Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52 results about "Stall torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stall torque is the torque produced by a mechanical device whose output rotational speed is zero. It may also mean the torque load that causes the output rotational speed of a device to become zero, i.e., to cause stalling. Electric motors, steam engines and hydrodynamic transmissions are all capable of developing torque when stalled.

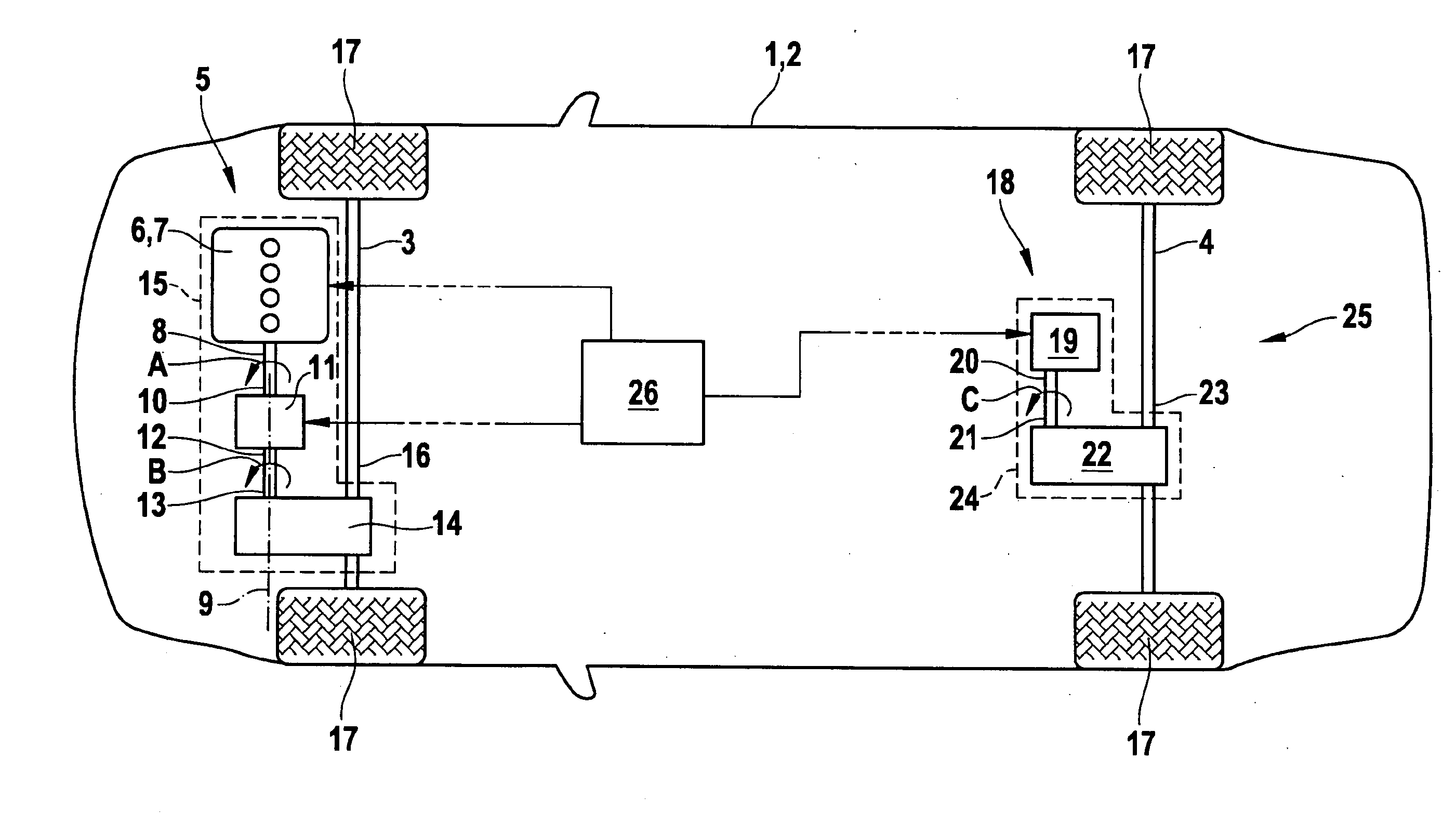

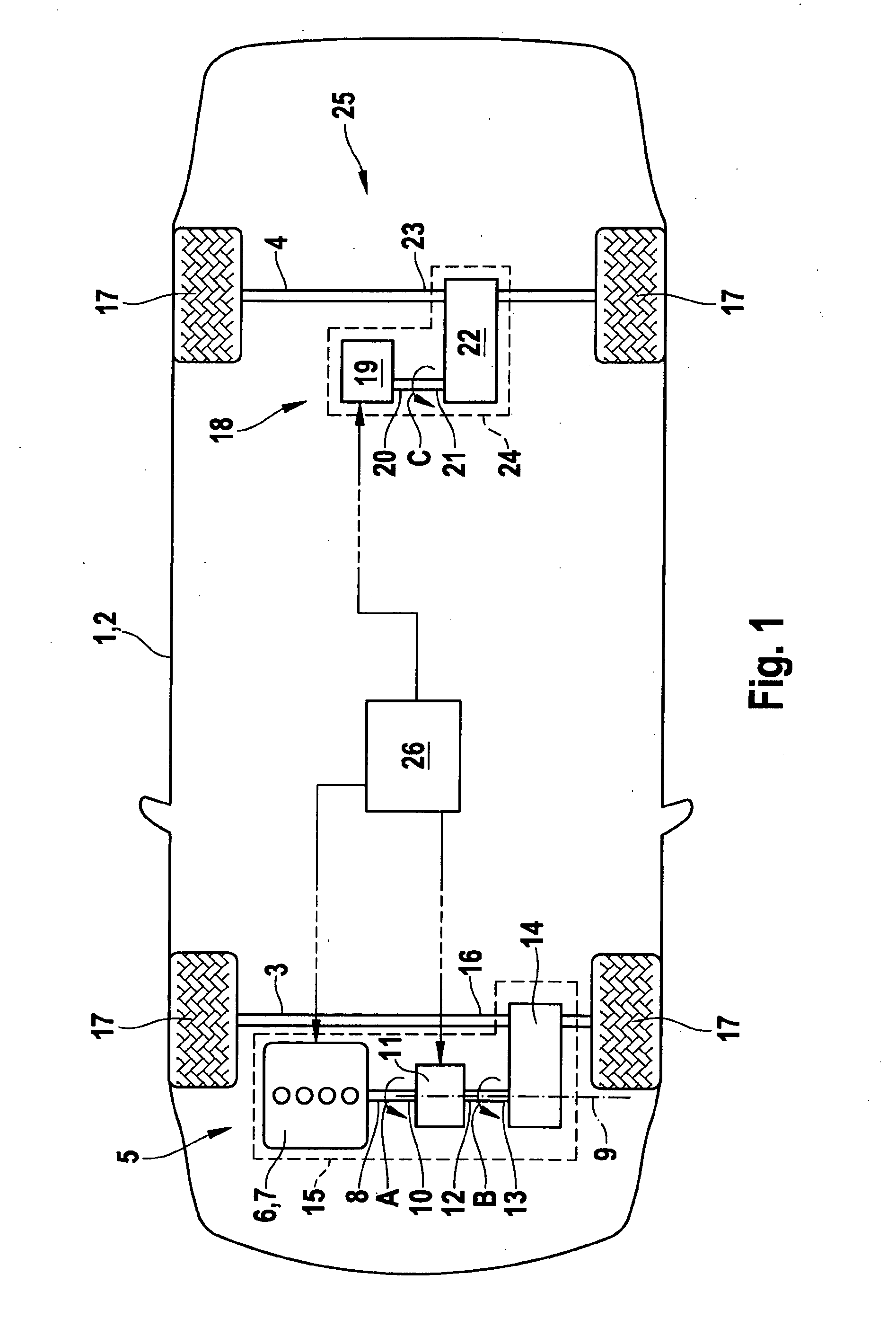

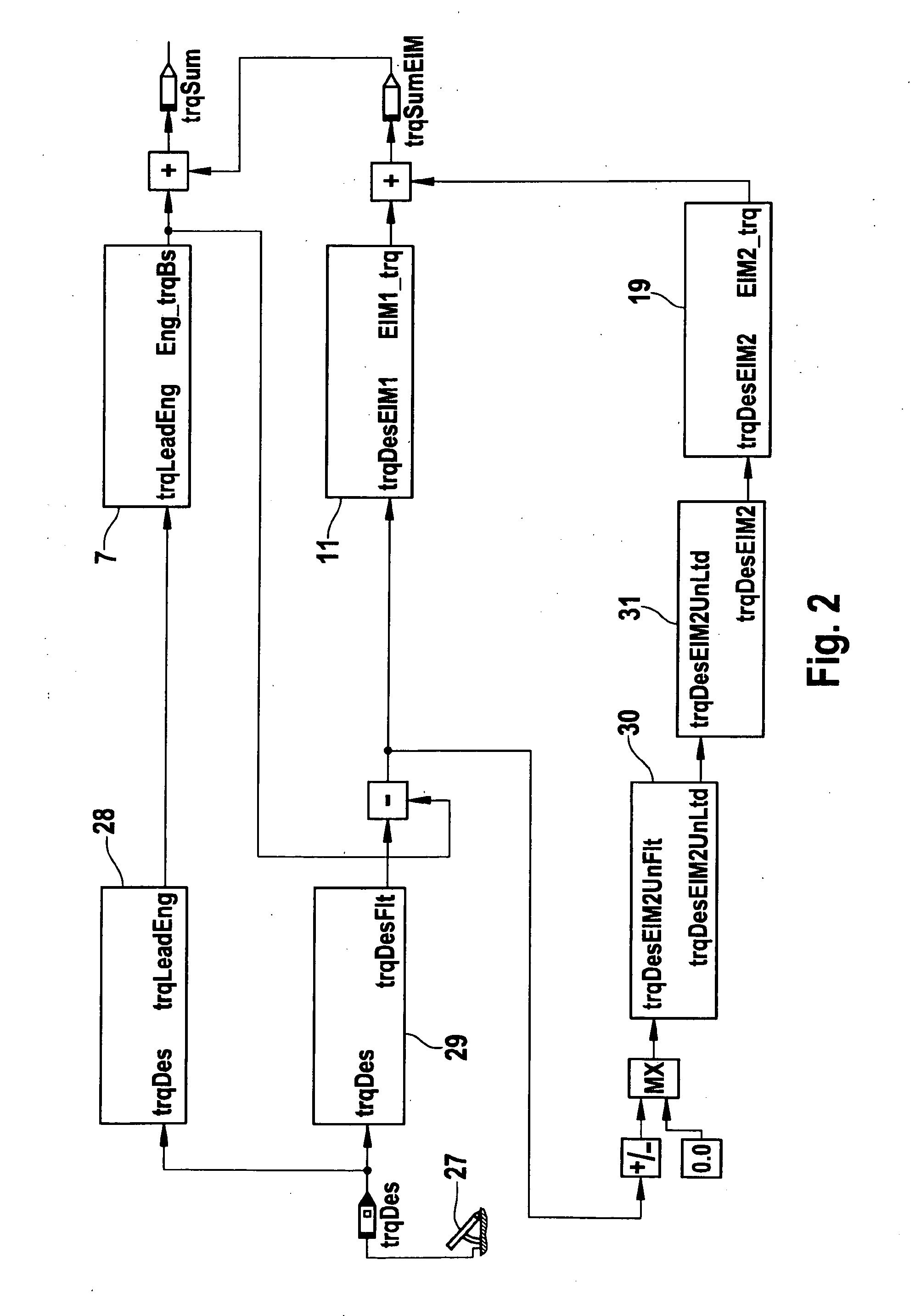

Method for operating a hybrid drive of a motor vehicle

ActiveUS20100167869A1Good dynamic responseReduce usageDC motor speed/torque controlDigital data processing detailsControl theoryStall torque

In a method for operating a hybrid drive of a vehicle having at least one internal combustion engine and at least one first electric machine as drive machines of a first drive train of the vehicle, and an associated first transmission, the total torque of the drive machines is adapted in a shifting operation of the transmission in order to reduce the load at the transmission and / or in order to modify rotational speeds according to the new transmission ratio, and / or the torque gradient of the drive machines is restricted to a specifiable, maximum torque gradient of the resulting total torque of the drive machines of the first drive train in a transition between acceleration operation and trailing throttle operation.

Owner:ROBERT BOSCH GMBH

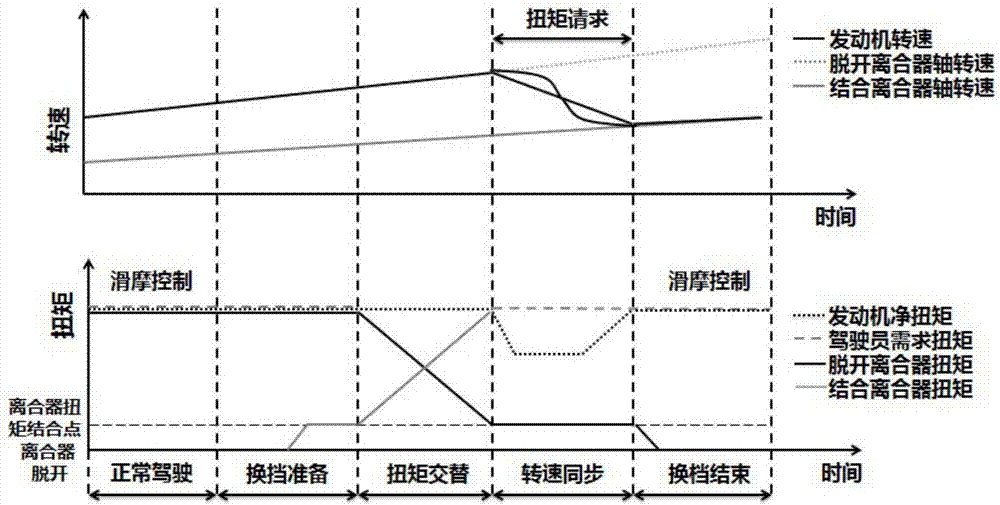

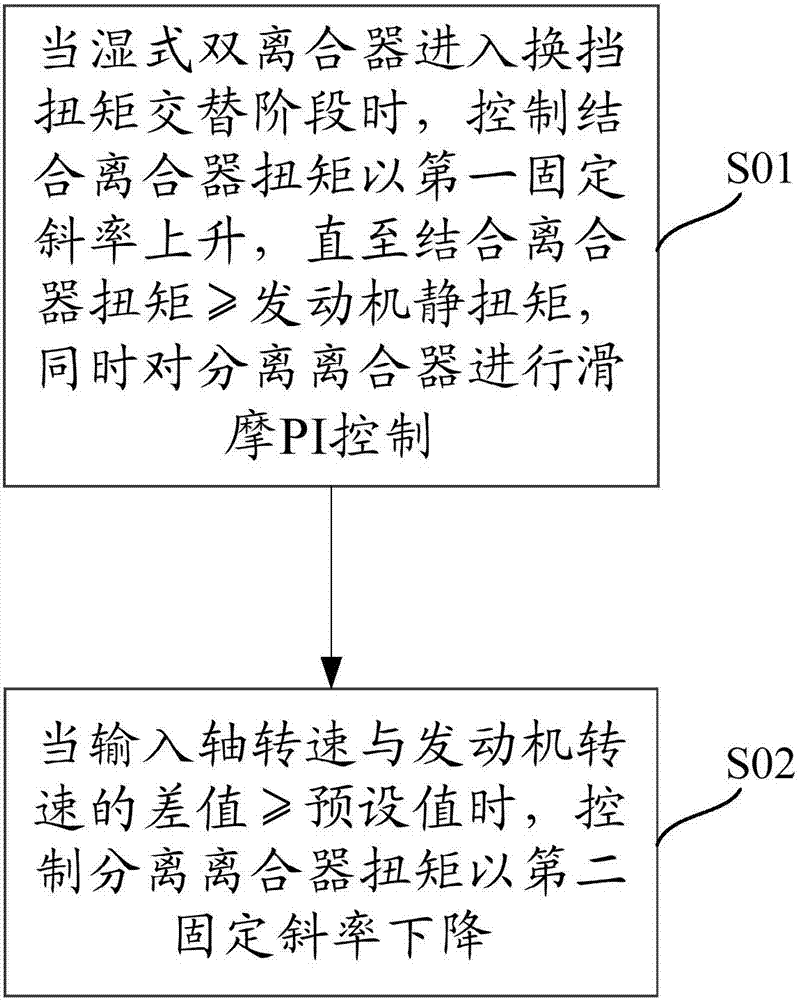

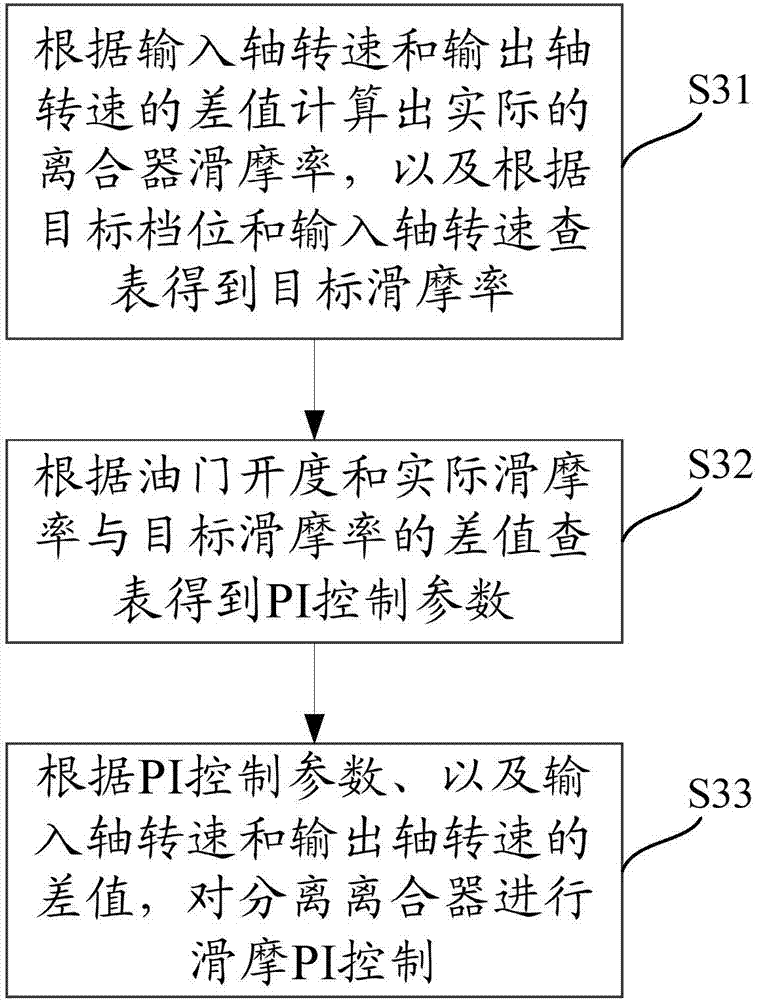

Upshifting control method and system for wet type double-clutch automatic gearbox

The invention discloses an upshifting control method and system for a wet type double-clutch automatic gearbox. The upshifting control method comprises the steps that when wet type double clutches enter a gear shifting torque alternating stage, the torque of the combination clutch is controlled to be increased by the first fixed slope till the torque of the combination clutch is larger than or equal to the static torque of an engine, and sliding friction PI control is conducted on the separation clutch at the same time; then whether the difference value between the rotation speed of an input shaft and the rotation speed of the engine is larger than or equal to the preset value is judged; in addition, when the difference value between the rotation speed of the input shaft and the rotation speed of the engine is larger than or equal to the preset value, it is indicated that the current engine rotation speed drops too low, and impact is prone to being produced if sliding friction control is still conducted; at the moment, the torque of the separation clutch is controlled to be decreased by the second fixed slope; the processes are repeated till the separation clutch is separated; and in this way, the impact phenomenon at the torque alternating stage in the accelerator stepping power upshifting process in the prior art can be effectively avoided, and the driving experience degree is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

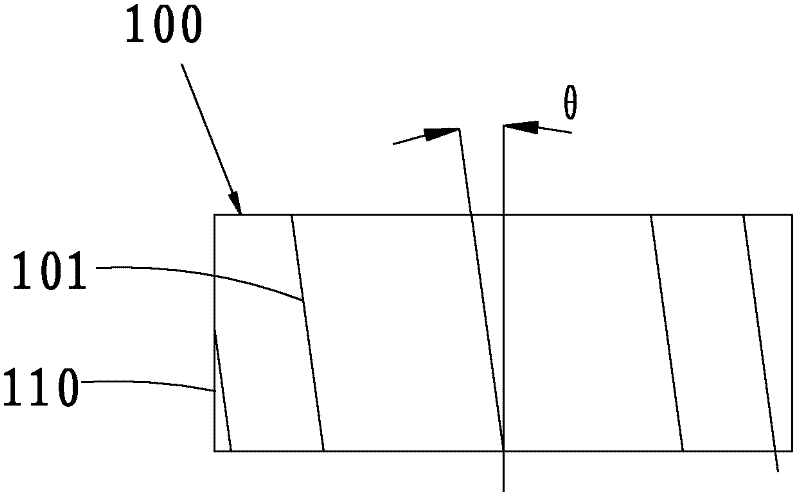

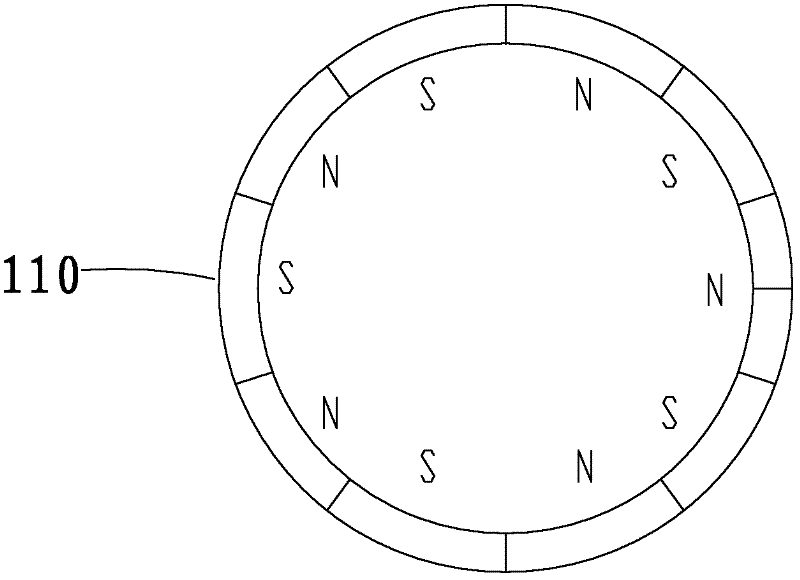

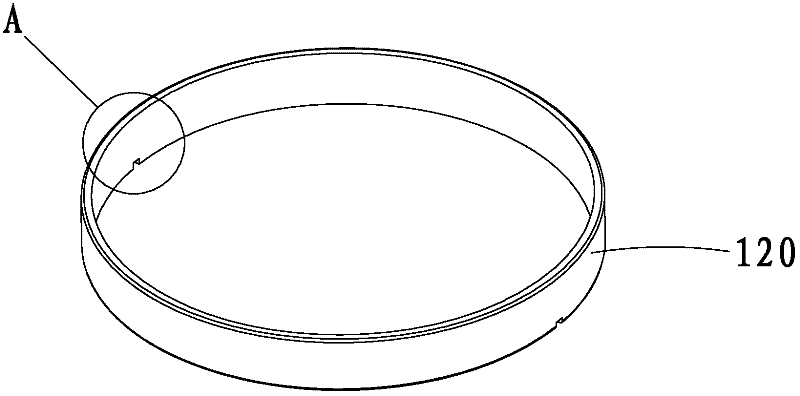

Magnetic component, motor and ceiling fan comprising motor

ActiveCN102510137AReduce stall torqueReduce torque rippleWindingsMagnetic circuit rotating partsCeiling fanStall torque

The invention is suitable for the technical field of a motor and discloses a magnetic component, a motor and a ceiling fan comprising the motor. The magnetic component is a rubber magnetic ring, and a magnetic induction line of the rubber magnetic ring is bias arranged relative to an axis of the rubber magnetic ring. The motor comprises a stator component and a rotor component, wherein the stator component comprises a spindle and a stator iron core fixedly sleeved on the spindle; the rotor component comprises a shell part and the magnetic component arranged in the shell part; the magnetic component is the rubber magnetic ring; and the magnetic induction line of the rubber magnetic ring is bias arranged relative to the axis of the rubber magnetic ring. The ceiling fan comprises the motor. In the magnetic component, the motor and the ceiling fan comprising the motor provided by the invention, the rubber magnetic ring, of which the magnetic induction line is bias arranged relative to the axis of the rubber magnetic ring, is arranged, so that a stall torque and a torque pulse of the motor are greatly reduced, the running of the motor is stable and the reliability is high.

Owner:CHIAPHUA COMPONENTS SHENZHEN

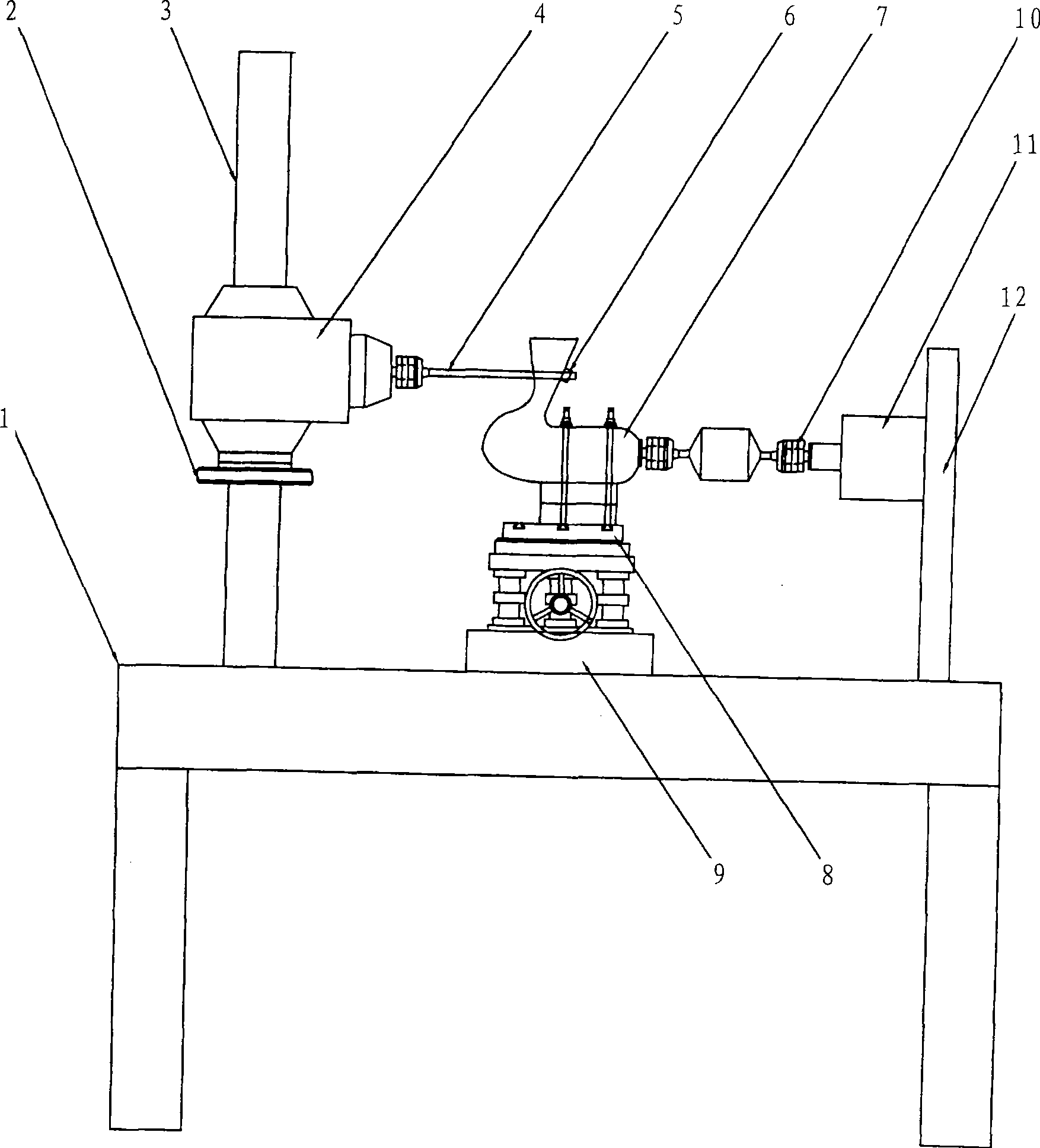

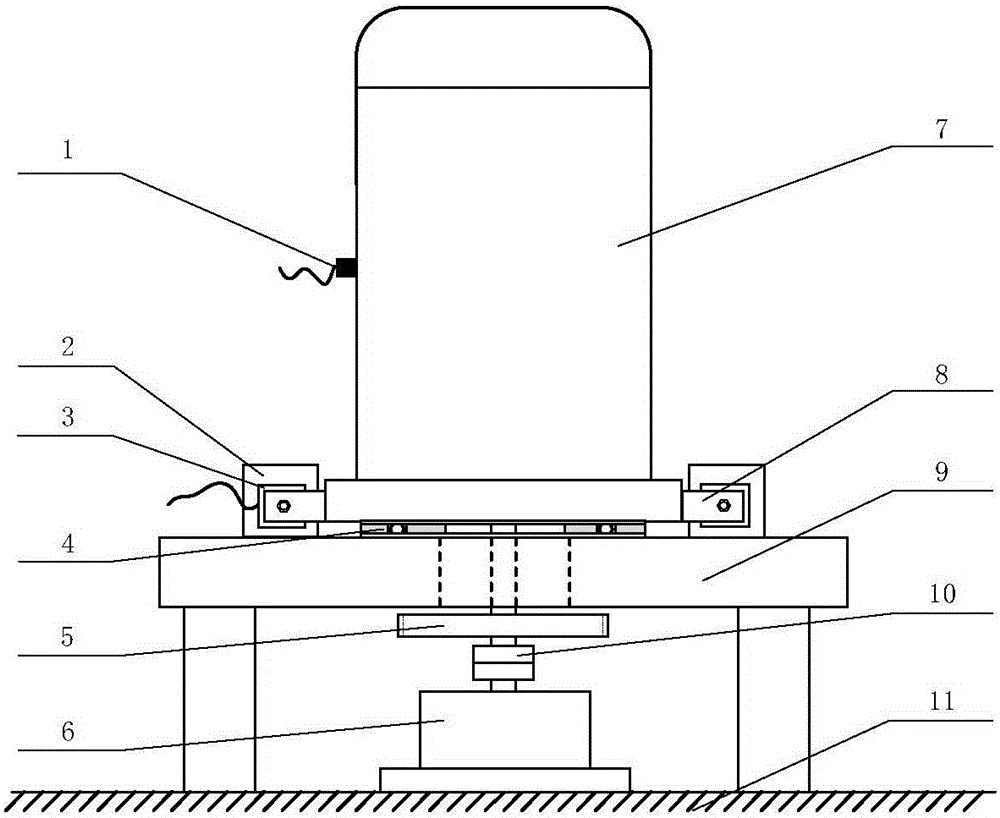

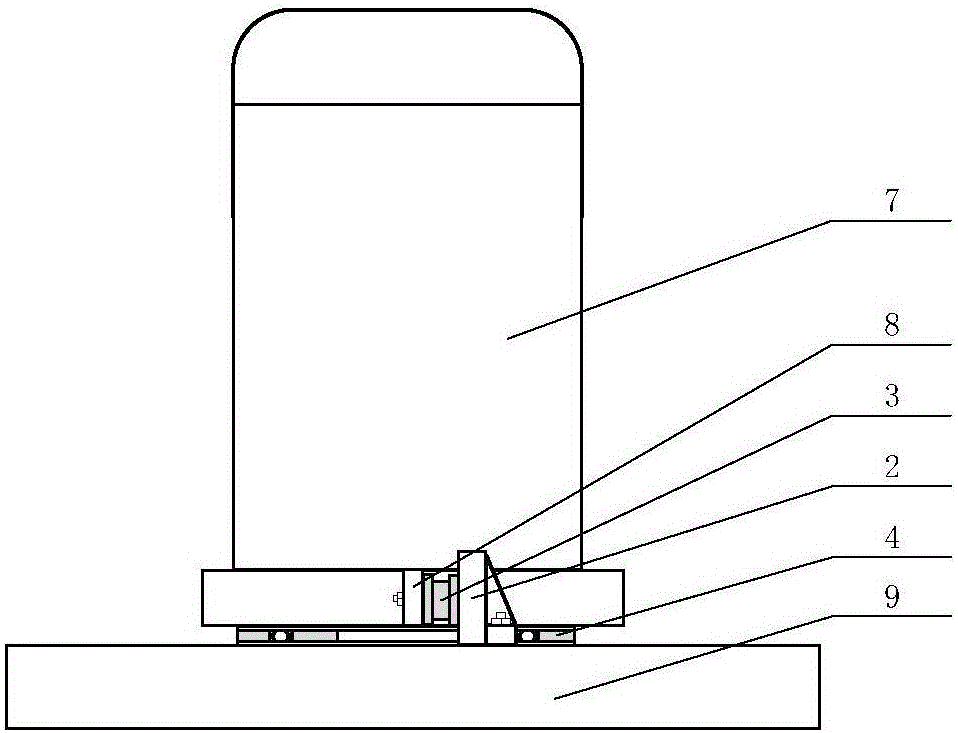

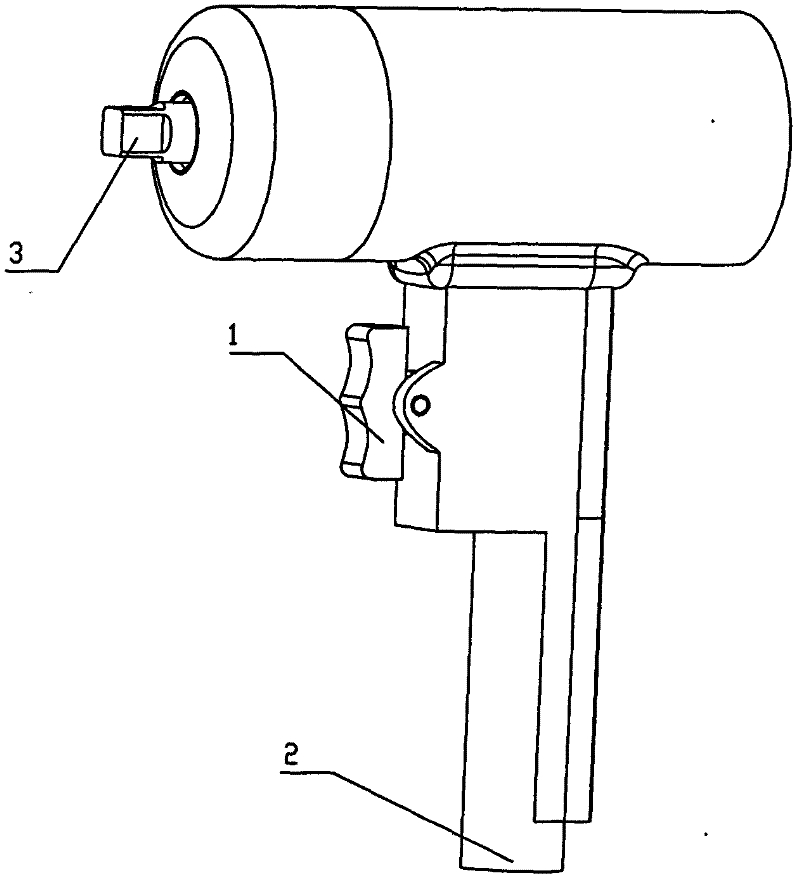

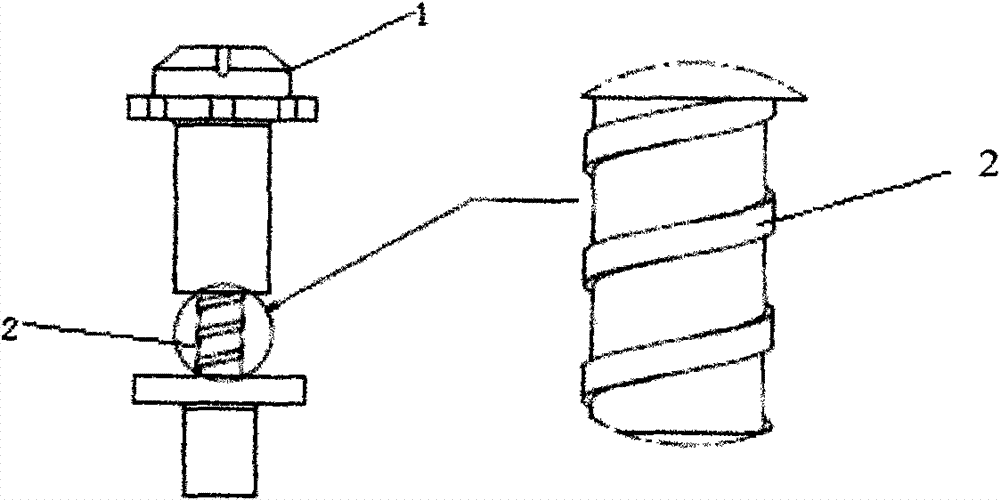

Testing bench for stalling torque of electric tool

InactiveCN101487752AAvoid measurement errorsApparatus for force/torque/work measurementElectric machinePower tool

The invention relates to a test bed for measuring static stalling torque of an electric tool. The test bed comprises a stander, a motor workbench, an upright post, a linear stepping motor, a driving screw, a switch operating element, an inclinable clamping table, a three-dimensional workbench, a static sensor and a supporting seat, wherein, the upright post is fixed on the stander, and the motor workbench is arranged on the upright post, can move up and down on the motor workbench, and is clamped and fixed at a proper position; the linear stepping motor is fixed on the motor workbench, one end of the driving screw is connected with the linear stepping motor, and the other end of the driving screw is connected with the switch operating element; the three-dimensional workbench is fixed on the stander, one side of the inclinable clamping table is articulated with the three-dimensional workbench, and the middle of the bottom surface of the inclinable clamping table is provided with a lifting device which can be a jack; the table surface of the inclinable clamping table and the three-dimensional workbench form an included angle of 0-20 degrees; and the static sensor is fixed on the supporting seat which is fixed on the stander.

Owner:JINHUA ENTRY EXIT INSPECTION & QUARANTINE BUREAU OF PRC

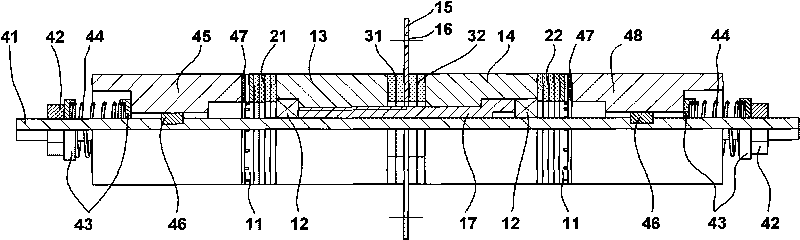

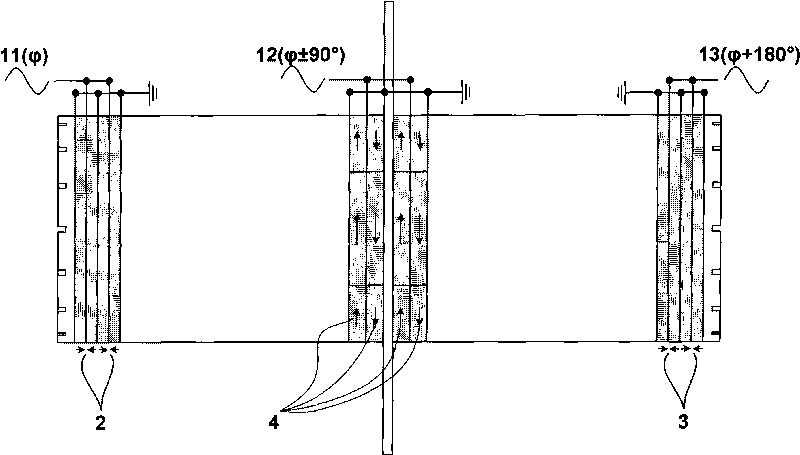

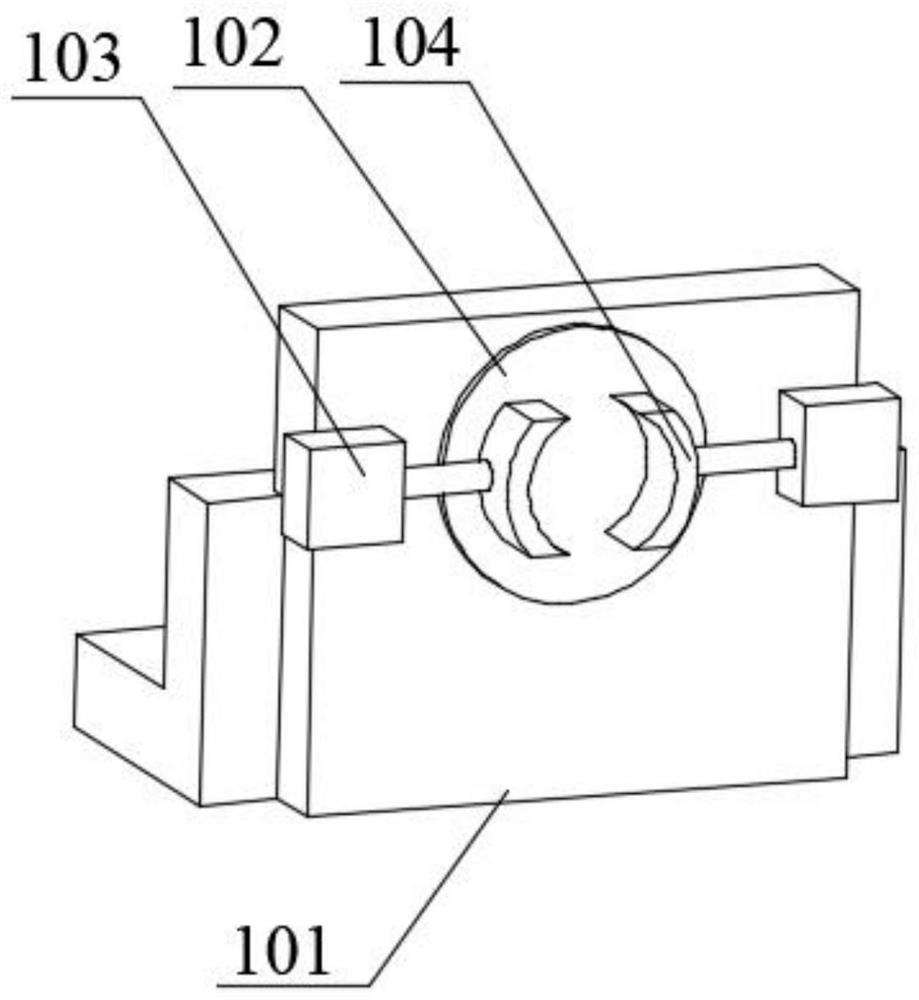

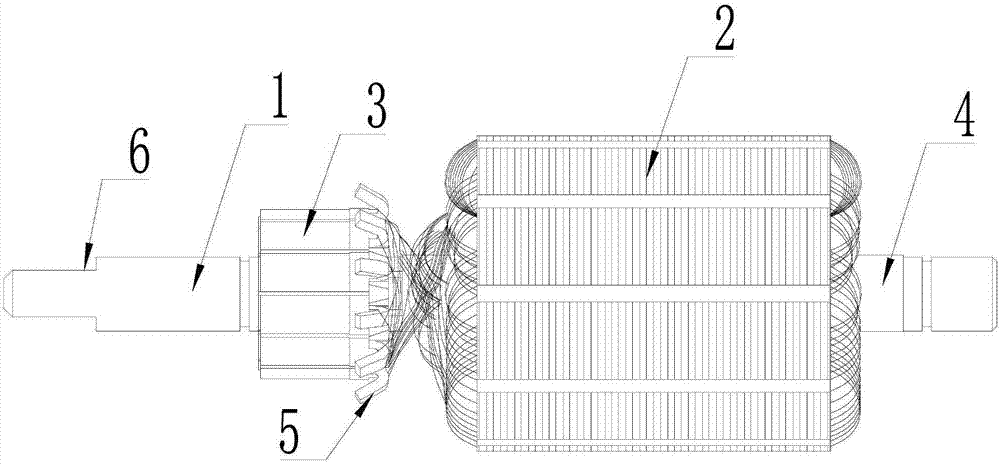

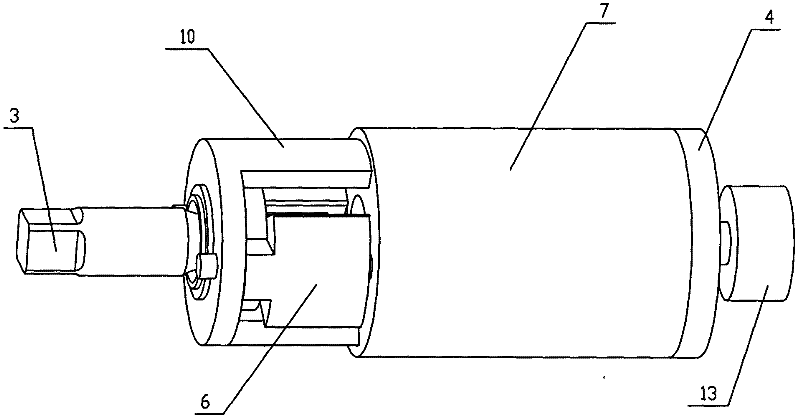

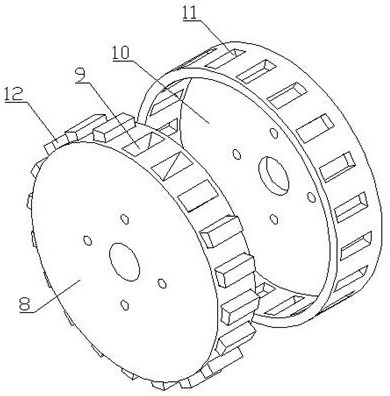

Large-moment double-rotor stress type longitudinal-torsional composite ultrasonic motor and electric excitation method thereof

InactiveCN101719735ALarge stall torquePiezoelectric/electrostriction/magnetostriction machinesElectric machineLongitudinal vibration

The invention discloses a large-moment double-rotor stress type longitudinal-torsional composite ultrasonic motor and an electric excitation method thereof, belonging to the technical field of ultrasonic motors. The motor comprises a stator assembly and a rotor assembly, wherein the stator assembly comprises a friction sheet, a first group of longitudinal vibration piezoelectric ceramics, a first balance weight block, a first group of torsional vibration piezoelectric ceramics, a flange, a second group of torsional vibration piezoelectric ceramics, a second balance weight block, a second group of longitudinal vibration piezoelectric ceramics, a fastening bolt and two radial bearings; and the rotor assembly comprises a rotating shaft, a locking nut, a spring cover, a spring, a first rotor, a key, a friction material and a second rotor. The method is operated by the first-order torsional vibration in a stator and the second-order longitudinal vibration in the whole of the motor, and the longitudinal vibration piezoelectric ceramics are placed near the contact surface of the stator and the rotors, namely the pitch plane of the longitudinal vibration to fully excite and apply the longitudinal vibration of the motor. Compared with the prior art, the invention has larger rotor blocking torsion.

Owner:JIANGSU FENGKE ULTRASONIC MOTORS TECH

Torque control method for artificial refueling before creeping speed of electric automobile

ActiveCN108638915AAvoid feeling tiredImprove stabilitySpeed controllerElectric energy managementElectric machineryDrive motor

The invention relates to a torque control method for artificial refueling before creeping speed of an electric automobile. The torque control method specifically includes the steps that under the conditions that a braking pedal and an accelerator pedal of the electric automobile are not treaded and the gear of a gearbox is engaged to the forward gear or the reversing gear, the electric automobileis accelerated to approach a target creeping speed according to a preset creeping control scheme, and at the moment, if the accelerator pedal is manually treaded, the torque of a driving motor is controlled as follows: 1, the currently required torque of the driving motor is calculated by checking a torque table under the normal driving condition of the electric automobile; and 2, the calculated torque and the driving motor torque corresponding to the creeping control scheme at the moment are compared, and the larger torque is selected as the actual torque of the driving motor. The torque control method can avoid the automobile weak feeling generated by reduced required torque when a driver treads an accelerator, so that driving stability and comfort are good.

Owner:JIANGLING MOTORS

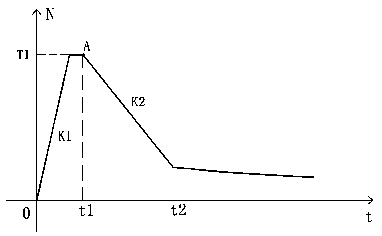

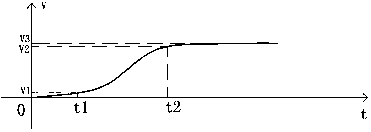

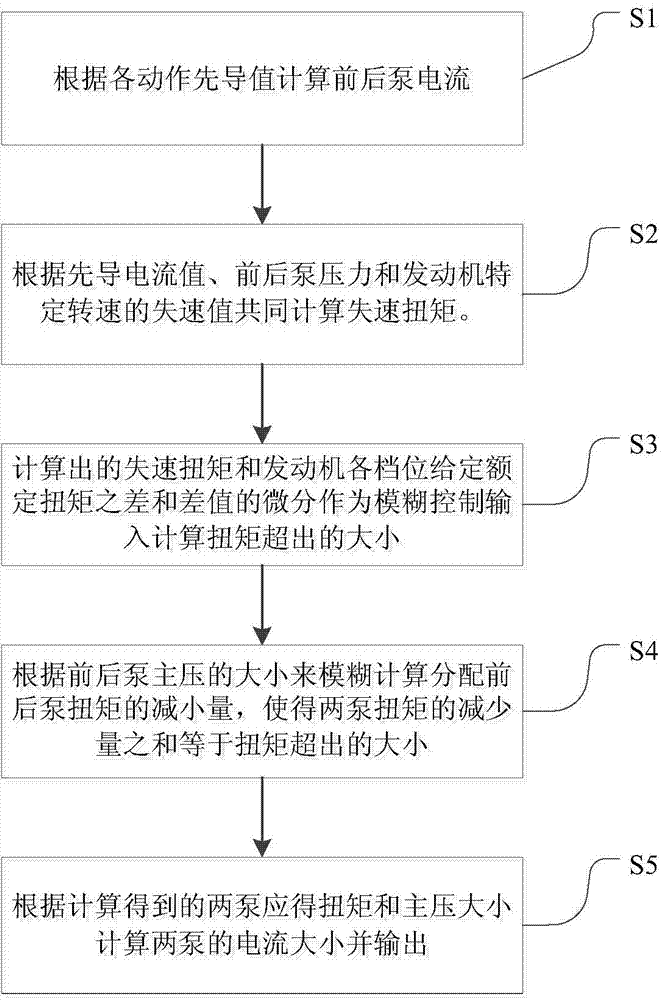

Control method and system used for excavator electric control pump

InactiveCN103696453AAvoid instabilityEnables full power distributionSoil-shifting machines/dredgersPower flowWork performance

The invention discloses a control method and system used for an excavator electric control pump. The control method used for the excavator electric control pump comprises the steps of calculating the current of front and rear pumps according to the pilot pressure value of each action; jointly calculating stall torque according to the pilot current value, the front and rear pump pressure and the stall value of the specific rotating speed of an engine; calculating the exceeding magnitude of the torque by taking the difference value between the calculated stall torque and the given torque of each gear of the engine and the differential of the difference value as fuzzy control input; carrying out fuzzy computing to distribute the reduced amount of the torque of the front and rear pumps according to the magnitude of the front and rear pump main pressure; enabling the sum of the reduced amount of the pilot expected torque of the two pumps to equal to the exceeding magnitude of the torque; calculating and outputting the magnitude of the current of the two pumps according to the deserved torque of the two pumps and the magnetite of the main pressure which are obtained by calculation. According to the control method and the control system used for the excavator electric pump, on basis of fuzzy control, the working performance of an excavator adopting the electric control pump is further improved.

Owner:SANY HEAVY MACHINERY

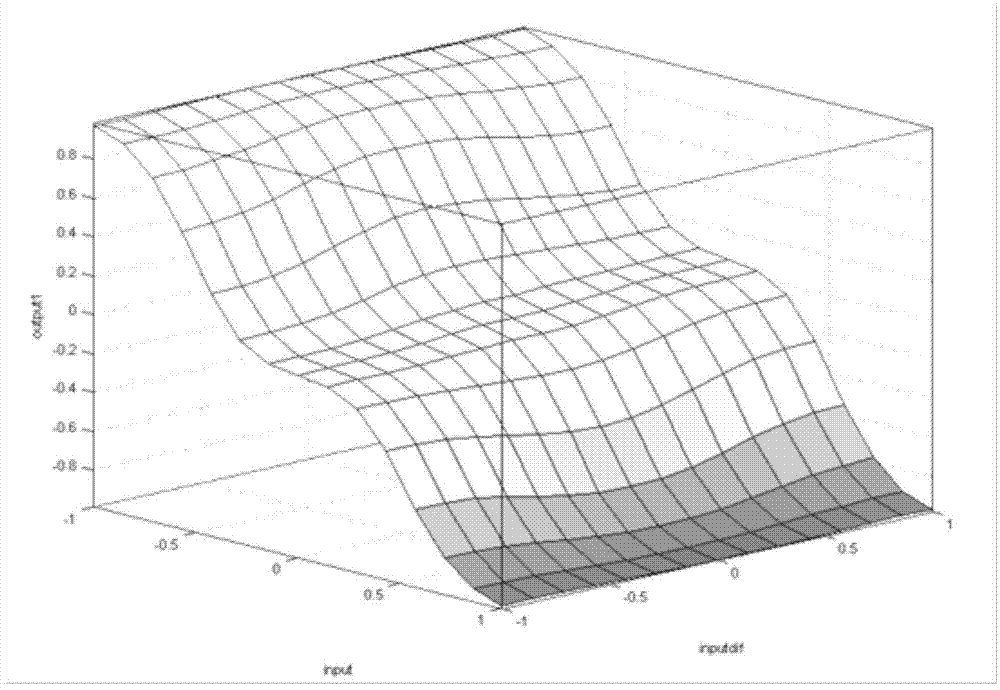

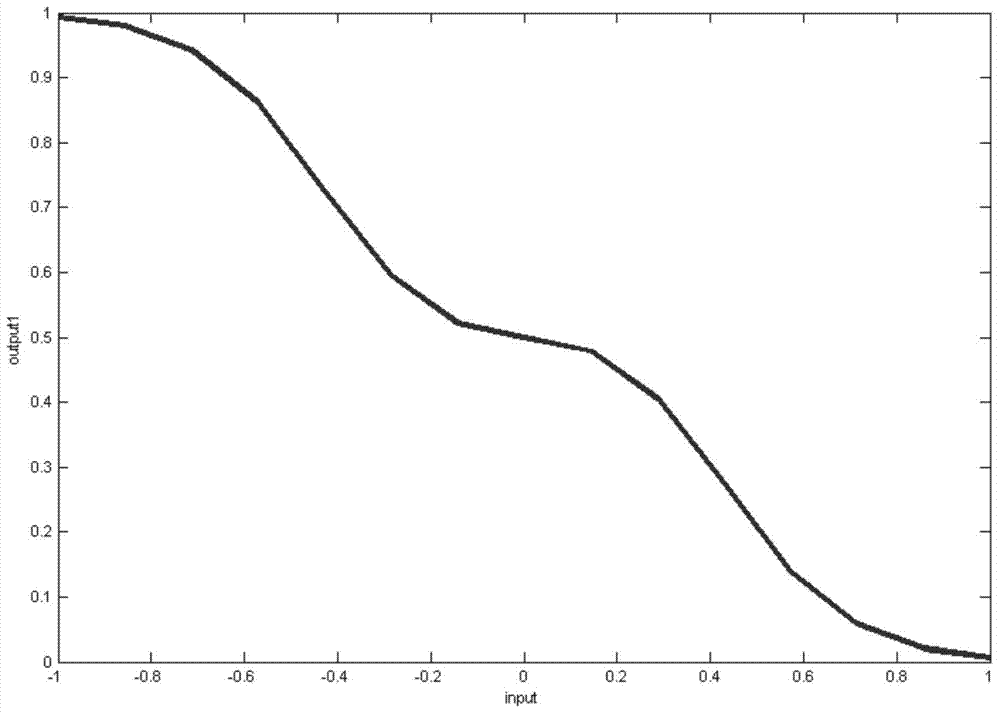

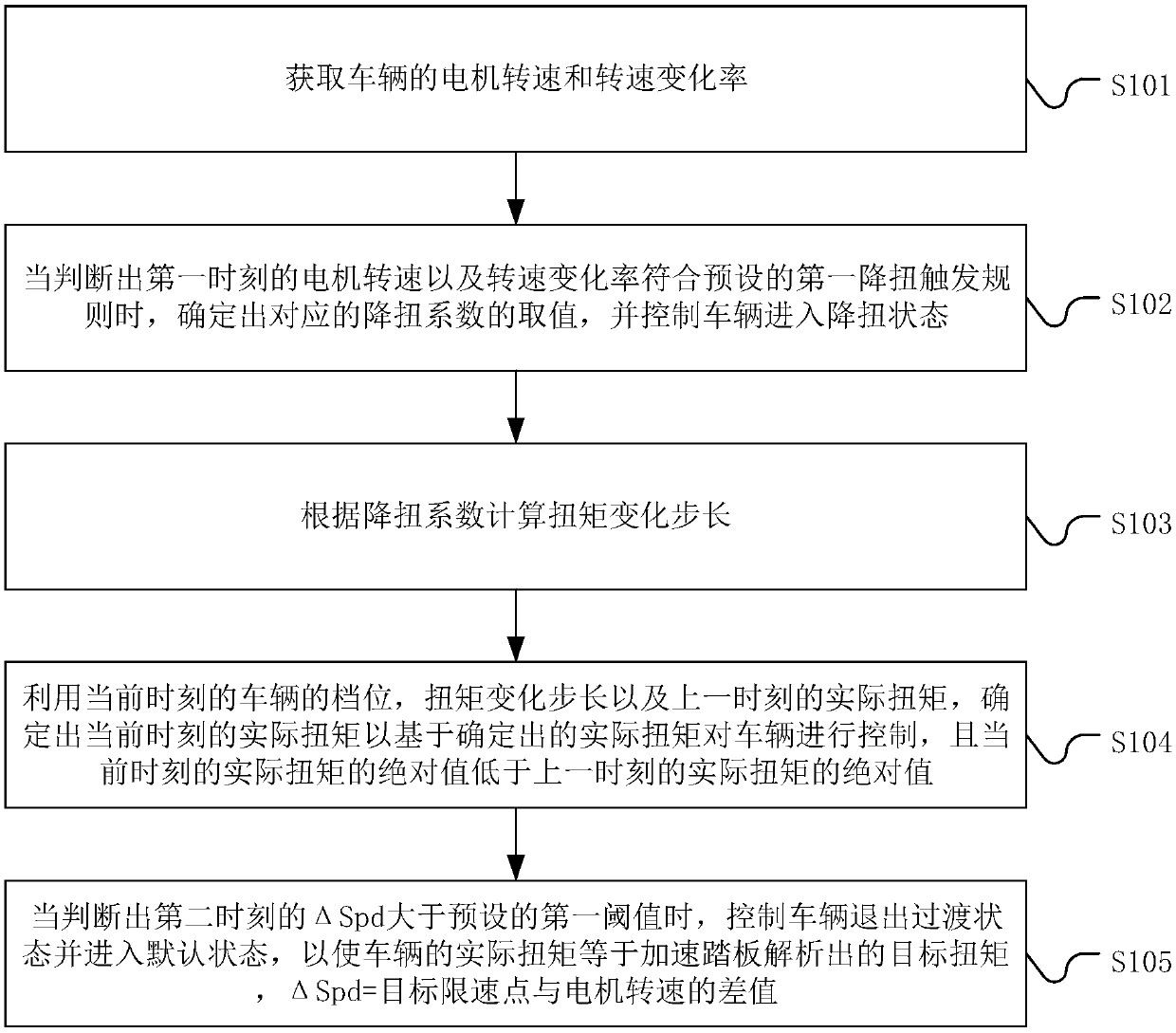

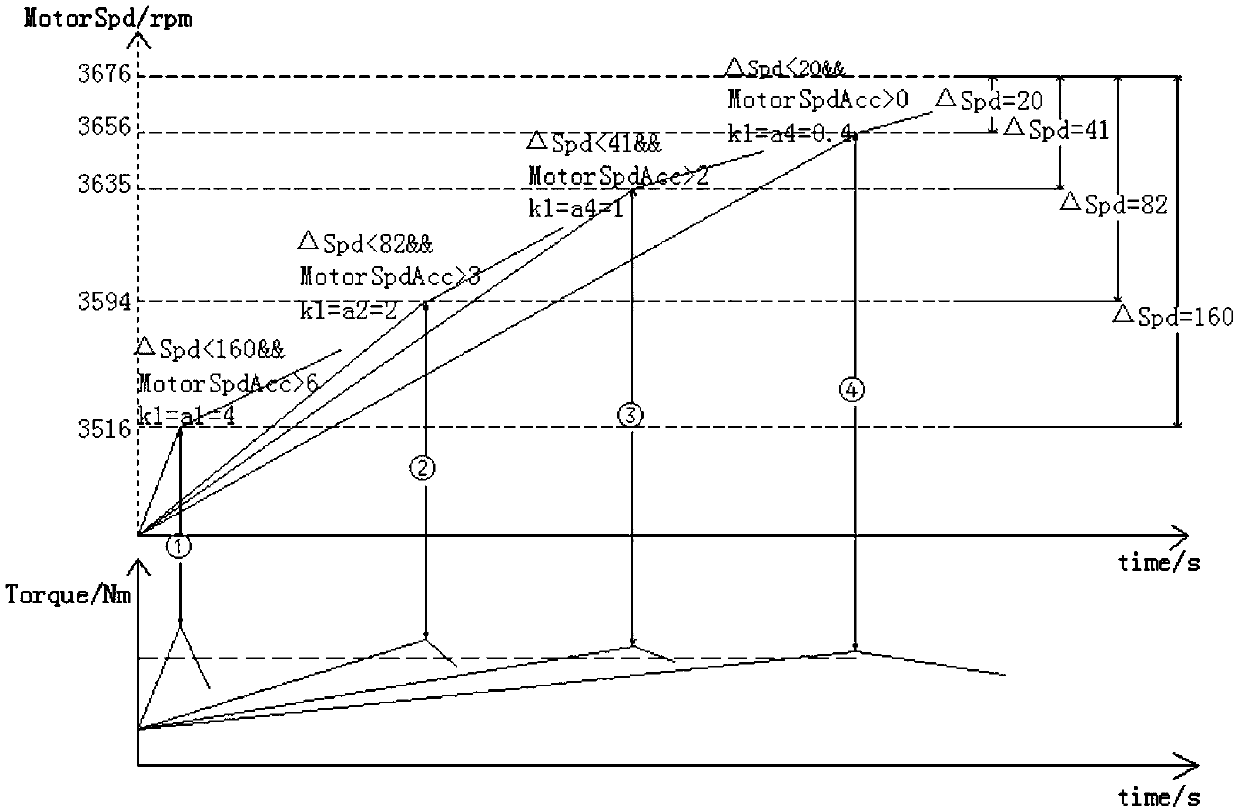

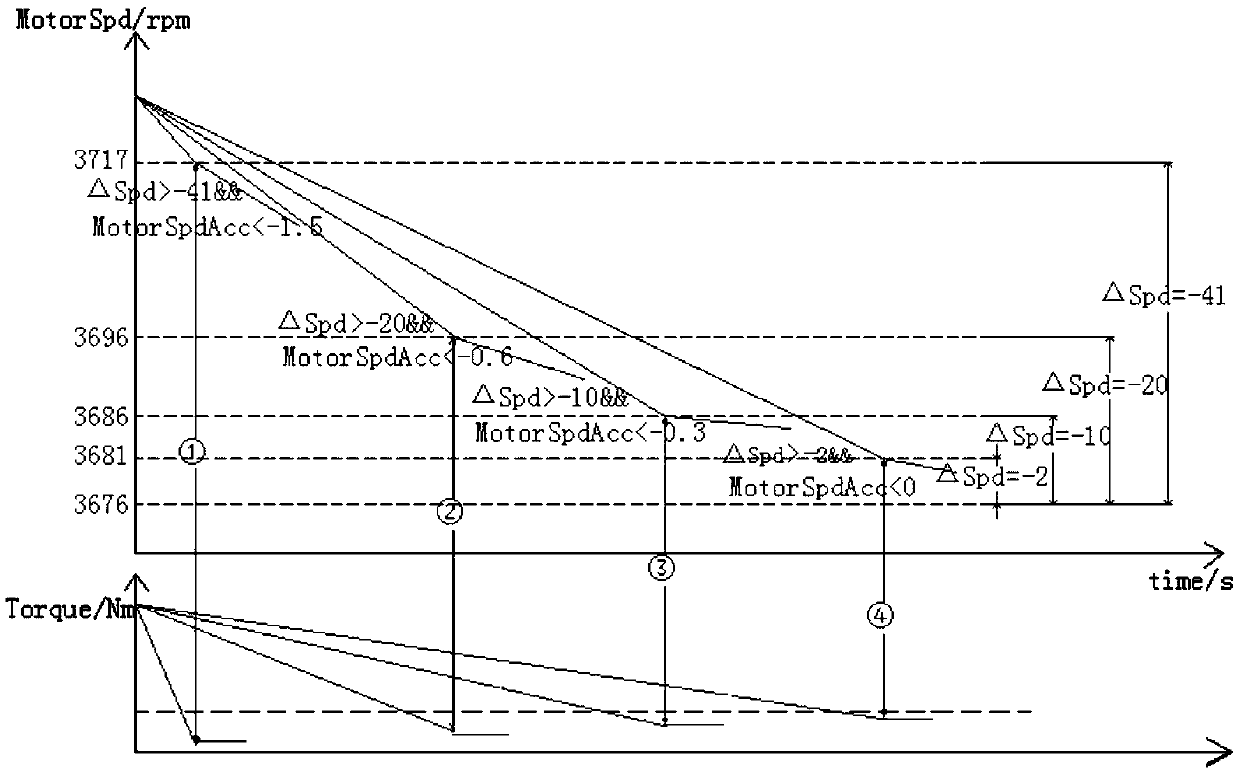

Speed limiting control method and system of new energy vehicle

ActiveCN109515213AReduce the overall heightEasy to implementSpeed controllerElectric energy managementNew energyControl system

The invention discloses a speed limiting control method of a new energy vehicle. The method comprises the following steps: the motor rotating speed and the rotating speed change rate of the vehicle are obtained; when the motor rotating speed and the rotating speed change rate at the first moment meet first torque reduction trigger rules, values of corresponding torque reduction coefficients are determined, and the vehicle is controlled to enter a torque reduction state; the actual torque at the present time is determined according to the vehicle gear at the present time, the torque change steplength calculated by the torque reduction coefficients and the actual torque at the previous moment, and the absolute value of the actual torque at the present time is lower than the absolute value of the actual torque at the previous moment; and when the difference value between the target speed limiting point at the second moment and the motor rotating speed is higher than the preset first threshold, the vehicle is controlled to enter the defaulted state, and the actual torque is equal to the target torque analyzed by an acceleration pedal. The method can conveniently control the speed limiting. The invention further discloses a speed limiting control system of the new energy vehicle, and achieves corresponding effects.

Owner:INVT ELECTRIC VEHICLE DRIVE TECH SHENZHEN CO LTD

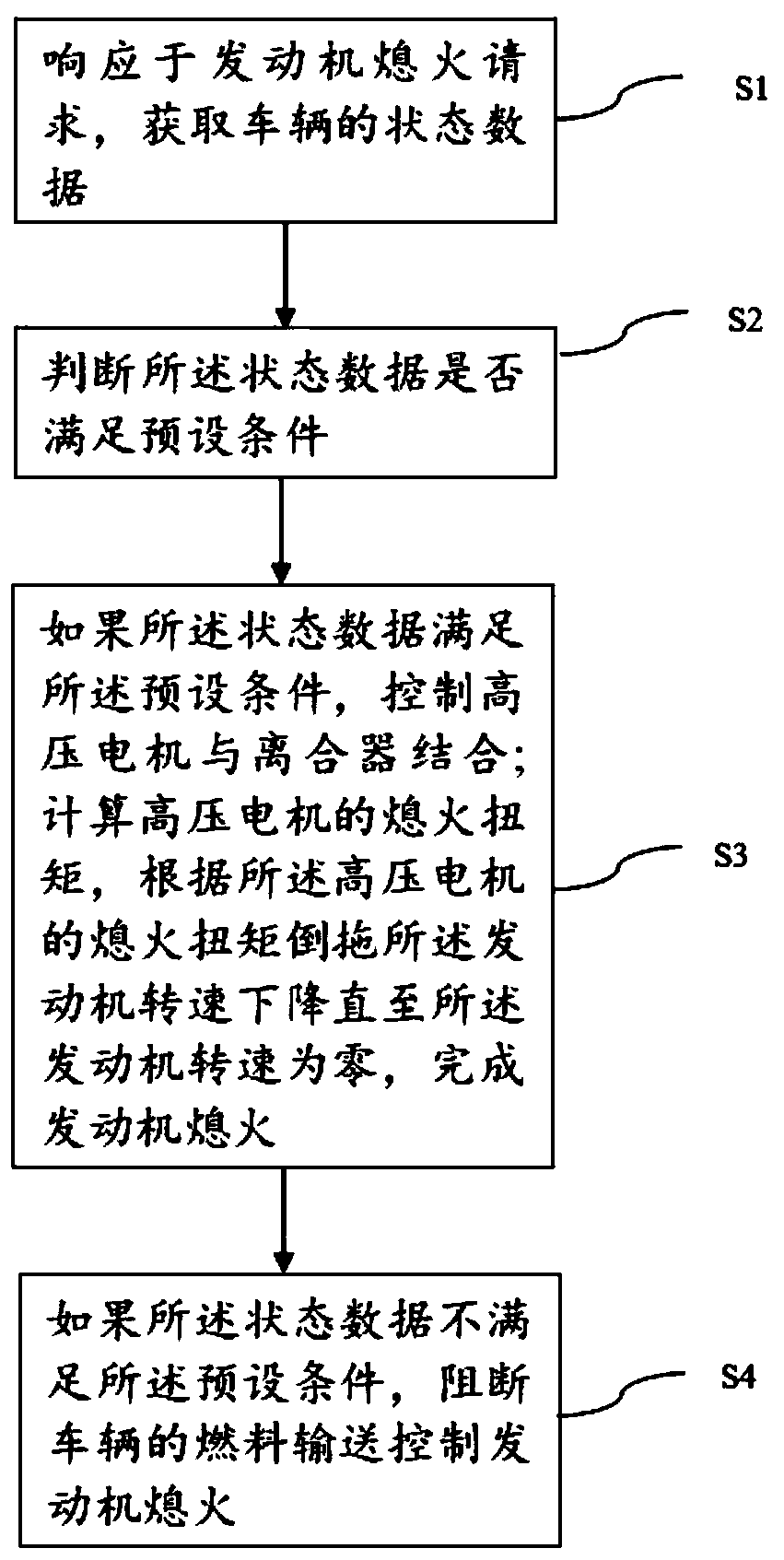

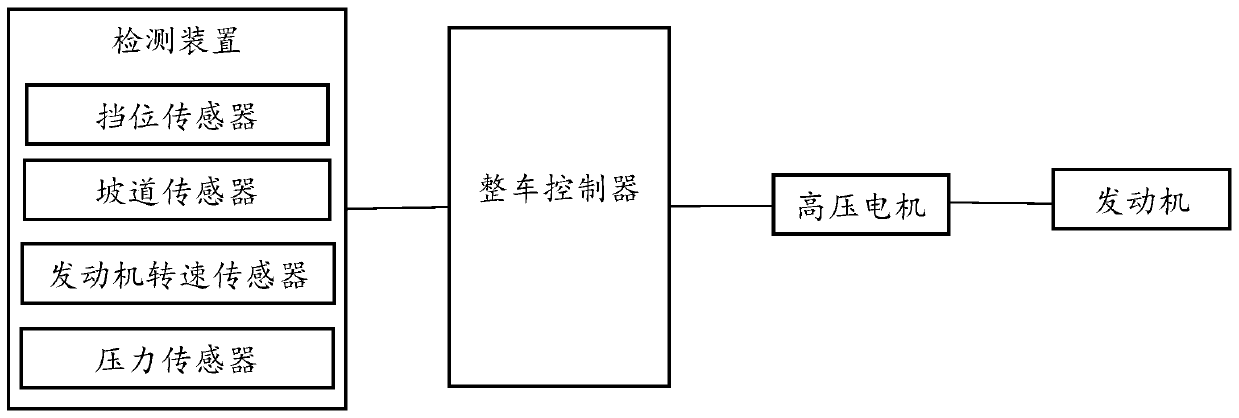

Hybrid vehicle engine stalling control method and system

ActiveCN110103943AIncrease speedImprove impact performanceHybrid vehiclesExternal condition input parametersHigh pressureHybrid vehicle

The invention discloses a hybrid vehicle engine stalling control method and system. The hybrid vehicle engine stalling control method comprises the following steps of responding to an engine stallingrequest to obtain state data of a vehicle; judging whether the state data satisfy a preset condition or not; if the state data satisfy the preset condition, controlling a high voltage motor to be combined with a clutch; calculating a stalling torque of the high voltage motor; reversely towing an engine to enable an engine rotation speed to descend till the engine rotation speed is zero according to the stalling torque of the high voltage motor so as to finish engine stalling; and if the state data do not satisfy the preset condition, blocking the fuel transmission of the vehicle to control theengine to stall. According to the hybrid vehicle engine stalling control method and system, by using the high voltage motor to tow the engine during stalling, the engine rotation speed is rapidly reduced to 0 so that the stalling process is more smooth; and meanwhile, the high voltage motor reversely tows the engine when the engine stalls, the process is equivalent to that the engine outputs an output torque to charge a battery, and therefore, a small quantity of kinetic energy can be recovered, and the cost can be saved.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

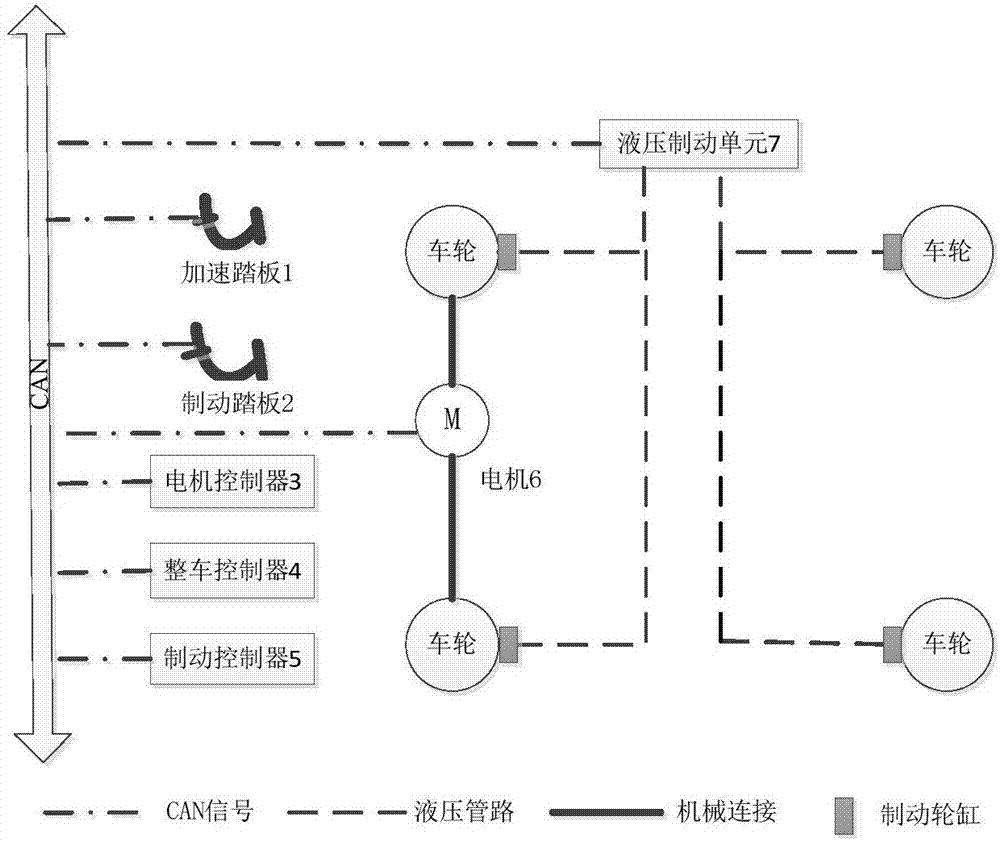

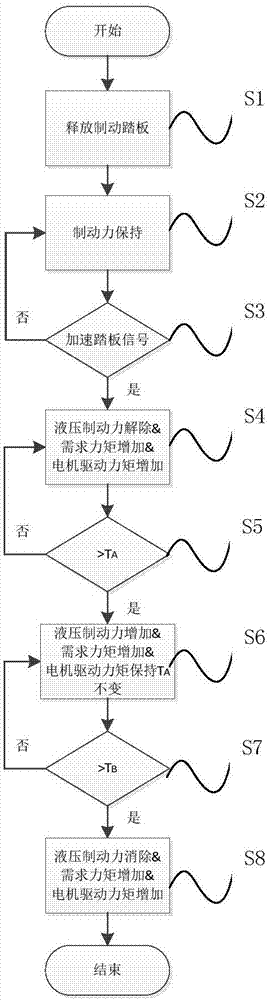

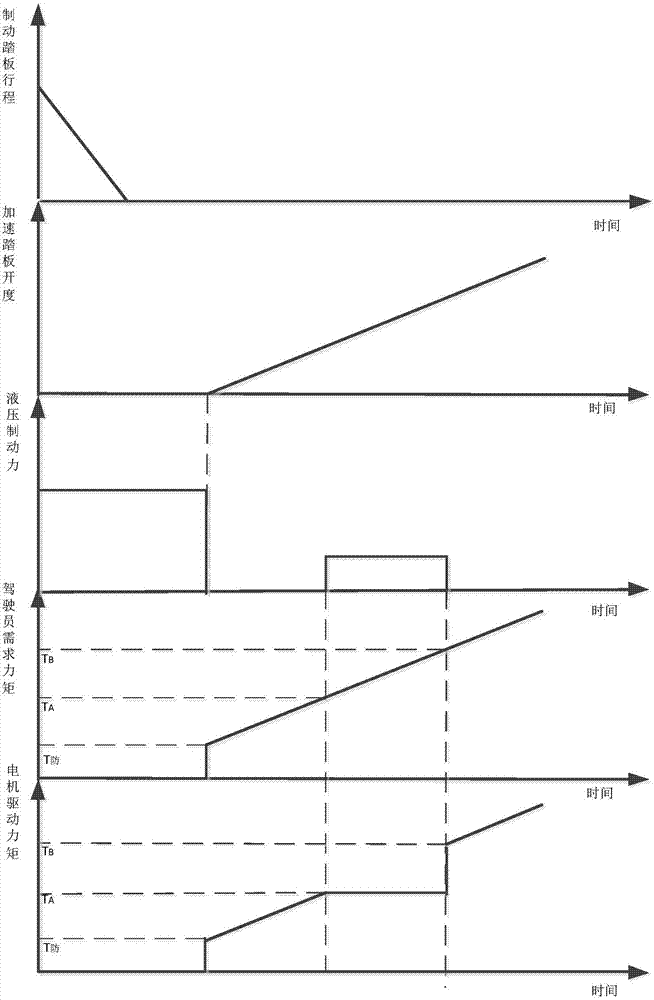

Electric automobile slope starting auxiliary control device

ActiveCN106904158AAvoid stallingNo start shockSpeed controllerElectric energy managementDriver/operatorMotor drive

The invention provides an electric automobile slope starting auxiliary control device, which comprises the following steps that in the slope starting process, a vehicle keeps still under the hydraulic braking force effect before an acceleration pedal is pedaled down; after an acceleration pedal is pedaled down, the driver requiring torque is increased along with the opening degree increase of the acceleration pedal; when the driver requiring torque is greater than the motor allowable long-time stalling torque, and the vehicle still cannot advance, the motor driving torque cannot be increased along with the driver requiring torque; the torque keeps unchanged; meanwhile, the hydraulic braking force is subjected to dynamic compensation control; the vehicle keeps still under the combined effect of the motor driving torque and the hydraulic braking force; when the driver requiring torque is greater than the vehicle running resistance, the motor driving torque is increased to be identical to the driver requiring torque so as to drive the vehicle to run. The control method provided by the invention has the advantages that no impact of the automobile in the starting process is ensured; the adverse influence on a motor is avoided.

Owner:CHINA FIRST AUTOMOBILE

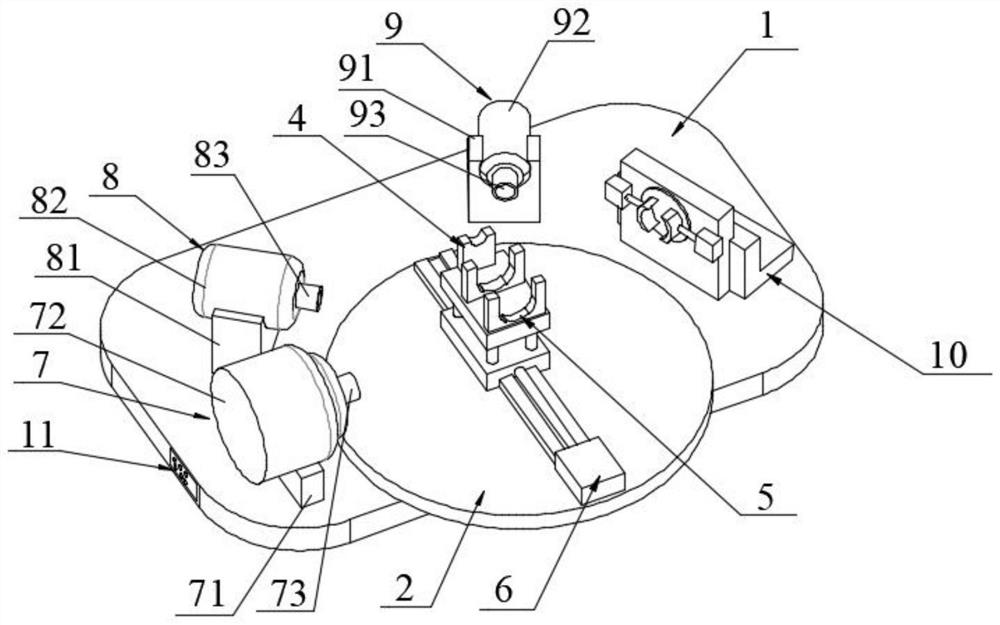

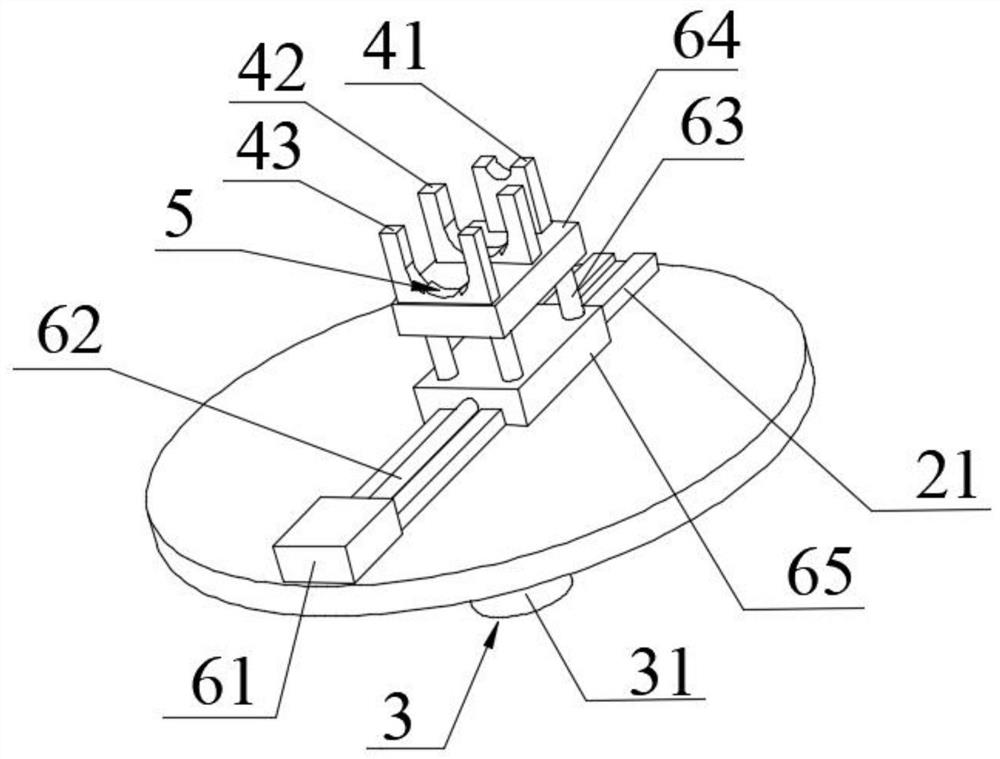

Test device and method for automobile power assembly

InactiveCN112098115AReduce labor inputAccurate detectionVehicle testingMeasurement instrument housingNew energyMotor vibration

The invention relates to the technical field of new energy automobiles, in particular to a test device and method for an automobile power assembly. The device comprises a machine platform, a rotatingdisc disposed on the machine platform, and a rotating disc driving mechanism used for driving the rotating disc to rotate intermittently, wherein the rotating disc is provided with a motor clamp; a vibration detection mechanism disposed on the motor clamp; a clamp driving device used for driving the motor clamp to move; a no-load detection mechanism, a load detection mechanism, a torque detectionmechanism and a locked-rotor torque detection mechanism which are sequentially arranged around the rotary disc, wherein a controller is arranged on one side of the machine table. After the motor in the automobile power assembly is clamped once, motor no-load, motor load, motor torque, motor stalling torque and motor vibration of the motor are automatically detected, a detection report is automatically generated after detection, labor investment is reduced, detection is accurate, and production requirements are met.

Owner:云动(上海)汽车技术有限公司

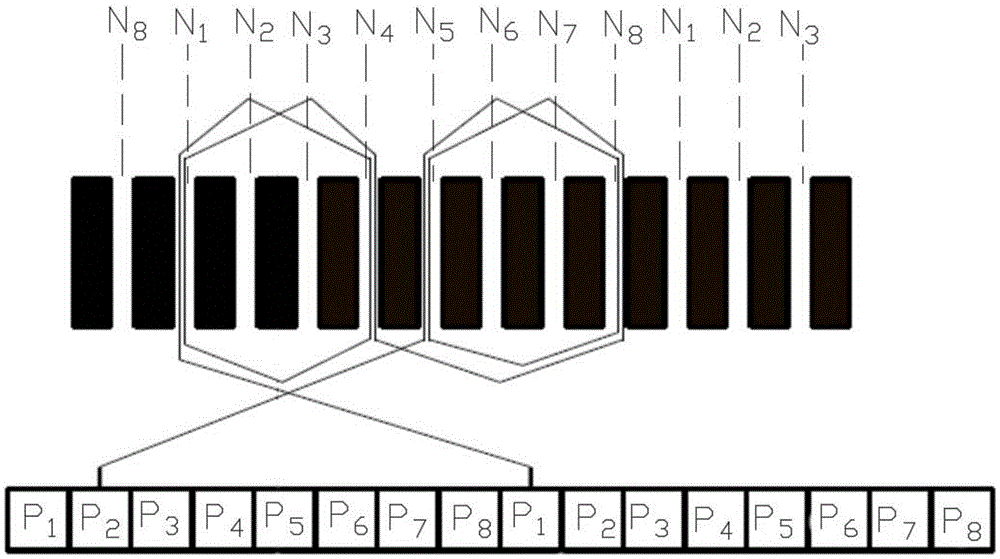

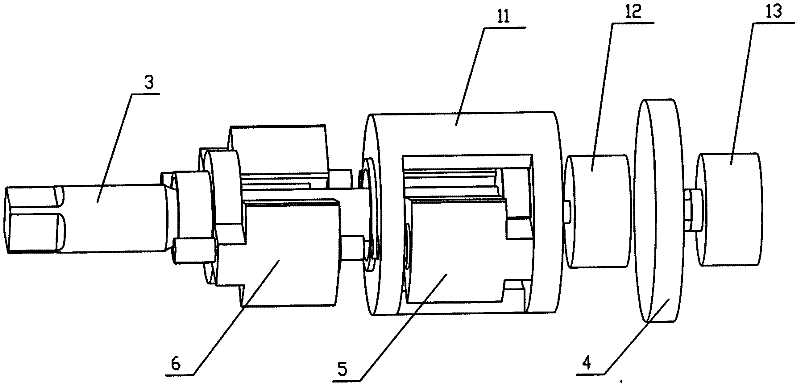

Motor rotor winding method

ActiveCN105634219ASmall stall torque deviationReduce energy lossManufacturing dynamo-electric machinesElectric machineMagnetic poles

The invention discloses a motor rotor winding method, which comprises a rotor rotating shaft, an insulating sleeve and a coil, wherein the insulating sleeve and the coil sleeve the rotor rotating shaft; the insulating sleeve is sequentially sleeved with a commutator and a winding skeleton; a magnetic pole group is arranged on the outer side surface of the winding skeleton; eight line through grooves are sequentially arranged on the winding skeleton along the circumference; the line through grooves are sequentially numbered N1, N2, N3, N4, N5, N6, N7 and N8 along the circumference; the commutator is sequentially provided with eight brass hooks along the circumference; the brass hooks are sequentially numbered P1, P2, P3, P4, P5, P6, P7 and P8 along the circumference; an included angles between the central line of an armature stack and the central line of the corresponding commutator is 4.5-8.5 degrees; the central line of the commutator is close to a left pole end of a rotor. By double groove-crossing, double groove-crossing is required for each winding of each hook, so that the resistance of a motor rotor winding is evenly distributed; the stalling torque deviation of the motor is relatively small; the energy loss of the motor is reduced; and the service lifetime of the motor is prolonged.

Owner:HAIAN LIANKE AUTOMOBILE PARTS

Online synchronous test device and method for dynamic/static torque of motor

ActiveCN106017758AHigh measurement accuracyHigh accuracy of resultsWork measurementTorque measurementVibration accelerationPower flow

The invention provides an online synchronous test device and method for the dynamic / static torque of a motor. The test device comprises an installation support arranged on a rigid base, the end portion of the tested motor is placed on the installation support horizontally, a force sensor is rigidly connected between the end portion of the tested motor and the installation support, and an output shaft of the measured motor is connected to a magnetic powder brake, fixed on the rigid base, via a shaft coupling. A signal collector measures the tangential force in an end cap of the motor and the vibration acceleration of the motor body, the tangential force is multiplied by an action moment arm to obtain the dynamic / static torque of the motor, and voltage and current of the motor are tested synchronously to calculate the torque of the motor. The current of the magnetic powder brake is adjusted to obtain different load conditions, and further the dynamic / static torque of the motor in different loads can be measured. The test device and method can be used to test the dynamic / static torques for realizing zero load, loads and different external imbalance forces of the motor.

Owner:HARBIN ENG UNIV

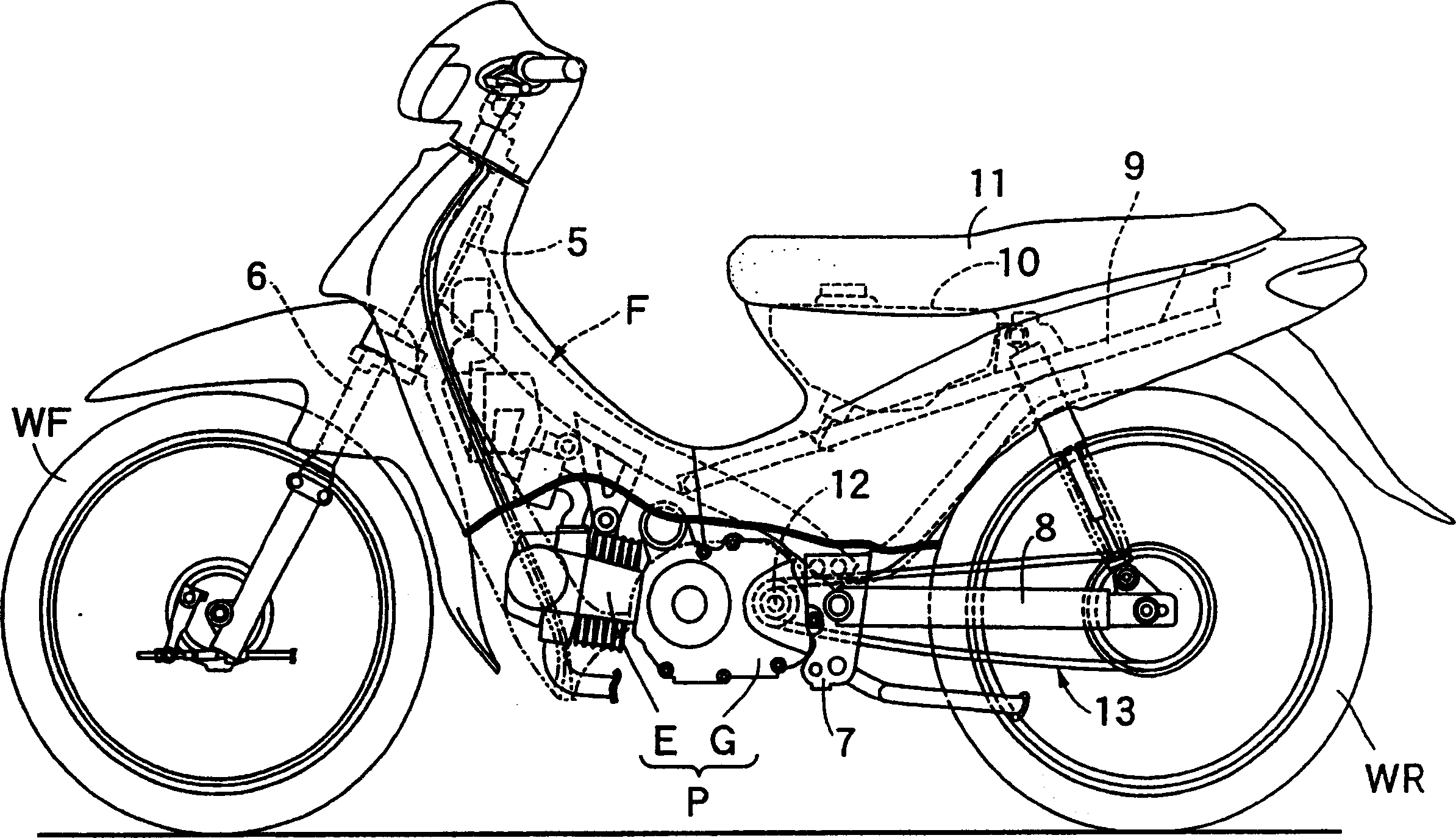

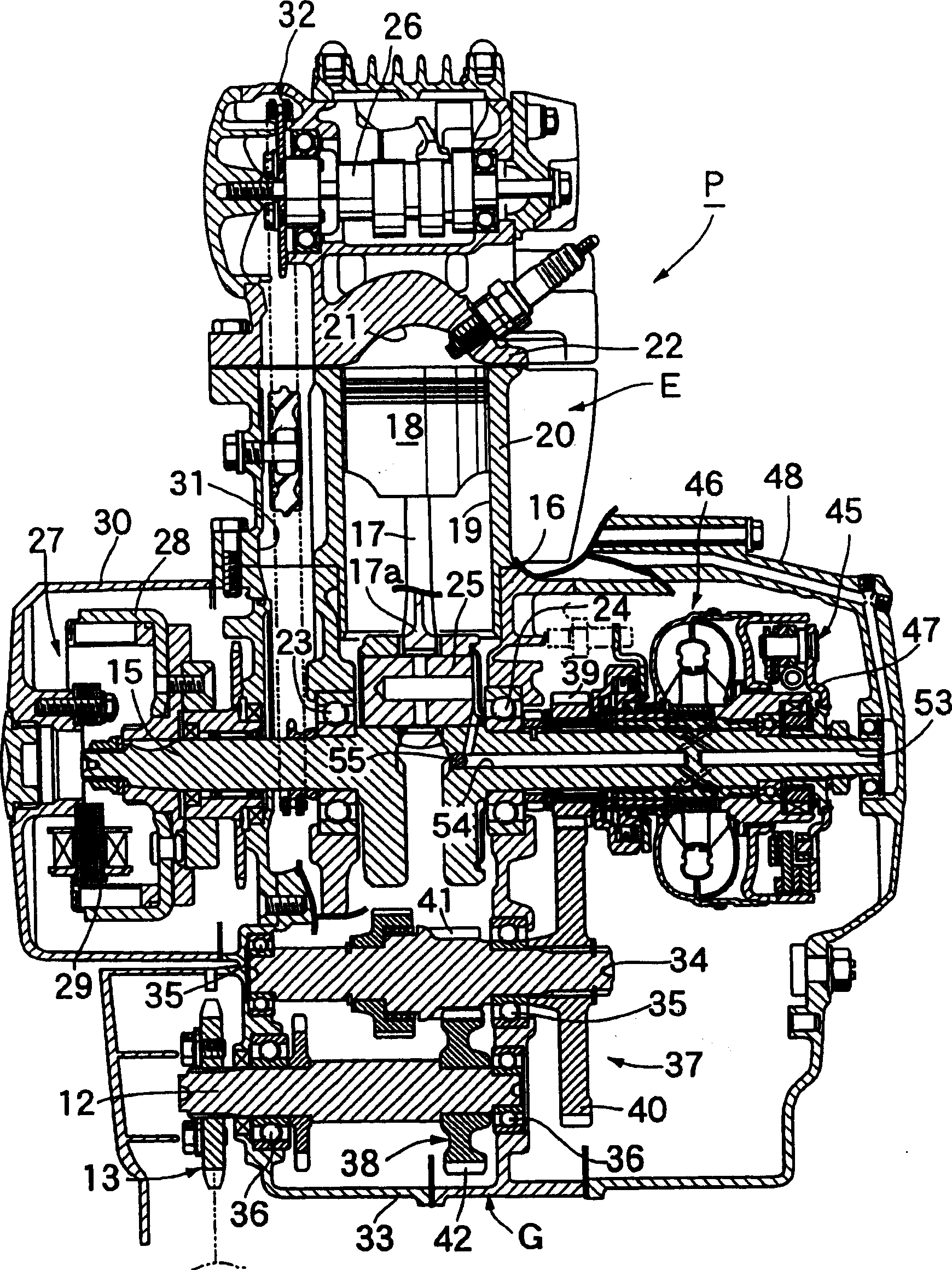

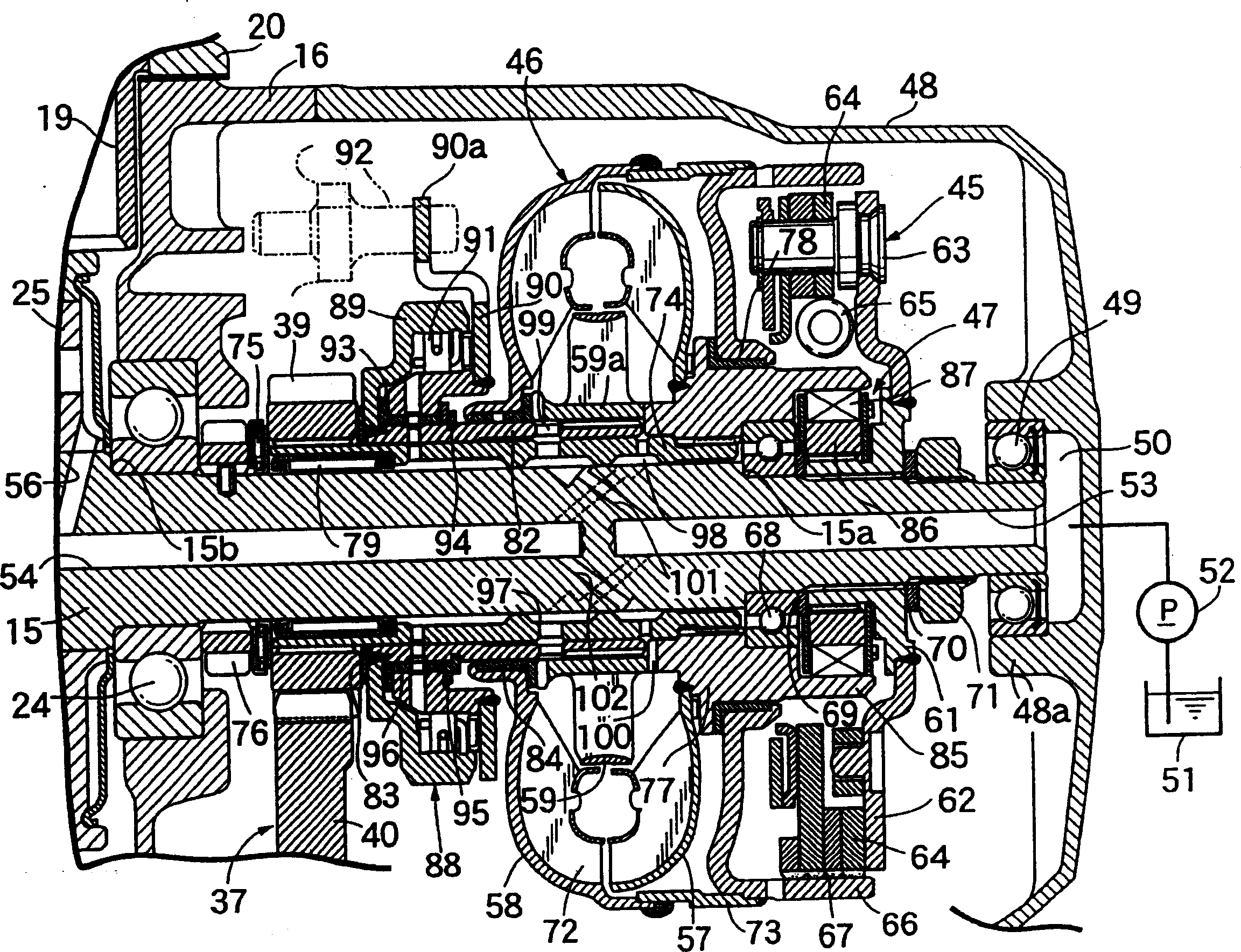

Transmission gear

InactiveCN1730981AImprove transfer efficiencyAccess miniaturizationFluid gearingsControl devicesRotational axisImpeller

The present invention refers to a transmission device comprising an oil passage for supplying oil to a stalling torque converter, where a turbine rotor, a pump rotor, and a stator rotor are supported on a rotating axis and on a passage for discharging oil, said passage leading the oil discharged from the converter. The turbine, pump and stator rotors are axially arranged with regard to the rotary axis and spaced therebetween. The flow resistance can be avoided by ensuring a continuous oil flow at the front and rear portion of the converter, thereby improving the efficiency of the converter transmission and increasing the freedom degree in the arrangement. The invention comprises a stalling torque converter 46 attached to the rotary axis 15, where a turbine rotor 57 is placed adjacent the oil supply passage 53; a pump rotor 58 is placed adjacent an oil discharge passage 54; a tilted oil passage is placed adjacent the oil supply passage 101 for leading oil from the oil supply passage 53 to the pump rotor 58, and finally a tilted oil passage is placed adjacent the oil discharge passage 102 for leading the oil discharged from the turbine rotor 57.

Owner:HONDA MOTOR CO LTD

Friction material used for piezoelectric motor and preparation method and application thereof

ActiveCN108359198AIncrease coefficient of frictionHigh hardnessOther chemical processesGlass fiberElectricity

The invention discloses a friction material used for a piezoelectric motor and a preparation method and an application thereof. The friction material comprises the following raw materials: polytetrafluoroethylene, polyether-ether-ketone, polybenzoate, carbon fiber, and glass fiber, wherein the feeding mass ratio of polytetrafluoroethylene to polyether-ether-ketone to polybenzoate to carbon fiber to glass fiber is 4-11: 0.5-3:1:0.5-4:0.5-3; The preparation method comprises the following steps: 1) mixing the raw materials according to a formula amount, drying a mixture, and crushing the mixture;2) performing cold press molding on the processed mixture obtained in the step 1), and demoulding to obtain a friction material prefabricated product; and 3) performing sintering molding on the prefabricated product to obtain the friction material. The invention also provides an application of the friction material in the piezoelectric motor. The friction material can achieve excellent effects onfriction coefficient and hardness, can improve the easy tooth trapping and starting difficulty of the friction material, and increases the stalling torque of the friction material.

Owner:苏州行远精密控制系统有限公司

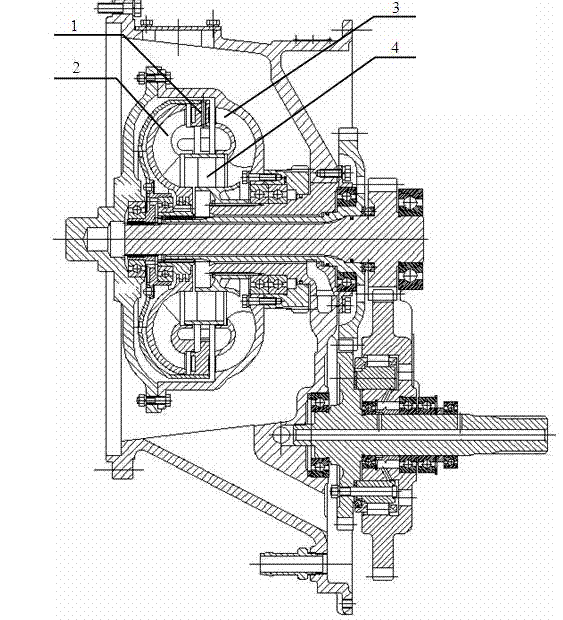

Novel double-turbine hydraulic torque converter

ActiveCN103591244AImprove reliabilityReasonable matching positionFluid gearingsImpellerTurbine blade

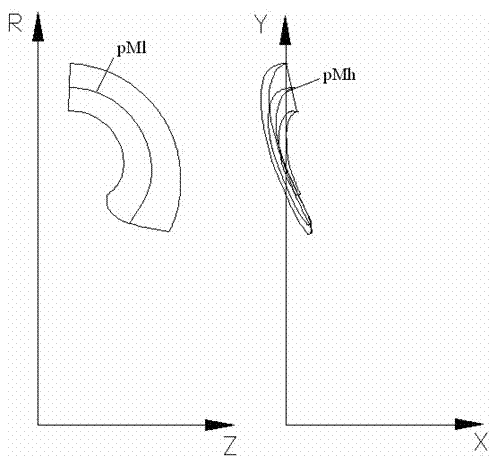

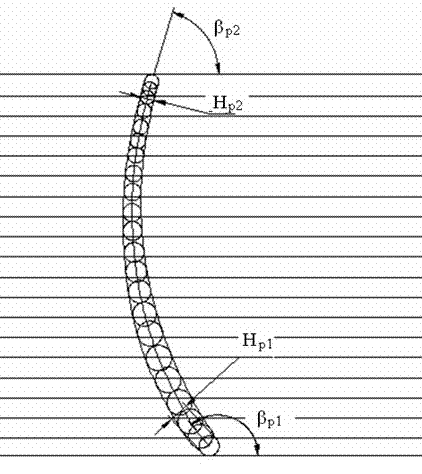

The invention provides a novel double-turbine hydraulic torque converter which is characterized in that the circulating circle diameter D is equal to 288-295mm. In a blade grid system, an intermediate flow line inlet angle beta p1 of a pump impeller blade is equal to 105 degrees-120 degrees, an intermediate flow line outlet angle beta p2 of the pump impeller blade is equal to 70 degrees-80 degrees, the intermediate ring surface inlet side thickness Hp1 of the pump impeller blade is equal to 4.8-5.8mm, and the intermediate ring surface outlet side thickness Hp2 of the pump impeller blade is equal to 2.5-3.5mm; an inlet angle beta1 of a primary turbine blade is equal to 88 degrees-98 degrees, an outlet angle beta2 of the primary turbine blade is equal to 148 degrees-155 degrees, the inlet side round head radius R1 of the primary turbine blade is equal to 4.6-5.6mm, and the outlet side round head radius R2 of the primary turbine blade is equal to 0.8-1.2mm; an intermediate flow line inlet angle beta1 of a secondary turbine blade is equal to 55 degrees-65 degrees, an intermediate flow line outlet angle beta2 of the secondary turbine blade is equal to 130 degrees-140 degrees, the intermediate ring surface inlet side thickness H1 of the secondary turbine blade is equal to 2.5-4.0mm, and the intermediate ring surface outlet side thickness H2 of the secondary turbine blade is equal to 1.5-2.5mm; and an inlet angle betas1 of a guide wheel blade is equal to 72 degrees-80 degrees, an outlet angle betas2 of the guide wheel blade is equal to 30 degrees-38 degrees, the inlet side round head radius Rs1 of the guide wheel blade is equal to 8.8-9.5mm, and the outlet side round head radius Rs2 of the guide wheel blade is equal to 0.6-1.0mm. The novel double-turbine hydraulic torque converter has the advantage that efficiency of a first peak reaches 0.78-0.81, efficiency of a second peak reaches 0.796-0.829, stall torque ratio is 4.05-4.15, pump impeller nominal torque under stall working conditions is 75-80N-m, and reliability, power performance and fuel economy of a whole machine are improved.

Owner:柳工柳州传动件有限公司

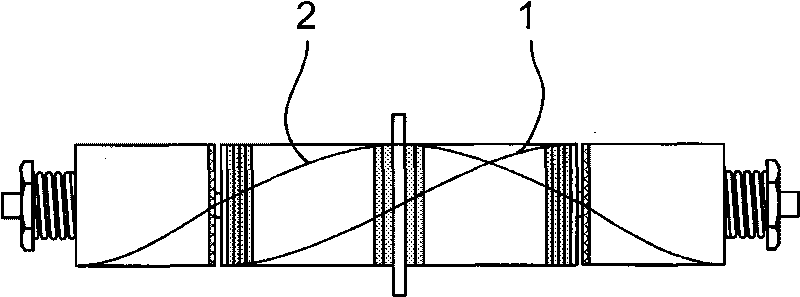

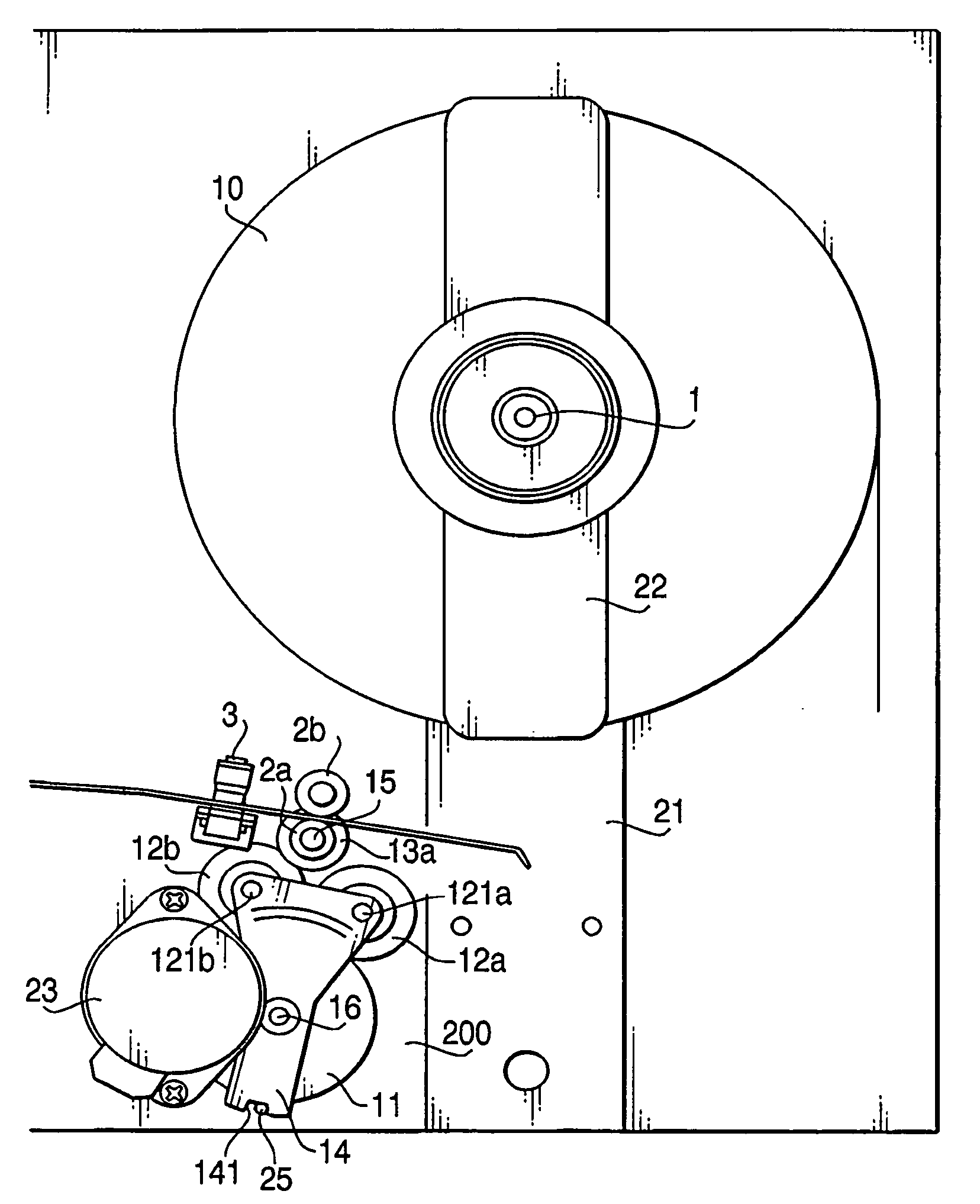

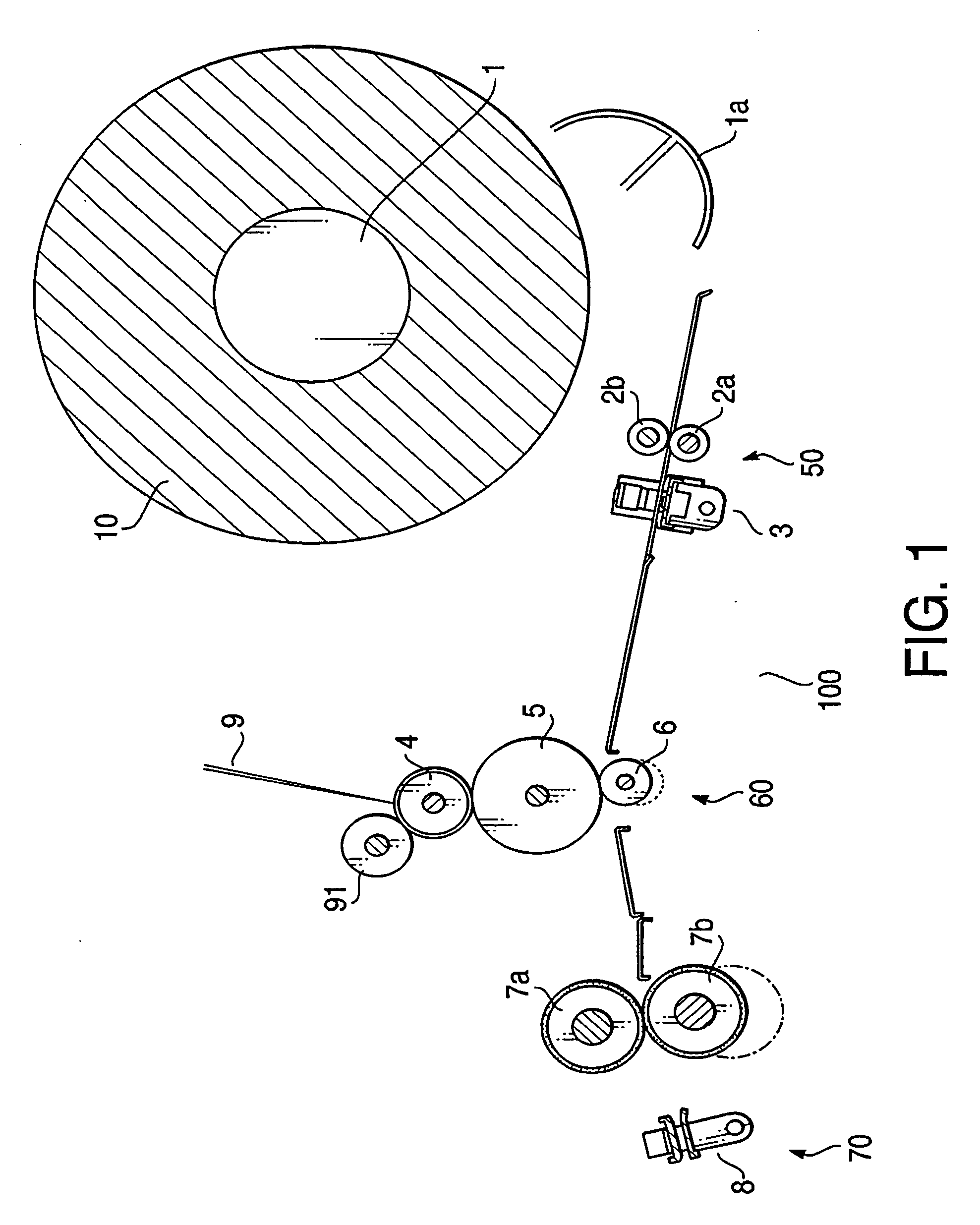

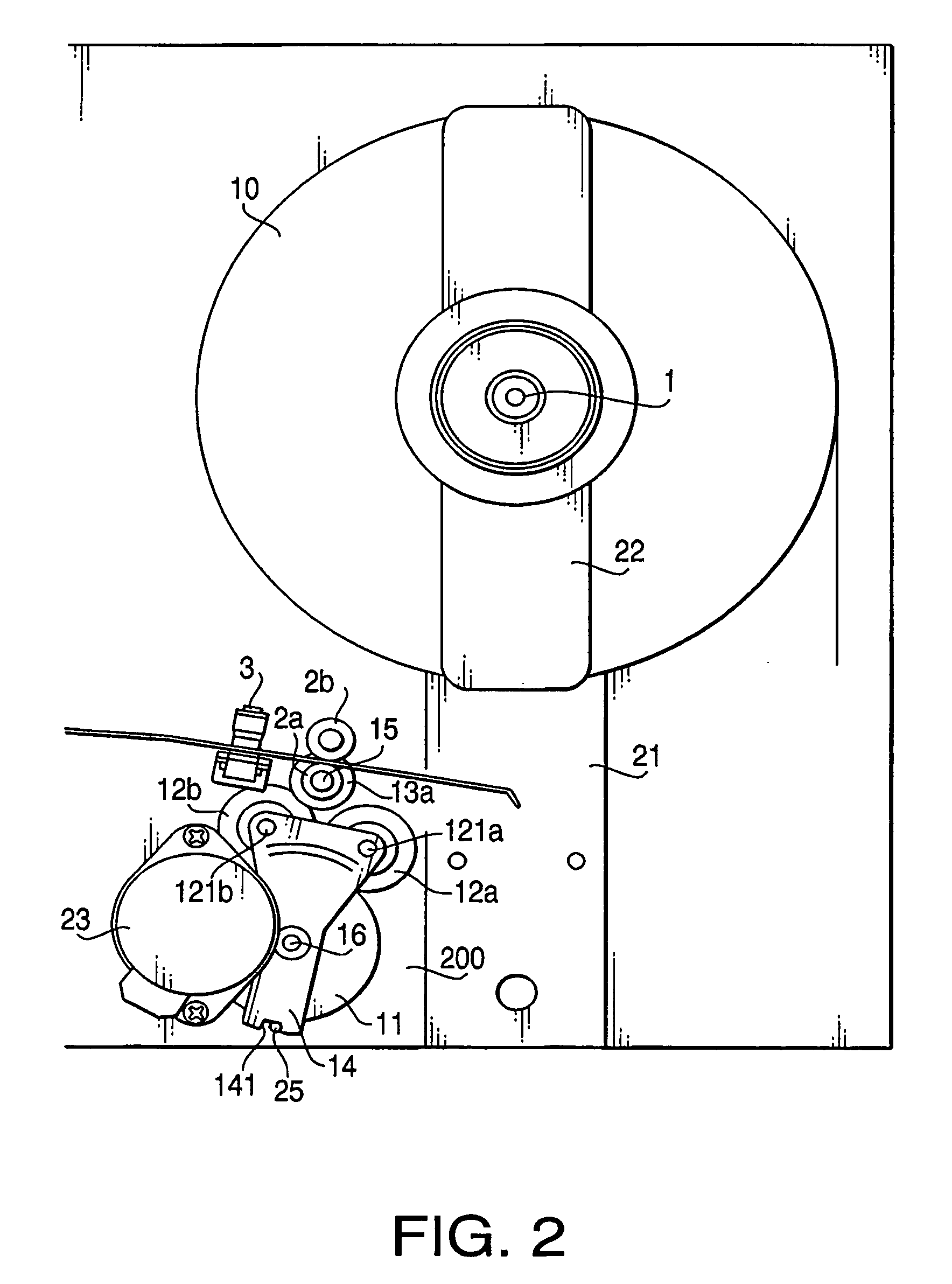

Sheet feeding unit for continuous form recording medium

InactiveUS20060257181A1Prevent looseningRestrict movementElectrographic process apparatusElectric machineEngineering

A feeding unit for a continuous form recording medium, having a feed roller, a drive motor, a first transmitting system, a second transmitting system, is provided. The first transmitting system is adapted to transmit rotating force from the drive motor to the feed roller so that the feed roller is rotated in a normal feeding direction to carry the continuous form recording medium and to allow the feed roller to be rotated in the normal feeding direction by external force. The second transmitting system is adapted to transmit the rotating force from the drive motor to the feed roller so that the feed roller is rotated in a reverse feeding direction. The switching system transmits stalling torque of the drive motor to the feed roller associated by the second transmitting system before and after the continuous form recording medium is processed through an image forming operation.

Owner:ASAHI KOGAKU KOGYO KK

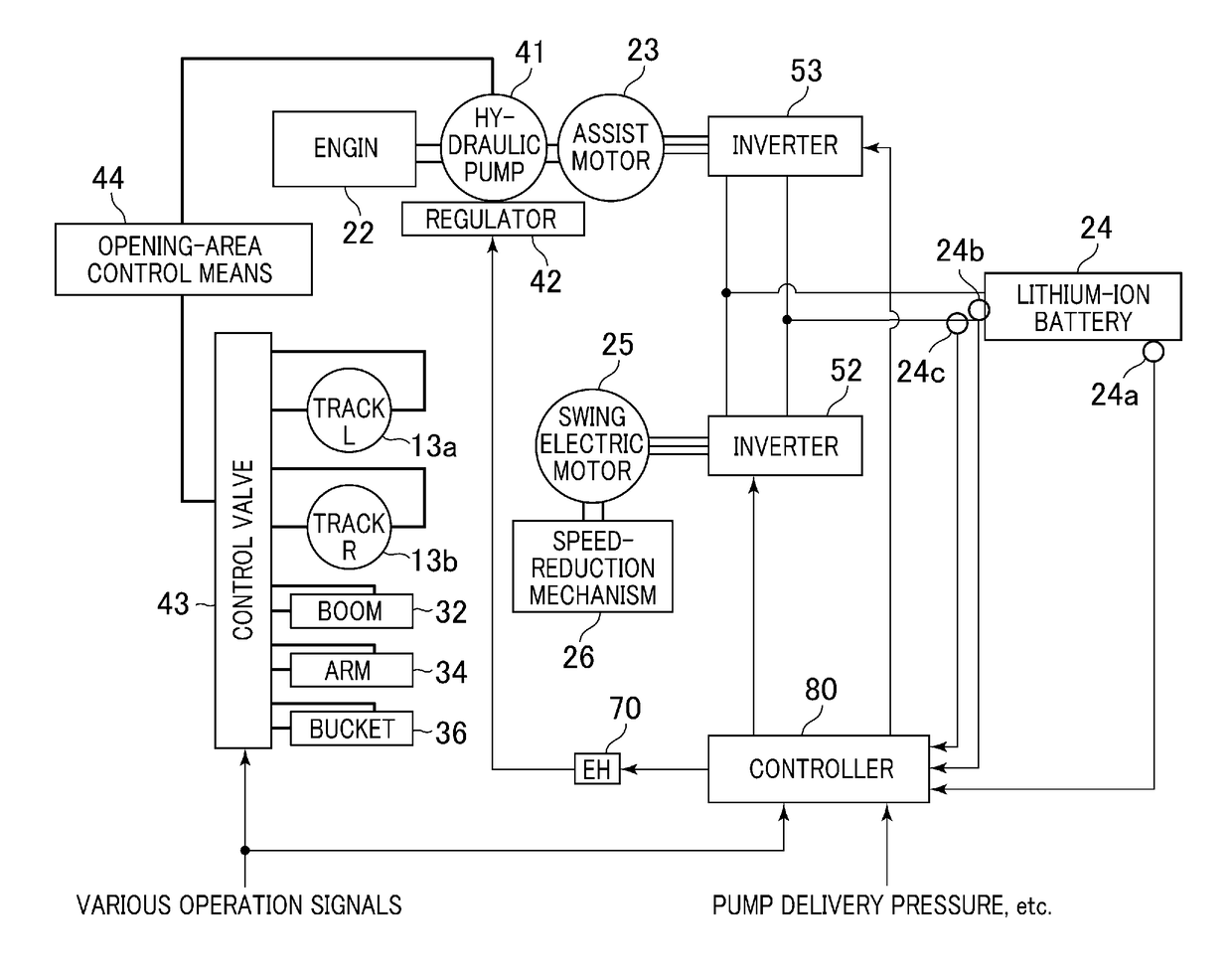

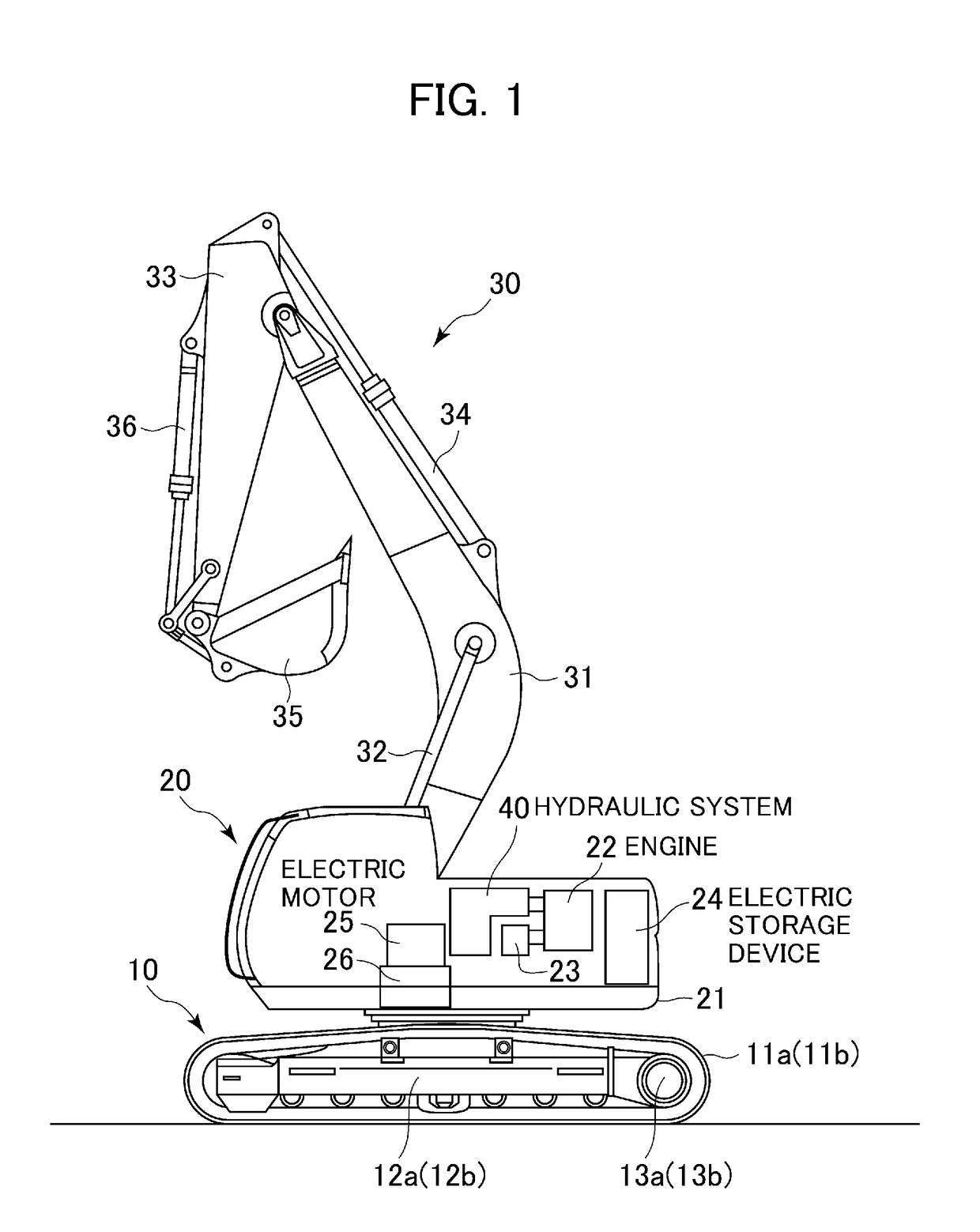

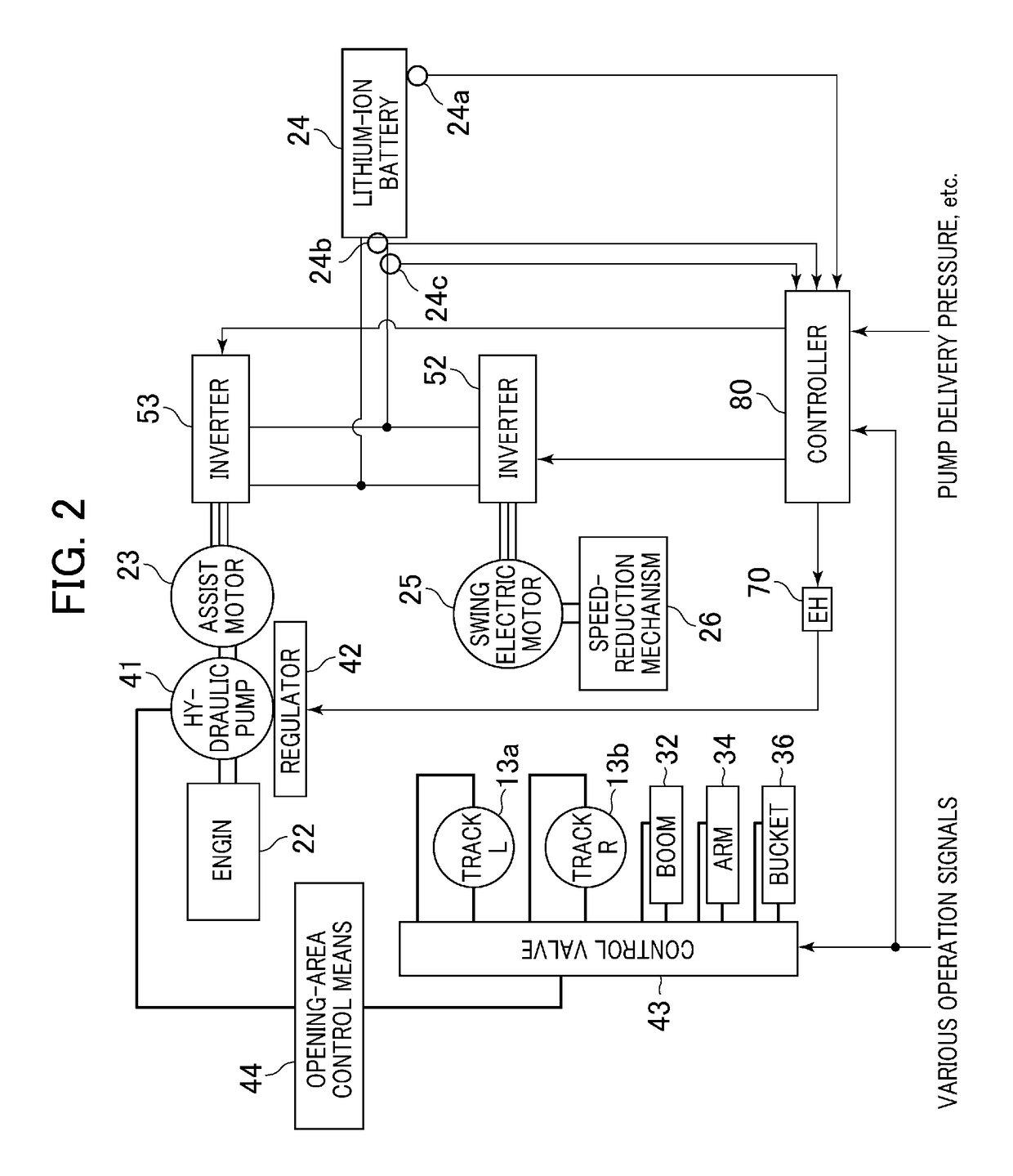

Hybrid Work Machine

ActiveUS20170145658A1InhibitionHybrid vehiclesMechanical machines/dredgersBrake torqueHydraulic pump

Provided is a hybrid work machine capable of performing a warm-up operation on an electric storage device by charging and discharging while suppressing the occurrence of lug-down or over-revolution to an engine. The hybrid work machine includes: an engine; an assist motor mechanically connected to the engine, causing a discharge by generating a drive torque, and generating electric power by generating a brake torque; a hydraulic pump driven by a total torque of the engine and the assist motor; an electric storage device storing the electric power generated by the assist motor and supplying the electric power when the assist motor is discharged; and a controller outputting a torque command signal in order to control the drive torque or the brake torque of the assist motor. The hybrid work machine further includes a torque-command-value arithmetic unit calculating a hydraulic pump torque necessary to drive the hydraulic pump, and calculating the torque command signal that is equal to or lower than a value obtained by subtracting a preset minimum torque of the engine from the hydraulic pump torque.

Owner:HITACHI CONSTR MASCH CO LTD

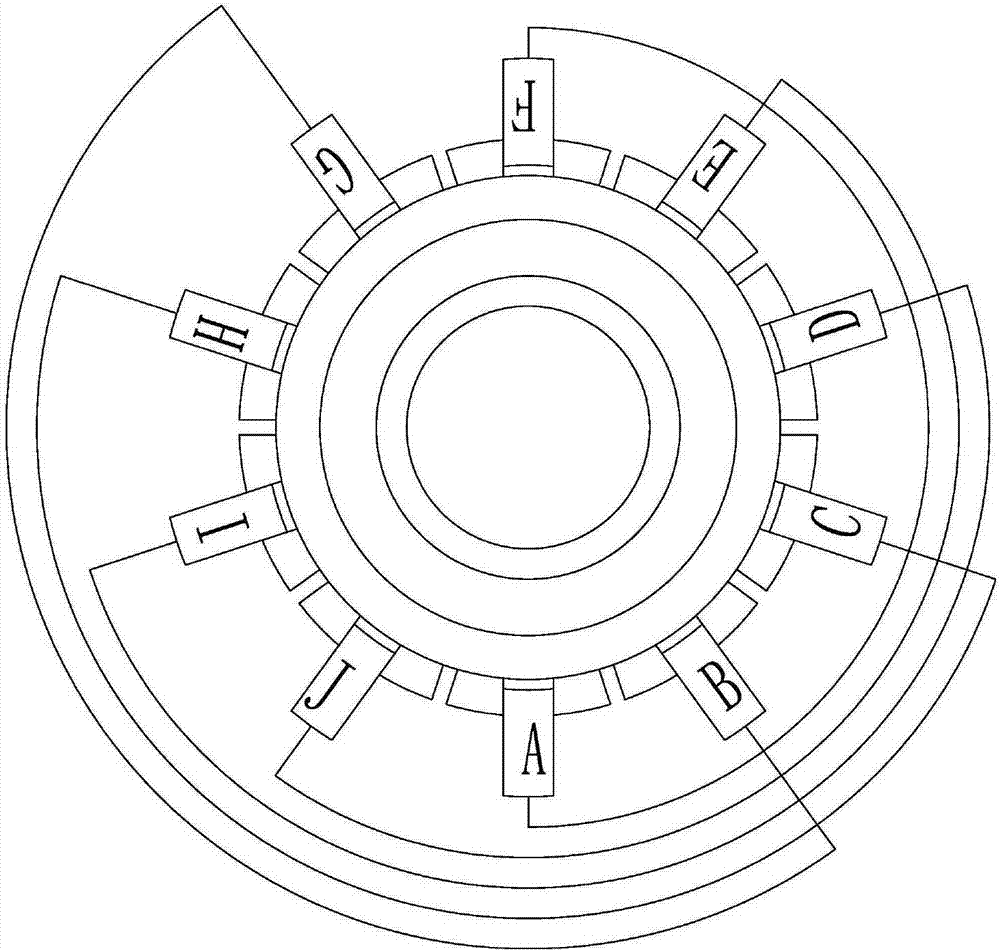

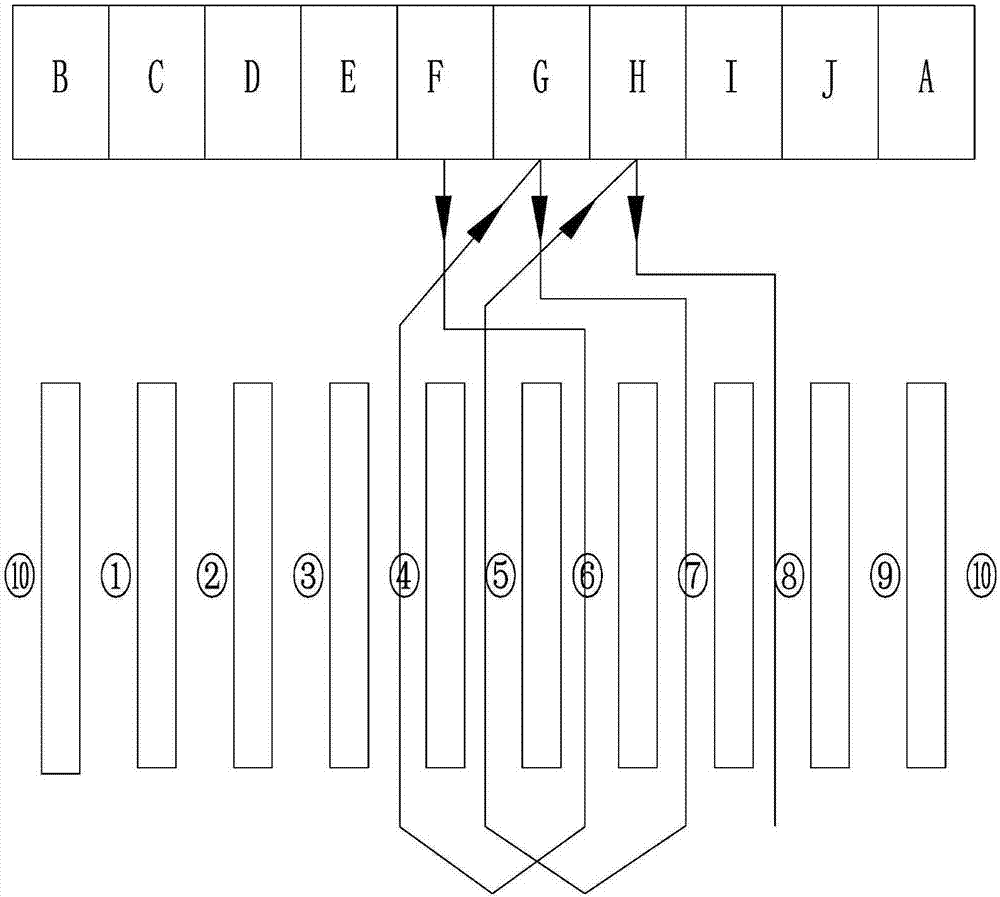

Winding method of motor rotor

InactiveCN107070140AIncrease stall torqueImprove electromagnetic compatibilityManufacturing dynamo-electric machinesEngineeringControl theory

The invention discloses a winding method for a motor rotor. The winding of a rotor has four steps: in a step S1, a wire segment is wound around the rotating shaft of the motor for 360 DEG, then is hung on a winding hook F on a commutator of the motor rotor, and is hang on a winding hook A after winding along the rotation shaft of the motor for 180 DEG; in a step S2, a tail wire segment is wound into a silicon steel groove (4) from a starting winding groove, and is wound around the rotation shaft of the motor for 360 DEG, then is hung on a winding hook G after winding, then rotates along the rotation shaft of the motor for 180 DEG and is hung on a winding hook B, and then is wound along the motor shaft of the motor for 180 DEG and hung into a silicon steel groove (7), and the relative position of the silicon steel groove (7) in the starting winding groove is the same as the relative position of the winding hook G in the winding hook F. Compared with the prior art, the method improves the stall torque of the motor, so that the starting speed of the motor is fast, the starting current is small. Meanwhile, the voltage of the motor is stable in the process of commutation, commutation sparks are avoided, and the motor electromagnetic compatibility is improved.

Owner:重庆奥兴嘉科技有限公司

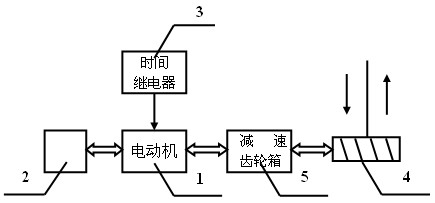

Automatic ship mooring machine and mooring rope tension setting method

InactiveCN101966866AImprove safety and reliabilityReduce labor intensityMooring equipmentDC - Direct currentControl engineering

The invention relates to an automatic ship mooring machine and a mooring rope tension setting method. The automatic ship mooring machine comprises an electromotor, a mooring rope and a time relay, wherein the non drive end of the electromotor is provided with a direct current (DC) electromagnetic brake; the electromotor is connected with the mooring rope through a reduction gear box; and the electromotor is electrically connected with the time relay and is intermittently started under the control of the time relay. The automatic ship mooring machine and the mooring rope tension setting method realize automatic ship mooring through intermittent start operation by setting the stall torque of the electromotor as a tension detection setting value, improve safety and reliability of ships and reduce labor intensity of crews.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP

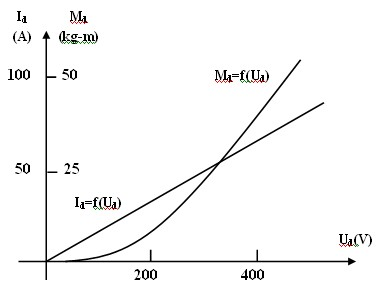

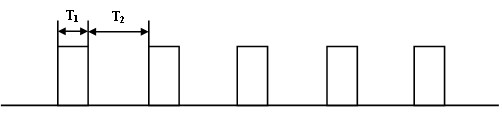

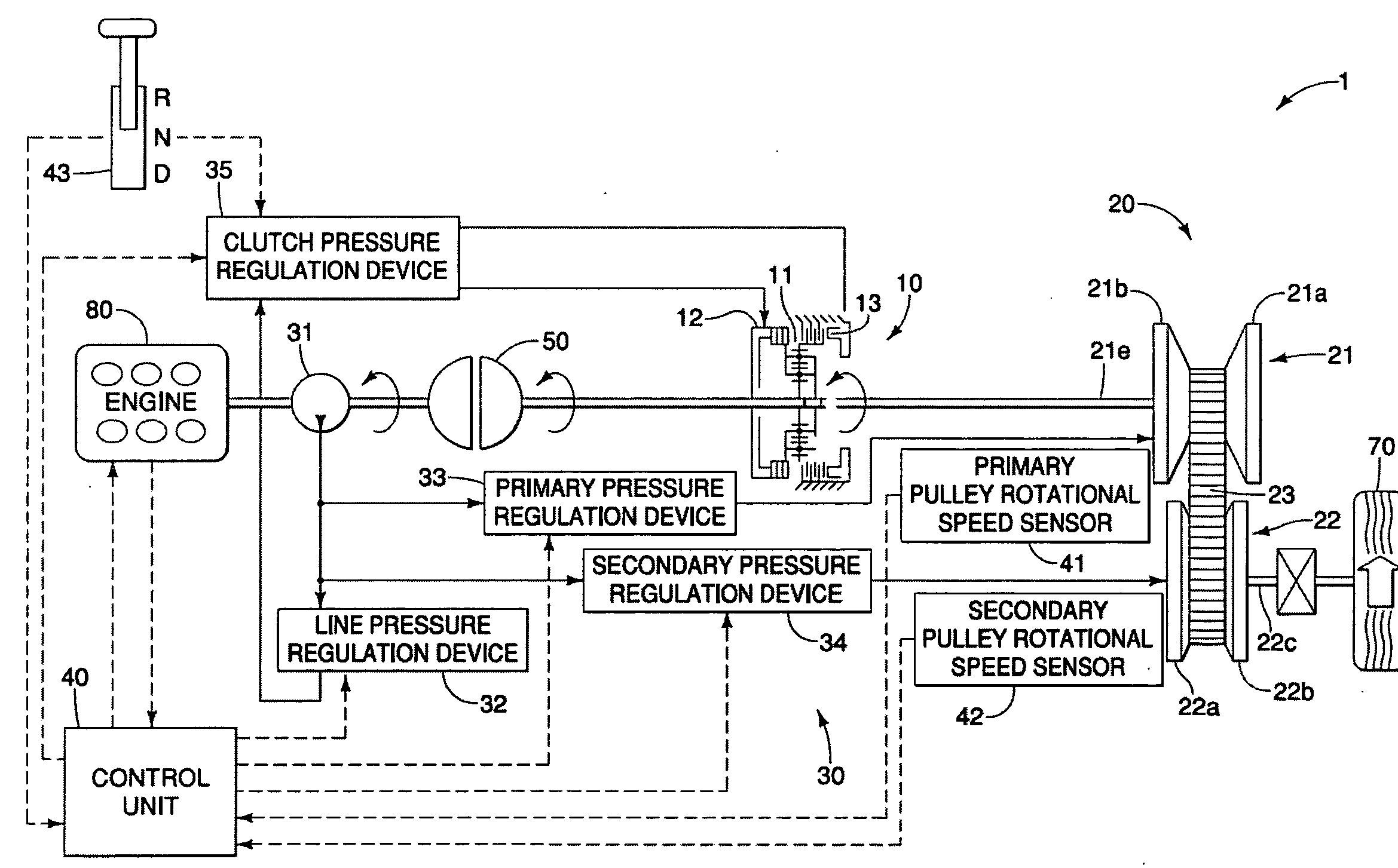

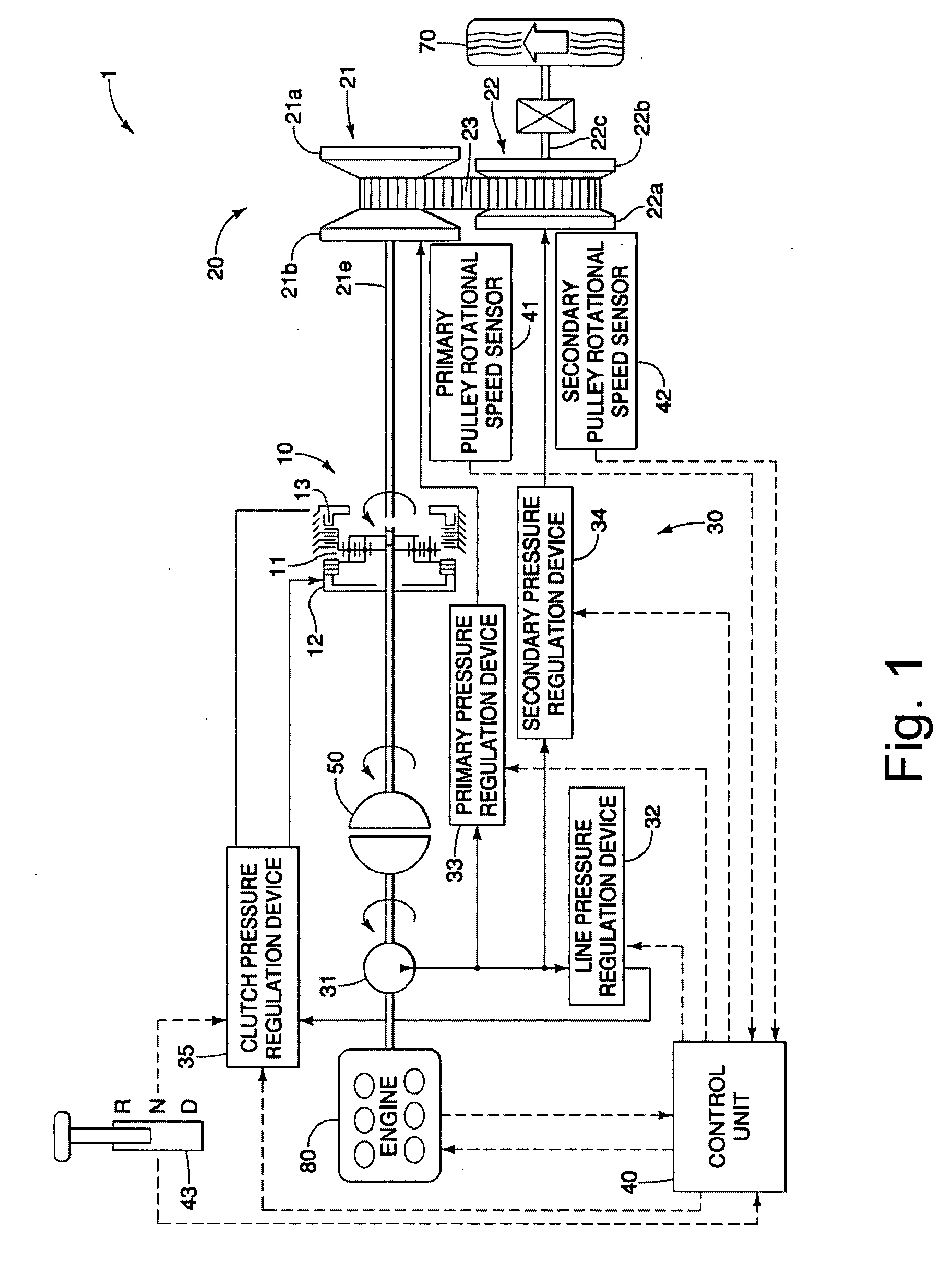

Torque control device for continuously variable transmission

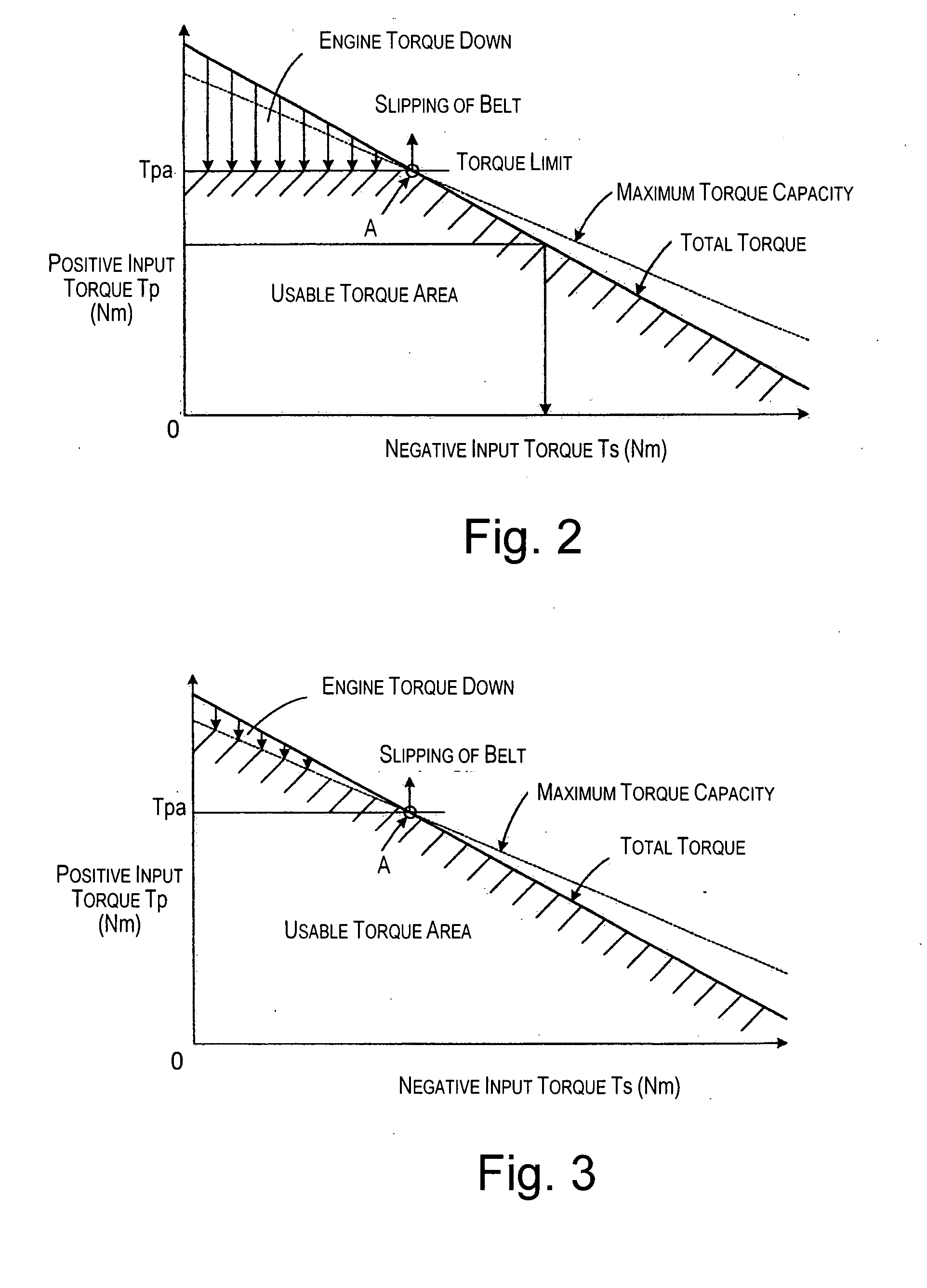

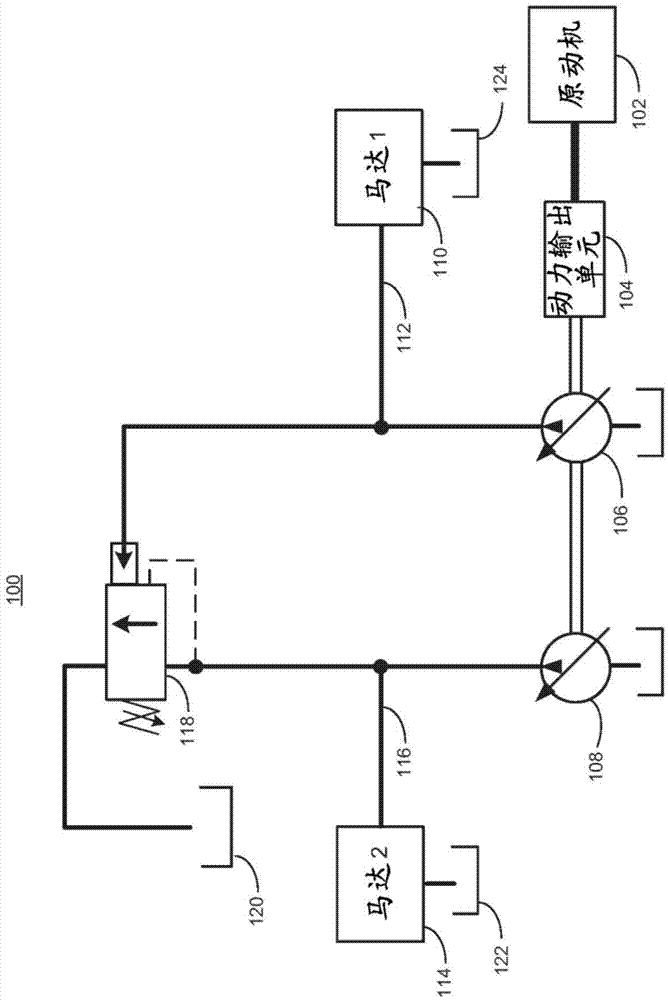

InactiveUS20070203631A1Short response timePrevent slippingDigital data processing detailsGearingDrive wheelControl theory

A torque control device is provided to prevent slipping of a belt of a belt type continuously variable transmission. The torque control device calculates a positive input torque inputted from an engine to a primary pulley, and calculates a negative input torque inputted from a drive wheel to the primary pulley based on the positive input torque and a speed ratio of a continuously variable section. The torque control device then restricts an output torque from the engine so that the total torque can be lower than or equal to the torque capacity of the belt when the vehicle is in a running state in which the negative input torque is likely to occur and the total torque which is the sum of the positive input torque and the negative input torque exceeds the torque capacity.

Owner:JATCO LTD

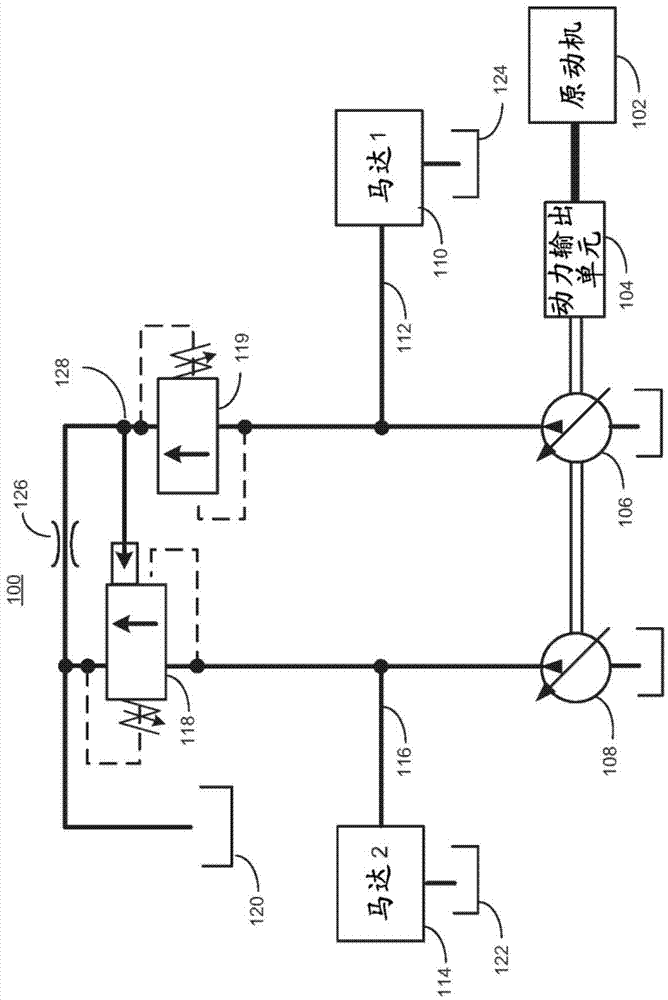

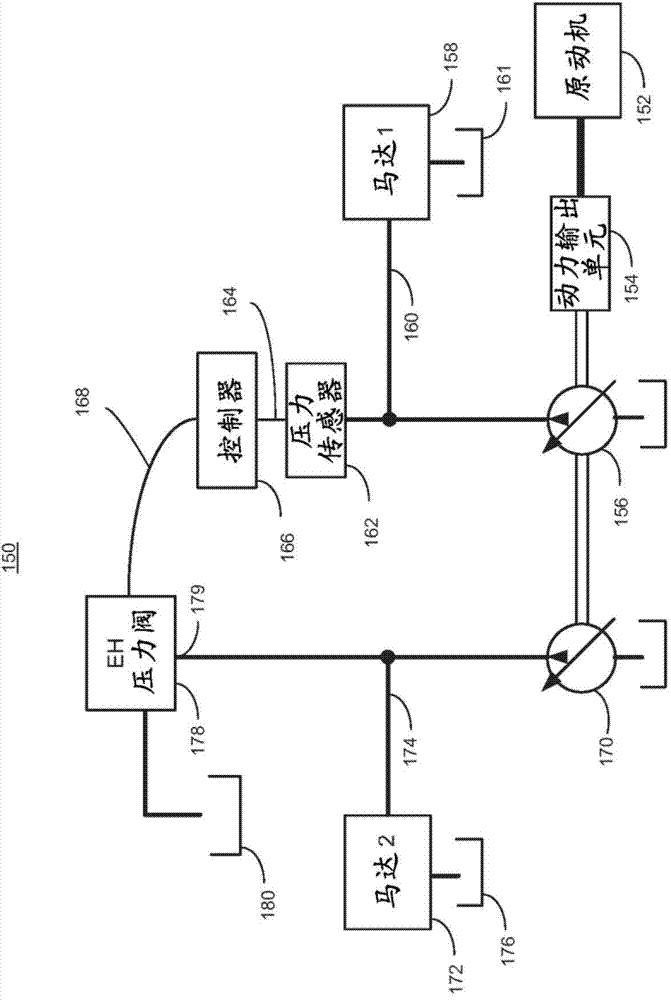

Torque limit control

A prime mover transfers power to a separate hydraulic circuits via a power take off (PTO). In some situations, a peak torque demand in one of the hydraulic circuits may cause the total torque of all hydraulic circuits to exceed a rated torque at the PTO. An apparatus measures hydraulic fluid pressure in a first hydraulic circuit and adjusts the hydraulic fluid pressure in a second hydraulic circuit. Because pressure is directly correlated to torque at a pump, by adjusting the pressure in the second circuit based on the current pressure in the first hydraulic circuit, the total torque may be capped below the maximum torque rating at the PTO. The first hydraulic circuit may have a higher priority function, such as steering, compared to that of the second hydraulic circuit which may, for example, power a tool.

Owner:CATERPILLAR PAVING PROD INC

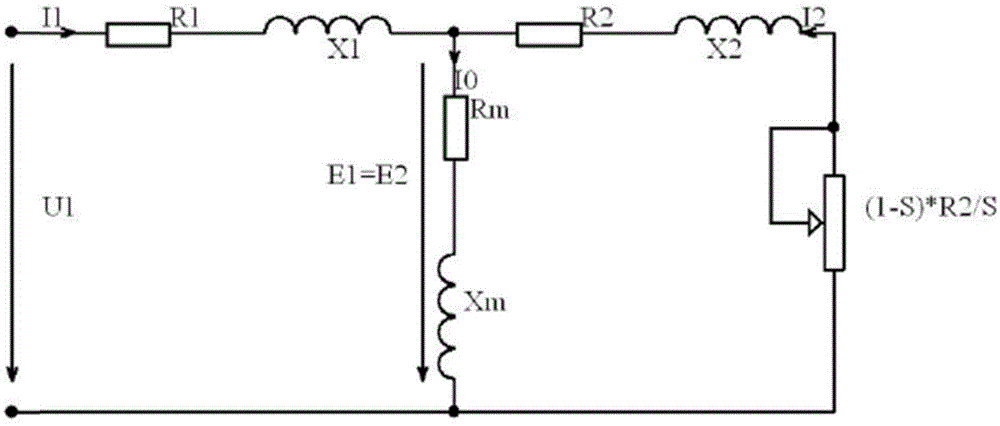

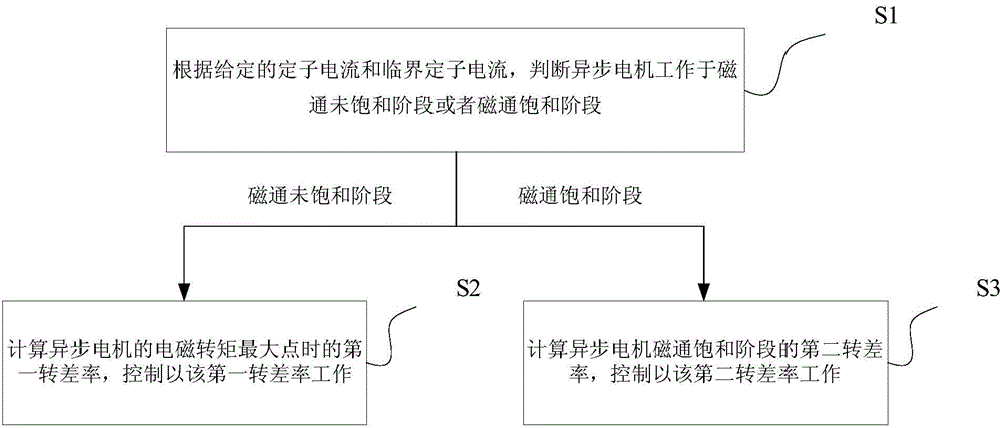

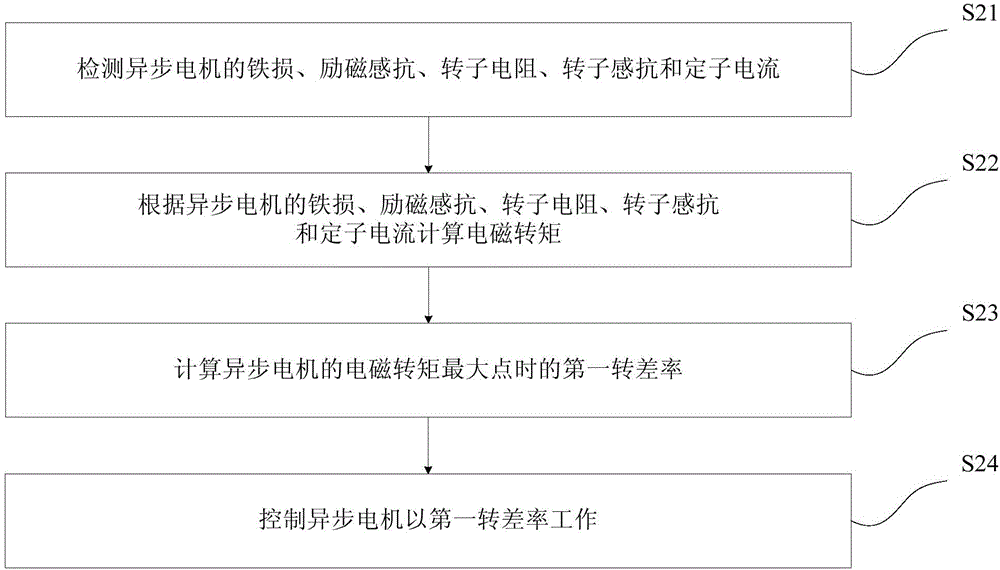

Asynchronous motor control method

InactiveCN104158466AImprove efficiencyIncrease profitMotor parameters estimation/adaptationMaximum torqueExcitation current

An asynchronous motor control method provided by the present invention comprises the following steps of S1, determining an asynchronous motor works at a magnetic flux unsaturation stage or a magnetic flux saturation stage according to a given stator current and a critical stator current; S2 obtaining a first slip ratio of the asynchronous motor at a maximum electromagnetic torque point, and controlling the asynchronous motor to work at the first slip ratio at the magnetic flux unsaturation stage; S3 calculating a second slip ratio of the asynchronous motor at the magnetic flux saturation stage, and controlling the asynchronous motor to work at the second slip ratio at the magnetic flux saturation stage. According to the present invention, and under a light load small torque, a field current is adjusted dynamically, so that the matching of the field current and a rotor current is at a maximum torque point, at the same time, the maximum torque point is basically an optimum electromagnetic torque point, and accordingly, the energy utilization rate is improved, namely, the efficiency of the motor is improved under the small torque. The method enables the power supply energy consumption to be saved to a large extent when being used in the crowded vehicle condition of an actual city.

Owner:SINOEV TECH

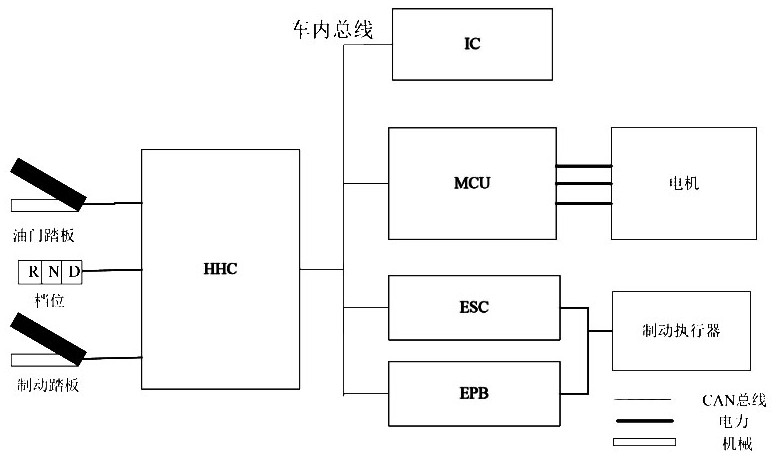

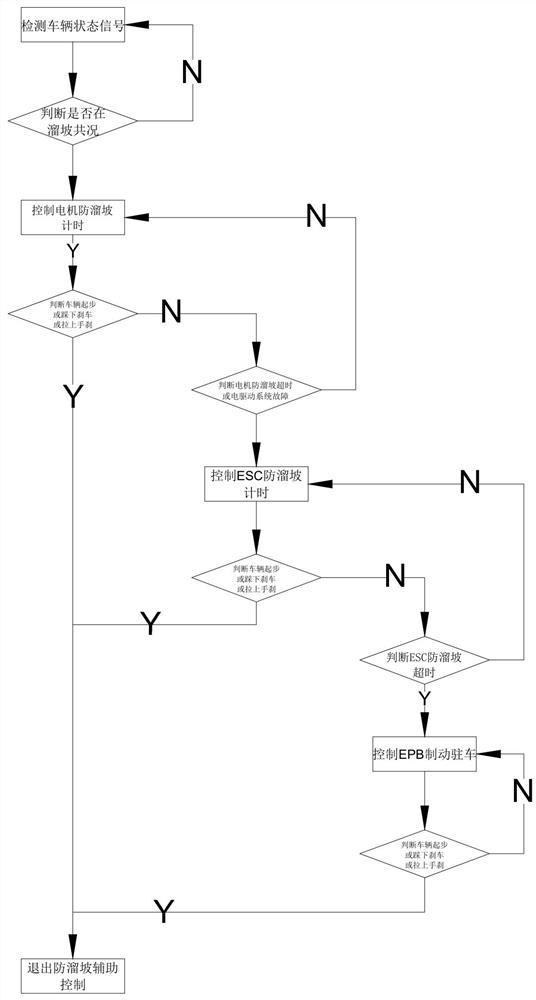

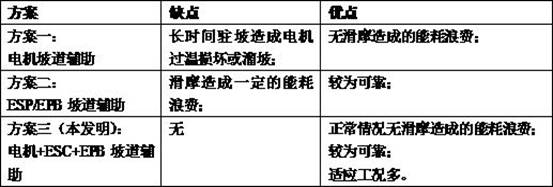

A new energy vehicle anti-slope auxiliary control method

ActiveCN112265544BAddresses the issue of insufficient reliability of the hill assist functionAddresses lack of accessibility reliability issuesSpeed controllerElectric energy managementDriver/operatorNew energy

The invention discloses a new energy vehicle anti-slope auxiliary control method. After the anti-slope system recognizes the start-up slope condition, the motor is controlled to output the locked-rotor torque to prevent the slope; When the system fails to maintain the anti-slope stall torque failure, and the vehicle does not start or the brake is applied or the handbrake is applied, the vehicle body stability controller is used to control the brake actuator to output the driving braking force to prevent the slope; when the anti-slope system recognizes When the anti-slip slope of the body stability controller is timed out and the vehicle has not yet stepped on the brake or pulled up the handbrake, the electronic parking controller is controlled to control the slope, and the electronic parking controller controls the brake actuator to continue outputting mechanical braking force for parking. When the driver operates the vehicle to start or step on the brake or apply the handbrake, the system automatically releases the motor stall torque or mechanical braking force. The invention solves the problem of insufficient reliability of the slope auxiliary function caused by relying solely on the motor to prevent the slope from slipping, and greatly improves the driver's operating comfort and safety.

Owner:JIANGLING MOTORS

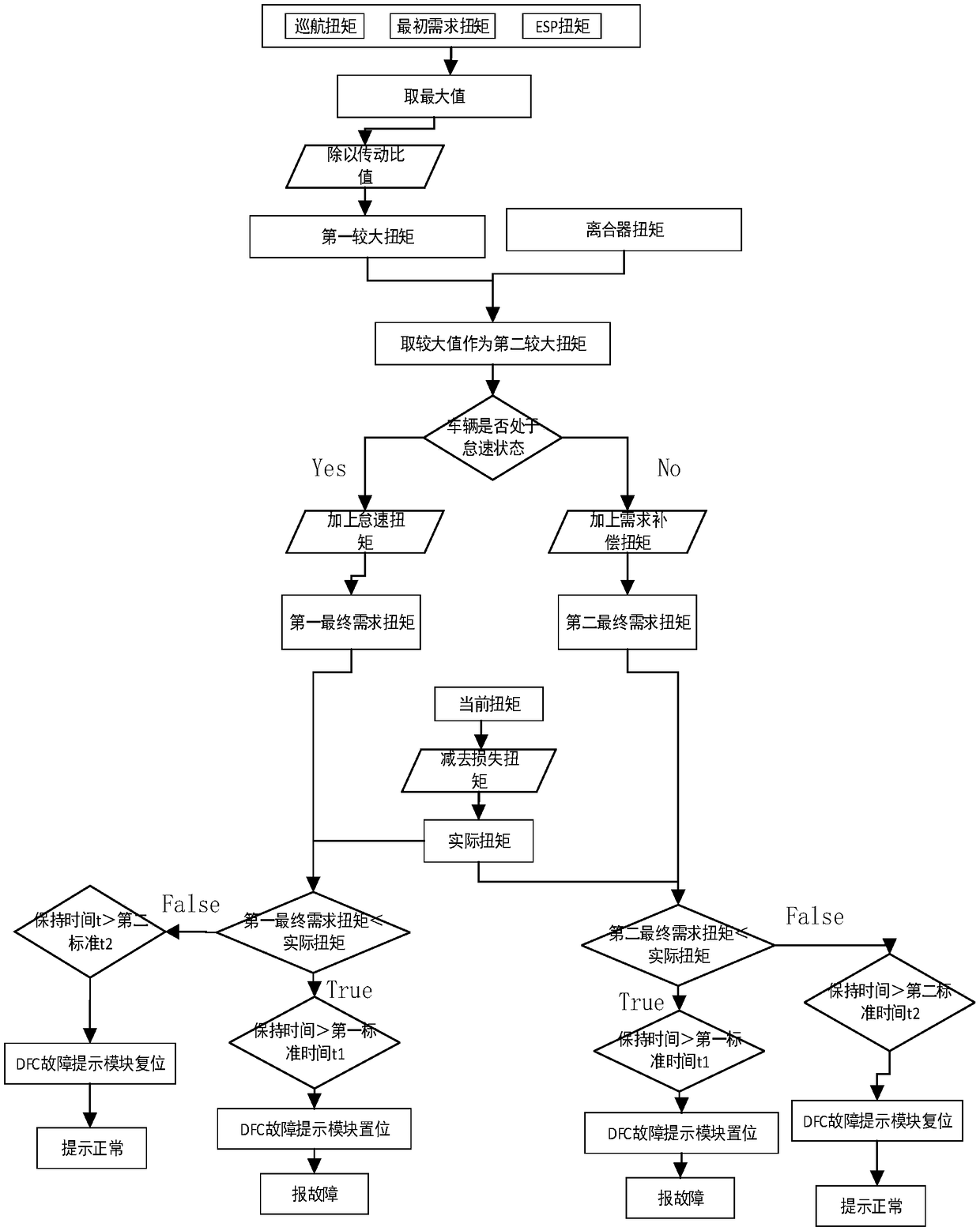

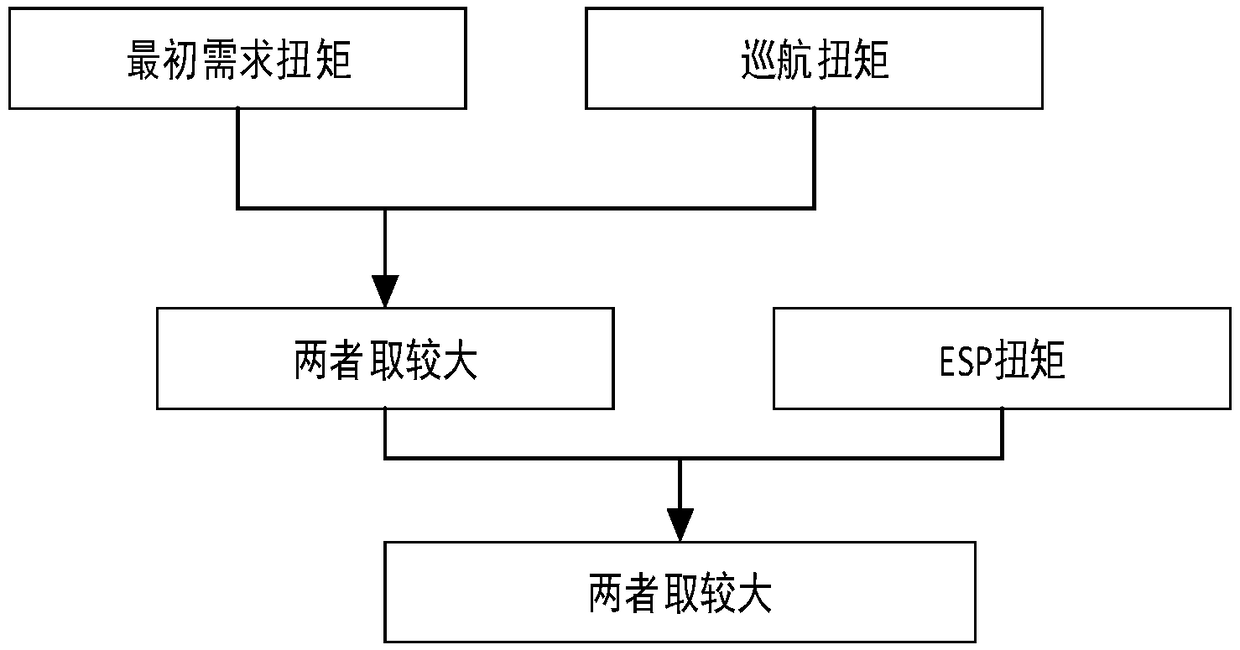

ACC go-and-stop torque monitoring control strategy

The invention provides an ACC go-and-stop torque monitoring control strategy. The ACC go-and-stop torque monitoring control strategy comprises the steps that initial demand torque, cruise torque, electronic stability program (ESP) torque, clutch torque, the transmission ratio and actual torque are obtained; the magnitude of the initial demand torque, the magnitude of the ESP torque and the magnitude of the cruise torque are compared, and final demand torque is calculated by combining the transmission ratio, the clutch torque and the current state of a vehicle; and the magnitude of the final demand torque and the magnitude of the actual torque are compared, and a DFC fault indication module is controlled to be set or reset according to the maintaining state of the magnitude relation betweenthe final demand torque and the actual torque. According to the ACC go-and-stop torque monitoring control strategy, by introducing the ESP torque, the torque monitoring mode of the vehicle in the go-and-stop state is perfected; and judging is further conducted according to the maintaining state of the magnitude relation between the actual torque under the different working conditions of the vehicle and the final demand torque of a driver, the vehicle is prevented from slipping, a monitoring signal is delayed, the influence of signal jump on driving safety of the vehicle is eliminated, and thedriving safety is improved.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

Pneumatic digital-display torque wrench

InactiveCN102501207AAvoid errorsAvoid energy consumptionSpannersWrenchesElectric power transmissionInterference resistance

The invention discloses a pneumatic digital-display torque wrench, which consists of a dynamic torque measuring device and a static torque measuring device, which are coaxial torque measuring devices. Dynamic torque and static torque can be measured by using one torque wrench, a power source of a static torque measuring sleeve is coaxial with the static torque measuring sleeve, and power can be directly transmitted through a cylinder so that errors and energy consumption caused by power transmission through belts and the like can be avoided. In addition, a casing of the pneumatic digital-display torque wrench can be relatively regularly cast into a whole, and thereby tightness, environmental interference resistance and stability of the pneumatic digital-display torque wrench are improved.

Owner:XIHUA UNIV +1

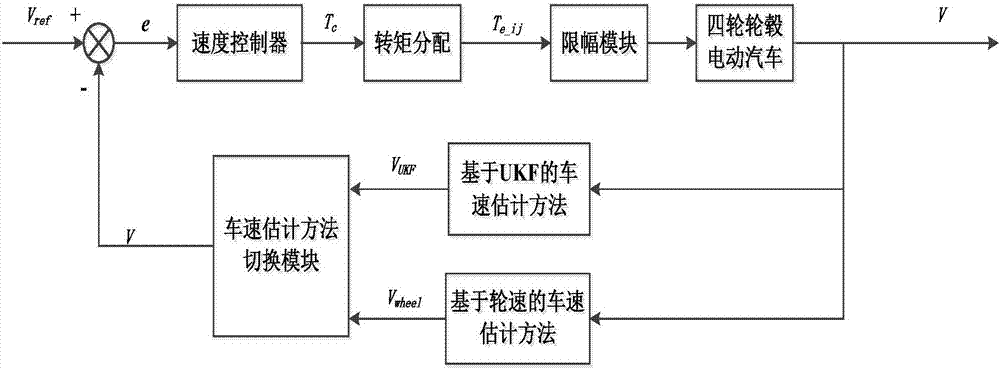

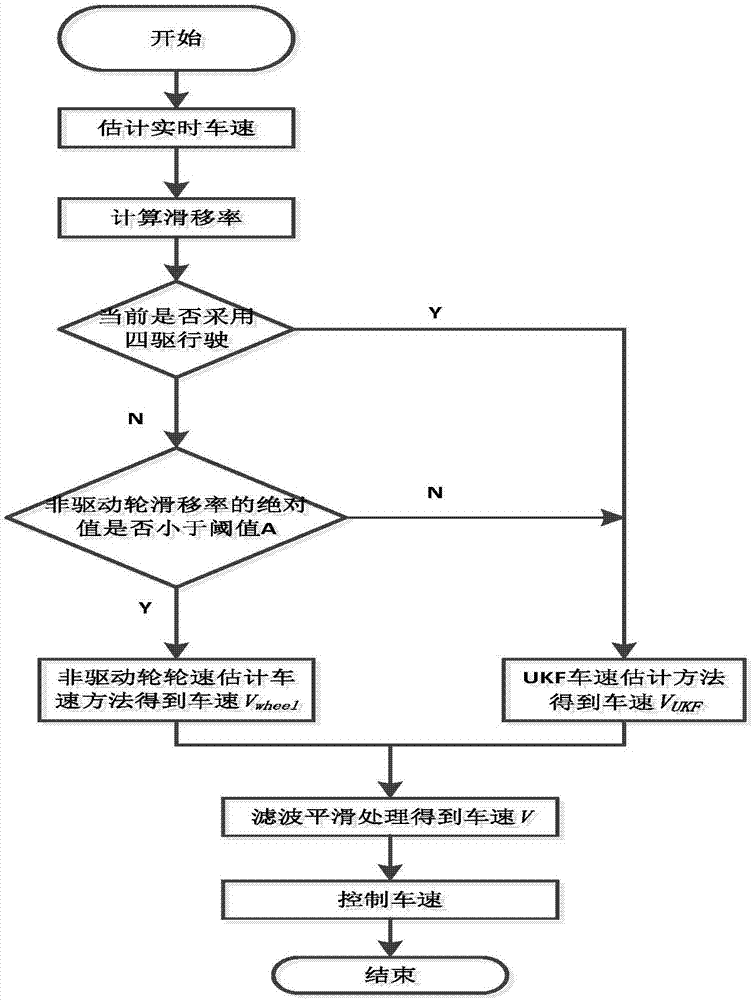

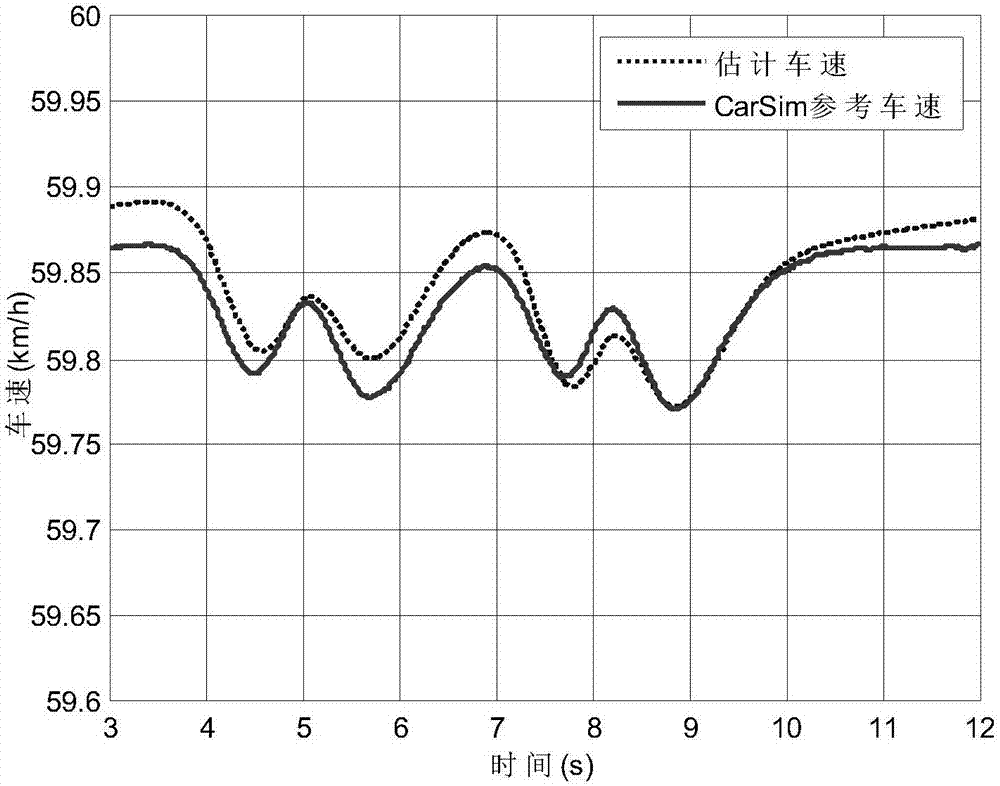

A method for controlling the speed of a four-wheel electric vehicle

InactiveCN105835721BSpeed controlReduced stabilitySpeed controllerOperating modesElectric machineEngineering

The invention discloses a vehicle speed control method for a four-wheel hub electric vehicle. A suitable vehicle speed estimation module is selected through the current driving mode, that is, a UKF-based vehicle speed estimation module or a wheel speed-based vehicle speed estimation module, and the current vehicle speed is estimated in real time; at the same time , smoothing and filtering the vehicle speed jump when the driving mode is switched; then, with the desired vehicle speed as the control target, the PID controller is used to control the output of the total torque; finally, the total torque is input to each The motor controller, and then controls the speed of the electric vehicle to achieve the desired speed.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

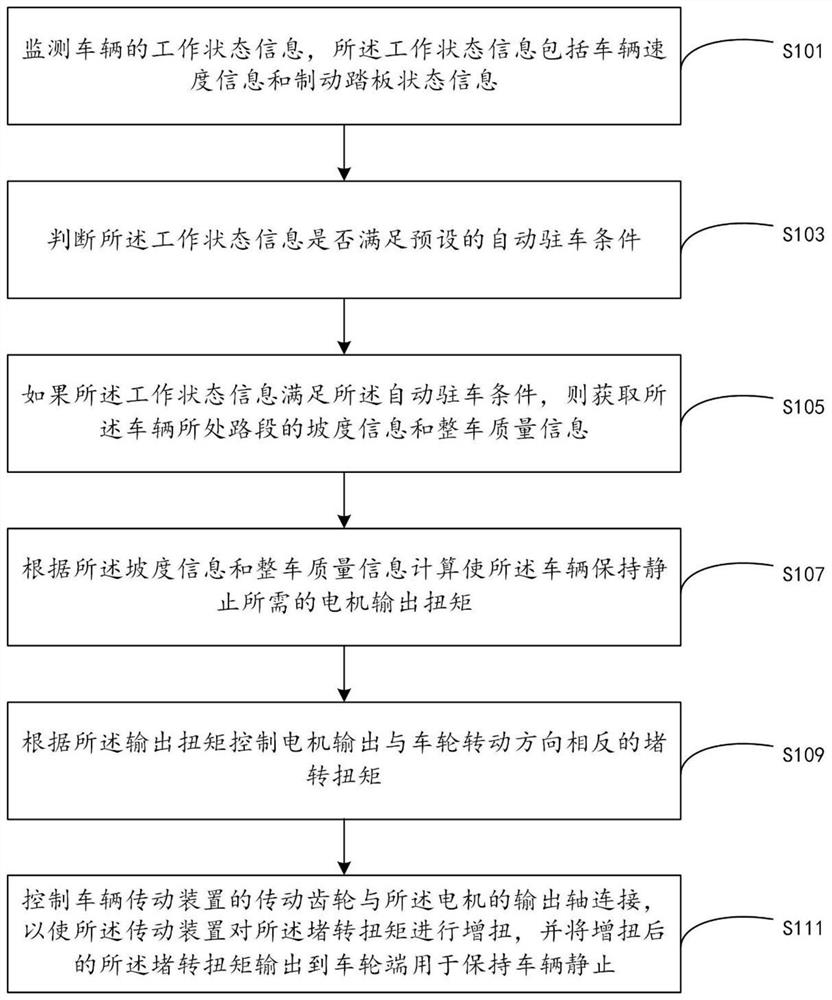

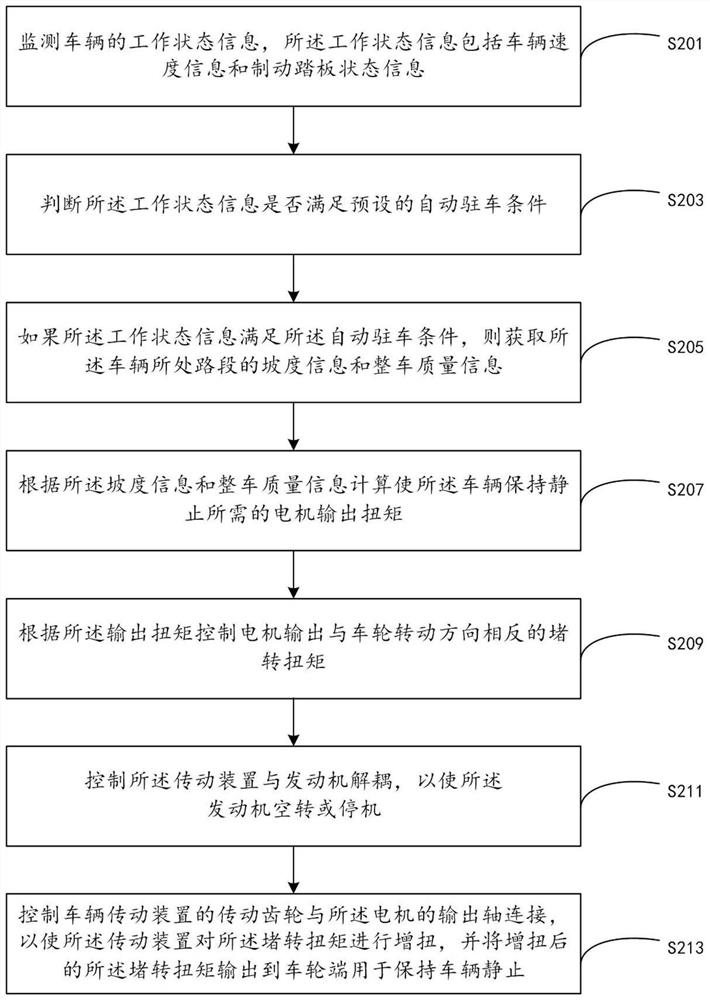

An automatic parking control method, system and terminal

ActiveCN111169441BLow costReduce fuel consumptionBraking action transmissionAutomatic initiationsGear wheelControl engineering

The invention discloses an automatic parking control method, which includes: monitoring the working state information of the vehicle; judging whether the working state information satisfies the preset automatic parking condition; if so, obtaining the slope information of the road section where the vehicle is located and vehicle quality information; calculate the motor output torque required to keep the vehicle stationary according to the slope information and the vehicle quality information; control the motor to output a locked-rotor torque opposite to the rotation direction of the wheels according to the output torque; The transmission gear of the control vehicle transmission is connected to the output shaft of the motor, so that the transmission increases the locked-rotor torque, and outputs the increased locked-rotor torque to the wheel end for maintaining The vehicle is stationary. The technical solution provided by the invention can realize the value-added function of automatic parking by using the existing devices of the vehicle, without the need of specially equipped with an ESP system for this purpose, and effectively reduces the cost of the whole vehicle.

Owner:NINGBO GEELY AUTOMOBILE RES & DEV CO LTD +1

A three-phase asynchronous motor with improved stall torque and reduced stall current

ActiveCN112134431BAvoid damageExtended service lifeAssociation with control/drive circuitsAsynchronous induction motorsThree phase asynchronous motorElectric machine

The invention discloses a three-phase asynchronous motor capable of increasing stall torque and reducing stall current, comprising a frame, an end cover, a casing, a rectifier, a junction box, a rotating shaft, and an eccentric drive part. The front end of the frame is mounted with bolts There is a vertical end cover, and the rear end of the base is bolted to a horizontal cover. While meeting the normal power demand, the present invention can increase the locked-rotor torque and reduce the locked-rotor current. When the motor is locked, the torque can be increased by itself, so as to force the motor to overcome the excessive load and resume normal rotation. At the same time, when the motor is locked, it can connect the consumption resistance to the circuit by itself, which can reduce the current of the locked rotor and reduce the damage to the stator winding, thus prolonging the service life of the motor, and also saving the maintenance time and reducing the trouble. Necessary resources are wasted, so as to be more environmentally friendly and efficient.

Owner:温州广众科技有限公司

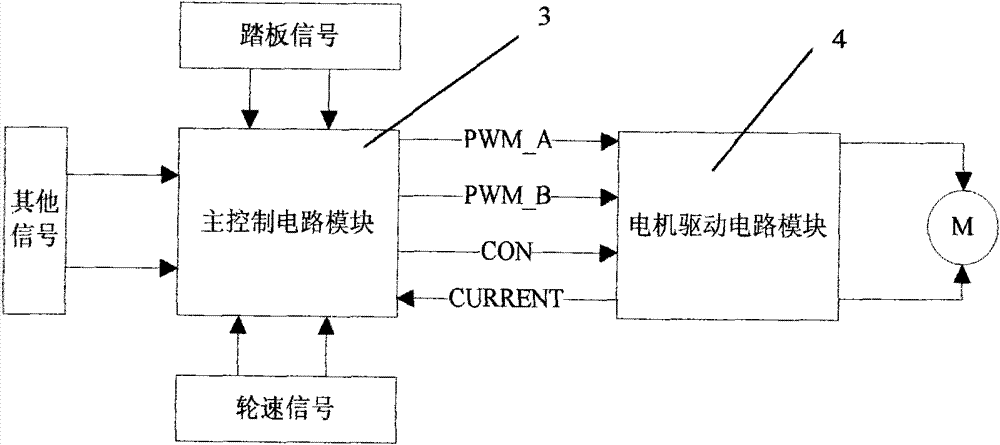

Wire control braking system and braking method thereof

ActiveCN101708718BShort response timeAdaptive adjustment to overcomeBraking action transmissionDrive motorStall torque

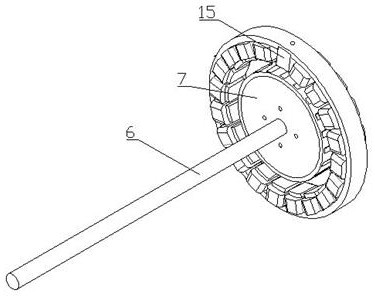

The invention discloses a wire control braking system and a braking method thereof. The wire control braking system comprises a control system and a mechanical actuating mechanism, wherein the control system comprises a main control circuit module and a motor drive module; the main control circuit module controls the rotating speed, the rotating direction and the output torque of a motor through duty ratio signals of PWM_A and PWM_B, controls whether to output the duty ratio signals through an enabling control port CON, and judges stalling and loading conditions of the motor through feedback current signals; the mechanical actuating mechanism comprises a drive motor, a speed-reducing torque-increasing structure and a screw propelling structure, and the screw propelling structure is a non-self-locking structure; and when the torque is decreased, by reducing the set PWM duty ratio and with the help of the repulsion of pressing force, the pressing force between a friction plate and a braking disc can be adjusted to the required stalling torque. Through the technique provided by the invention, the self-adjustment of a gap between the friction plate and the braking disc and the self-adaptive control of the pressing force can be achieved, and the response time for adjusting the pressing force is shortened.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com