Process of fabrication of submicron aligned hydrophobic and oleophilic fibre from polystyrene waste with controllable geometry using-citrus peel extract as solvent

A polystyrene, sub-micron technology, applied in the direction of single-component polystyrene artificial filament, fiber treatment, spinning solution preparation, etc., can solve environmental hazards and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

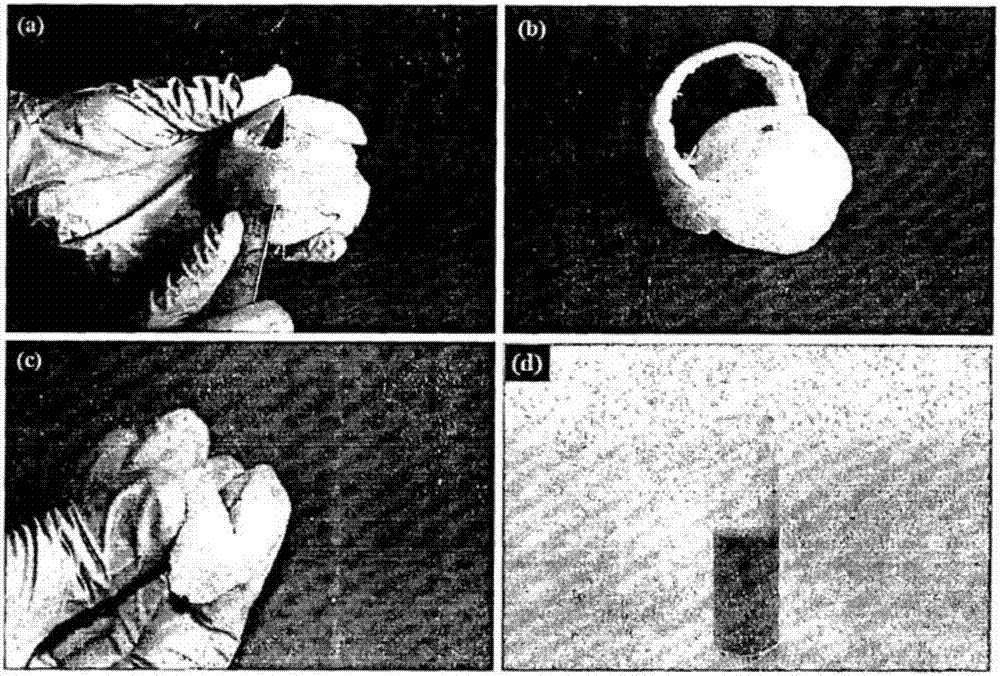

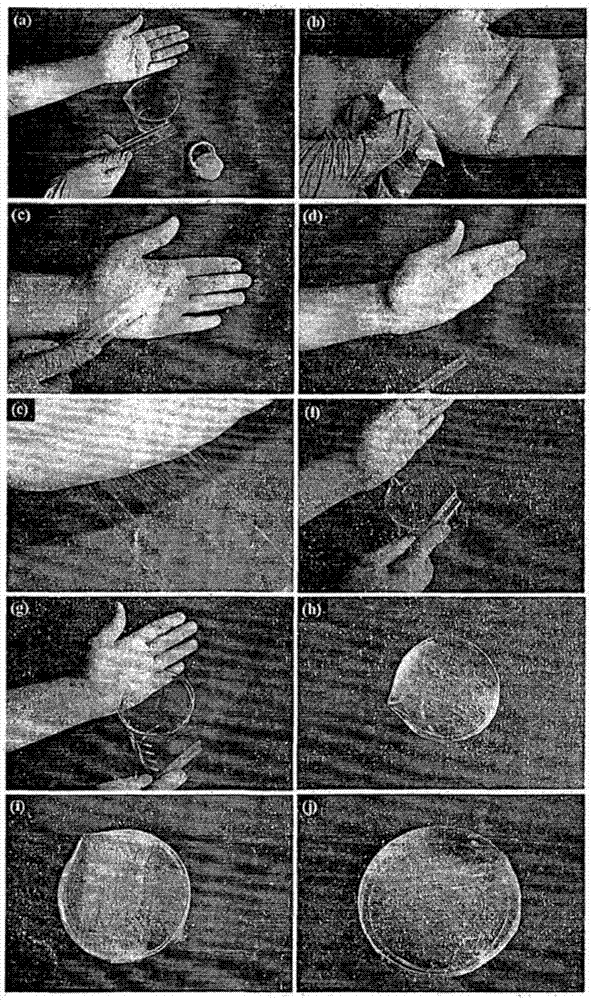

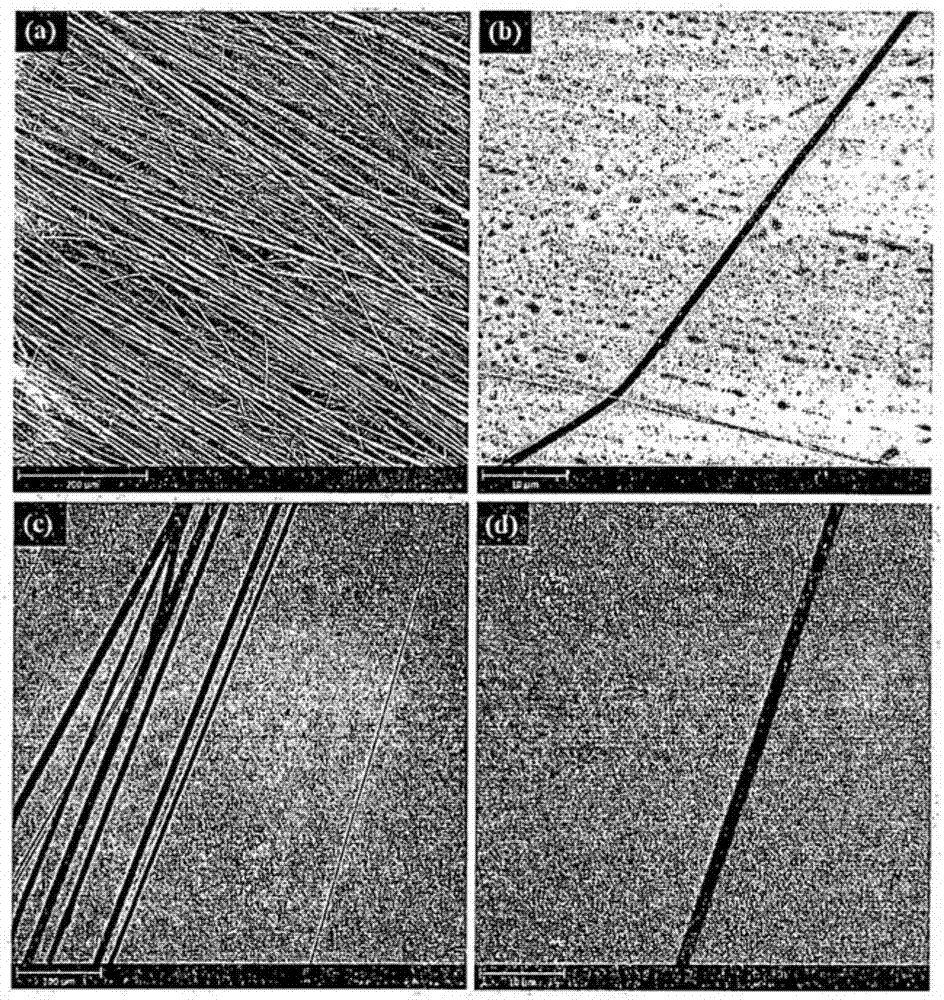

Method used

Image

Examples

Embodiment Construction

[0032] Reference will now be made in detail to one or more exemplary embodiments of the invention. Before describing detailed embodiments in accordance with the present disclosure, it should be observed that embodiments pertain primarily to combinations of process / method steps and products.

[0033] As used herein, the terms "comprises," "comprising," or any other variation thereof, are intended to cover a non-exclusive inclusion such that a process, product, method, article, apparatus, or A device does not include only those elements, but may also include other elements not expressly listed or inherent in such a process, product, method, article, device or device. An element beginning with "comprising..." does not (without further limitations) exclude the presence of additional identical elements in the process, product, method, article, device or equipment that includes the element.

[0034] Any implementation described herein is not necessarily to be construed as preferred...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com