Preparation method and application of conjugated polymer film layer

A technology of conjugated polymers and high molecular polymers, which is applied in the direction of conjugated synthetic polymer artificial filaments, chemical post-treatment and coating of synthetic polymer artificial filaments, etc. Problems such as short carrier transmission length and transition, achieve high carrier mobility, improve carrier mobility, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

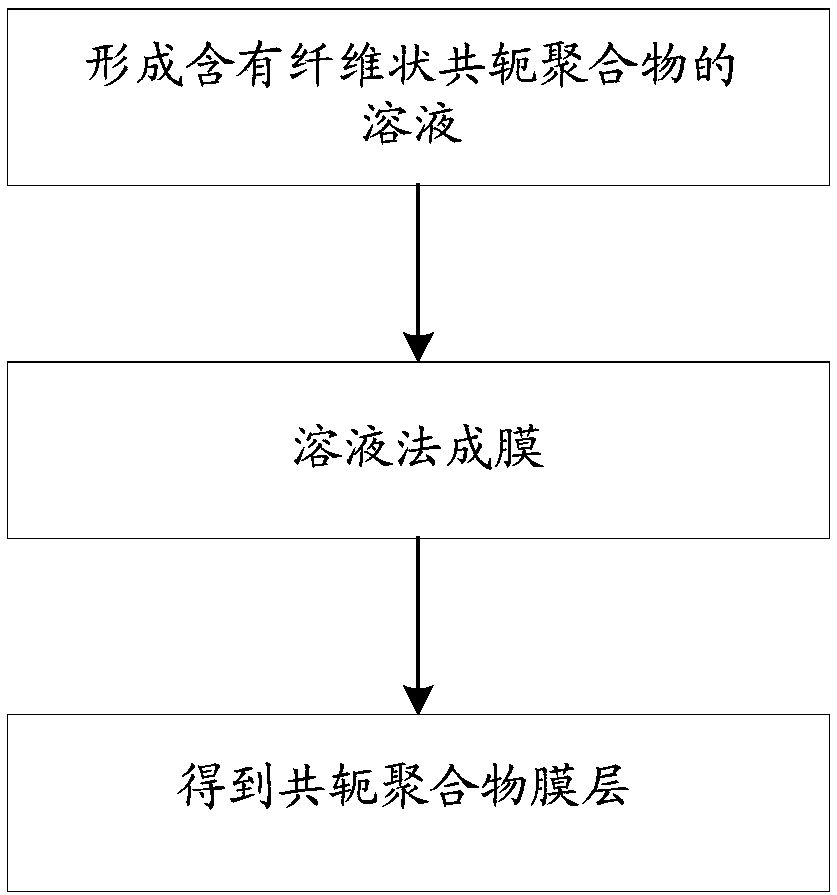

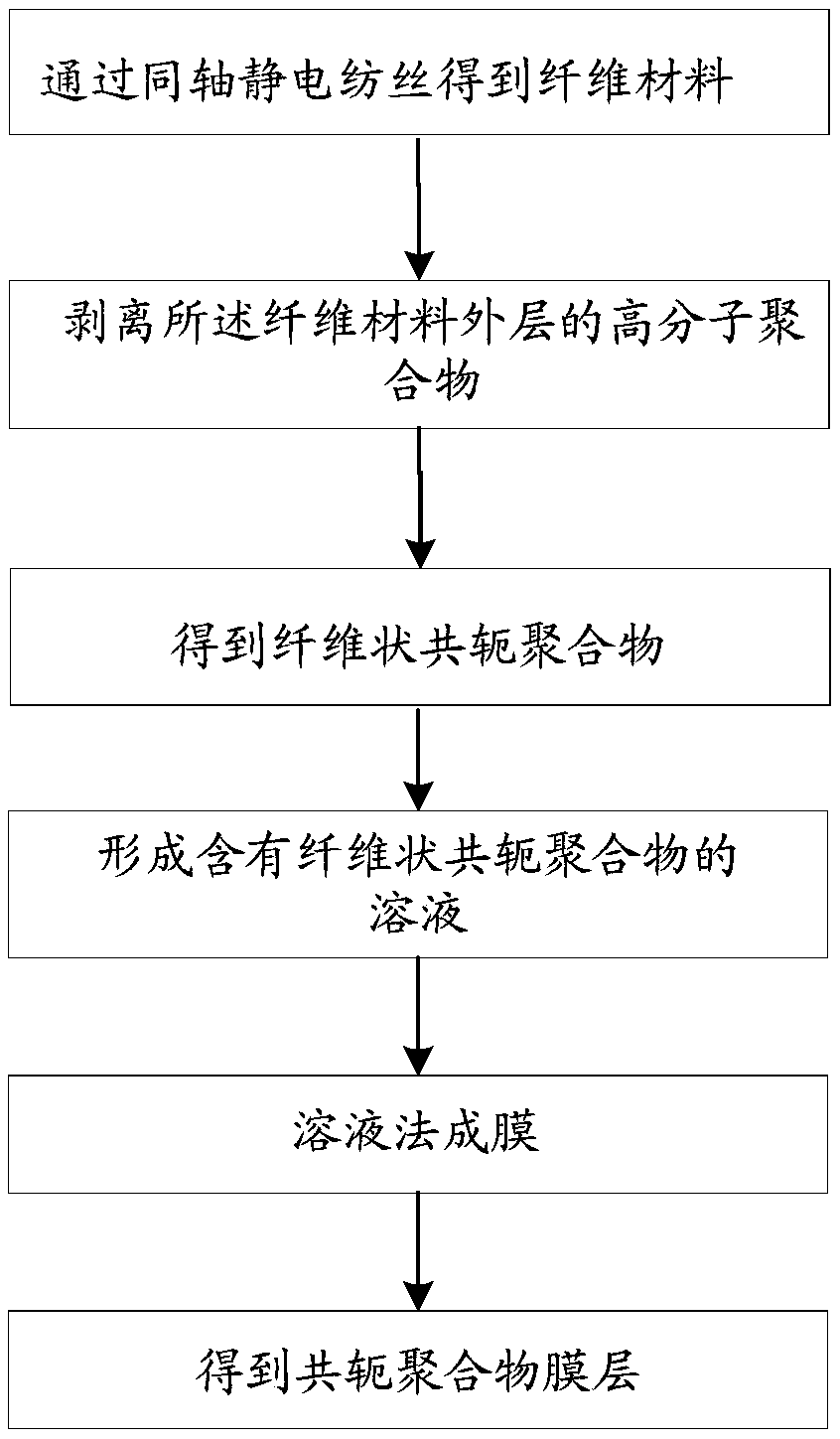

[0034] The embodiment of the present invention discloses a preparation method of a conjugated polymer film layer, including the following steps, see for details figure 1 :

[0035] A solution containing a fibrous conjugated polymer is formed, and a conjugated polymer film layer is obtained by a solution film forming method.

[0036] The conjugated polymer film layer of the present invention can be used in devices involving the use of semiconductors, such as organic light-emitting diodes or solar cells. The present invention uses fibrous conjugated polymer as raw material. Since the fibrous conjugated polymer has a certain length and orientation, it has high electron mobility in its dimensional direction, and can well improve carrier migration. Rate, thereby improving device performance.

[0037] The solution film forming method may include any one of an inkjet printing method, a screen printing method, and a spin coating method.

[0038] In the present invention, specifically, the so...

Embodiment 1

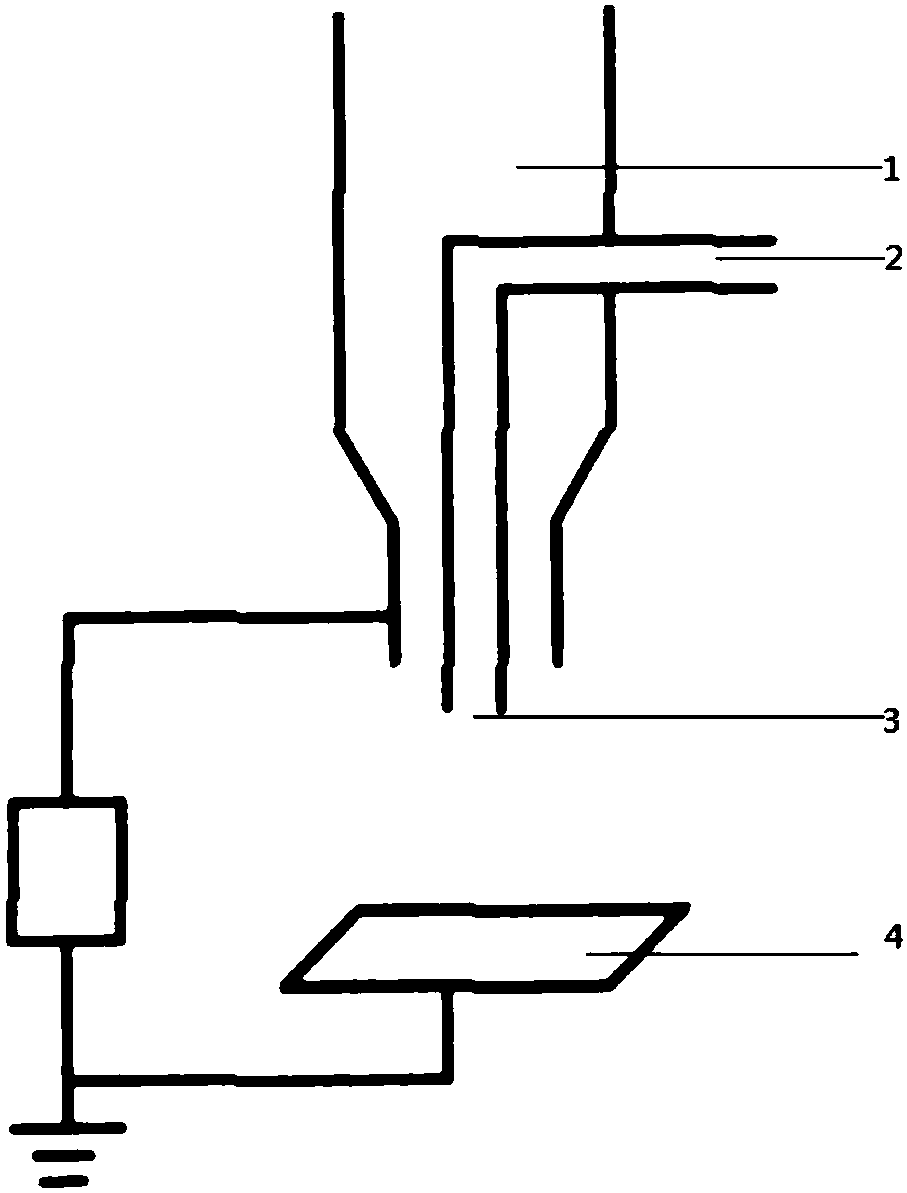

[0083] The chloroform solution of poly-3-hexylthiophene with a concentration of 8% by mass is used as the inner spinning solution, and the ethanol solution of polyethylene terephthalate with a concentration of 3% by mass is used as the outer solution. The working voltage is 30KV, the distance between the needle and the plate electrode is 20CM, and the pumping rate of 0.1ul / h is used to obtain the nanofiber material. Among them, the diameter of the nanofiber material is uniformly stable at about 100nm, and the aspect ratio reaches more than 2000.

[0084] The material fiber material is immersed in methanol, heated, oscillated and ultrasonically processed, and repeated three times to completely peel off the outer layer of polyethylene terephthalate to obtain nanofiber-shaped poly-3-hexylthiophene. Figure 4 It is a scanning electron micrograph of the nanofibrous conjugated polymer.

[0085] The nanofibrous poly-3-hexylthiophene is formed into a solution, and the poly-3-hexylthiophene...

Embodiment 2

[0088] The chloroform solution of the conjugated polymer of naphthalimide and thiophene with a concentration of 5% by mass was used as the inner spinning solution, and the ethanol solution of polyethylene terephthalate with a concentration of 3% by mass was used as the outer spinning solution. Layer solution, under the spinning working voltage of 45KV, the distance between the needle and the plate electrode of 20CM and the pumping rate of 0.1ul / h, the nanofiber material is obtained. Among them, the diameter of the nanofiber material is uniformly stable at about 150nm, and the aspect ratio reaches more than 2000.

[0089] The nanofiber material is soaked in methanol, heated, oscillated and ultrasonically processed, and repeated three times to completely peel off the outer polyethylene terephthalate to obtain nanofiber-like naphthalimide and thiophene Conjugated polymer. Figure 5 It is a scanning electron micrograph of the nanofibrous conjugated polymer.

[0090] The nanofibrous n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com