A dual-indication smart label for identifying meat quality, its production method and application

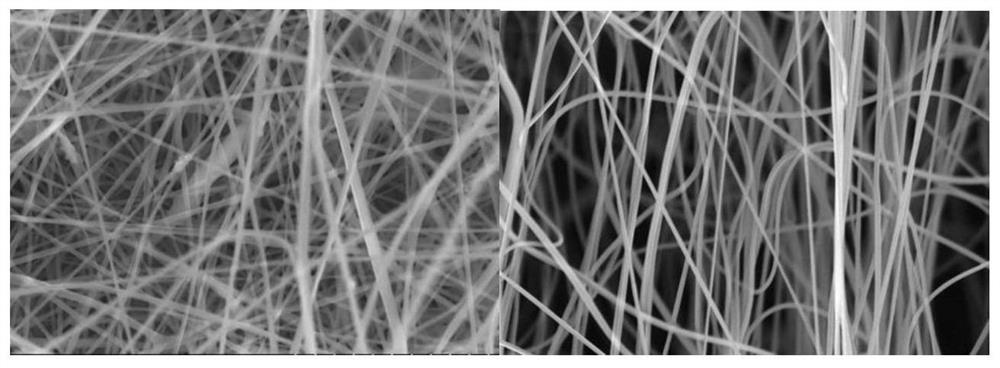

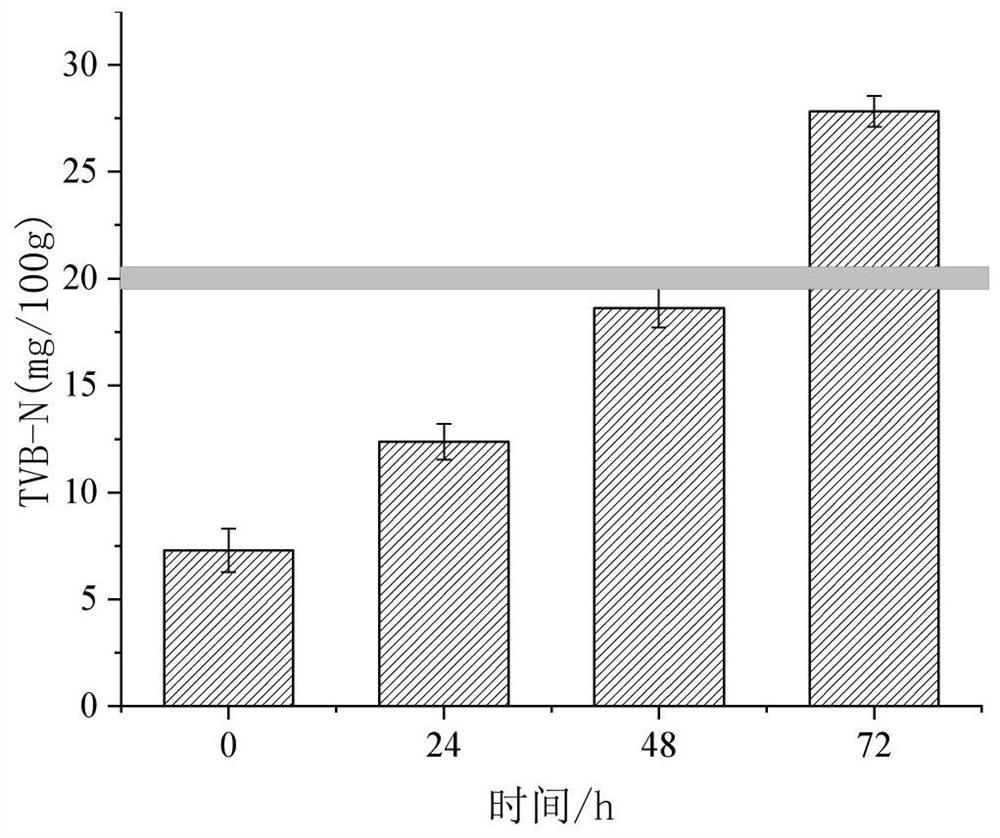

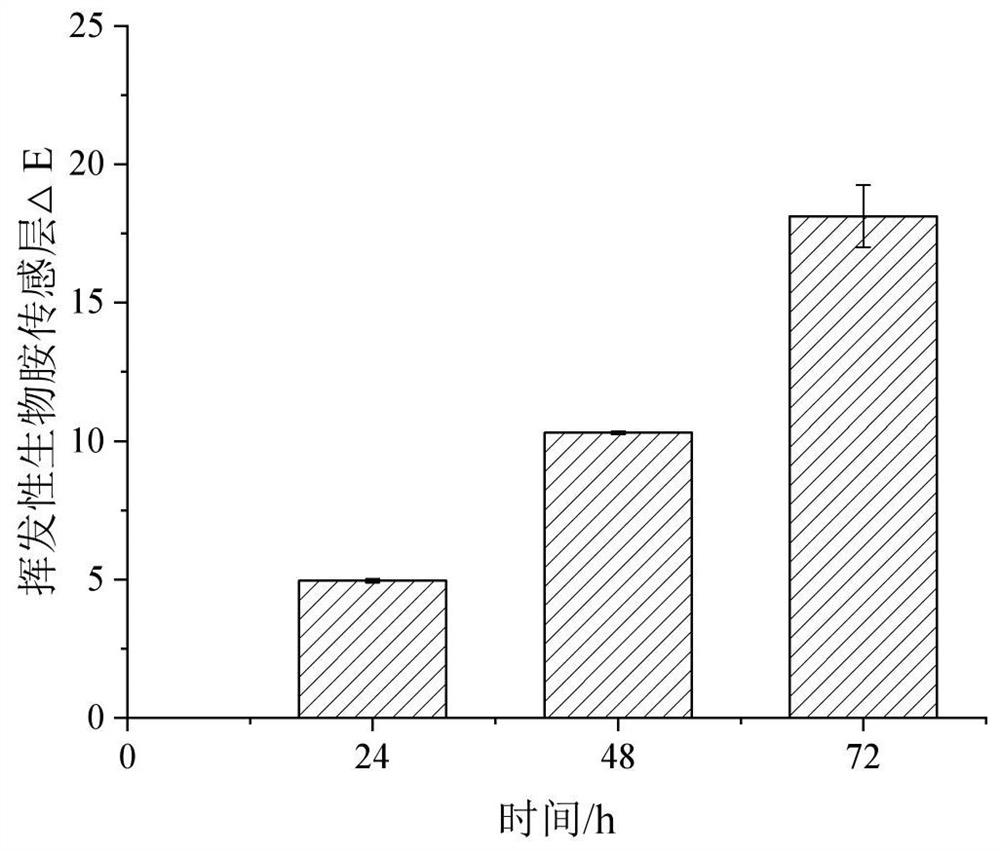

A production method and technology of smart labels, which can be applied in material analysis, rayon manufacturing, textile and paper making by observing the impact on chemical indicators, can solve the problems of single function and low sensitivity, and achieve wide application prospects and extended The shelf life of fresh meat and the effect of real-time monitoring of meat freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125] Embodiment 1: The production of the dual indication smart label of the present invention

[0126] The implementation steps of this embodiment are as follows:

[0127] A. Preparation of primary spinning solution

[0128] Under the conditions of room temperature and stirring, 5 parts by weight of polylactic acid hydrophobic polymers are dissolved in 62 parts by weight of hexafluoroisopropanol oily solvent, while 30 parts by weight of polyvinyl alcohol hydrophilic polymers are dissolved in 86 parts by weight In the water solvent, two different basic spinning solutions are thus obtained;

[0129] B. Preparation of volatile biogenic amine sensing layer spinning solution

[0130] Under the conditions of room temperature and stirring, 8.0 parts by weight of anthocyanin pH indicator dyes are dissolved in 10 parts by weight of N,N-dimethylamide solvent, and 20 parts by weight of polylactic acid hydrophobic polymer are dissolved in 70 parts by weight In the hexafluoroisopropan...

Embodiment 2

[0137] Embodiment 2: the production of the dual indication smart label of the present invention

[0138] The implementation steps of this embodiment are as follows:

[0139] A. Preparation of primary spinning solution

[0140] Under the conditions of room temperature and stirring, 14 parts by weight of polystyrene hydrophobic polymers are dissolved in 50 parts by weight of trifluoroethanol oily solvent, while 35 parts by weight of polyethylene oxide hydrophilic polymers are dissolved in 74 parts by weight of In the aqueous solvent of dimethyl sulfoxide, two kinds of different base spinning solutions are thus obtained;

[0141] B. Preparation of volatile biogenic amine sensing layer spinning solution

[0142] Under the conditions of room temperature and stirring, 1.0 parts by weight of phenolphthalein pH indicator dye was dissolved in 30 parts by weight of N,N-dimethylamide solvent, and 15 parts by weight of polystyrene hydrophobic polymer was dissolved in 74 parts by weight ...

Embodiment 3

[0149] Embodiment 3: The production of the dual indication smart label of the present invention

[0150] The implementation steps of this embodiment are as follows:

[0151] A. Preparation of primary spinning solution

[0152] Under the conditions of room temperature and stirring, 21 parts by weight of cellulose acetate hydrophobic polymers are dissolved in 86 parts by weight of trifluoroacetic acid oily solvent, and 5 parts by weight of chitosan hydrophilic polymers are dissolved in 50 parts by weight of dimethyl In the water-based solvent of sulfoxide, two different basic spinning solutions are obtained;

[0153] B. Preparation of volatile biogenic amine sensing layer spinning solution

[0154] Under the conditions of room temperature and stirring, 0.01 parts by weight of methyl red pH indicator dye was dissolved in 18 parts by weight of N,N-dimethylamide solvent, and 5 parts by weight of cellulose acetate hydrophobic polymer was dissolved in 78 parts by weight In the tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com