Orientation groove micro/nano-fibres and preparation method for same

A nanofiber, groove technology, applied in fiber processing, filament/thread forming, single-component polystyrene rayon, etc., to achieve the effect of improving filtration efficiency, reducing filtration resistance, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of preparation method of orientation groove micro / nanofiber concrete steps are as follows:

[0043] (1) The concentration of preparing different solvent ratios is 0.20g / mL polystyrene (M W ≈350,000g / mol) solution (the solvent is a mixed solvent of THF and DMF, the volume ratios of THF / DMF are: 5 / 1, 4 / 1, 3 / 1, 2 / 1), magnetically stirred for 12 hours to form a uniform solution After spinning separately;

[0044] (2) Add the spinning solution prepared in step 1 into the syringe, adjust the voltage to 12kV, the distance from the nozzle to the receiver is 15cm, the speed of the propulsion pump is 1.5mL / h, the relative humidity is 60%, and the temperature is 20°C. Turn on the electrospinning equipment, and the micro / nanofibers with orientation grooves can be obtained on the collection device;

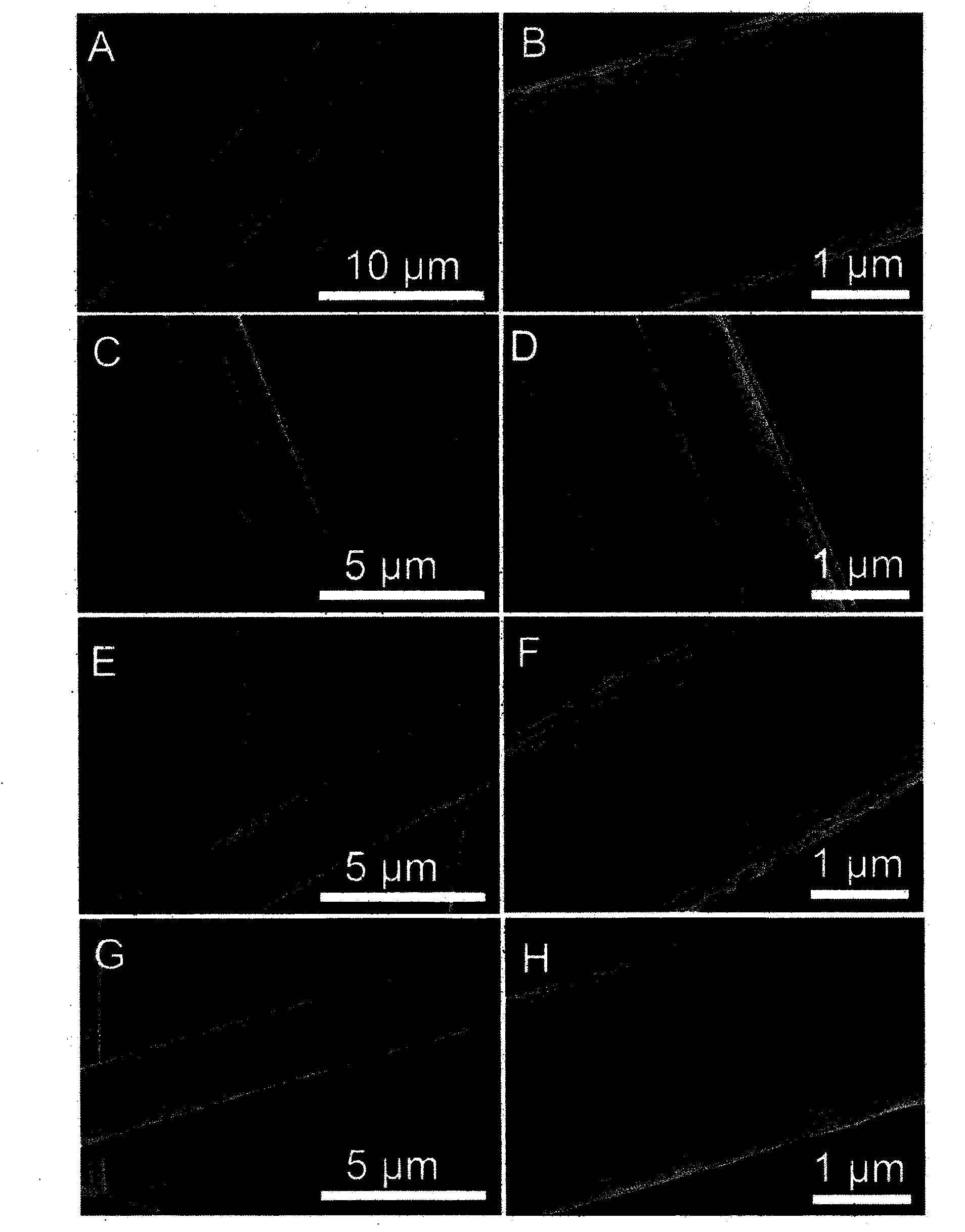

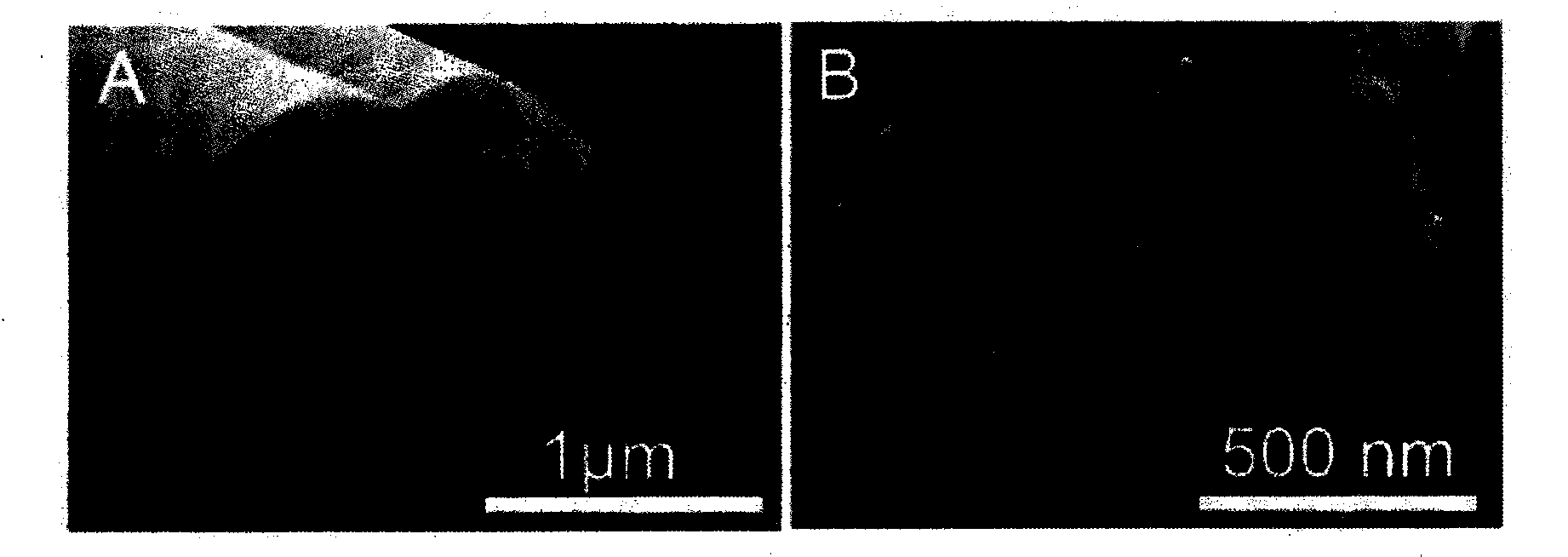

[0045] (3) Observing the morphology of the micro / nanofibers prepared in step 2 with a scanning electron microscope. The obtained fiber has a single-groove structure, such as ...

Embodiment 2

[0047] A kind of preparation method of orientation groove micro / nanofiber concrete steps are as follows:

[0048] (1) The concentration of preparing different solvent ratios is 0.10g / mL polystyrene (M W ≈350,000g / mol) solution (the solvent is a mixed solvent of THF and DMF, the volume ratios of THF / DMF are: 5 / 1, 4 / 1, 3 / 1, 2 / 1), magnetically stirred for 12 hours to form a uniform solution After spinning separately;

[0049] (2) Add the spinning solution prepared in step 1 into the syringe, adjust the voltage to 12kV, the distance from the nozzle to the receiver is 15cm, the speed of the propulsion pump is 1.5mL / h, the relative humidity is 60%, and the temperature is 20°C. Turn on the electrospinning equipment, and the micro / nanofibers with orientation grooves can be obtained on the collection device;

[0050] (3) Observing the morphology of the micro / nanofibers prepared in step 2 with a scanning electron microscope. The obtained fiber has a beaded structure, such as image ...

Embodiment 3

[0052] A kind of preparation method of orientation groove micro / nanofiber concrete steps are as follows:

[0053] (1) Prepare the polystyrene (M W ≈350,000g / mol) solution (the solvent is a mixed solvent of THF and DMF, the volume ratio of THF / DMF is respectively: 1 / 1), magnetically stirred for 12 hours to form a uniform solution and then spun separately;

[0054] (2) Add the spinning solution prepared in step 1 into the syringe, adjust the voltage to 5kV or 12kV, the distance from the nozzle to the receiver is 15cm, the speed of the propulsion pump is 1.5mL / h, the relative humidity is 40% or 60%, and the temperature 20°C. Turn on the electrospinning equipment, and the micro / nanofibers with orientation grooves can be obtained on the collection device;

[0055] (3) Observing the morphology of the micro / nanofibers prepared in step 2 with a scanning electron microscope. When the relative humidity is 60% and the load voltage is 12kV, the obtained micro / nanofibers are multi-groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com