Fiber array controllable preparation method based on super-bi-hydrophobic surface

A super-amphiphobic surface and super-amphiphobic technology, which is applied in the direction of fiber chemical characteristics, melt spinning, and bundles of newly extruded filaments, can solve the problems of limited regularity of fiber arrays, and achieve simple and easy preparation methods. The effect of flexible and controllable fiber array and high regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for the controllable preparation of fiber arrays based on a superamphiphobic surface, comprising the following steps:

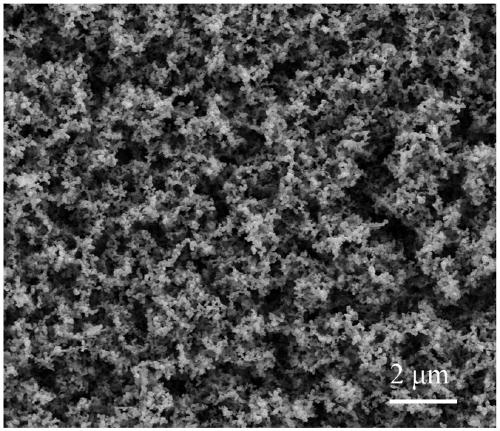

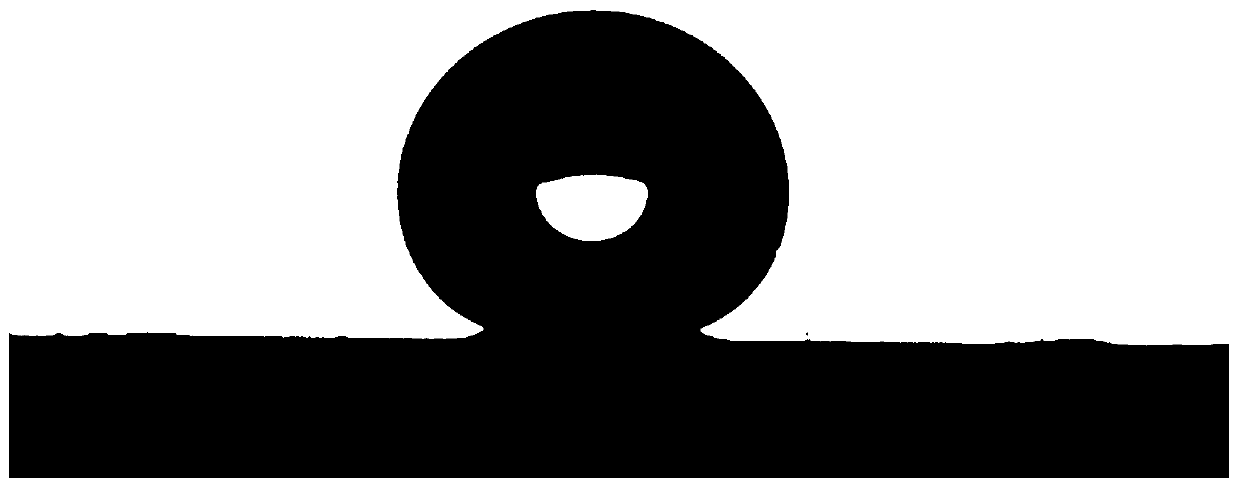

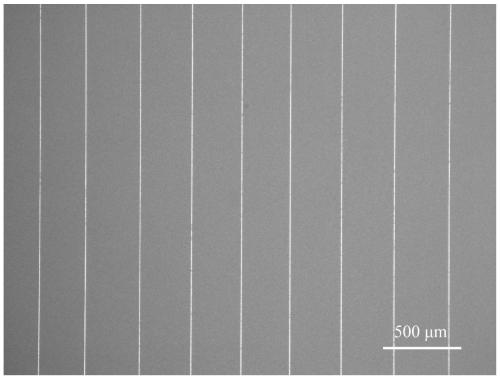

[0035] Step 1. Take a 30mm×30mm×0.17mm glass sheet and move it slowly and evenly in the burning candle flame for 1min to collect the carbon nanoparticles in the candle flame and deposit them evenly on the glass sheet. A 30mm×30mm×0.17mm glass piece is placed in a desiccator with a bottom diameter of 240mm. Take 4mL tetraethyl orthosilicate and 4mL ammonia water and place them in two separate beakers and place the beakers in the desiccator. Vacuumize the desiccator to -0.08MPa and maintain the sealed state for 24 hours. Tetraethyl orthosilicate and ammonia water in the desiccator deposit silica nanoparticles on the carbon nanoparticles on the surface of the glass sheet by the stober method; take out the glass sheet and place it in a horse In a Furnace, heat up to 600°C to remove carbon particles on the glass sheet, take out the glass sheet, and...

Embodiment 2

[0040] A method for the controllable preparation of fiber arrays based on a superamphiphobic surface, comprising the following steps:

[0041] Step 1. Take a 30mm×30mm×0.17mm glass sheet and move it slowly and evenly in the burning candle flame for 1min to collect the carbon nanoparticles in the candle flame and deposit them evenly on the glass sheet. A 30mm×30mm×0.17mm glass piece is placed in a desiccator with a bottom diameter of 240mm. Take 4mL tetraethyl orthosilicate and 4mL ammonia water and place them in two separate beakers and place the beakers in the desiccator. Vacuumize the desiccator to -0.08MPa and maintain the sealed state for 24 hours. Tetraethyl orthosilicate and ammonia water in the desiccator deposit silica nanoparticles on the carbon nanoparticles on the surface of the glass sheet by the stober method; take out the glass sheet and place it in a horse In a Furnace, heat up to 600°C to remove carbon particles on the glass sheet, take out the glass sheet, and...

Embodiment 3

[0046] A method for the controllable preparation of fiber arrays based on a superamphiphobic surface, comprising the following steps:

[0047] Step 1. Take a 30mm×30mm×0.17mm glass sheet and move it slowly and evenly in the burning candle flame for 1min to collect the carbon nanoparticles in the candle flame and deposit them evenly on the glass sheet. A 30mm×30mm×0.17mm glass piece is placed in a desiccator with a bottom diameter of 240mm. Take 4mL tetraethyl orthosilicate and 4mL ammonia water and place them in two separate beakers and place the beakers in the desiccator. Vacuumize the desiccator to -0.08MPa and maintain the sealed state for 24 hours. Tetraethyl orthosilicate and ammonia water in the desiccator deposit silica nanoparticles on the carbon nanoparticles on the surface of the glass sheet by the stober method; take out the glass sheet and place it in a horse In a Furnace, heat up to 600°C to remove carbon particles on the glass sheet, take out the glass sheet, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com