Automatic ship mooring machine and mooring rope tension setting method

A cable and ship technology, which is applied in the field of automatic ship mooring machine and its cable tension setting, can solve the problems such as difficulty in adjusting the tension of the cable by the crew, prone to accidents, etc., and achieve the effect of improving safety and reliability and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

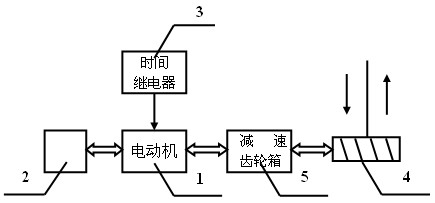

[0020] figure 1 It is a structural schematic diagram of the automatic ship mooring machine of the present invention.

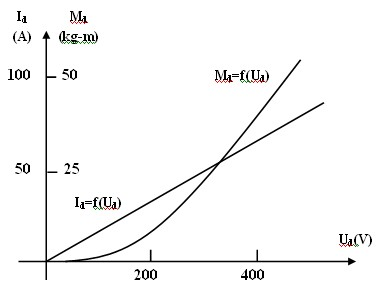

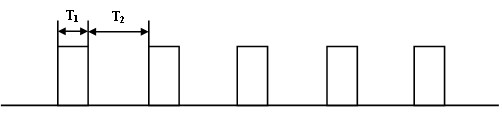

[0021] See figure 1 The automatic ship mooring machine provided by the present invention comprises a motor 1, the non-shaft end of the motor 1 has a DC electromagnetic brake 2, the motor 1 is connected to the cable drum 4 through a reduction gear box 5, and the motor 1 and The time relay 3 is electrically connected and intermittently started under the control of the time relay. The cable pull force setting method of the automatic ship mooring machine provided by the invention uses a motor to detect the pull force of the cable. The specific steps are as follows: the electric motor starts and runs intermittently in the direction of cable take-up with a predetermined cycle, and the locked-rotor torque of the electric motor is the tensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com