Scaffold

A scaffold material and fiber technology, applied in cell culture supports/coatings, methods of supporting/immobilizing microorganisms, biochemical instruments, etc., can solve problems such as fiber accumulation density changes, uneven packing density, and difficulty in maintaining potential differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] (Preparation of spinning dope)

[0102] A lactic acid-glycolic acid copolymer (molar ratio = 50 / 50) was dissolved in a mixed solvent of methylene chloride and ethanol to prepare a 15% by weight spinning stock solution.

[0103] (spinning)

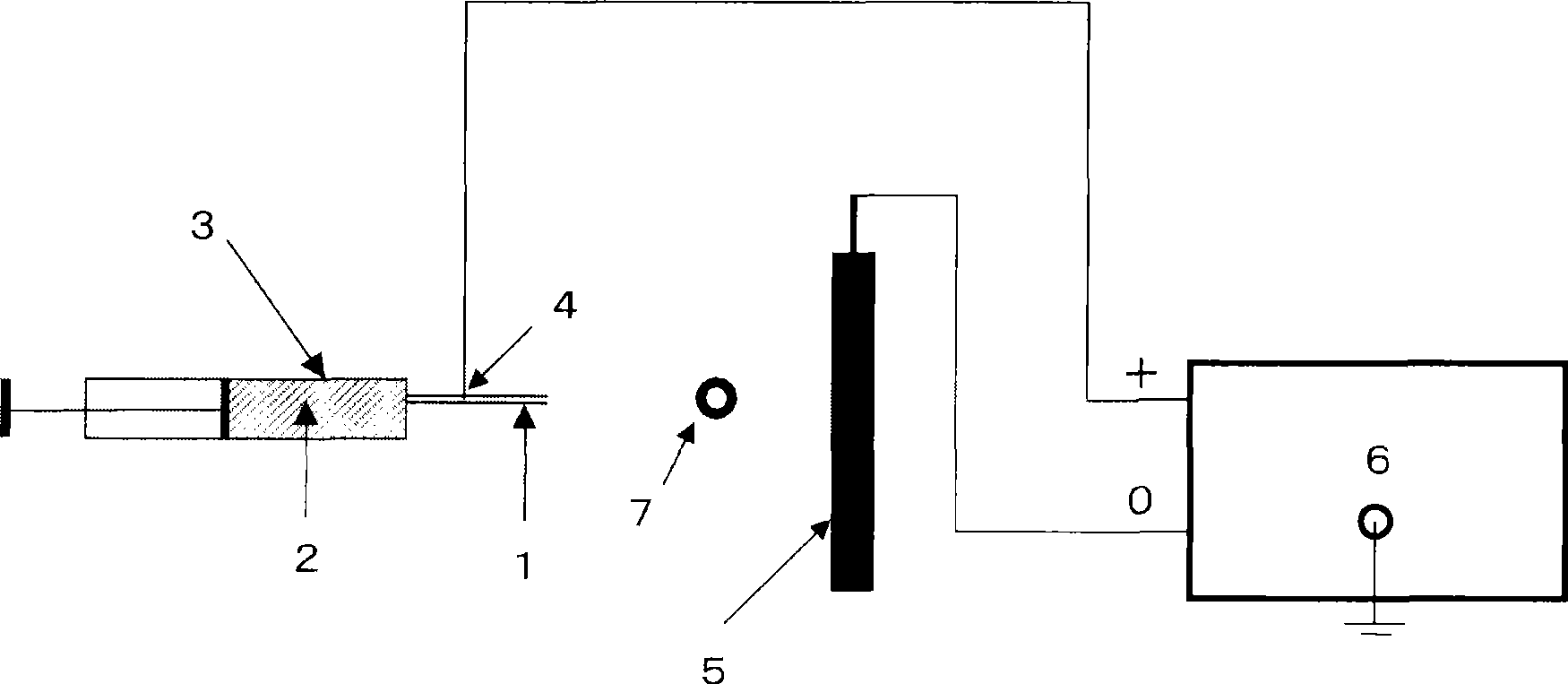

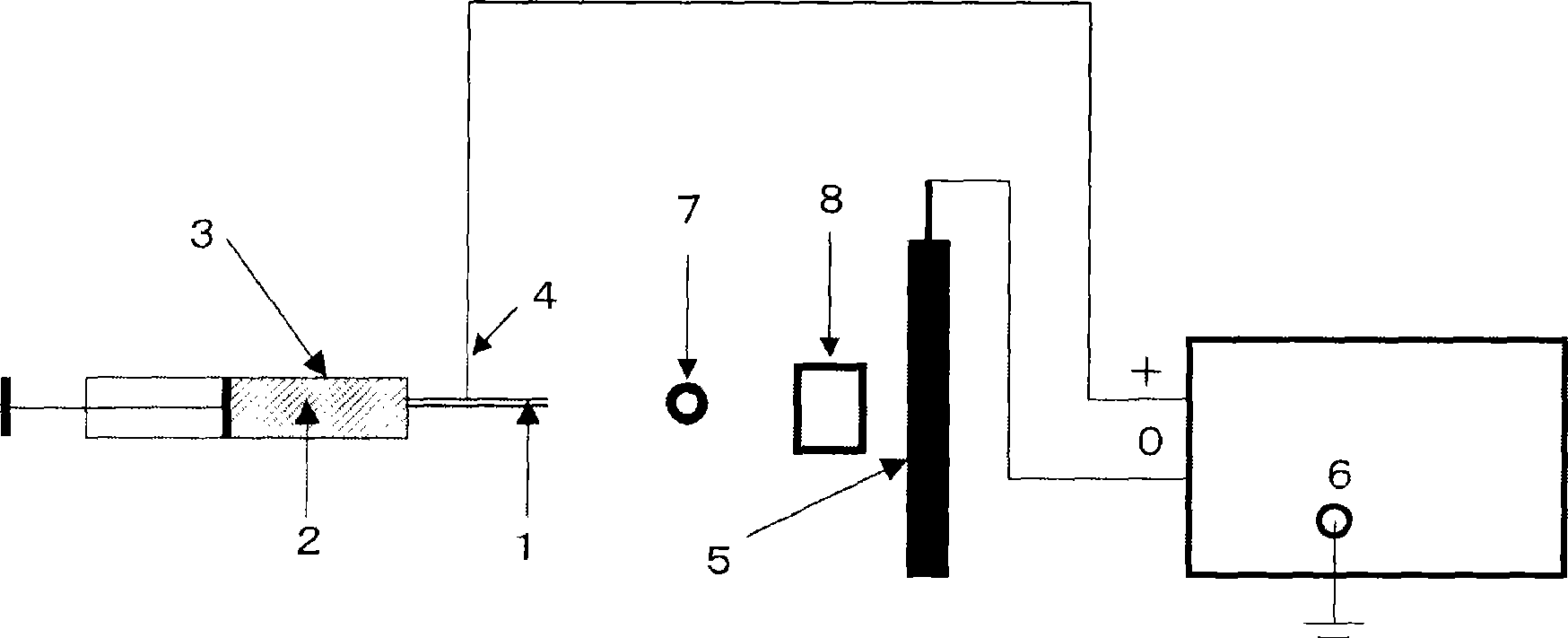

[0104] use Figure 4 In the shown device, a cylindrical roll comprising a fiber assembly is obtained by electrospinning. The inner diameter of the nozzle (1) is 1.3 mm. The distance from the nozzle (1) to the winding device (7) is 20 cm, and the distance from the nozzle (1) to the static elimination device (8) is 35 cm. The applied voltage was 15 kV. A winding device (7) and a static eliminator (8) manufactured by Kasuga Denki Co., Ltd. were installed between the nozzle (1) and the negative electrode (5). A positive electrode (4) is inserted into the spinning dope holding tank (3). The rotation speed of the winding device (7) was set at 100 rpm.

[0105] Put the spinning stock solution into the spinning stock solution holding ...

Embodiment 2

[0123] (Preparation of spinning dope)

[0124] It prepared using the lactic acid-glycolic acid copolymer similarly to Example 1 so that it might become 10 weight%.

[0125] (spinning)

[0126] A cylindrical roll including a fiber aggregate was obtained by the same method as in Example 1, except that the discharge time was 90 minutes and the heat treatment was performed at 70° C. for 10 minutes.

[0127] (Cut out)

[0128] Using the same method as in Example 1, cut out the corresponding Figure 5 10 cylindrical stent materials of diameter 5mm x height 5mm. will be parallel to the corresponding Figure 5 The micrograph (magnification 15 times) of the section of the bottom surface of the scaffold material of 10 is shown in Figure 6 (top bottom) and Figure 7 (lower bottom). It can be seen that the fibers are accumulated in layers.

[0129] (characteristic evaluation)

[0130] The characteristics were measured by the same method as in Example 1. The results are shown in...

Embodiment 3

[0145] (manufacturing of bracket materials)

[0146] Repeat the same operation as in Example 2 to obtain the corresponding Figure 5 12 cylindrical stent materials with a diameter of 5 mm x a height of 5 mm. Table 1 shows the results of measuring the properties.

[0147] will be perpendicular to the corresponding Figure 5 The micrograph (magnification 200 times) of the section of the bottom surface of the scaffold material of 12 is shown in Figure 10 . The fibers are oriented in the plane direction. Additionally, the parallel to the corresponding Figure 5 The micrograph (magnification 15 times) of the section of the bottom surface of the scaffold material of (12) is shown in Figure 11 (top bottom) and Figure 12 (lower bottom). It can be seen that the fibers are densely packed like a mesh.

[0148] (biological evaluation)

[0149] Using the obtained scaffold material, cells were cultured by the same method as in Example 2, and the amount of DNA was measured. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com