Method for preparing synthetic polymer nano-fiber membrane by freeze-drying

A technology for synthesizing macromolecules and nanofiber membranes, applied in the chemical characteristics of fibers, single-component synthetic polymer rayon, single-component polyether rayon, etc. Problems such as troublesome post-processing and poor repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

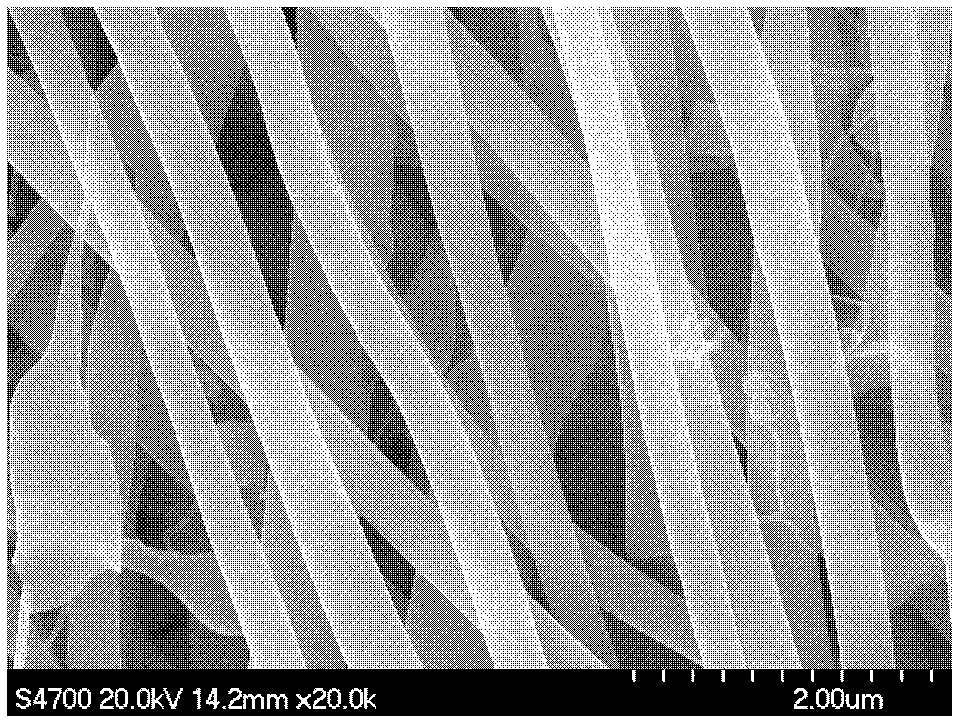

Image

Examples

Embodiment 1

[0018] (1) Polyoxyethylene is dissolved in deionized water to prepare a solution with a weight percentage of 0.001 wt%, and then the solution is fully stirred so that it is completely dissolved to obtain a polyoxyethylene solution.

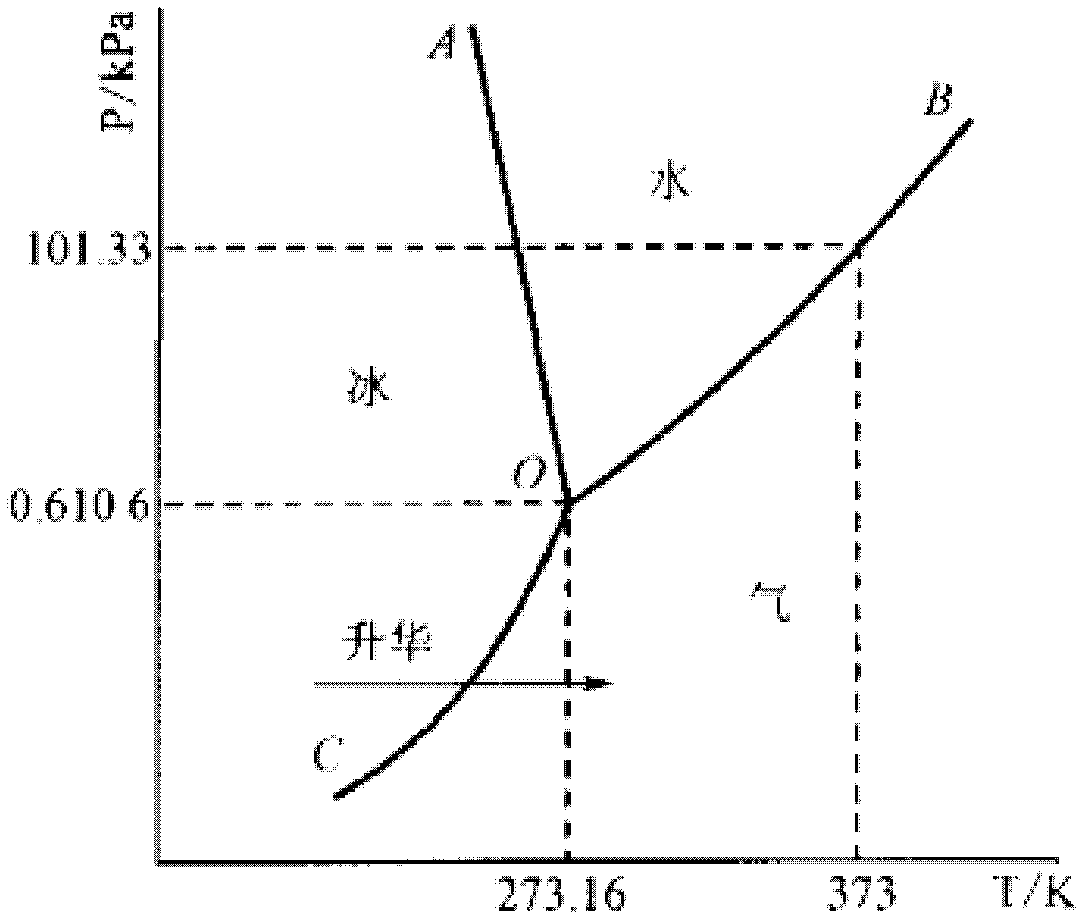

[0019] (2) The polyethylene oxide solution prepared in step (1) is transferred to a liquid nitrogen freezing device, the freezing device is opened, and the prepared polyethylene oxide solution is rapidly frozen in a liquid nitrogen environment, and then the frozen polyethylene The ethylene oxide solution was transferred to a freeze dryer, and freeze-dried for 12 hours at a temperature of -10° C. and a vacuum of 100 Pa to obtain polyethylene oxide nanofibers.

Embodiment 2

[0021] (1) Dissolving polyvinylpyrrolidone in deionized water to prepare a solution with a weight percentage of 0.1 wt%, and then fully stirring the solution so as to completely dissolve, thus obtaining a polyvinylpyrrolidone solution.

[0022] (2) Transfer the polyvinylpyrrolidone solution prepared in step (1) to a liquid nitrogen freezer, open the freezer, freeze the prepared polyvinylpyrrolidone solution rapidly in a liquid nitrogen environment, and then freeze the frozen polyvinylpyrrolidone The solution was transferred to a freeze dryer, and freeze-dried for 48 hours at a temperature of -80° C. and a vacuum of 600 Pa to obtain polyvinylpyrrolidone nanofibers.

Embodiment 3

[0024] (1) Polyethylene glycol is dissolved in deionized water to form a solution with a weight percentage of 0.01 wt%, and then the solution is fully stirred so that it is completely dissolved to obtain a polyethylene glycol solution.

[0025] (2) The polyethylene glycol solution prepared in step (1) is transferred to a liquid nitrogen freezing device, the freezing device is opened, and the prepared polyethylene glycol solution is rapidly frozen in a liquid nitrogen environment, and then the frozen polyethylene glycol solution is frozen. The ethylene glycol solution was transferred to a freeze dryer, and freeze-dried for 24 hours at a temperature of -40° C. and a vacuum of 300 Pa to obtain polyethylene glycol nanofibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com