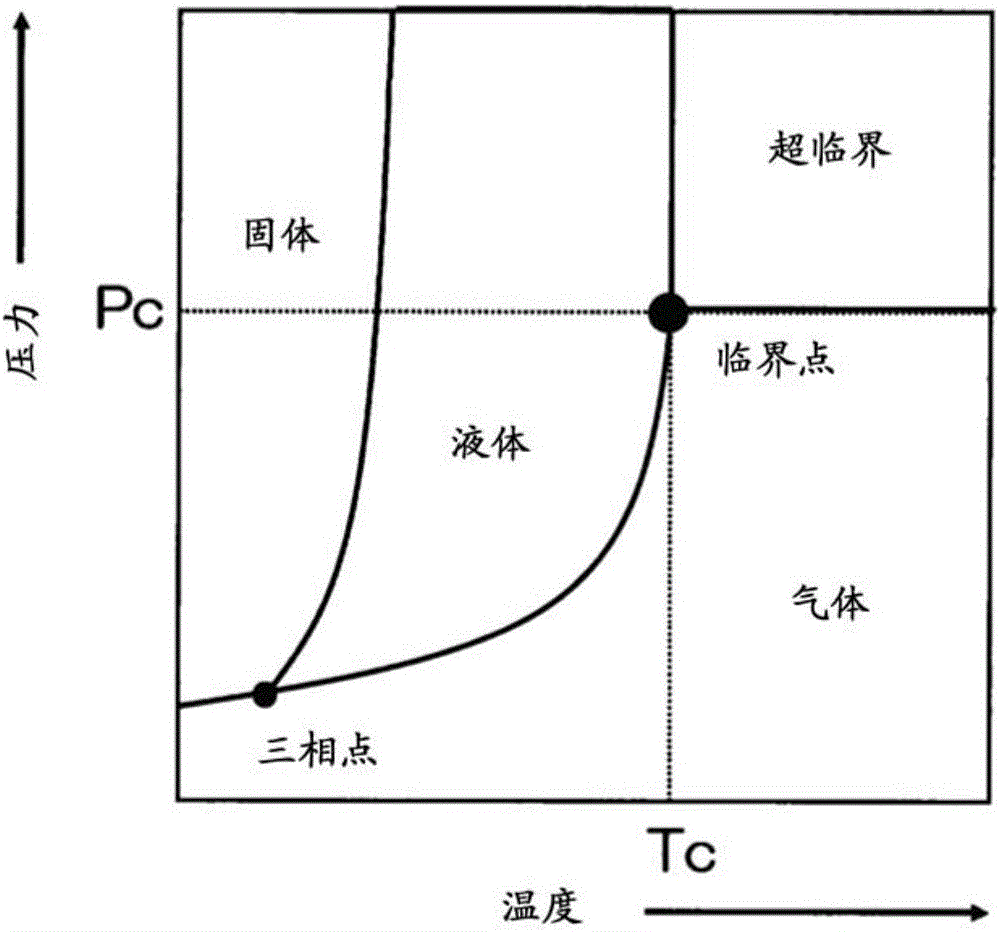

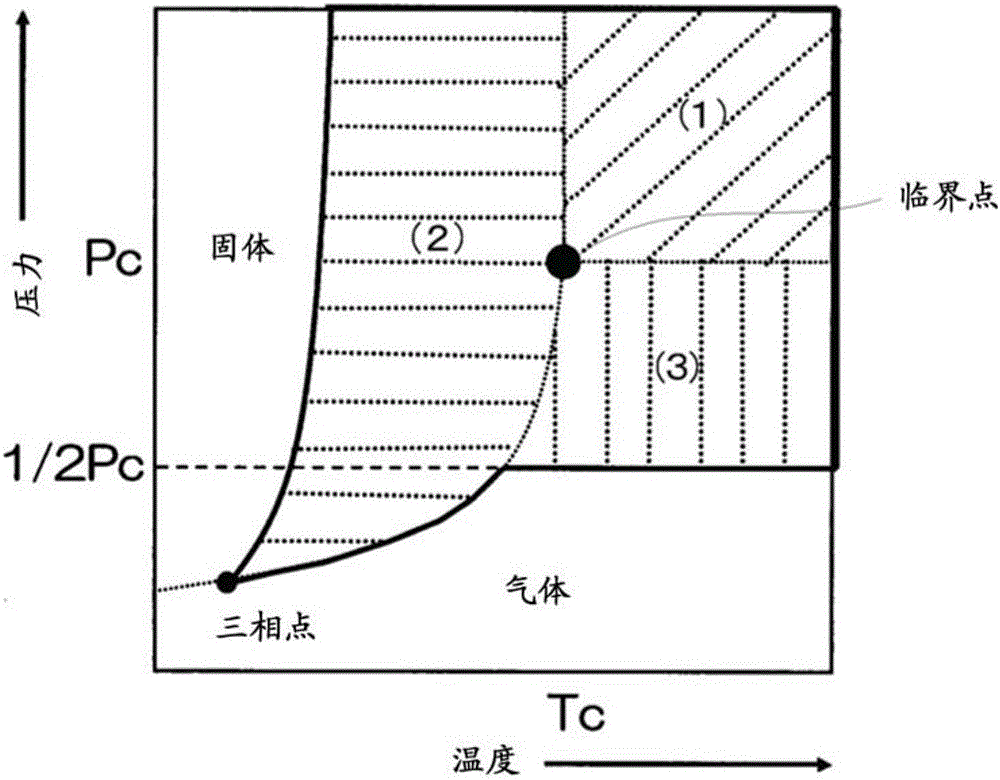

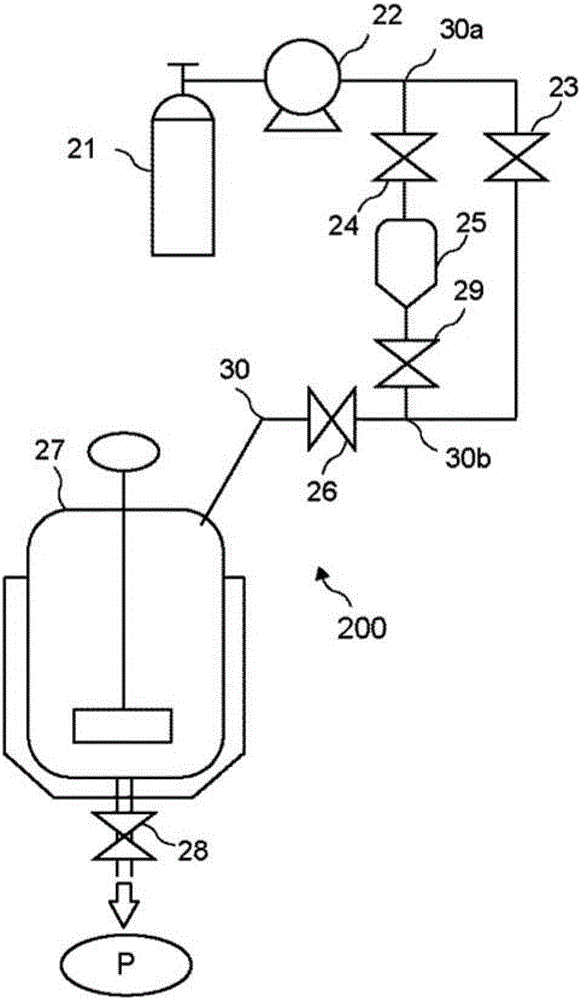

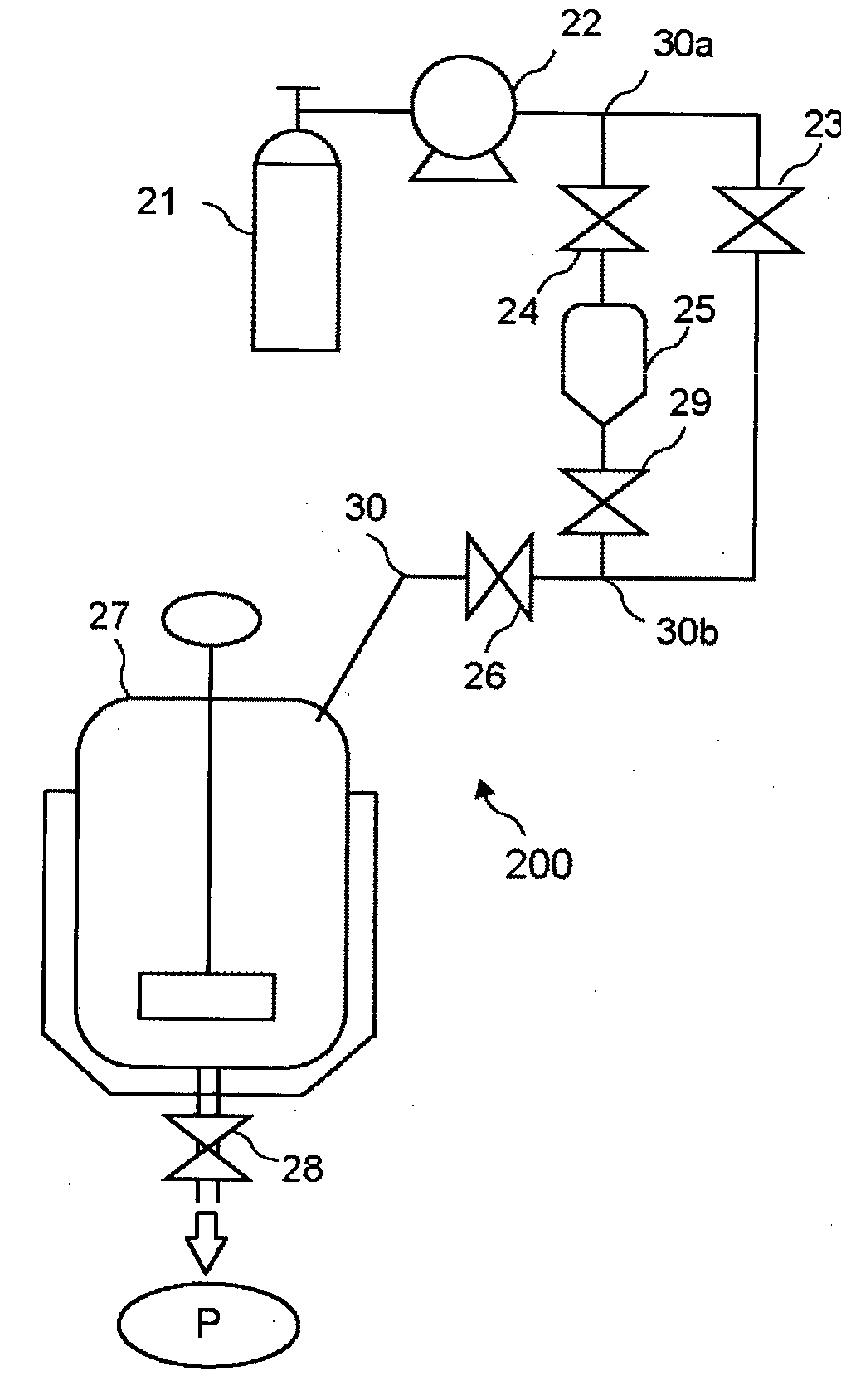

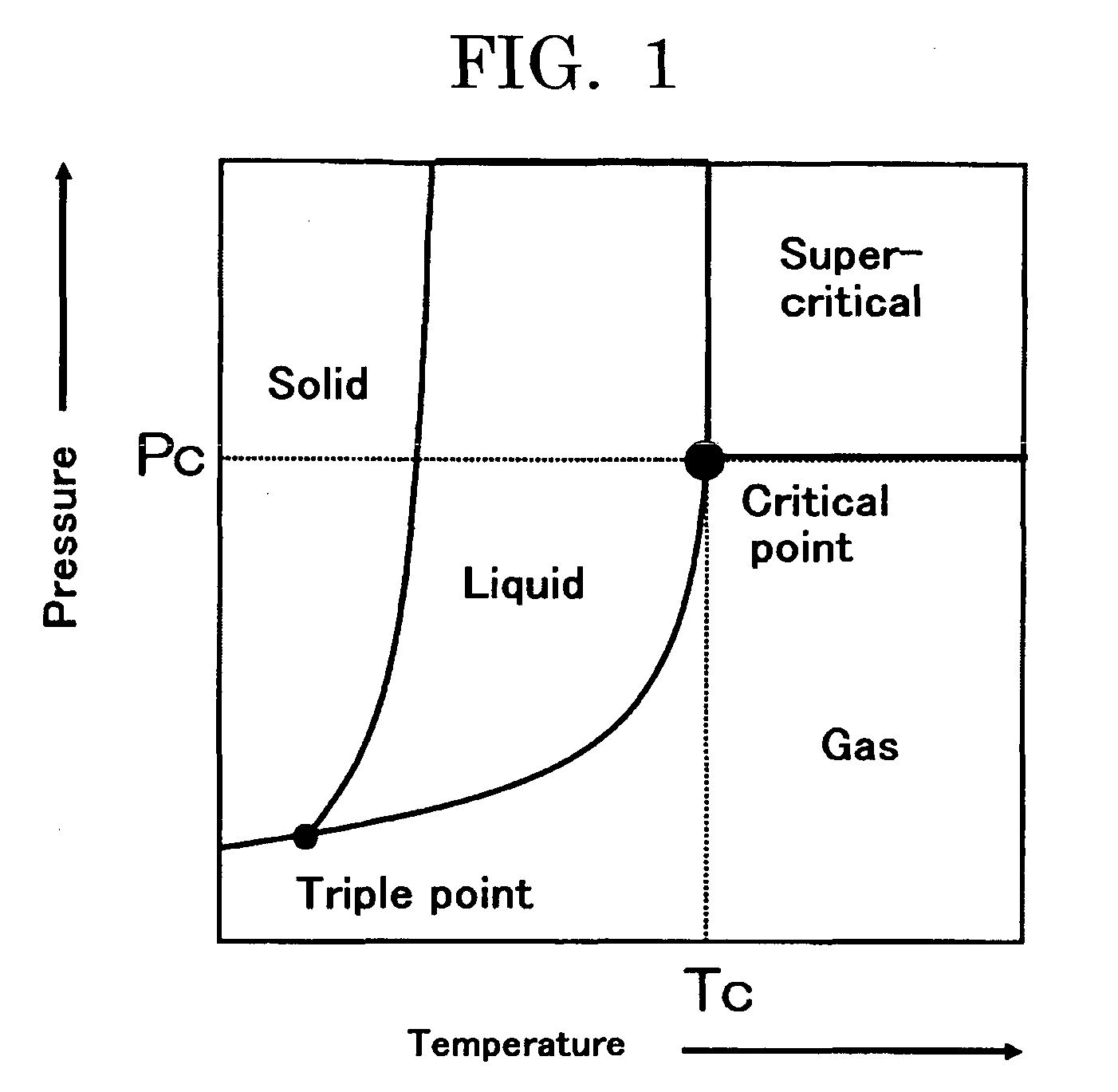

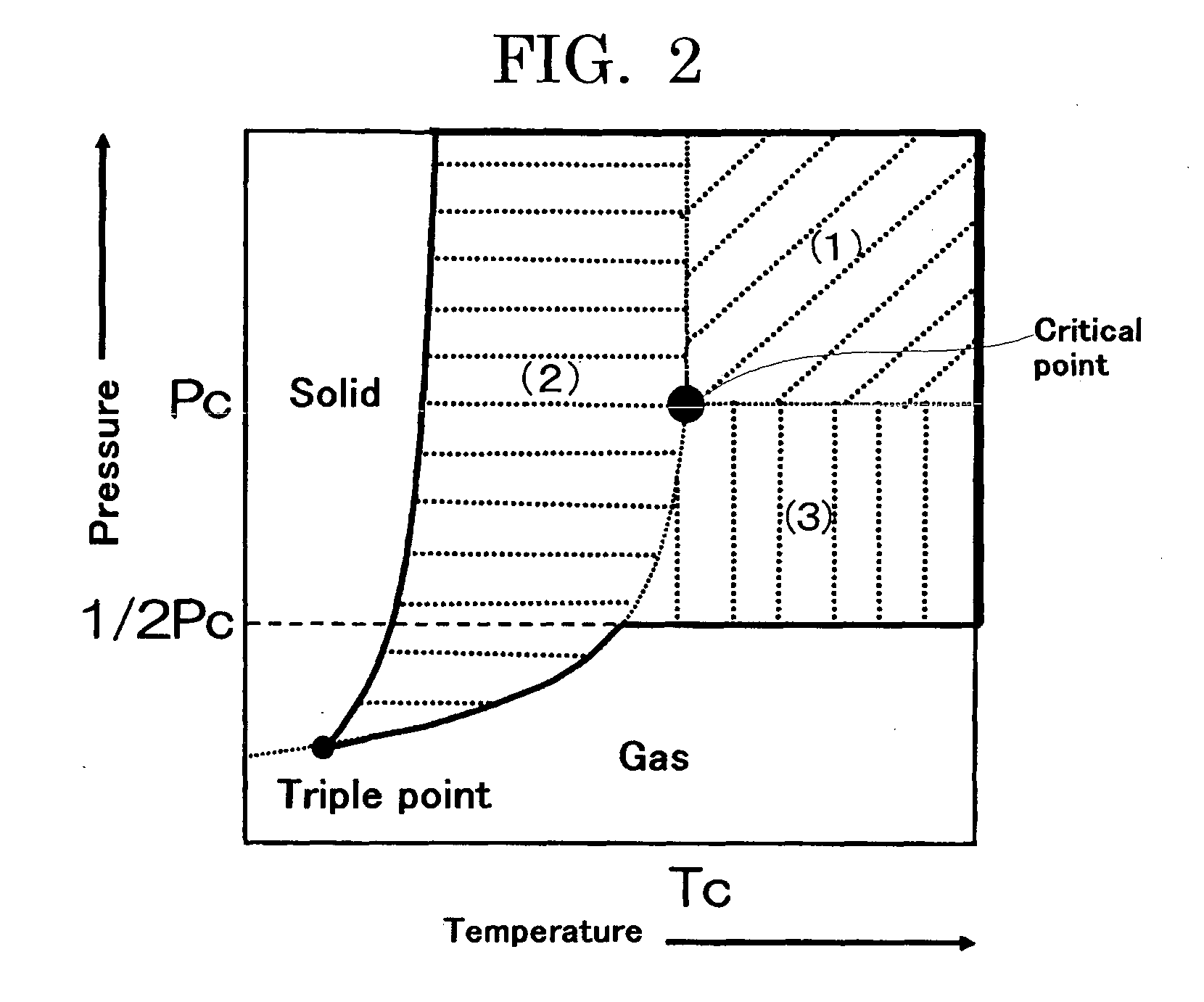

Polymer production method, polymer product, particles, film, molded article, and fibers

A method for producing a polymer, which contains: bringing a monomer containing a vinyl bond into contact with a compressive fluid and melting or dissolving the monomer containing a vinyl bond, followed by carrying out addition polymerization of the monomer containing a vinyl bond in the presence of an initiator.

Owner:RICOH KK

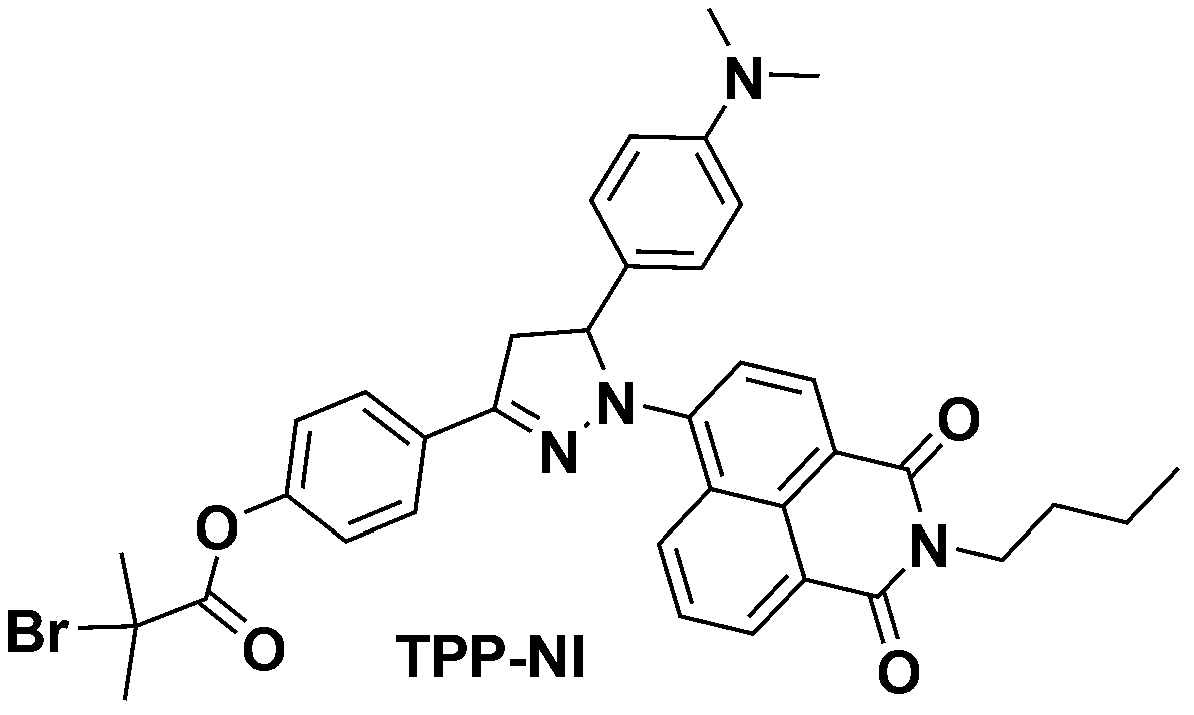

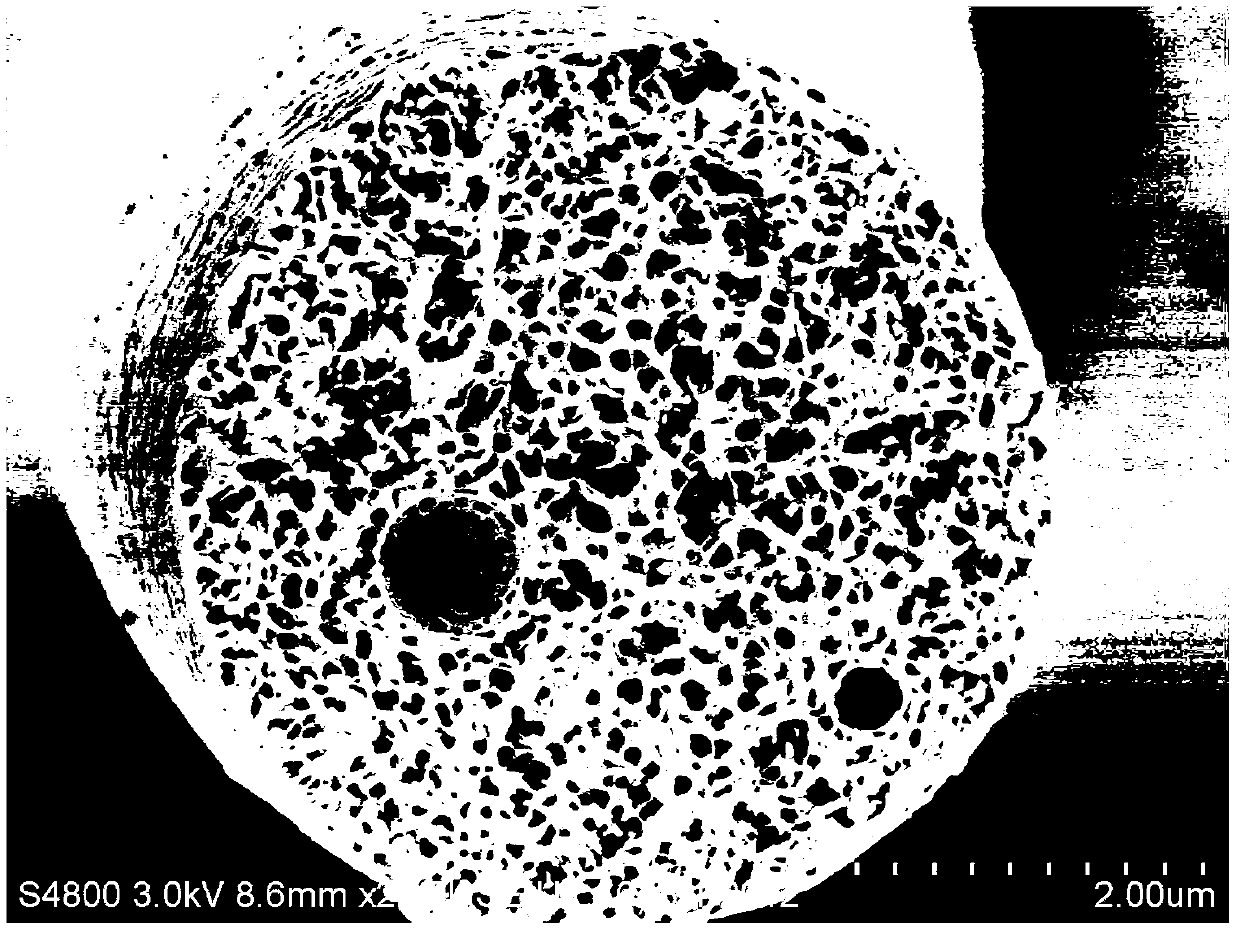

Method for preparing porous oil absorbing fibers with fluorescent response

ActiveCN103276467AGood fluorescence responseImprove luminous efficiencyMonocomponent polystyrene artificial filamentLuminescent compositionsPolymer dissolutionFiber

The invention discloses a method for preparing porous oil absorbing fibers with fluorescent response. The method is characterized by comprising the following steps of: 1) preparing a polymer with aggregation induced emission (AIE) effect; 2) dissolving the obtained polymer with the AIE effect into an organic solvent to form 15 to 35 weight percent spinning solution; and 3) preparing the porous oil absorbing fibers from the spinning solution by adopting the electrostatic spinning process. By adopting the method, the porous oil absorbing fibers with high luminous efficiency can be obtained; and the porous oil absorbing fibers have a good oil absorbing effect, and the fluorescent strength after the porous oil absorbing fibers absorb oil is remarkably reduced, namely the porous oil absorbing fibers have good fluorescent response.

Owner:SUZHOU UNIV

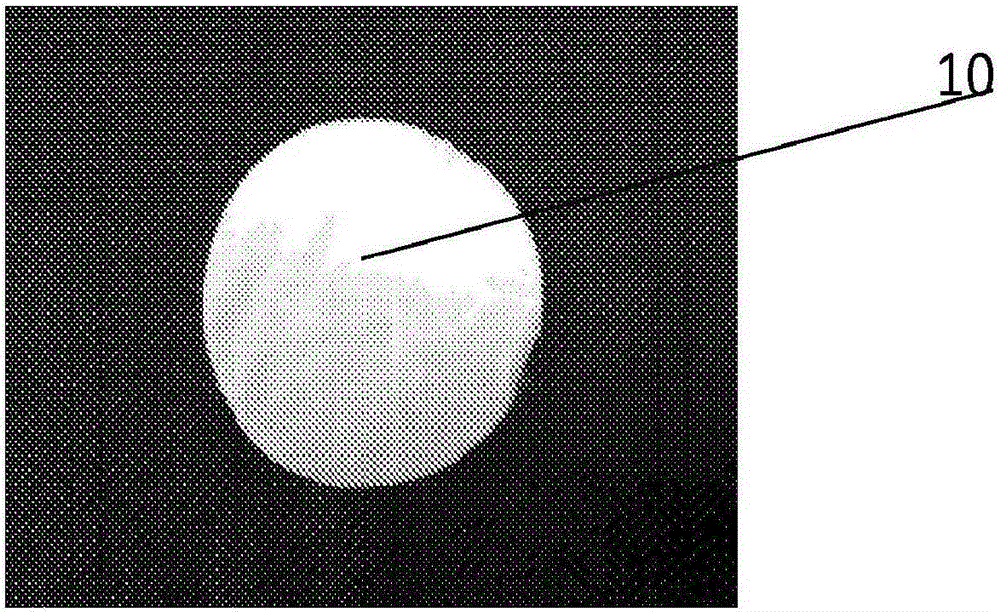

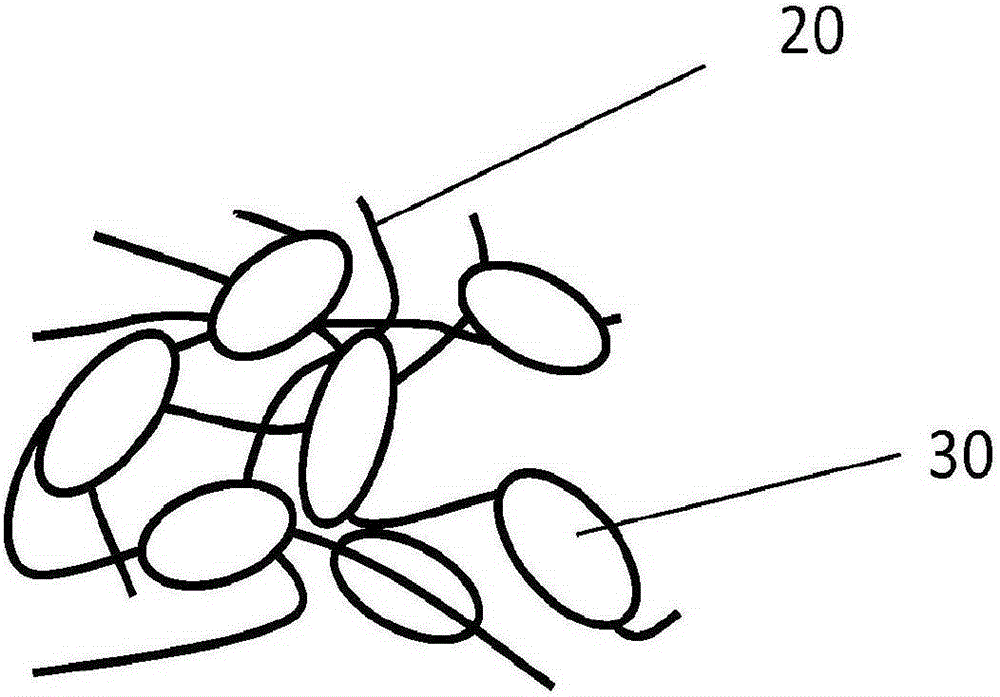

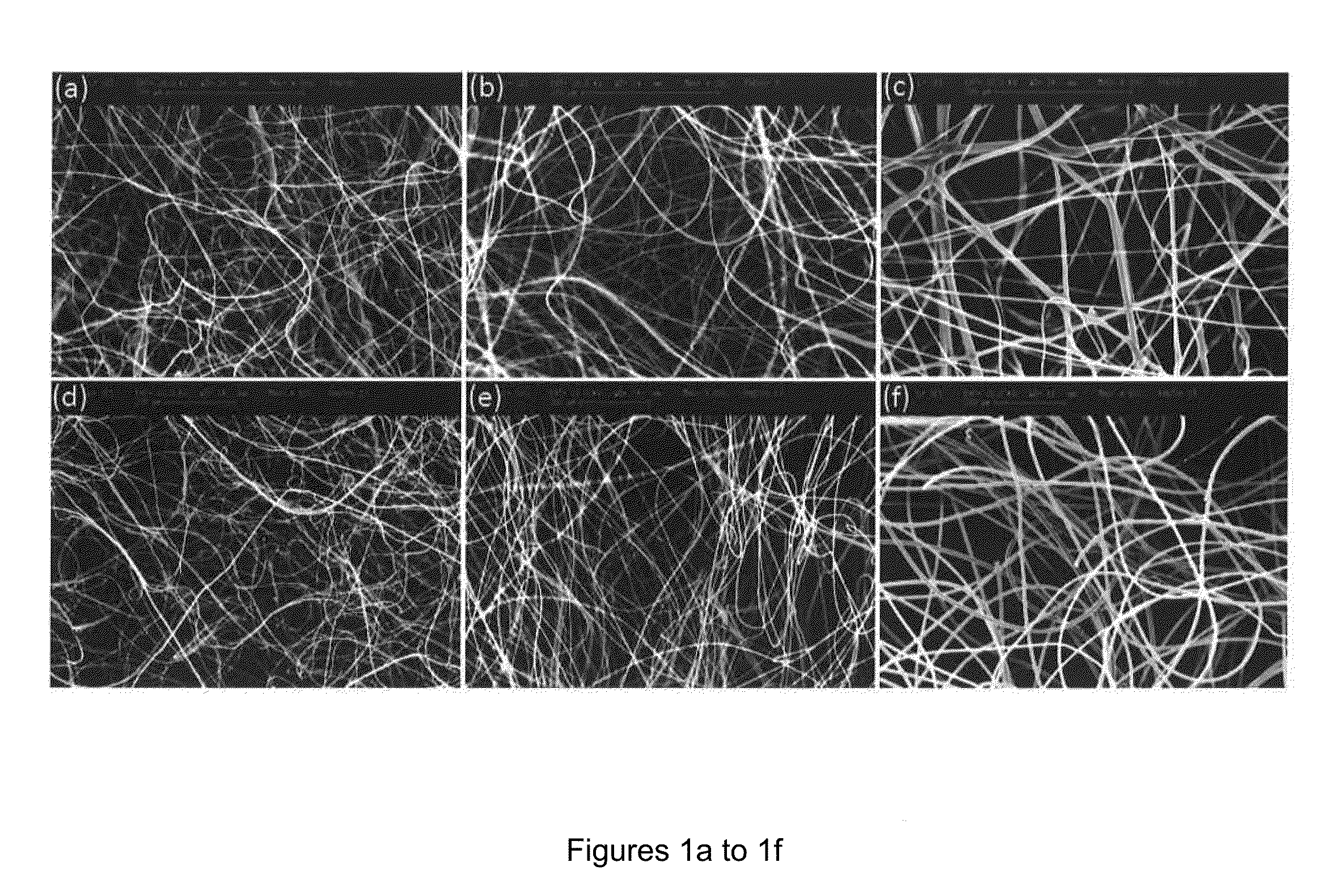

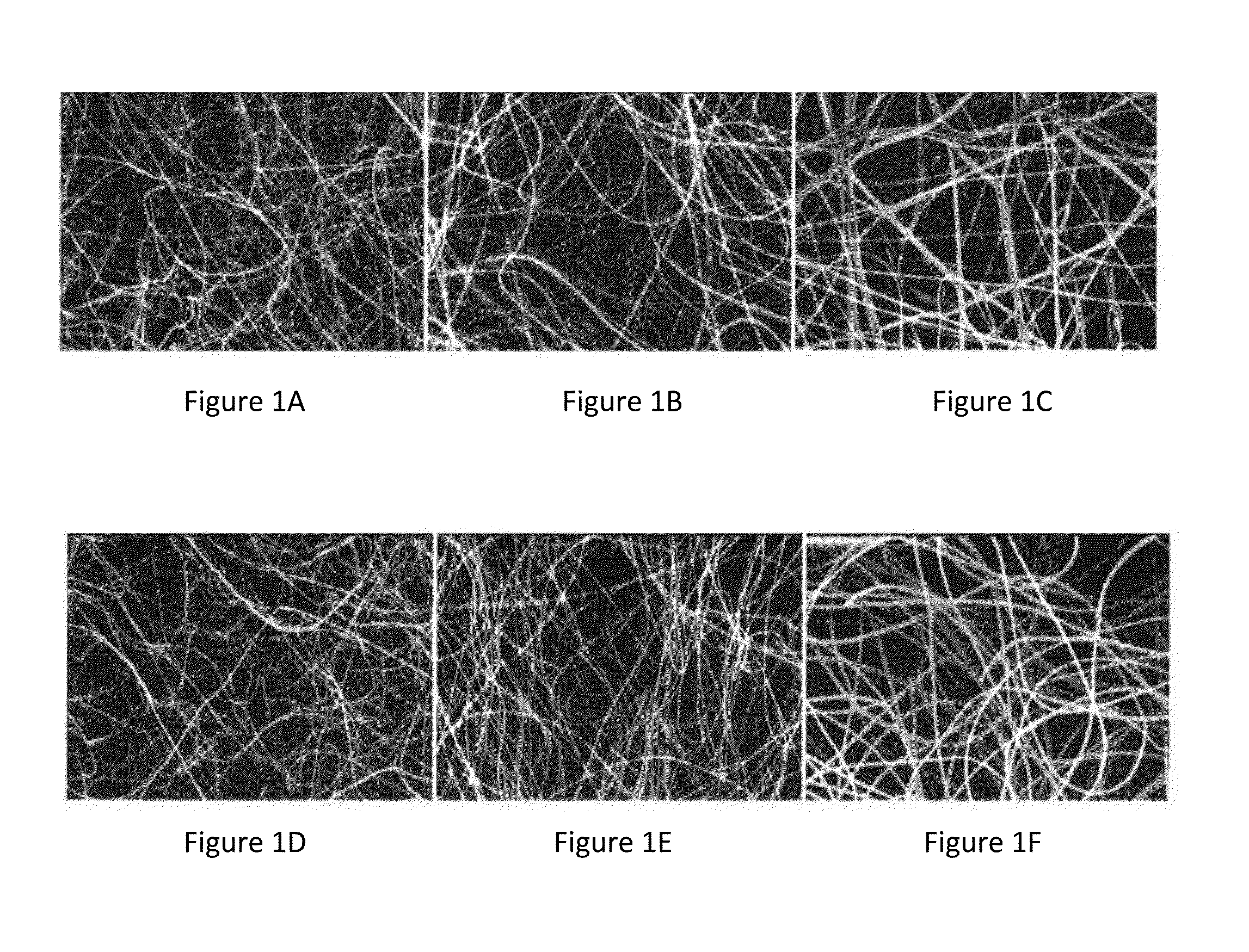

Three-dimensional structures for cell or tissue culture

InactiveUS20140363890A1Enhance cell spreading and cell attachment and cell growth and differentiation of cellElectro-spinningCell culture supports/coatingFiberBiology

Among others, the present invention provides devices for cell or tissue culture, comprising a three-dimensional structure, which further includes fibrils with beads and / or particles. The present invention also relates to novel methods for manufacturing devices for cell or tissue culture.

Owner:SNS NANO FIBER TECH

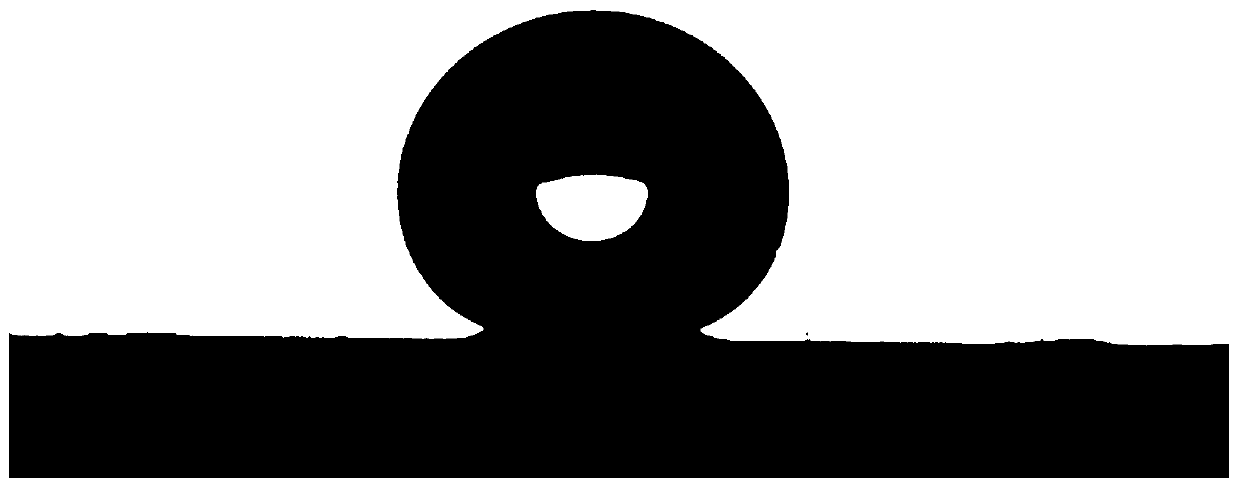

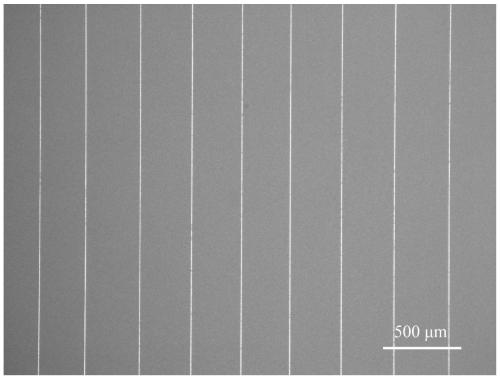

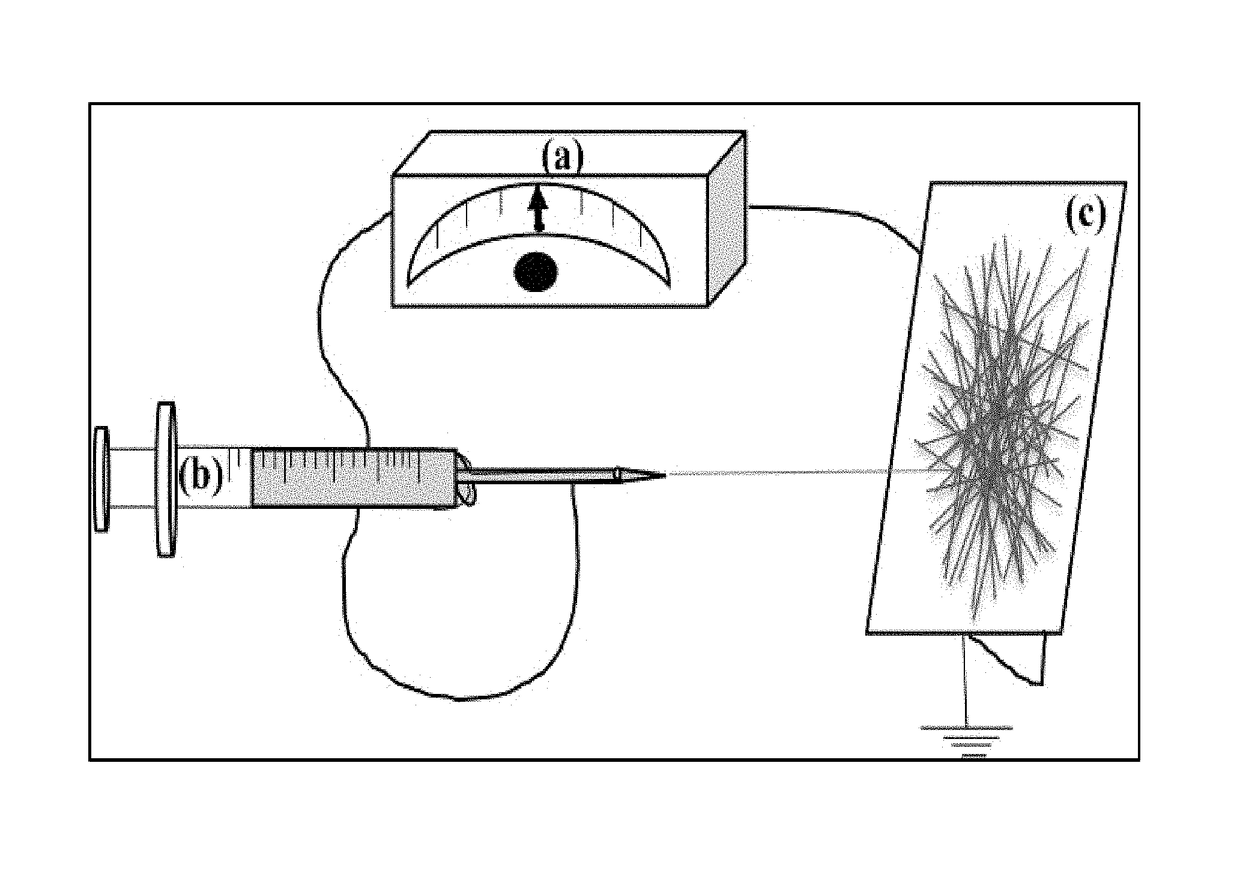

Fiber array controllable preparation method based on super-bi-hydrophobic surface

ActiveCN109881266AImprove uniformitySimple manufacturing methodNew-spun product collectionMonocomponent polyethers artificial filamentFiberPolymer science

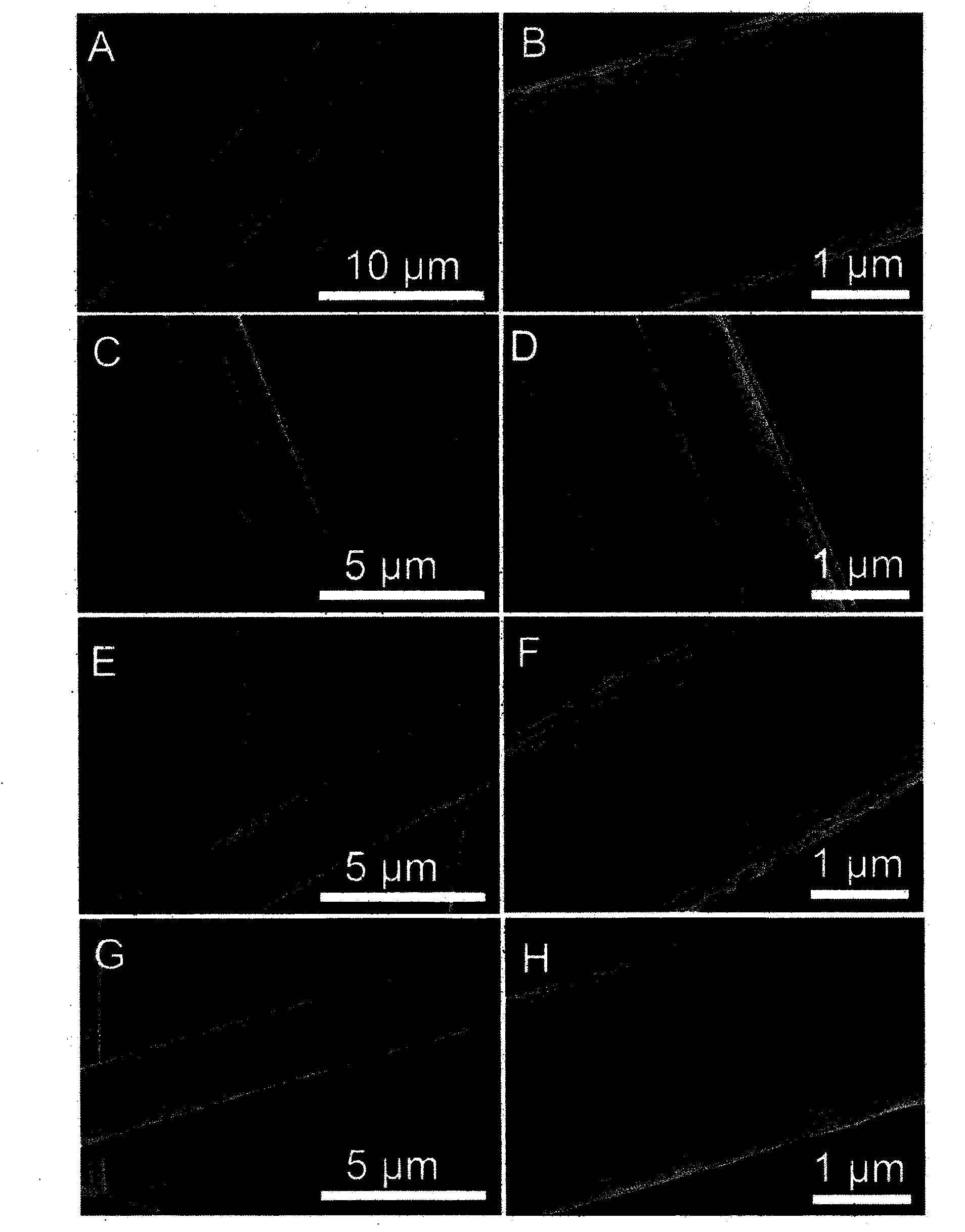

The invention discloses a fiber array controllable preparation method based on a super-bi-hydrophobic surface. The method includes the following steps that a, the super-bi-hydrophobic surface is prepared on one face of a 30 mm*30 mm*0.17 mm glass sheet, and a super-bi-hydrophobic surface glass sheet is obtained; b, a polymer and a solvent are fully stirred and mixed according to different mass ratios, and a polymer spinning solution is prepared; c, the super-bi-hydrophobic surface glass sheet is put on a clamp of a stepping device of a microfluid spinning machine, and the glass sheet rotates at the speed of 50 r / min-500 r / min; d, an injector is used for extracting the prepared polymer spinning solution, the polymer spinning solution is extruded to the upper face of the super-bi-hydrophobicsurface glass sheet at the speed of 0.05 mL / min-0.5 mL / min through a microflow pump of the microfluid spinning machine, the stepping device of the microfluid spinning machine transversely moves at the speed of 1 mm / s-10 mm / s, the polymer spinning solution is collected from the super-bi-hydrophobic surface glass sheet, and regularly-arranged polymer fibers are obtained. According to the method forcarrying out microfluid spinning on the super-bi-hydrophobic surface to prepare a fiber array, the obtained fiber array is higher in regularity, and the preparation method is simpler and easier to carry out.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Highly selective, ultralight, electro-spun filter media for separating oil-water mixtures

A filter medium for oil-water separation, the filter medium being a composite, nanofibrous mat formed from electrospinning a single solution of one natural polymer and one synthetic polystyrene polymer together, where fibers of the natural polymer are reinforced by fibers of the synthetic polystyrene polymer. The nanofibrous mat may initially be hydrophobic and oleophilic, making it a suitable filter medium for separating oil from oil-water mixtures. The mat may be treated with one or more surfactants to change the surface wettability of the mat to hydrophilic and oleophobic for separating water from oil-water mixtures or to hydrophobic and oleophobic for separating oil and water droplets from wet gas.

Owner:UNIVERSITY OF TULSA

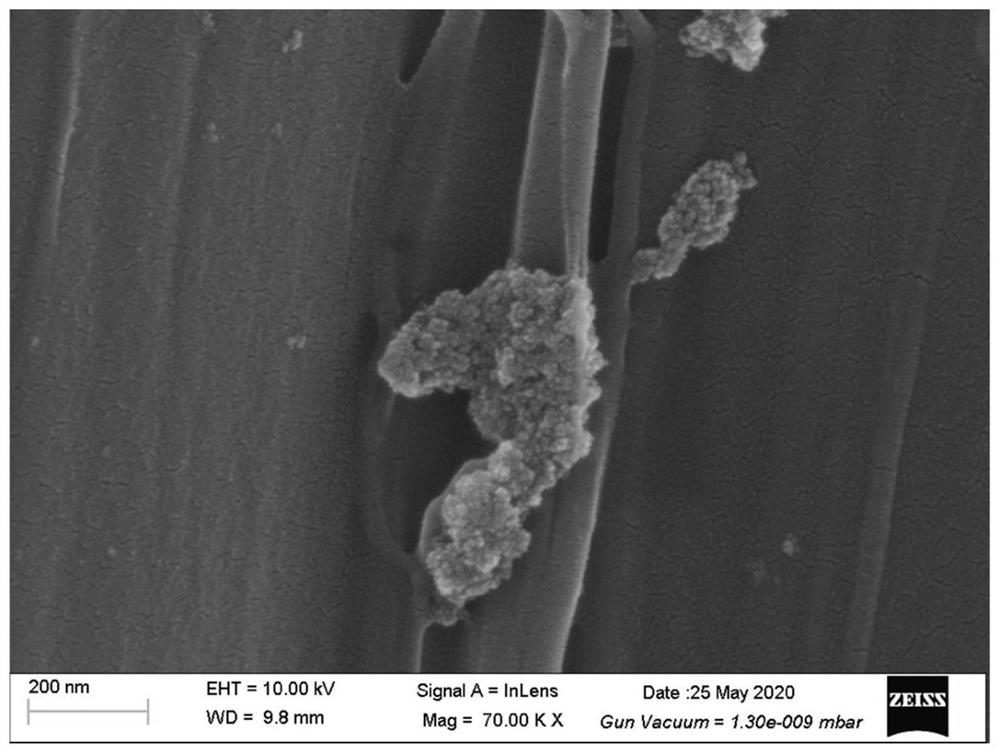

Preparation method of HNTs, method used for preparing high polymer/HNTs mixed solution from HNTs, and method used for preparing high polymer nanofiber from high polymer/HNTs mixed solution

ActiveCN105603553ALow priceImprove thermal stabilityFilament/thread formingMonocomponent polystyrene artificial filamentFiberPolymer science

The invention relates to a preparation method of HNTs, a method used for preparing a high polymer / HNTs mixed solution from HNTs, and a method used for preparing polymer nanofiber from the high polymer / HNTs mixed solution. HNTs is subjected to surface modification so as to solve an intermiscibility problem of HNTs with a high polymer substrate; and electrostatic spinning is used for improving orientation of HNTs nanotubes in the high polymer, and improving fiber mechanical properties.

Owner:YANGZHOU SPED CHEM +1

Fiber spinning process using a weakly interacting polymer

A fiber spinning process comprising the steps of providing a polymer solution, which comprises at least one weakly interacting polymer dissolved in at least one weakly interacting solvent to a spinneret; issuing the polymer solution in combination with a blowing gas in a direction from at least one spinning nozzle in the spinneret and in the presence of an electric field; forming fibers and collecting the fibers on a collector.

Owner:DUPONT SAFETY & CONSTR INC

Three-dimensional structures for cell or tissue culture

Among others, the present invention provides devices for cell or tissue culture, comprising a three-dimensional structure, which further includes fibrils with beads and / or particles. The present invention also relates to novel methods for manufacturing devices for cell or tissue culture.

Owner:SNS NANO FIBER TECH

Porous nano-fiber prepared by combining electrostatic spinning with anti-solvent technology and preparing method

ActiveCN104928789AEasy to prepareSpinning environment requirements are smallFilament/thread formingMonocomponent polystyrene artificial filamentFiberAnti solvent

The invention discloses porous nano-fiber prepared by combining electrostatic spinning with the anti-solvent technology and a preparing method. The porous nano-fiber is prepared according to the following specific steps that 1, a spinning solution is formed by mixing, by mass, 60-90% of solvent, and 10-40% of spinnable polymer, and the mass sum of the components is 100%; 2, the spinning solution is placed into a propeller of an electrostatic spinning machine for carrying out electrostatic spinning, the spinning solution is ejected from a spinning needle head to obtain liquid fiber, the liquid fiber enters a container containing anti-solvent to react with the anti-solvent, and polymer nano-fiber is obtained after reaction is finished; 3, the polymer nano-fiber is dried to obtain porous nano-fiber. The preparing method is simple, the requirement for the spinning environment is low, the mechanical property is approximate to that of common fiber, and the specific surface area is large.

Owner:XIAN UNIV OF TECH

Aerogel composite fiber material as well as preparation method and application thereof

InactiveCN112981575AThe dispersant disperses the airgel particles, forming a convenientPromote formationFlame-proof filament manufactureWet spinning methodsFiberSpinning

Owner:纳诚(邢台)新材料科技有限公司

Fiber spinning process using a weakly interacting polymer

A fiber spinning process comprising the steps of providing a polymer solution, which comprises at least one weakly interacting polymer dissolved in at least one weakly interacting solvent to a spinneret; issuing the polymer solution in combination with a blowing gas in a direction from at least one spinning nozzle in the spinneret and in the presence of an electric field; forming fibers and collecting the fibers on a collector.

Owner:DUPONT SAFETY & CONSTR INC

Degradable synthetic fiber composition, preparation method thereof and product

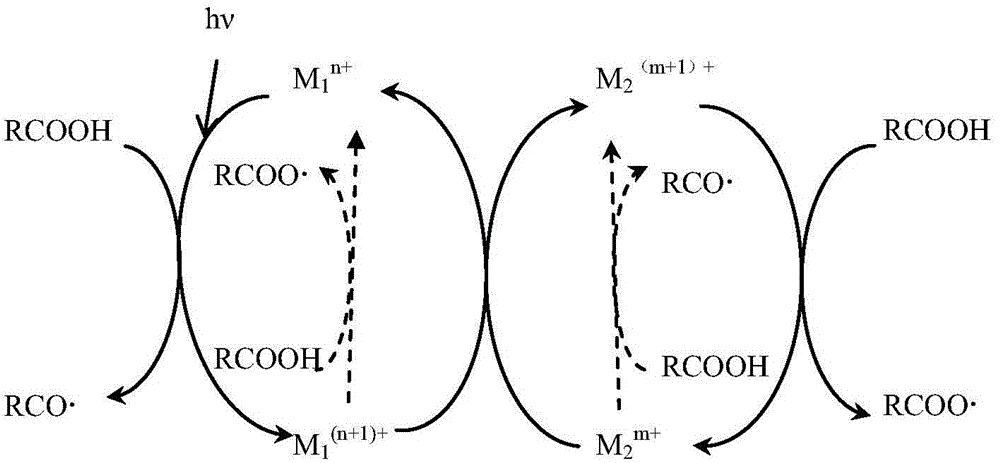

InactiveCN106032422AImprove light utilizationHigh utilization rate of visible lightMonocomponent polystyrene artificial filamentArtifical filament manufacturePolyesterPolymer science

The invention relates to a degradable synthetic fiber composition, a preparation method thereof and a prepared biodegradable synthetic fiber product. The biodegradable synthetic fiber composition comprises a polymer and two or more transition metal salts dispersed in the polymer; and at least one of the transition metal salts is a polyvalent metal salt. The invention can degrade polyester, polyamide and styrene polymers, and selects more than two transition metal additives to produce synergistic effect, so as to directly improve the utilization rate of ultraviolet and visible light; and oxidation-biodegradation is applied to artificial fiber synthesis for the first time, and the existing equipment can be directly used for commercial production. The formula and method of the invention in particular can be directly applied to the non-woven fabric weaving technology to further reduce environmental pollution caused by wastes.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

Polymer production method, polymer product, particles, film, molded article, and fibers

A method for producing a polymer, which contains: bringing a monomer containing a vinyl bond into contact with a compressive fluid and melting or dissolving the monomer containing a vinyl bond, followed by carrying out addition polymerization of the monomer containing a vinyl bond in the presence of an initiator.

Owner:RICOH KK

Micron fiber/nanofiber composite filter material and preparation method thereof

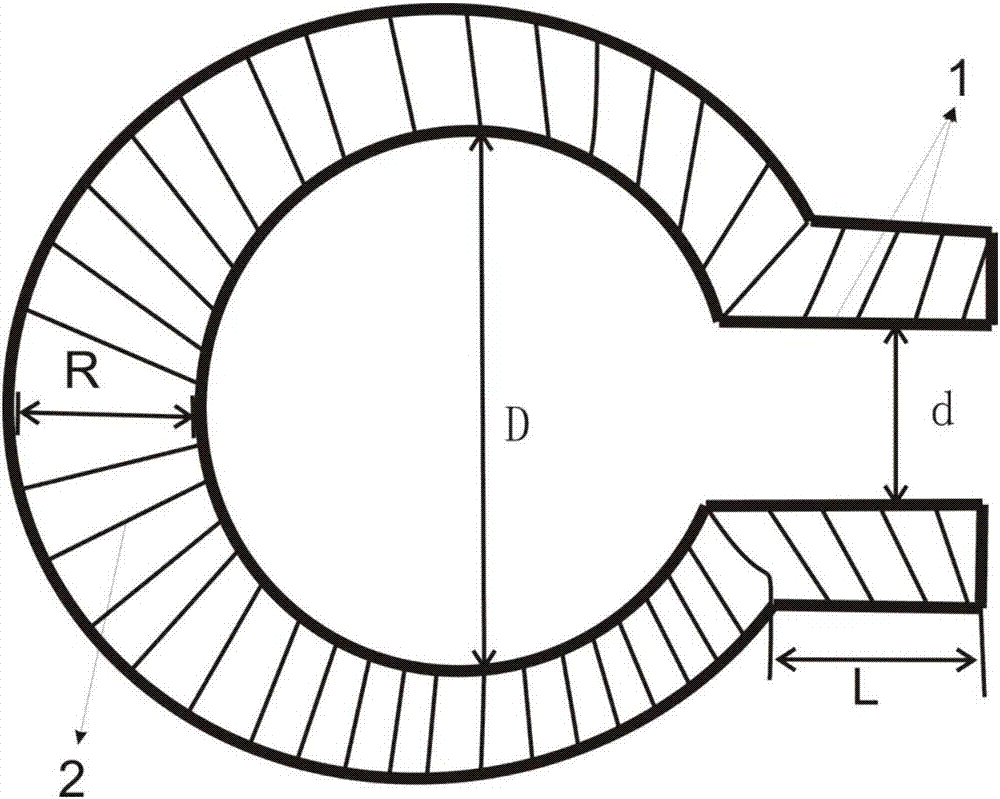

ActiveCN107366030AGood molding effectEasy to prepareFilament/thread formingMonocomponent polystyrene artificial filamentParticulatesSolvent vapor

The invention relates to a micron fiber / nanofiber composite filter material and a preparation method thereof. The preparation method includes: in an electrostatic spinning process, an annular gradient solvent vapor quick removing device is adopted for one-step forming on a receiving substrate to obtain the micron fiber and nanofiber integrated three-dimensional structural composite filter material according to a double-region isolation spinning control technique. Efficiency of the micron fiber / nanofiber composite filter material in filtering of 0.02-10micron particles reaches 99.95% or above, and resistance pressure drop is smaller than 40Pa. The preparation method is simple in process, controllability in fiber diameter and pore diameter is achieved, the obtained composite filter material is of micron / nano scale in fiber diameter and pore diameter, a great filtration performance is achieved, and the composite filter material is widely applicable to air purifying products such as mask filter elements, air purifiers and air conditioners.

Owner:DONGHUA UNIV

Sound absorption and sound insulation earplug and preparing method thereof

InactiveCN106963551AWide range of muting frequenciesImprove sound absorptionEarplugsMonocomponent polystyrene artificial filamentHelmholtz resonatorEngineering

The invention relates to a sound-absorbing and sound-insulating earplug and a manufacturing method thereof. The sound-absorbing and sound-insulating earplug includes two parts, an elastic shell and a shell interlayer. The elastic shell imitates the shape of a Helmholtz resonator and consists of a spherical cavity and a neck. The shell The interlayer is filled with porous sound-absorbing materials, which can be adapted to deal with different noise environments by adjusting the size of the new sound-absorbing earplugs and the spinning parameters of the porous sound-absorbing materials. It has the advantages of wide noise reduction frequency and good sound absorption effect.

Owner:SUZHOU UNIV

Method For Treating Oil

A method for treating an oil spill includes providing a polystyrene-based sorbent in the form of polystyrene microfibers having a sorption capacity in the range of between 30 g / g to 217 g / g, measured as grams of oil sorbed per one gram of the sorbent; drenching the polystyrene microfibers in the oil spill to be treated; collecting the oil drenched polystyrene microfibers; and removing excess oil from the oil drenched polystyrene microfibers by compressing the microfibers. The method further includes dissolving the oil drenched polystyrene microfibers in a petroleum-based solvent in the form of gasoline having an octane number of ninety one, in which both the oil drenched polystyrene microfibers and the oil is soluble, thereby forming a solution comprising the gasoline having dissolved therein the polystyrene microfibers and the oil; and utilising the solution as a feedstock for feeding a refinery.

Owner:UNITED ARAB EMIRATES UNIVERSITY

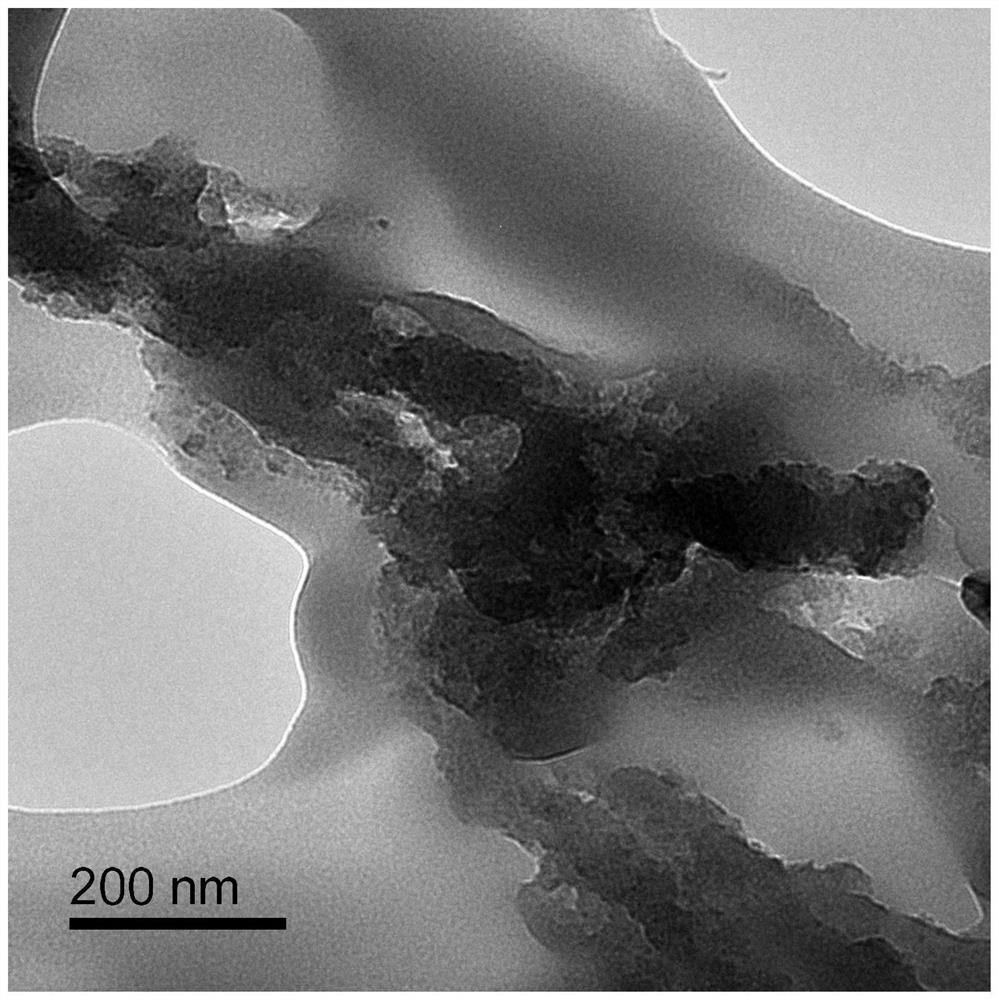

Emulsion composition, polystyrene nano-fiber, polystyrene nano-fiber product, preparation method, and use thereof

PendingUS20220098395A1Stable and controllable three-dimensional structureImprove preparation efficiencyOther chemical processesFilament/thread formingFiberPolymer science

An emulsion composition, a polystyrene nano-fiber, a polystyrene nano-fiber product and a preparation method and use thereof, wherein the emulsion composition comprises a dispersed phase and a continuous phase, the dispersed phase contains a soluble salt and a first solvent, the continuous phase contains polystyrene, a second solvent and sulfonated polystyrene being syndiotactic polystyrene and / or isotatic polystyrene; the preparation of the emulsion composition: under heating and stirring, dropwise adding the dispersed phase into the continuous phase; the preparation of the polystyrene nano-fiber or polystyrene nano-fiber product: crystallize the above emulsion composition; the polystyrene nano-fiber prepared by the above emulsion composition has a pore structure, and the prepared product has a stable and controllable three-dimensional structure and multi-level and / or intercommunicated pore structure, and also has a high preparation efficiency, therefore the above polystyrene nano-fiber or product has excellent application prospects in absorption, adsorption, oil-water separation, and construction of special wettability surfaces.

Owner:JIANGSU GUOWANG HIGH TECH FIBER CO LTD

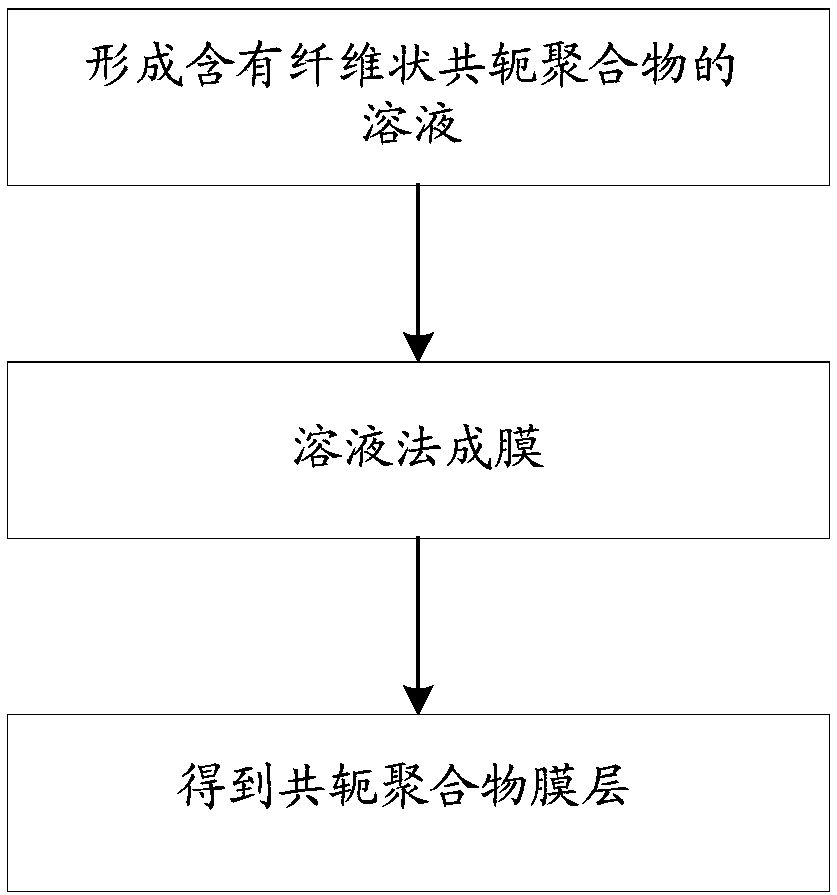

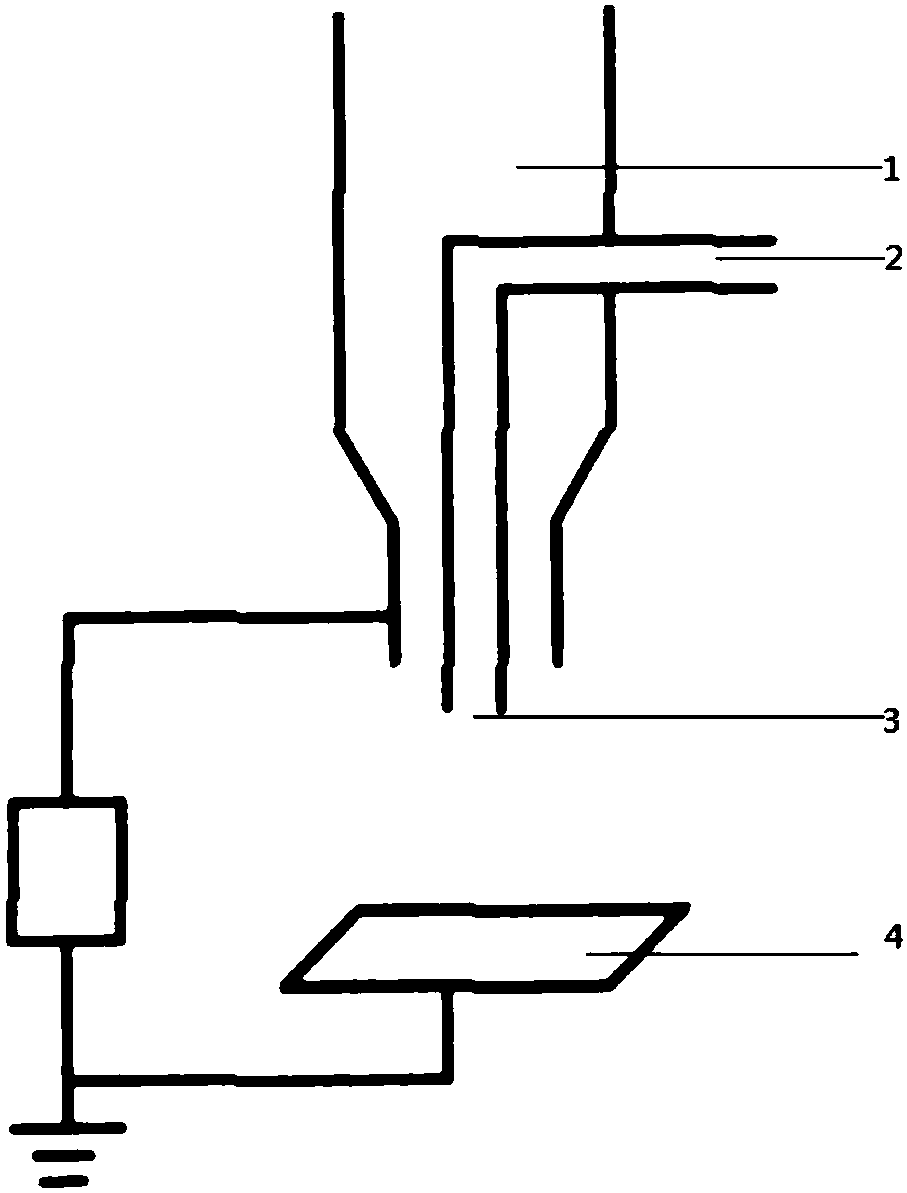

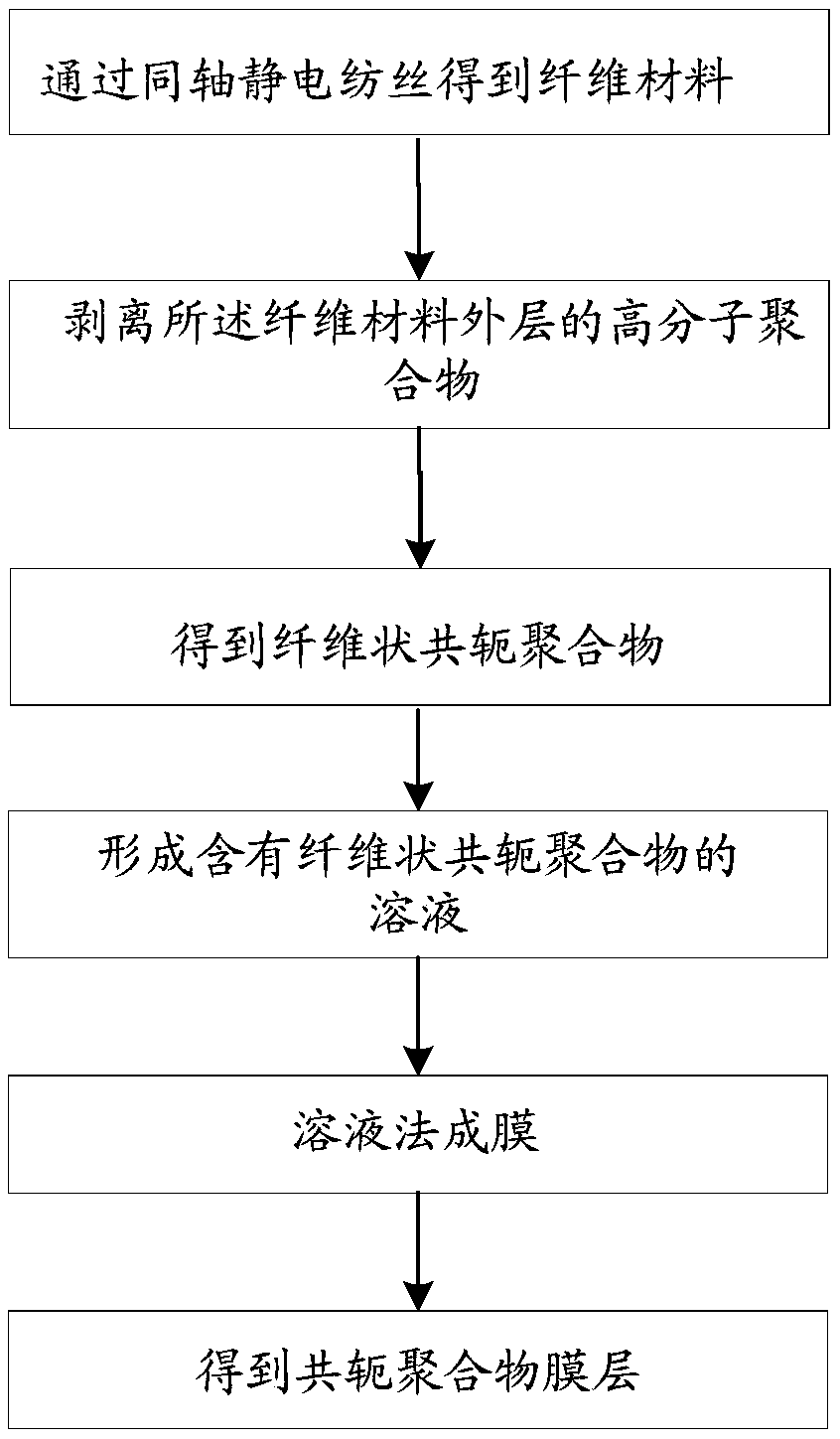

Preparation method and application of conjugated polymer film layer

InactiveCN108486685AImprove mobilityImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingPolymer scienceCharge carrier mobility

The invention relates to the field of display, in particular to a preparation method and application of a conjugated polymer film layer. The preparation method of the conjugated polymer film layer comprises the following steps; forming a solution containing a fibrous conjugated polymer and obtaining the conjugated polymer film layer by a solution film forming method. The fibrous conjugated polymerhas certain length and orientation and has high electron mobility in dimensionality direction of the fibrous conjugated polymer, so that carrier mobility can be well improved. When the conjugated polymer film layer prepared by the method is used for an organic light emitting diode or a solar cell, the conjugated polymer film layer has higher carrier mobility, so that the performance of a device is improved.

Owner:BOE TECH GRP CO LTD +1

Process of fabrication of submicron aligned hydrophobic and oleophilic fibre from polystyrene waste with controllable geometry using-citrus peel extract as solvent

The invention discloses a process of fabrication of a submicron aligned hydrophobic and oleophilic fibre from polystyrene waste with controllable geometry using-citrus peel extract as a solvent. The present invention discloses a simple mechanical method of fabrication of sub-micron aligned free standing hydrophobic and oleophilic fibers of polystyrene waste using extracts obtained from the peel of any citrus fruit such as orange, lemon, sweet lime, kinnow etc. as solvent. Fibers are aligned and useful in making different geometries. Process of making film using this process is facile and fast and film obtained is free standing film. Process set-up have minimum requirement and is inexpensive. This method is simple and flexible with respect to set-up and process. This process has the potential of being industrialized. Therefore, this method can be beneficial in dealing with both the orange peel and polystyrene waste.

Owner:印度海得拉巴理工学院

A dual-indication smart label for identifying meat quality, its production method and application

ActiveCN111472092BMonitor freshness in real timeReal-time monitoring of freshness statusMaterial analysis by observing effect on chemical indicatorMonocomponent polyethers artificial filamentBiotechnologyFiber

The present invention relates to a dual-indication smart label for meat quality identification, a manufacturing method of the dual-indication smart label, and an application of the dual-indication smart label. The manufacturing method of the double-indicating smart label includes preparing the spinning solution for the base layer, preparing the spinning solution for the sensing layer of the volatile biogenic amine, and preparing the volatile H 2 S sensing layer spinning solution and preparation of double-layer fiber membrane and other steps. The dual-indication smart label of the present invention can not only provide relevant information such as meat type, weight, and meat product manufacturer, but also has multiple functions such as extending the shelf life of fresh meat and monitoring the freshness of meat in real time. Therefore, the smart label of the present invention has Very broad application prospects.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY +1

Popular searches

Textile treatment by spraying/projecting Monocomponent halogenated hydrocarbon artificial filament Monocomponent polyesters artificial filament Monocomponent polycarbonates artificial filament Monocomponent polyamides artificial filament Staple fibre formation Monocomponent polypropylene artificial filament Monocomponent polyolefin artificial filament Domestic walls Spectral modifiers

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com