Polymer production method, polymer product, particles, film, molded article, and fibers

A manufacturing method and polymer technology, applied in the direction of single-component synthetic polymer rayon, textile and papermaking, fiber chemical characteristics, etc., can solve the problems of unsuitable free radical polymerization, widening molecular weight distribution of polymer products, etc. The effect of easy polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

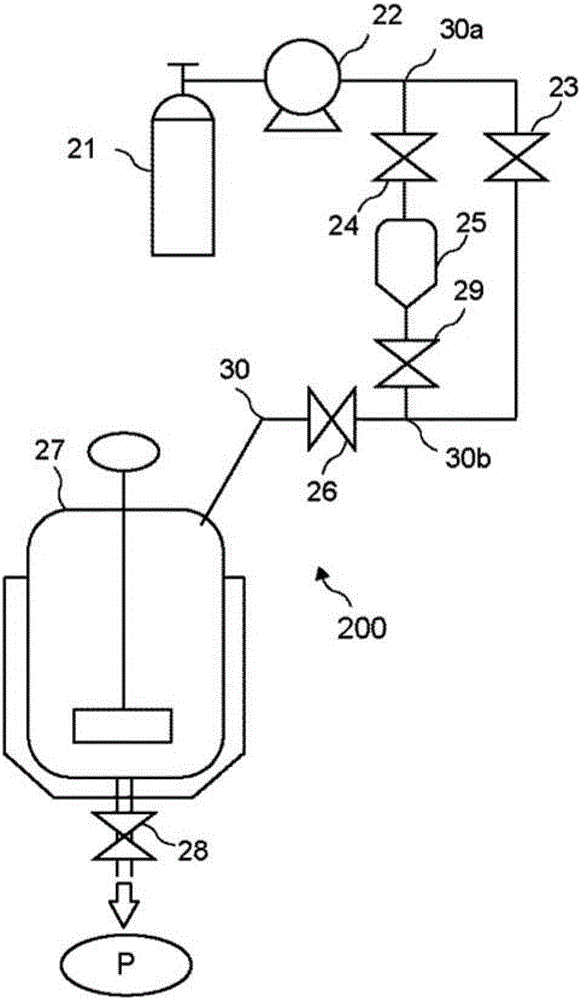

[0148] by image 3 The polymerization reaction device 200 performs the polymerization of methyl methacrylate (MMA). Note that the 1 / 4 inch SUS316 pipe is sandwiched between the valves (24, 29) and used as the feeding pot 25. The feeding pot 25 was previously charged with tin 2-ethylhexanoate (0.02 mL, 0.05 mmol) as a reducing agent.

[0149] To the reaction vessel 27 were added copper chloride (70.0 mg, 0.5 mmol) as a catalyst, tris[2-(dimethylamino)ethyl)amine (manufactured by Sigma-Aldrich Co., LLC.) as a ligand for the ATRP catalyst. Manufacturing) (0.244 g, 1.10 mmol), and ethyl 2-bromoisobutyrate (0.45 g, 0.0024 mol) as an ATRP initiator. Methyl methacrylate (MMA) (50.0 mL, 0.47 mol) from which the polymerization inhibitor has been removed through the alumina column was added to the reaction vessel 27 in such a manner that the molar ratio of the monomer to the initiator was 2,000 / 1.

[0150] The metering pump 22 is operated, and the valves (23, 26) are released to supply the...

Embodiment 2

[0152] The polymers of Examples 2-5 were each obtained in the same manner as in Example 1, provided that the initiator was replaced with an equimolar amount of the following bifunctional initiator (Example 2), trifunctional initiator (implementation Example 3), tetrafunctional initiator (Example 4), or hexafunctional initiator (Example 5). The physical properties of the obtained polymer measured by the above method are shown in Table 1.

[0153]

Embodiment 6-9

[0155] The polymers of Examples 6-9 were each obtained in the same manner as in Example 1, provided that the reaction temperature and reaction pressure were changed as depicted in the column of Examples 6-9 in Table 2, respectively. The physical properties of the obtained polymer measured by the above method are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com