Light source device and projection system

A light source device and light source technology, applied in the field of projection, to achieve the effect of ensuring uniformity, avoiding spot position deviation, and ensuring that the imaging position remains unchanged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example part

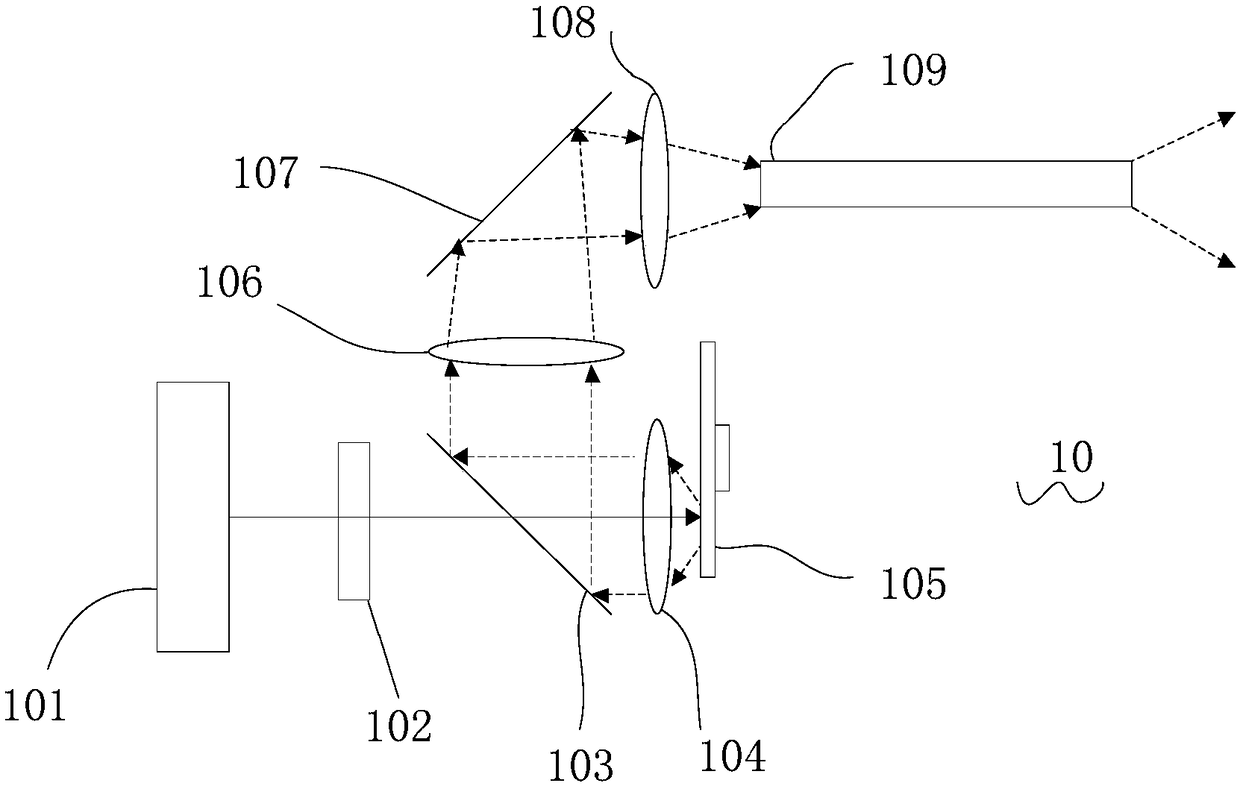

[0040] See image 3 , image 3 It is a schematic structural diagram of a light source device according to Embodiment 1 of the present invention. The light source device includes a first light source 201 , a pair of fly-eye lenses 202 , a light guiding system and a wavelength conversion device 206 , wherein the light guiding system includes a first light splitting component 204 , a collecting lens 205 , a relay lens 207 and an optical path correction component 209 . In addition, the light source device further includes an integrating rod 212 .

[0041] In this embodiment, the first light source 201 emits the first excitation light L1, and the first excitation light L1 is homogenized by the fly-eye lens pair 202 and then enters the light guide system, and is guided to the wavelength conversion device 206 by it. Specifically, the first excitation light L1 is transmitted through the first region of the first light splitting component 204 of the light guidi...

Embodiment 2

[0061] Example two

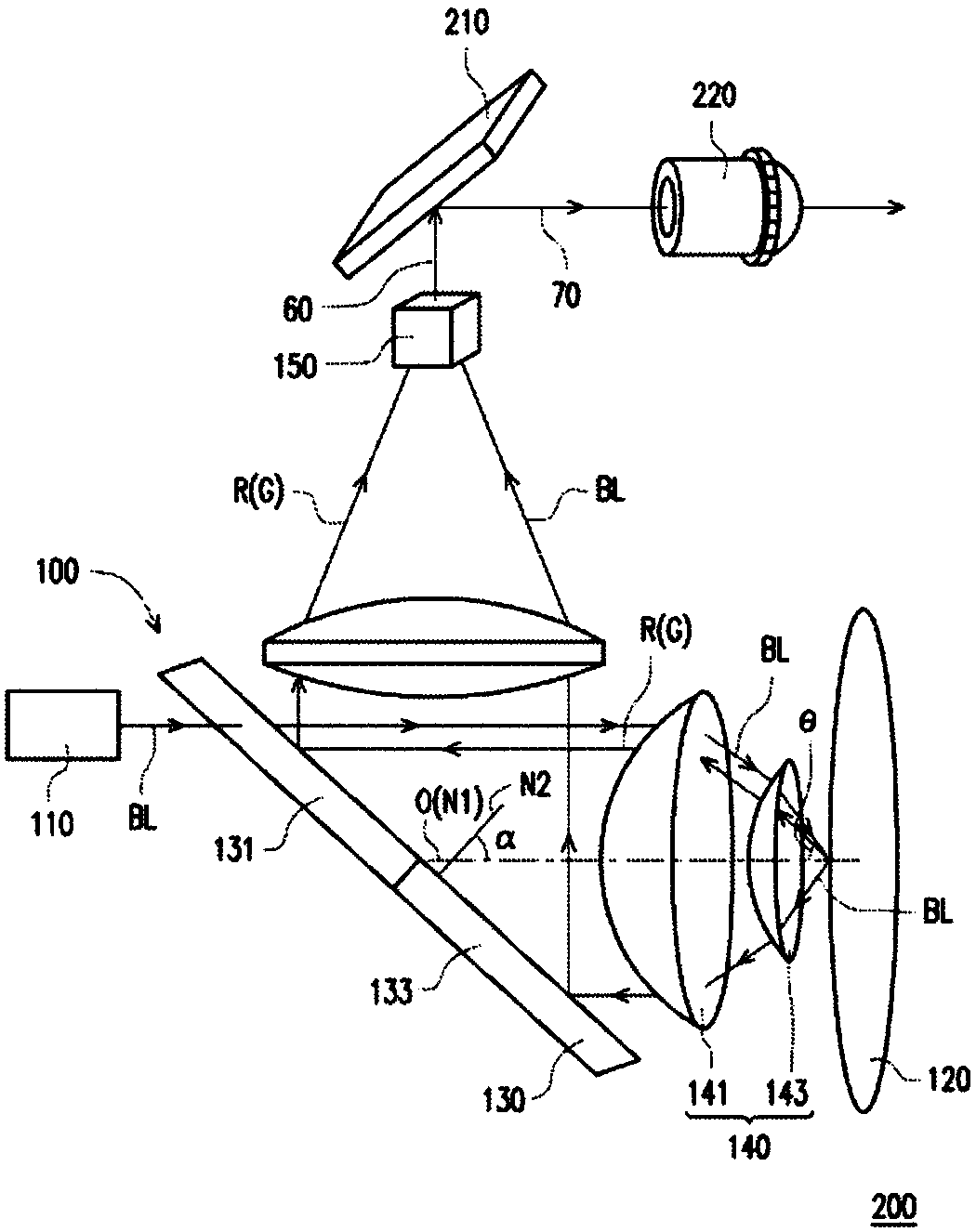

[0062] See Figure 5 , Figure 5 It is a schematic structural diagram of a light source device according to Embodiment 2 of the present invention. The light source device includes a first light source 201, a pair of fly-eye lenses 202, a light guiding system, and a wavelength conversion device 206, wherein the light guiding system includes a first light splitting component 204, a collection lens 205, a first relay lens 207, and a second relay lens 210, a reflective sheet 208 and an optical path correction component 209a. In addition, the light source device further includes an integrator rod 212 , a filter wheel 211 and a beam angle reflector 214 .

[0063] Compared with Embodiment 1, this embodiment has several differences, and each difference can exist as an independent feature and be combined with Embodiment 1 or other modified embodiments to form an implementable technical solution of the present invention.

[0064] First of all, the first point is...

Embodiment 3

[0076] The third part of the embodiment

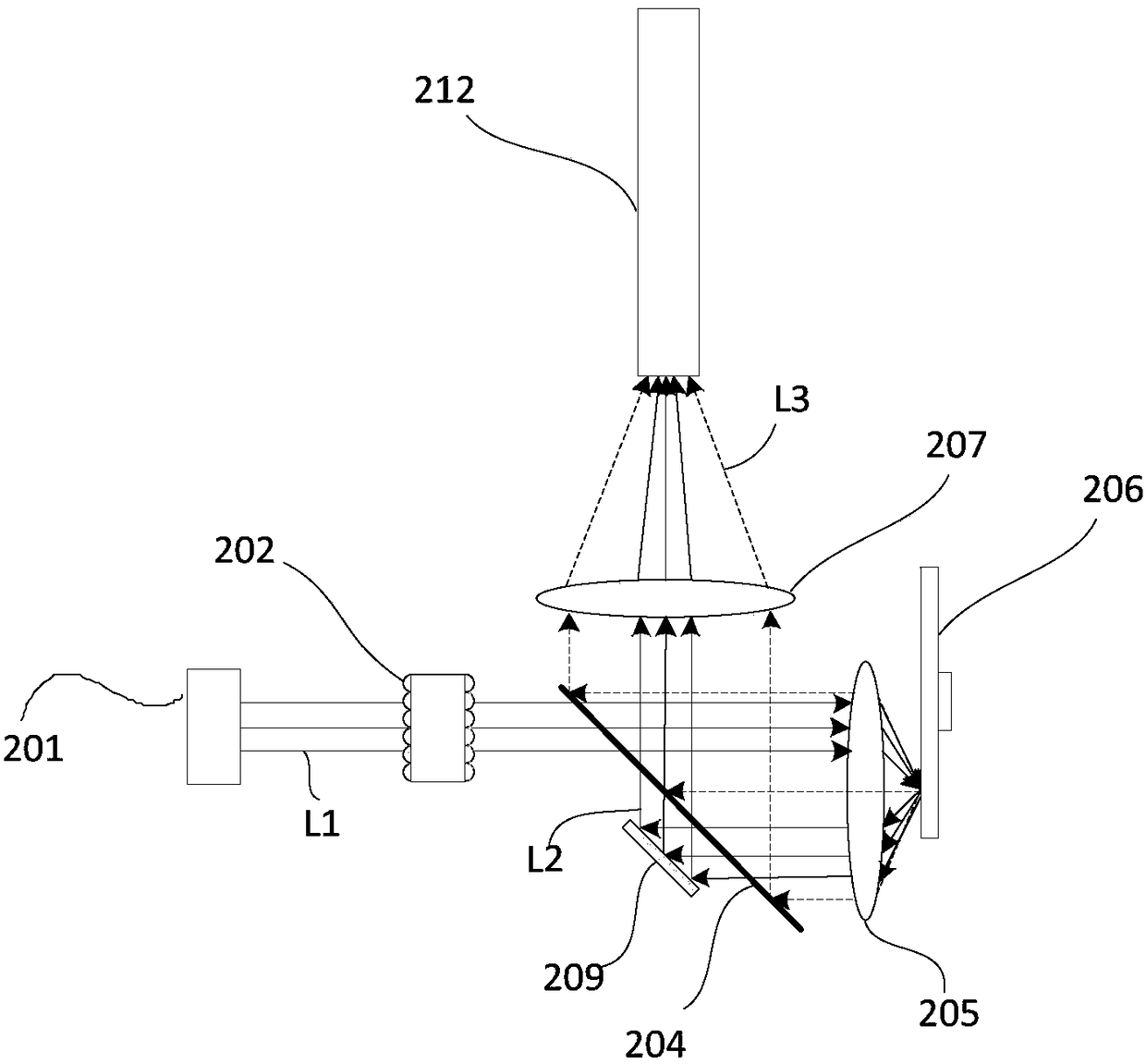

[0077] See Figure 7 , is a schematic structural diagram of a light source device according to Embodiment 3 of the present invention. The light source device includes a first light source 201, a pair of fly-eye lenses 202, a light guiding system, and a wavelength conversion device 206, wherein the light guiding system includes a first light splitting component 204, a collection lens 205, a first relay lens 207, and a second relay lens 210, a reflective sheet 208 and an optical path correction component 209b. In addition, the light source device further includes an integrator rod 212 , a filter wheel 211 and a beam angle reflector 214 .

[0078] The difference between this embodiment and the third embodiment lies in that the type and position of the optical path correction component 209b have changed.

[0079] In this embodiment, the optical path correction component 209b is an optical element including a concave reflective surface, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com