Intelligent label for identifying and prolonging quality of meat products and preparation method and use thereof

A production method and technology of smart labels, which can be applied in rayon manufacturing, textile and papermaking, single-component polyester rayon, etc., can solve the problems of inability to inhibit the growth and reproduction of microorganisms, single function, and low sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

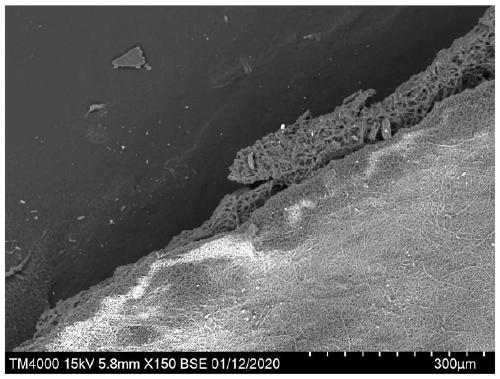

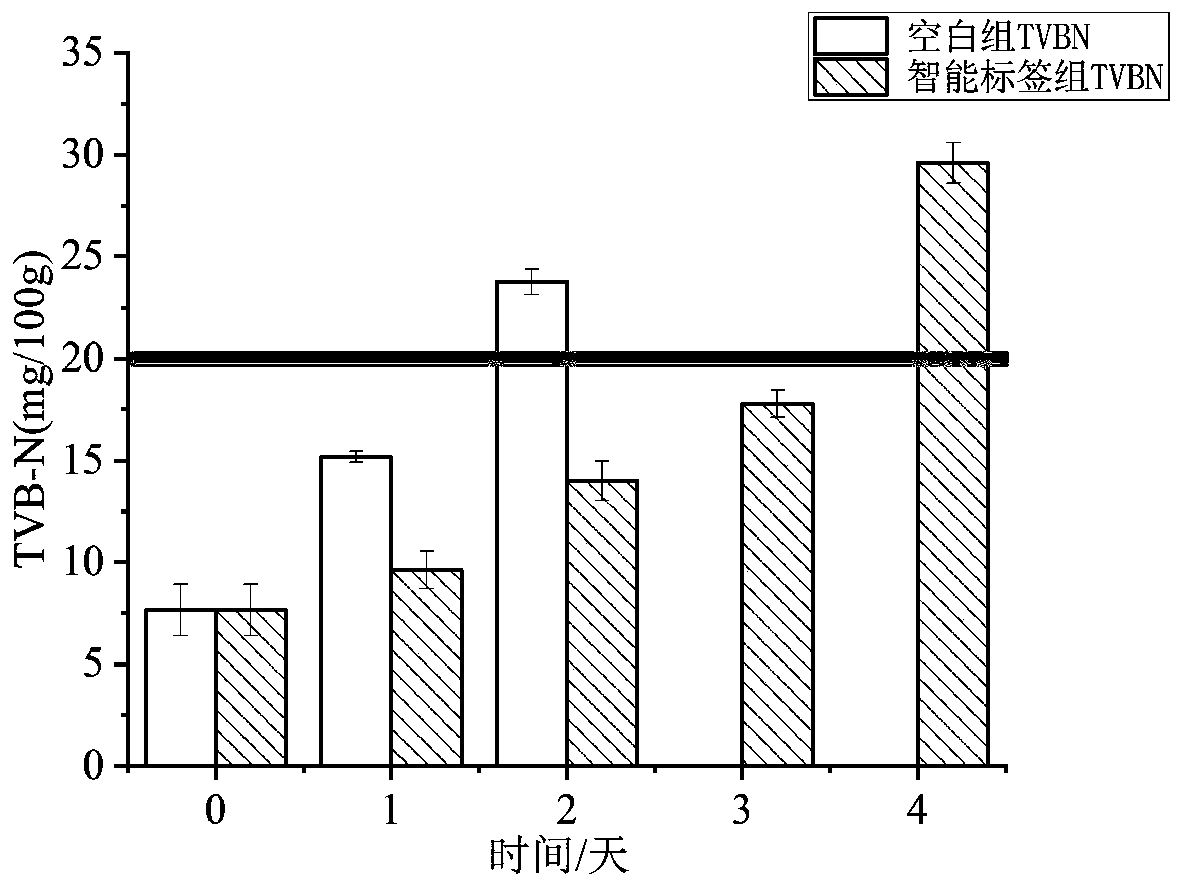

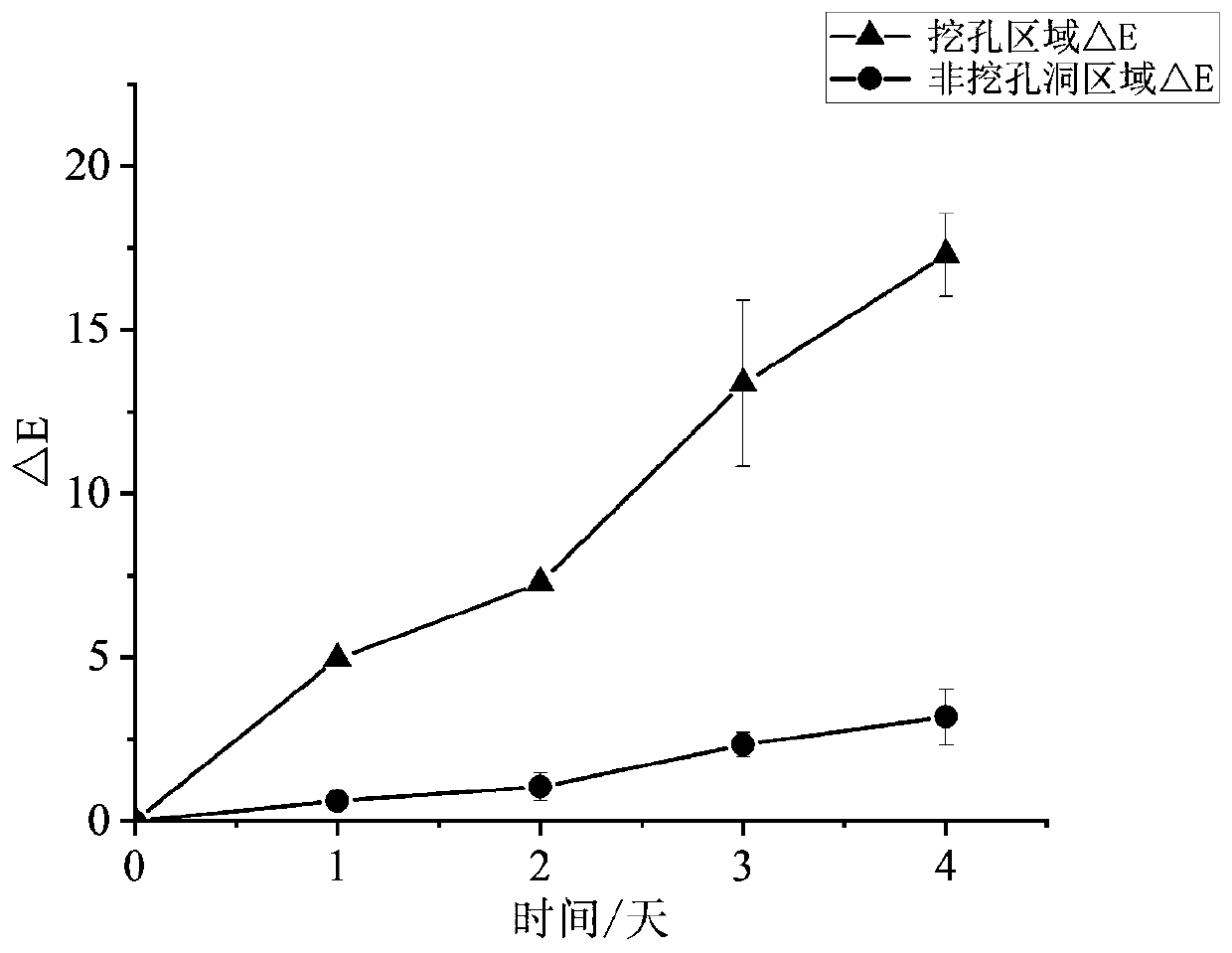

[0108] Embodiment 1: the making of smart label of the present invention

[0109] The implementation steps of this embodiment are as follows:

[0110] A. Preparation of antibacterial layer spinning solution

[0111] Under the condition of room temperature, use magnetic stirrer to stir under the condition of rotating speed 100rpm, add 5 parts by weight of cinnamaldehyde antibacterial agent to 74 parts by weight of hexafluoroisopropanol solvent, allow this antibacterial agent to dissolve completely, then add 6 parts by weight of polylactic acid polymer, allow this polymer to dissolve completely, stir 10h altogether, thus obtain described antibacterial layer spinning solution;

[0112] B. Preparation of sensing layer spinning solution

[0113] At room temperature, use a magnetic stirrer to stir at a speed of 800rpm, add 1 part by weight of anthocyanin pH indicator dye to 90 parts by weight of hexafluoroisopropanol solvent, let the pH indicator dye completely dissolve, and then a...

Embodiment 2

[0119] Embodiment 2: the making of smart label of the present invention

[0120] The implementation steps of this embodiment are as follows:

[0121] A. Preparation of antibacterial layer spinning solution

[0122] Under the condition of room temperature, use magnetic stirrer to stir under the condition of rotating speed 1000rpm, add 14 parts by weight of tea tree essential oil bacteriostatic agent to 110 parts by weight of trifluoroethanol solvent, allow this bacteriostatic agent to dissolve completely, then add 12 parts by weight Part polystyrene polymer, allow this polymer to dissolve completely, stir 8h altogether, thus obtain described antibacterial layer spinning solution;

[0123] B. Preparation of sensing layer spinning solution

[0124] At room temperature, use a magnetic stirrer to stir at a speed of 600rpm, add 0.05 parts by weight of phenolphthalein pH indicator dye to 95 parts by weight of trifluoroethanol solvent, let the pH indicator dye completely dissolve, a...

Embodiment 3

[0130]Embodiment 3: the making of smart label of the present invention

[0131] The implementation steps of this embodiment are as follows:

[0132] A. Preparation of antibacterial layer spinning solution

[0133] Under the condition of room temperature, use magnetic stirrer to stir under the condition of rotating speed 800rpm, add 24 parts by weight of thymol antibacterial agents to 98 parts by weight of trifluoroacetic acid solvent, allow this antibacterial agent to dissolve completely, then add 30 parts by weight Part of cellulose acetate polymer, allow this polymer to dissolve completely, stir 6h altogether, thus obtain described antibacterial layer spinning solution;

[0134] B. Preparation of sensing layer spinning solution

[0135] At room temperature, use a magnetic stirrer to stir at a speed of 100rpm, add 0.01 parts by weight of methyl red pH indicator dye to 100 parts by weight of trifluoroacetic acid solvent, let the pH indicator dye dissolve completely, then add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com