Method for preparing branched polyacrylonitrile

A branched polyacrylonitrile and branched monomer technology, which is applied in the directions of chemical characteristics of fibers, single-component synthetic polymer rayon, textiles and papermaking, etc. Easy operation, simple and easy preparation method, high monomer conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

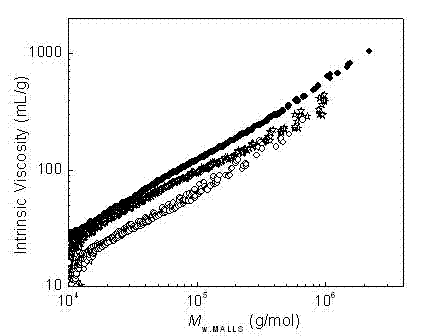

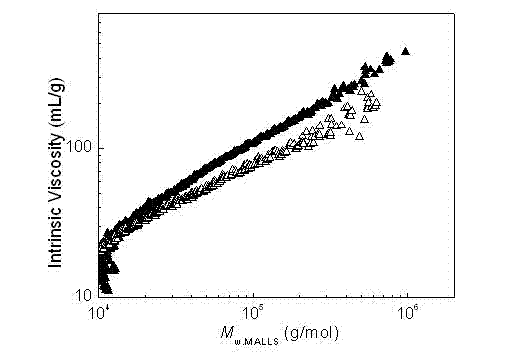

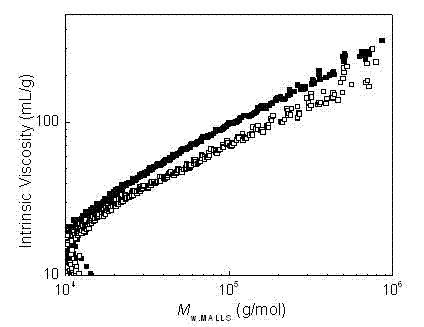

[0017] Acrylonitrile (4.6647g, 0.088mol), vinyl acetate (0.9463g, 0.011mol), branched monomer mercaptopropionyloxyethyl methacrylate (0.0436g, 0.2mmol), initiator AIBN (0.1643g , 1mmol) and the solvent DMF (18.1425g) were added into the reaction flask, and reacted at 60°C for 35 hours. The measured conversion rate of acrylonitrile was 95.5%, and the conversion rate of vinyl acetate was 82.4%. The polymer was analyzed by three-detection gel permeation chromatography, and the results were as follows: light scattering weight average molecular weight M w.MALLS =30400, molecular weight distribution PDI=1.93, Mark-Houwink index α =0.602, average branching factor g '=0.66, confirming that the obtained polymer has a branched structure. The trends of intrinsic viscosity and branching factor with molecular weight are shown in figure 1 with Figure 4 .

Embodiment 2

[0019] Acrylonitrile (4.6611g, 0.088mol), vinyl acetate (0.9471g, 0.011mol), branched monomer mercaptopropionyloxyethyl methacrylate (0.0868g, 0.4mmol), initiator AIBN (0.1641g , 1mmol) and the solvent DMF (18.1405g) were added to the reaction flask, and reacted at 60°C for 35 hours. The measured conversion rate of acrylonitrile was 94.4%, and the conversion rate of vinyl acetate was 78.3%. The polymer was analyzed by three-detection gel permeation chromatography, and the results were as follows: light scattering weight average molecular weight M w.MALLS = 27700, molecular weight distribution PDI = 1.66, Mark-Houwink index α =0.590, average branching factor g ' = 0.62, confirming that the obtained polymer has a branched structure.

Embodiment 3

[0021] Acrylonitrile (4.6655g, 0.088mol), vinyl acetate (0.9451g, 0.011mol), branched monomer mercaptopropionyloxyethyl methacrylate (0.1305g, 0.6mmol), initiator AIBN (0.1647g , 1mmol) and the solvent DMF (18.1385g) were added to the reaction flask, and reacted at 60°C for 40 hours. The measured conversion rate of acrylonitrile was 99.1%, and the conversion rate of vinyl acetate was 86.8%. The polymer was analyzed by three-detection gel permeation chromatography, and the results were as follows: light scattering weight average molecular weight M w.MALLS =48600, molecular weight distribution PDI=1.55, Mark-Houwink index α =0.488, average branching factor g '=0.42, confirming that the obtained polymer has a branched structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com