Degradable synthetic fiber composition, preparation method thereof and product

A technology of synthetic fibers and compositions, applied in the field of degradable synthetic fiber products, can solve problems such as poor degradation effect, and achieve the effects of significant degradation effect, improved utilization rate, and intuitive and reliable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

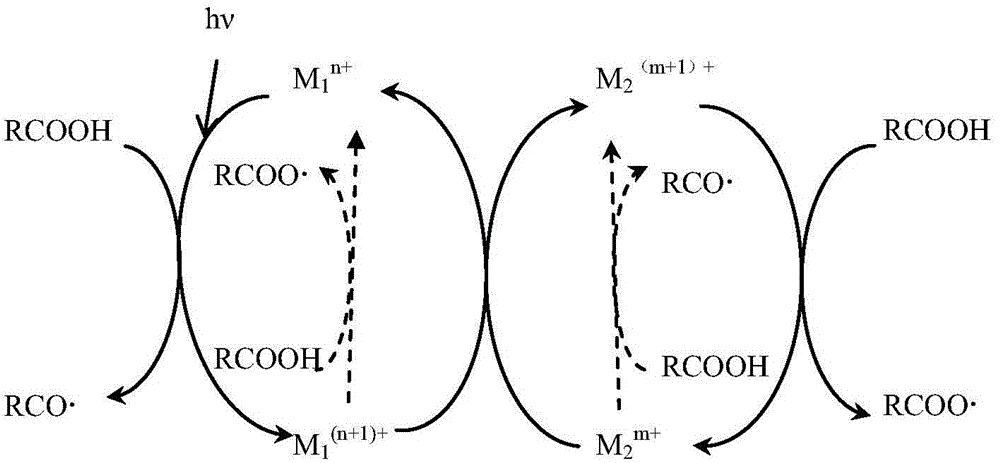

[0063] The present invention also provides a preparation method of the above-mentioned degradable synthetic fiber composition, the steps are: mixing all raw materials such as polymers such as polyester, polyamide or polystyrene, and transition metal salts through a twin-screw mixer, and the molten state Polymer strips are extruded from the die orifice of the head, the strips are solidified, and after cooling, they are cut into pellets. According to actual needs, antioxidants, transition metal salts and polymers can be mixed.

[0064] Specifically, the degradable masterbatch of the degradable synthetic fiber composition of the present invention is prepared by a mixer, and the constant speed of the double screw of the mixer is 50-500 rpm, preferably 100-280 rpm. One or at least two polyvalent transition metal salt powders of the target polymer resin and an appropriate amount of a pro-oxidant are fed into a feeder monitored by a feed system. After mixing, the still molten polyme...

Embodiment 1

[0073] Add polystyrene 100g together with transition metal salt (5g nickel stearate) in the twin-screw mixer, after mixing, the polymer strip in the molten state is extruded from the die hole of the machine head, the strip is solidified, and cooled Then it is cut into pellet form. Wherein, the rotational speed of the twin-screw mixer is 100-280 rpm.

[0074] A film of the degradable synthetic fiber composition was prepared by the aforementioned method, and the film was subjected to ultraviolet treatment for 6 weeks. like Figure 8 As shown, B represents the sample before UV treatment, and A represents the sample after UV treatment. Found through gel permeation chromatography test, the weight average molecular weight (M) of the degradable synthetic fiber composition of the present embodiment w ) was significantly reduced after 6 weeks of UV treatment, indicating that the samples started to degrade after exposure to UV light.

Embodiment 2

[0079] Add 100g of polyester (polyethylene terephthalate) and transition metal salt (3g iron stearate and 1g copper stearate) into the twin-screw mixer, after mixing, the molten polymer strip Extruded through the die orifice of the die, the strips are solidified and cut into pellets after cooling. Wherein, the rotational speed of the twin-screw mixer is 100-280 rpm.

[0080] A film of the degradable synthetic fiber composition was prepared by the aforementioned method, and the film was subjected to ultraviolet treatment for 6 weeks. like Figure 10 As shown, B represents the sample before UV treatment, and A represents the sample after UV treatment. Found through gel permeation chromatography test, the weight average molecular weight (M) of the degradable synthetic fiber composition of the present embodiment w ) was significantly reduced after 6 weeks of UV treatment, indicating that the samples started to degrade after exposure to UV light.

[0081] The following table 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com