Micron fiber/nanofiber composite filter material and preparation method thereof

A technology of microfibers and nanofibers, which is applied in the fields of filtration separation, fiber treatment, separation methods, etc., can solve the problems of complex production process, reduction of filtration resistance, non-reporting, etc., and achieve simple preparation method, strong process controllability, Effect of low resistance pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A microfiber / nanofiber composite filter material and a preparation method thereof, the preparation method mainly comprising the following steps:

[0031]1) Add polyvinylidene fluoride (weight-average molecular weight: 320,000) into N,N-dimethylformamide, seal it and place it in a water bath at 60°C for 10 hours with heating and stirring, and finally prepare a stable and uniform quality Concentration is the polymer spinning liquid A of 20wt%, is used for preparing nanofiber layer;

[0032] Similarly, polystyrene (with a weight average molecular weight of 80,000) was added to N, N-dimethylformamide, and after sealing, it was continuously stirred for 8 hours with a magnetic stirring device, and finally a stable and uniform concentration of 28% was prepared. The polymer spinning liquid B of is used for preparing micron fiber layer;

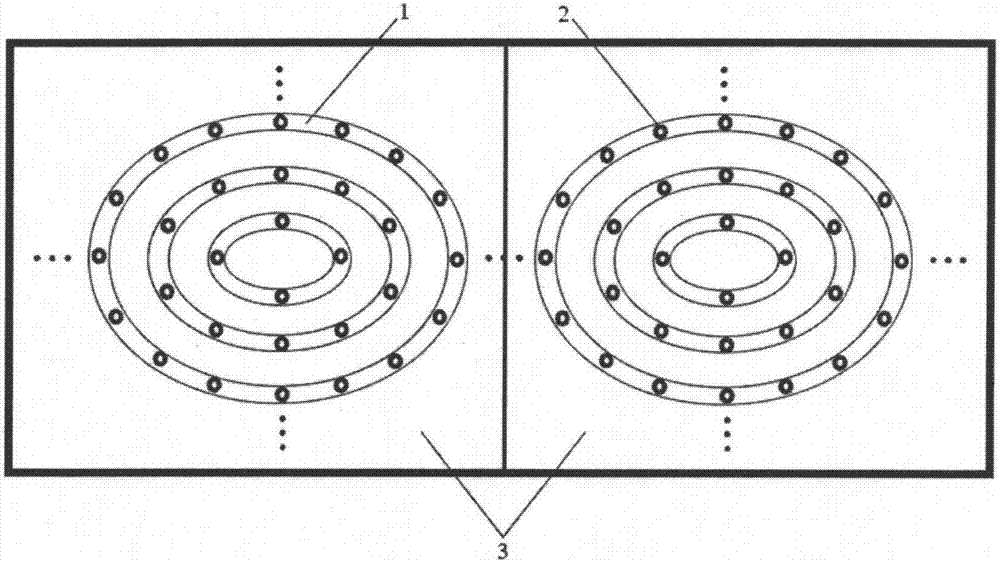

[0033] 2) The prepared polymer spinning solution A and the polymer spinning solution B are sucked into the spinning module through the liquid...

Embodiment 2

[0038] A microfiber / nanofiber composite filter material and a preparation method thereof, the preparation method mainly comprising the following steps:

[0039] 1) Add polyvinylidene fluoride (weight-average molecular weight: 570,000) into N,N-dimethylacetamide, seal it and place it in a water bath at 60°C for 8 hours with heating and stirring, and finally prepare a stable and uniform quality Concentration is the polymer spinning liquid A of 18wt%, is used for preparing nanofiber layer;

[0040] Similarly, polystyrene (with a weight average molecular weight of 80,000) was added to N, N-dimethylformamide, and after sealing, it was continuously stirred for 8 hours with a magnetic stirring device, and finally a stable and uniform concentration of 28% was prepared. The polymer spinning liquid B of is used for preparing micron fiber layer;

[0041] 2) The prepared polymer spinning solution A and the polymer spinning solution B are sucked into the spinning module through the liquid...

Embodiment 3

[0046] A microfiber / nanofiber composite filter material and a preparation method thereof, the preparation method mainly comprising the following steps:

[0047] 1) Add polyvinylidene fluoride (weight-average molecular weight: 570,000) into N,N-dimethylacetamide, seal it and place it in a water bath at 60°C for 8 hours with heating and stirring, and finally prepare a stable and uniform quality Concentration is the polymer spinning liquid A of 18wt%, is used for preparing nanofiber layer;

[0048] Similarly, polysulfone (with a weight-average molecular weight of 70,000) was added to N, N-dimethylacetamide, and after sealing, it was continuously stirred for 15 hours with a magnetic stirring device, and finally a stable and uniform concentration of 29% was prepared. Polymer spinning solution B is used to prepare micron fiber layer;

[0049] 2) The prepared polymer spinning solution A and the polymer spinning solution B are sucked into the spinning module through the liquid supply...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com