Aerogel composite fiber material as well as preparation method and application thereof

A technology of composite fiber and airgel, which is applied in the field of composite fiber materials, can solve the problems of reducing the thermal insulation performance of composite materials, and achieve the effect of maintaining thermal insulation performance and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

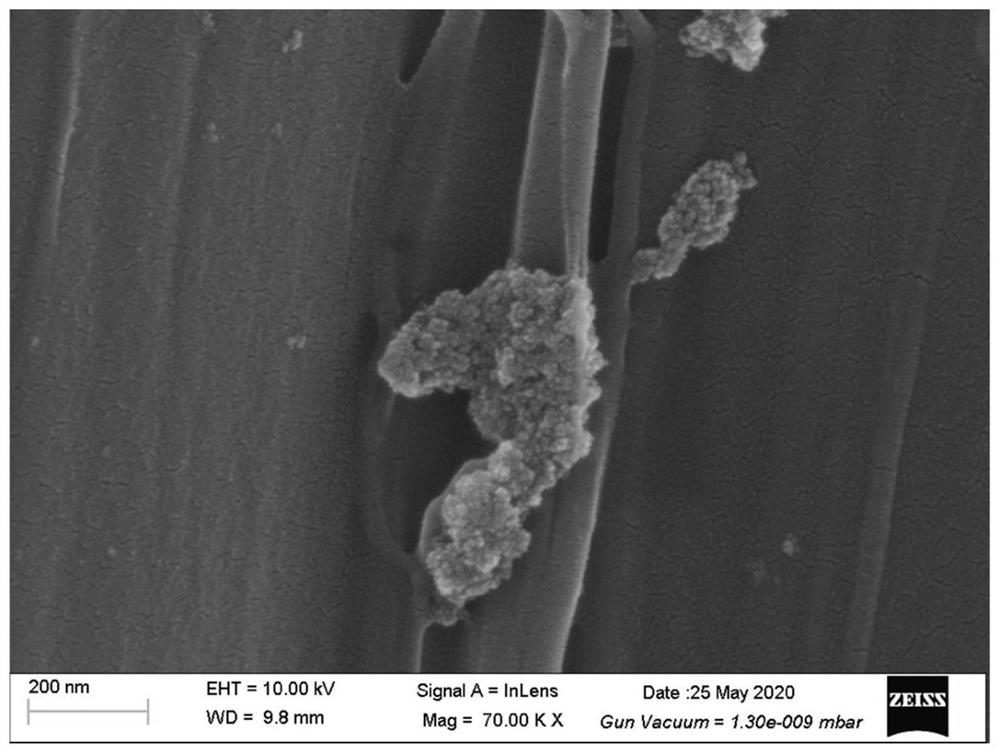

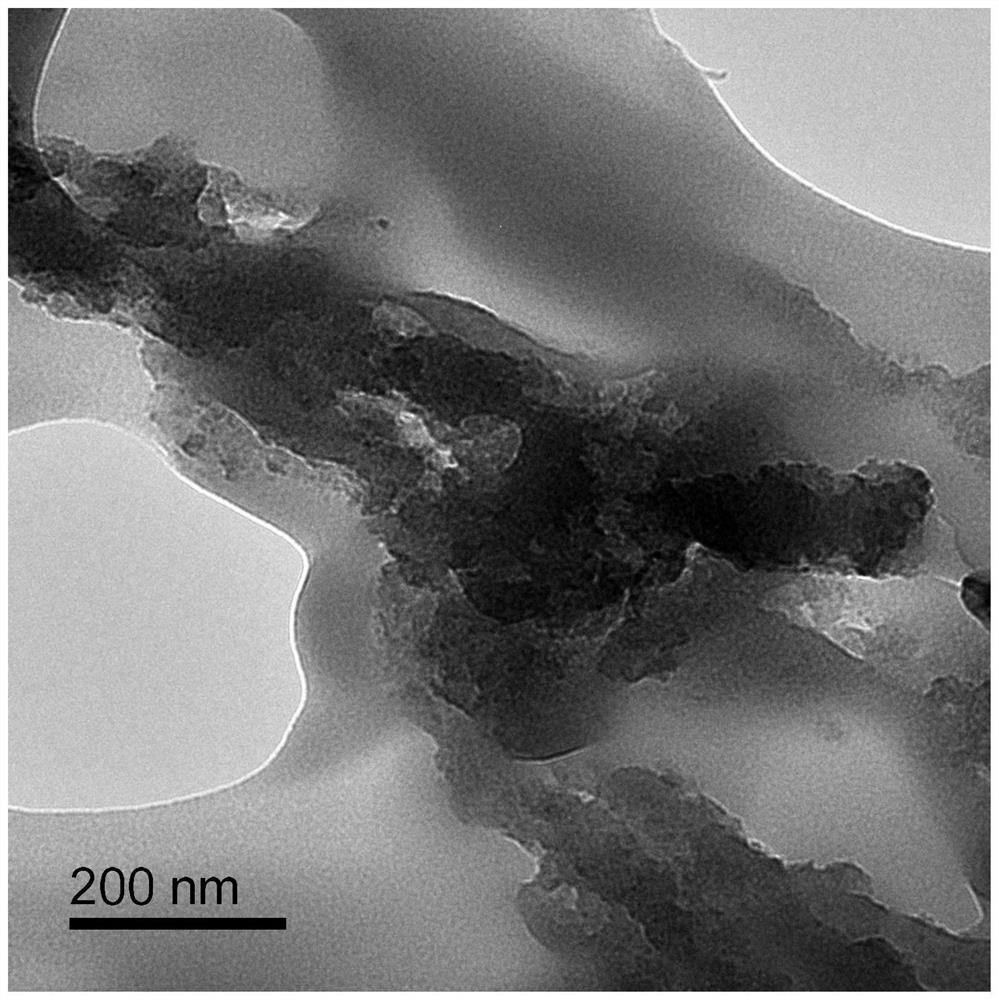

Image

Examples

Embodiment 1

[0032] This embodiment provides a kind of preparation method of airgel composite fiber material, it comprises the following steps:

[0033] S1. Add CTAB surfactant to 5000 mL of deionized water, the concentration of which is controlled to 1% as required, and slightly heated to dissolve to form an aqueous solution.

[0034] S2. Add 500 mL of silica airgel particles with an average particle size of 15 μm to the above aqueous solution gradually and slowly under high-speed shearing conditions, and continue stirring until an airgel dispersion is formed.

[0035] S3. Pour the airgel dispersion above into a ball mill, and add ceramic beads of different sizes to 2 / 3 of the volume of the dispersion to perform high-speed ball milling for 72 hours to obtain a slurry.

[0036] S4. After filtering the slurry, calculate the solid content of the slurry.

[0037] S5. Dissolving an appropriate amount of PVA in hot water at 95°C to prepare a polymer solution with a mass fraction of 16%, formin...

Embodiment 2

[0041] This embodiment provides a kind of preparation method of airgel composite fiber material, it comprises the following steps:

[0042] S1. Disperse 50 grams of silica airgel particle micropowder with an average particle diameter of 15 μm in tetrahydrofuran under high shear to form a tetrahydrofuran airgel dispersion.

[0043] S2. Pour the above-mentioned airgel dispersion into a ball mill, and add two-thirds of the volume of the dispersion into ceramic beads of different sizes for high-speed ball milling, and ball mill for 24 hours to obtain a slurry. During the ball milling process, keep the low temperature, and the temperature should not exceed 30 °C to obtain a slurry.

[0044] S3. After filtering the slurry, calculate the solid content of the slurry.

[0045] S4. Dissolving an appropriate amount of polystyrene in tetrahydrofuran at 50° C. to prepare a polymer solution with a mass fraction of 6%.

[0046] S5. After mixing the dispersed slurry with the polymer solutio...

Embodiment 3

[0050] This embodiment provides a kind of preparation method of airgel composite fiber material, it comprises the following steps:

[0051] S1. Add surfactant CTAB into 5000mL of deionized water, slightly heat and dissolve to form an aqueous solution, and control the concentration of CTAB to 1%.

[0052] S2. Add 500 mL of airgel particles with an average particle size of 15 μm to the above aqueous solution gradually and slowly under high-speed shearing conditions, and keep stirring until an airgel dispersion is formed.

[0053] S3. Pour the airgel dispersion above into a ball mill, and add ceramic beads of different sizes to 2 / 3 of the volume of the dispersion to perform high-speed ball milling for 24 hours to obtain a slurry.

[0054] S4. After filtering the slurry, calculate the solid content of the slurry.

[0055] S5. Dissolving an appropriate amount of PVA in hot water at 95° C. to prepare a polymer solution with a mass fraction of 10%.

[0056] S6. After mixing the dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com